Polymer Microsphere Synthesis

Polymer microspheres refer to spherical particles made from polymer materials, typically ranging in size from 1 micrometer to several hundred micrometers. They exhibit regular morphology, uniform particle size, and possess excellent dispersibility and stability. BOC Sciences focuses on the research and production of polymer chemicals, with profound technical expertise and extensive project experience in the synthesis, modification, characterization, and conjugation of polymer microspheres. Leveraging an advanced synthesis technology platform and a professional R&D team, we are committed to providing customers with high-quality, high-performance customized polymer microsphere solutions to meet the diverse needs across pharmaceuticals, materials science, electronics, environmental protection, cosmetics, and other industries and fields.

Services

Customized Polymer Microsphere Services

BOC Sciences is customer demand-oriented, offering comprehensive customized polymer microsphere services based on rich R&D experience and advanced synthesis techniques. Our services cover every step from material selection, particle size control, structural design to functional modification, ensuring each batch of microspheres precisely meets customers' specific application requirements.

Diversity in Material Customization

We synthesize various types of polymer microspheres, including synthetic polymers, natural polymers, and their copolymers, to satisfy performance demands across different industrial and research fields.

- Synthetic Polymers: Polystyrene (PS), polymethyl methacrylate (PMMA), acrylates, vinyl copolymers, etc.;

- Natural Polymers: Gelatin, chitosan, starch and derivatives;

- Functional Copolymer Microspheres: Responsive (pH, temperature, photosensitivity), conductive, or specific hydrophilic/hydrophobic microspheres.

Precise Control of Particle Size and Distribution

BOC Sciences utilizes advanced synthesis processes and reactor designs to precisely regulate polymer microsphere size ranges with narrow size distribution coefficients, meeting demands from nanometer to micrometer scales.

- Nanometer Microspheres (20–1000 nm): Suitable for drug delivery, nanocomposites;

- Micrometer Microspheres (1–1000 μm): Suitable for coating fillers, catalyst carriers, and environmental materials.

Diverse Structural Design Capabilities

BOC Sciences can design and synthesize polymer microspheres with various complex structures to meet specific structural and functional needs in different applications.

- Dense Microspheres: High mechanical strength, suitable for loading and filling;

- Porous Microspheres: Large specific surface area, suitable for adsorption and catalysis;

- Hollow Microspheres: Lightweight, suitable for drug sustained release and functional composites;

- Core-Shell Microspheres: Multi-layer functional combinations, suitable for high-end biomedical applications.

Surface Functionalization and Conjugation Technologies

Surface functionalization is key to achieving intelligent and multifunctional polymer microspheres. BOC Sciences has mature surface modification and chemical conjugation platforms to endow microspheres with rich functional properties.

- Functional Group Modification: Introduction of active groups such as carboxyl, amino, thiol;

- Biomolecule Conjugation: Linking antibodies, enzymes, nucleic acids, and other bioactive substances;

- Magnetic/Fluorescent Nanoparticle Coating: Achieving responsiveness and detectability.

Ready to Start Your Polymer Project?

BOC Sciences specializes in custom polymer synthesis, including block copolymers, functionalized polymers, and nanoparticle conjugates, tailored for drug delivery, diagnostics, and biomaterials research.

