Atom Transfer Radical Polymerization Technology

Atom transfer radical polymerization (ATRP) is a living radical polymerization wherein the transition metal catalyst mediates a radical-generating, halogen-transfer reversible redox process. BOC Sciences provides our customers with the most competitive polymer products and thoughtful synthesis services worldwide. Our experienced R&D teams, advanced technology platforms, and trustworthy quality can resolve your research challenges.

Introduction of Atom transfer radical polymerization (ATRP)

Atom transfer radical polymerization (ATRP), also known as metal-mediated radical polymerization, is a powerful controlled radical polymerization technique that enables the precise synthesis of functional polymers with a determined molecular weight within narrow molecular weight distribution. Due to its applicability to various monomers, solvents, catalysts, and reaction conditions, ATRP has been employed to prepare a broad range of advanced polymeric materials with controlled architecture and functionality. Moreover, because it can be carried out in an aqueous solution at room temperature, ATRP is particularly useful for the conjugation of polymer chains to biological entities, such as proteins, peptides, nucleic acids, viruses, and even live cells.

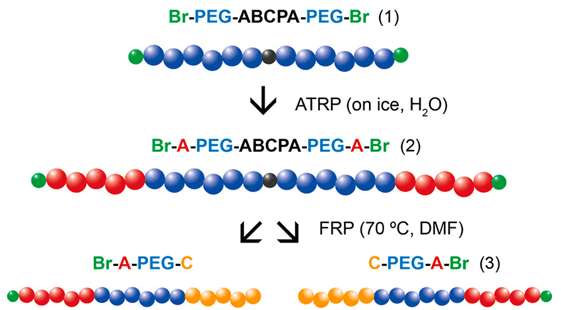

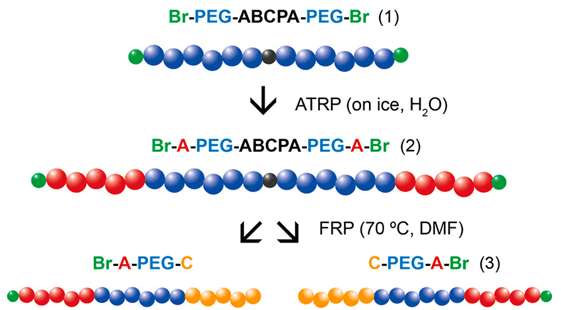

Fig. 1. Examples of polymers with a controlled composition prepared by ATRP (Macromolecules. 2017, 50(21): 8390-8397).

Fig. 1. Examples of polymers with a controlled composition prepared by ATRP (Macromolecules. 2017, 50(21): 8390-8397).

Matyjaszewski and Sawamoto first reported the concept of atom transfer radical polymerization (ATRP) in 1995. In this technique, molecular weight is predetermined by the ratio between monomer and initiator. Radicals are generated through a halogen-transfer process mediated by a metal catalyst, usually containing copper or ruthenium. The halogen is transferred from initiators to transition metals with increased oxidation states, and reverse reactions can then cap radicals. This activation-deactivation process provides control: when the deactivation rate is higher than activation rate, a low concentration of radicals is present and results in a low occurrence of termination events as well as constant growth of polymer chains. As a result, ATRP has been employed in polymerizing a wide range of monomers, including styrenes, alkyl(meth)acrylates, acrylonitrile, and (meth)acrylamides.

Applications of Atom transfer radical polymerization(ATRP)

- Functional Copolymers Synthesis. End-functional and telechelic copolymers, gradient copolymers, block copolymers, and comb polymers can be used as wetting agents, blend compatibilizers, pigment dispersants, and various surfactants.

- Nanogels Preparation. Stable biodegradable nanogels prepared by ATRP in inverse miniemulsion can be used for targeted drug delivery scaffolds that are degraded into lower molecular weight polymers to release encapsulated (bio)molecules.

- Surface Modification. ATRP can be used in the surface modification process of various materials. Segmented copolymers containing polyolefins segments and polar blocks/grafts enhance surface hydrophilicity, conductivity, and antibacterial properties in a spectrum of materials.

- Nanoparticles Grafting. ATRP was applied to grafting various nanoparticles and providing a simple approach for transportable and reusable water purification composites.

- Functionalized Solid Particles. ATRP functionalized solid particles are utilized as the stationary phase for analytical metal affinity chromatography columns to separate proteins and synthetic prion peptides.

What Can We Do For You?

The five most important variables involved with atom transfer radical polymerization (ATRP) are monomer, initiator, catalyst, ligand, and solvent. ATPR realized a controllable increase in molecular weight, molecular architecture, and polymer composition while maintaining a low polydispersity (1.05-1.2). BOC Sciences' R&D team is able to synthesize polymers through ATRP efficiently by putting together monomers in a controlled piece-by-piece fashion. Moreover, assembling polymers in such a manner has allowed our scientists to create a wide range of polymers with site-specific tailored functionalities targeting specific properties for high-value applications. However, with the rapid expansion of different monomers and biomolecules, ATRP remained a versatile tool to prepare polymer bioconjugates has also greatly evolved, especially under biologically relevant conditions. Based on this, we also offer the following new ATRP synthesis techniques, including activators regenerated by electron transfer (ARGET) ATRP, initiators for continuous activator regeneration (ICAR) ATRP, electrochemically mediated ATRP (eATRP), and photoinitiated ATRP (photo-ATRP), which allow the preparation of polymer conjugates with low catalyst loading under biologically benign polymerization conditions.

Representative Atom Transfer Radical Polymerization (ATRP) Monomers (Include but are not limited to the followings)

- Thiol Derivatives

- Styrene Derivatives

- Alkyl(meth)acrylate

- Acrylonitrile

- (Meth)acrylamide

- PEG Derivatives

- Protein

- Nucleic Acid

- Peptide

- Virus

- Live Cell

- etc.

Workflow of Atom transfer radical polymerization (ATRP)

References

- Weil, T. et al. Polymer bioconjugates: Modern design concepts toward precision hybrid materials. Progress in Polymer Science. 2020, 105: 101241.

- Lutz, J.F. et al.Modern trends in polymer bioconjugates design. Prog. Polym. Sci. 2008, 33:1-39.

- Maynard, H.D. et al. Protein-Polymer Conjugates. Polymer Science: A Comprehensive Reference. 2012, 9: 317-335.

- Matyjaszewski, k. Atom Transfer Radical Polymerization (ATRP): Current Status and Future Perspectives. Macromolecules. 2012, 45: 4015-4039.

Fig. 1. Examples of polymers with a controlled composition prepared by ATRP (Macromolecules. 2017, 50(21): 8390-8397).

Fig. 1. Examples of polymers with a controlled composition prepared by ATRP (Macromolecules. 2017, 50(21): 8390-8397).