Nitroxide-mediated Polymerization Technology

Nitroxide-mediated polymerization (NMP) is a controlled/living radical polymerization (CLRP) technique and enables the design of well-defined, functional, and complex macromolecular architectures. BOC Sciences provides our global customers with the most competitive polymer products and customized polymer synthesis services. We can support and guide you in developing a testable candidate matrix and defining the ideal polymer products for you.

Introduction of Nitroxide-mediated Polymerization (NMP)

Synthetic polymers are now considered an essential part of varied objects and materials in our everyday life. Nitroxide-mediated polymerization (NMP) is a reversible-deactivation radical polymerization (RDRP) technique synthesizes well-defined and complex macromolecular architectures with low polymer dispersity and high chain-end homogeneity. NMP is an inherently simple and industrially robust technique that often requires a single unimolecular initiator with a monomer to polymerize, followed by a simple precipitation/filtration to afford final products. Unlike other RDRP techniques, NMP provides clean, well-defined polymers without transition metal complexes, favorable for sensitive biological and electronic applications.

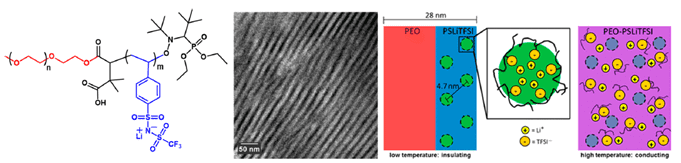

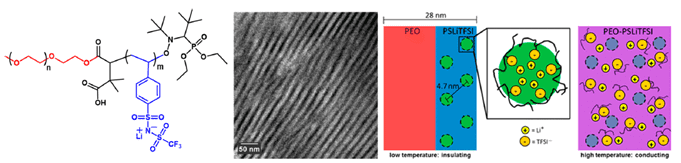

Fig. 1. Examples of nitroxide-mediated polymerization (NMP) applications (ACS Appl. Polym. Mater. 2020, 2, 12, 5327-5344).

Fig. 1. Examples of nitroxide-mediated polymerization (NMP) applications (ACS Appl. Polym. Mater. 2020, 2, 12, 5327-5344).

Historically, nitroxide-mediated polymerization (NMP) is the first widespread controlled radical polymerization method. In the NMP process, nitroxide derivatives control polymerization. Mechanistically, persistent aminoxyl radicals couple reversibly at high temperatures with macroradicals (i.e., growing polymer chains), leading to an equilibrium between a small fraction of active chains and a large fraction of inactive chains (a.k.a dormant chains) capped by an alkoxyamine moiety. Consequently, NMPs exhibit a controlled/living behavior and therefore allow wide possibilities of macromolecular engineering.

Applications of Nitroxide-mediated Polymerization (NMP)

- Lithium Batteries. In the development of lithium batteries, polymers' mechanical properties can be fine-tuned via synthesis to improve the electrochemical properties of coated anodes.

- Organic Electronics. Polymeric high-performing materials have been widely used in organic electronics such as organic photovoltaics (OPVs), organic light-emitting diodes (OLEDs), and organic thin-film transistors (OTFTs).

- Photoresists. Polymer properties enable the synthesis of complex patterns with specific functions, and different functional groups are employed to dictate the polymer's nanostructure to perform desired functions.

- Green Materials. Green polymer chains upregulate the solubility of polysaccharides for various solvents and activate surface functionalization for dispersion.

- Nanoparticles. Polymeric nanoparticles protect drugs from rapid metabolization, increase targeted cellular uptake, and protect nonaffected cells from the drug's intrinsic cytotoxicity.

- Antimicrobial Materials. Antimicrobial polymers are used as coatings on medical equipment or implants, hospital surfaces, and other high-contact areas.

What Can We Do For You?

The nitroxide-mediated polymerization (NMP) process is based on the reversible activation and deactivation of a stable free radical that facilitates the controlled, pseudo-living polymerization of a propagating chain with a given monomer. Based on the scale-up potential of NMP, BOC Sciences' researchers enable the production of highly defined polymer architectures without air-free transfers, transition metal catalysts, or problematic thiol agents. Our NMP polymerization products do not require additional purification of final polymers before being used for sensitive electronic or biological applications. Our experienced R&D teams, advanced technology platforms, and trustworthy quality will resolve your research challenges.

Representative Nitroxide-mediated Polymerization (NMP) Monomers (Include but are not limited to the followings):

- Styrene and Derivatives

- Vinylpyridines

- Acrylic esters

- Acrylonitriles

- Acrylic Acids

- Acrylamide and Derivatives

- Dienes

- Methacrylic Esters

- Cyclic Ketene Acetals

- Vinyl acetate

- N-vinylpyrrolidone (NVP)

- N-vinylcarbazole (NVC)

Workflow of Nitroxide-mediated Polymerization (NMP)

References

- Weil, T. et al. Polymer bioconjugates: Modern design concepts toward precision hybrid materials. Progress in Polymer Science. 2020, 105: 101241.

- Lutz, J.F. et al. Modern trends in polymer bioconjugates design. Prog. Polym. Sci. 2008, 33:1-39.

- Maynard, H,D. et al. Protein–Polymer Conjugates. Polymer Science: A Comprehensive Reference. 2012, 9: 317-335.

Fig. 1. Examples of nitroxide-mediated polymerization (NMP) applications (ACS Appl. Polym. Mater. 2020, 2, 12, 5327-5344).

Fig. 1. Examples of nitroxide-mediated polymerization (NMP) applications (ACS Appl. Polym. Mater. 2020, 2, 12, 5327-5344).