Free Radical Polymerization Technology

Free radical polymerization (FRP) is widely used in commercial polymers synthesis due to its suitability for multiple vinyl monomers. BOC Sciences is dedicated to offering comprehensive and advanced polymer synthesis services for multiple monomers. Our services are highly flexible in addressing your unique demands, and our experienced experts will work in close collaboration with your research team to effectively support the polymer development projects.

Introduction of Free Radical Polymerization (FRP)

Free radical polymerization (FRP) is a crucial synthesis route for obtaining a wide variety of different polymers and materials composites. This particular polymerization offers high compatibility with a wide range of monomers and makes the polymerization of highly specific monomers possible. FRP involves long-chain free radicals as propagating species, usually initiated by the attack of free radicals derived by thermal or photochemical decomposition of initiators. Polymerization proceeds by the addition of free radical chains to the double bonds of monomer molecules. Finally, two propagating species (growing free radicals) combine or disproportionate to terminate the chain growth. Because of its versatility, synthetic ease, compatibility with various functional groups, as well as tolerance to water and protic media, free radical polymerization has been widely used in industry and academia to synthesize different polymeric materials.

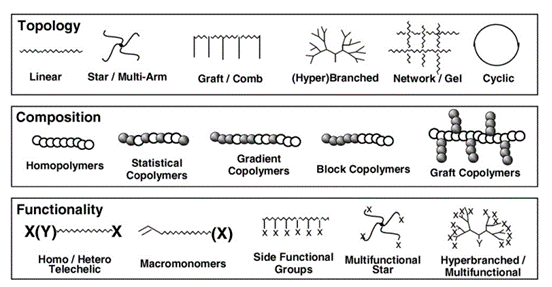

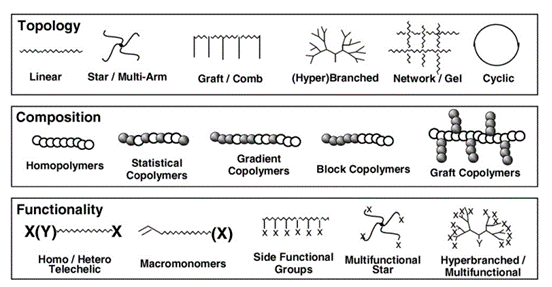

Fig. 1. Illustration of polymers with controlled topology, composition, and functionality (Prog. Polym. Sci. 2007, 32: 93-146).

Fig. 1. Illustration of polymers with controlled topology, composition, and functionality (Prog. Polym. Sci. 2007, 32: 93-146).

The popularity of free-radical polymerization is in substantial part due to the various advantages that this synthetic route offers with industrial applications. The polymerization process is noteworthy for its ease, convenience, and relative insensitivity to impurities, such as water and oxygen, which plague ionic polymerizations. Another advantage of free-radical polymerization is that it offers a convenient approach to designing and synthesizing various specialty polymers in almost every area. However, as the lifetime of an individual chain is short compared to the processing time, variations in the operating conditions (temperature, viscosity, monomer concentration, and composition) lead to increased heterogeneity in polymer composition, MW, and branching. Currently, free radical polymerization has found applications in the manufacture of polystyrene, thermoplastic block copolymer elastomers, cardiovascular stents, chemical surfactants, and lubricants. Nevertheless, free radical polymerization has uses in research as well, such as in the functionalization of carbon nanotubes and the synthesis of nanocomposite hydrogels.

Applications of Free Radical Polymerization (FRP)

- Block Copolymers. Free radical polymerization synthesizes polystyrene and thermoplastic block copolymer elastomers for adhesives, footwear, toys, etc.

- Tissue Engineering Scaffolds. Polycondensation polymers were harnessed to create biocompatible scaffolds such as PCL, PLA, PGA, and PLGA that are commonly used in biodegradable sutures.

- Molecularly Imprinted Polymer. Free radical polymerization is the most employed method to synthesize molecularly imprinted polymer (MIP) composites and MIPs, and different materials could be coupled to MIPs, such as magnetic nanoparticles, silica particles, graphene oxide, multiwalled carbon nanotubes, quantum dots, etc.

- Bionanocomposites. Free radical polymerization can fabricate bionanocomposites, a special class of nanostructured hybrid materials consisting of biological origin and particle constituents with at least one dimension in the range of 1-100 nm.

- Nanocomposite Hydrogels. Hydrogels are colloidal or gel-like substances made of three-dimensional polymer networks that contain more than 90% water, and free radical polymerization of low-molecular-weight monomers in the presence of a cross-linking agent can be used to produce hydrogels.

What Can We Do For You?

BOC Sciences has provided customized polymer synthesis services for our clients worldwide. We have established the most comprehensive free radical polymerization development process, including bulk polymerization, solution polymerization, suspension polymerization, emulsion polymerization, template polymerization, plasma polymerization, and sonication. We have been dedicating ourselves to supporting every customer in facilitating their projects in a highly productive and cost-effective way.

Representative Free Radical Polymerization (FRP) Monomers (Include but are not limited to the followings)

- Styrene

- Vinyl Chloride

- Vinyl Acetate

- Ethylene

- Acrylonitrile

- Methacrylate

- Methyl Methacrylate

- Acrylate

- Vinylpyridine

- Acrylamide

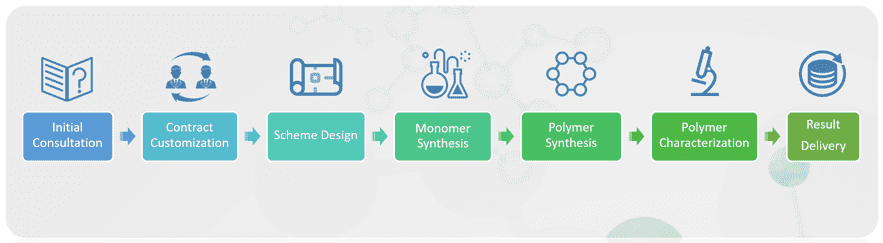

Workflow of Free Radical Polymerization (FRP)

References

- Penczek S., et al. Ring-Opening Polymerization. Reference Module in Chemistry, Molecular Sciences and Chemical Engineering. Elsevier. 2016.

- Hillmyer, M.A. Polymer Science: A Comprehensive Reference, Polymer Synthesis. 2012 (1): 31-45.

- Ma, X. Free radical polymerization in room temperature ionic liquids. Master's Thesis, University of Tennessee, 2006.

Fig. 1. Illustration of polymers with controlled topology, composition, and functionality (Prog. Polym. Sci. 2007, 32: 93-146).

Fig. 1. Illustration of polymers with controlled topology, composition, and functionality (Prog. Polym. Sci. 2007, 32: 93-146).