Technology

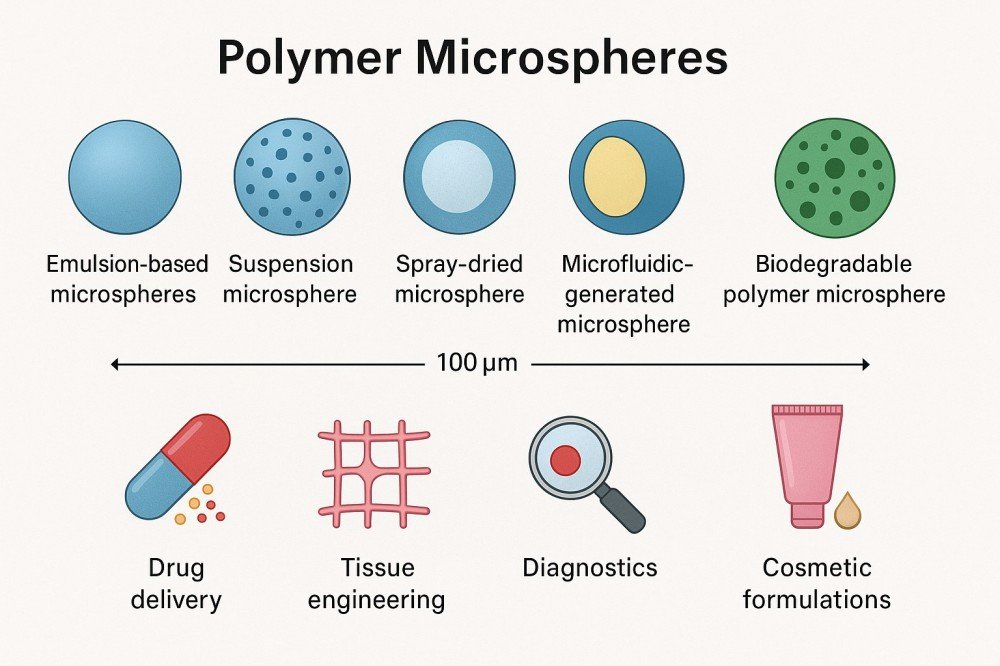

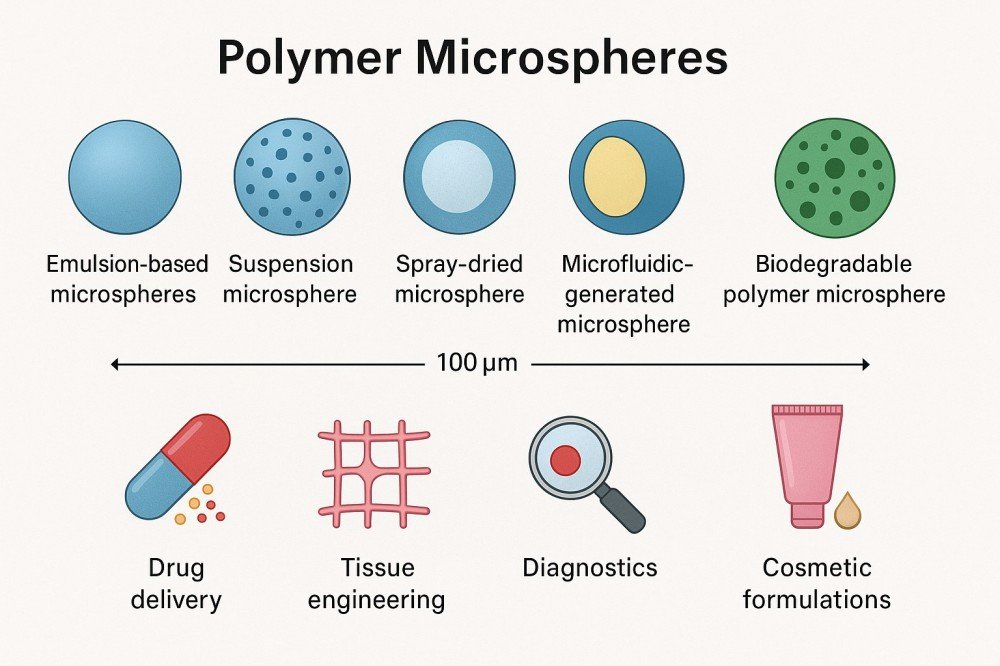

Polymer Microsphere Preparation Technologies

Based on years of polymer synthesis experience, BOC Sciences has built a diversified polymer microsphere preparation platform that covers traditional industrial processes and cutting-edge high-precision techniques. This allows flexible matching of the most suitable preparation routes according to different structural, size, functional, and application requirements. We focus not only on the composition and morphology of the microspheres but also emphasize process controllability, scalability, and application compatibility to ensure the optimal balance of performance, quality, and cost control in each batch.

1Emulsion Polymerization

Emulsion polymerization is a widely applied method at BOC Sciences for synthesizing polymer microspheres with smaller size and uniform distribution. This method uses water as the continuous phase; monomers are emulsified and polymerized under initiator action to form stable polymer particles. By controlling emulsifiers, reaction time, and temperature, particle size and functional group distribution can be precisely regulated. This method is commonly used for producing fluorescent microspheres, diagnostic carriers, and highly dispersed particles, suitable for biological, optical, and coating applications.

2Suspension Polymerization

Suspension polymerization forms large monomer droplets in water, within which polymerization occurs to obtain micrometer-sized polymer microspheres. This method is suitable for producing larger dense microspheres with a wide size range and is commonly used in industrial product development. Because it requires little emulsifier, has simple post-processing, and is easy to scale up, it is widely used for catalyst carriers, drug fillers, and structural materials, offering good cost-effectiveness and scalability.

3Microemulsion Polymerization

Microemulsion polymerization is a polymerization technology under highly dispersed systems, utilizing stable microemulsion systems to produce polymer microspheres as small as several tens of nanometers. Its remarkable features include extremely small particle size and narrow distribution, suitable for producing microsphere products with high sensitivity and excellent biocompatibility. BOC Sciences uses this technology to manufacture fluorescent labels, nano delivery carriers, and other products requiring very tight size control, applicable to high-end analysis, imaging, and biological probes.

4Solvent Evaporation

Solvent evaporation is commonly used to prepare microspheres loaded with drugs or biomolecules, especially biodegradable polymers like polylactic acid and PLGA. This method dissolves polymer and drug in an organic solvent, emulsifies it into an aqueous phase, and then evaporates the solvent to precipitate polymer forming microspheres. Particle size and structure are tunable, making it particularly suitable for developing controlled release formulations and targeted drug carriers, widely applied in drug delivery and vaccine carrier fields.

5Spray Drying/Spray Polymerization

BOC Sciences provides spray drying and spray polymerization technologies to efficiently produce large quantities of microspheres, suitable for heat-sensitive or fast-curing systems. This method atomizes polymer or monomer into fine droplets, which are then dried or polymerized by hot air to form microspheres. It is simple to operate, yields high output, and offers controllable structures, suitable for preparing hollow or porous microspheres, often applied in nutrient encapsulation, cosmetic sustained release materials, fragrance microcapsules, and other consumer and functional material sectors.

6Microfluidic Fabrication

Microfluidic technology precisely controls droplet formation to produce polymer microspheres with ultra-high monodispersity and controllable structures. This technology is especially suitable for customizing complex structures such as core-shell, bilayer, or hollow microspheres, with extremely low particle size variability, ideal for sensitive systems and high-demand biomedical development. BOC Sciences applies this technology to support innovations including single-cell encapsulation, 3D cell scaffold construction, and particle manufacturing in chip systems.

Characterization

Characterization Services for Polymer Microspheres

To ensure that each batch of polymer microspheres meets customers' technical standards and application requirements in terms of particle size, morphology, structure, and functionality, BOC Sciences is equipped with advanced analytical instruments and a comprehensive quality control system. We provide thorough and professional polymer microsphere characterization services. Beyond basic physical parameter measurements, we support in-depth structural analysis and functional verification, assisting customers in performance confirmation and quality tracking throughout the R&D to application process.

| Characterization Item | Technique | Analyzed Parameters | Applications |

|---|

| Particle Size & Distribution | Dynamic Light Scattering (DLS), Laser Diffraction | Average particle size, size distribution, polydispersity index | Assess particle uniformity, dispersion stability |

| Morphology & Structure | Scanning Electron Microscopy (SEM), Transmission Electron Microscopy (TEM) | Surface morphology, sphericity, porosity, shell/core thickness | Validate microsphere integrity, shape, and structural design |

| Surface Elemental Composition | Energy Dispersive X-ray Spectroscopy (EDS) | Elemental type and spatial distribution on the microsphere surface | Confirm coating composition or inorganic component distribution |

| Chemical Composition & Functional Groups | FTIR, NMR, Raman Spectroscopy | Polymer backbone structure, functional group identification | Verify functionalization (e.g., carboxyl, amine, fluorescent groups) |

| Thermal Properties | Thermogravimetric Analysis (TGA), Differential Scanning Calorimetry (DSC) | Decomposition temperature, thermal stability, glass transition temperature (Tg) | Evaluate processing stability and drug compatibility |

| Surface Area & Pore Structure | BET Nitrogen Adsorption/Desorption | Specific surface area, pore volume, pore size distribution | For porous microspheres, adsorbents, or sustained-release carriers |

| Surface Charge & Zeta Potential | Zeta Potential Analyzer | Zeta potential value, surface charge, colloidal stability | Assess stability in aqueous media and electrostatic interactions |

| Drug Loading & Release | HPLC, UV-Vis Spectroscopy | Drug encapsulation efficiency, loading capacity, release profile | For drug delivery systems and in vitro release studies |

| Surface Elemental States | X-ray Photoelectron Spectroscopy (XPS) | Elemental valence states, chemical binding energies | Analyze surface chemistry, confirm chemical modifications |

| Optical Properties (Optional) | UV-Vis Absorption, Fluorescence Spectroscopy | Absorption/emission wavelengths, quantum yield | For fluorescent microspheres or imaging probe development |

Advantages

Advantages of Synthesis Services

- Diverse Synthesis Technologies: Mastery of multiple preparation methods including emulsion, suspension, microemulsion, microfluidics, solvent evaporation, and spray drying to meet varying particle size and structural requirements.

- Precise Particle Size Control: Accurate adjustment within a size range of 20 nm to 1000 μm, with uniform size distribution to ensure product consistency.

- Varied Structural Designs: Support for multiple complex structures such as dense, porous, hollow, and core-shell microspheres, catering to diverse applications like drug sustained release and smart materials.

- Strong Surface Functionalization: Capability to introduce various functional groups and biomolecule conjugations for multifunctional microsphere designs such as targeting and responsiveness.

- Personalized Customization Services: Full-process customization from R&D design to mass production, with rapid response to customers' specific needs.

- Strict Quality Control: Comprehensive physicochemical characterization to guarantee product quality, ensuring batch stability and reliable performance.

- Professional Technical Support: Experienced team providing prompt and expert technical consultation and solutions to facilitate smooth project progress.

Service Process

Microsphere Synthesis Service Process

BOC Sciences is dedicated to providing efficient and customizable polymer microsphere synthesis services. Through a standardized service workflow—from requirement analysis and solution design to process development and quality control—we ensure each step is precise and reliable, meeting the application needs across research, pharmaceutical, and materials science fields.

1Requirement Communication and Project Evaluation

Customers provide project background, objectives, and technical requirements. The professional team at BOC Sciences conducts detailed communication, evaluates feasibility, and proposes preliminary solution suggestions.

2Solution Design and Confirmation

Based on customer needs, a polymer microsphere synthesis process plan is developed, including material selection, synthesis methods, particle size control, and functionalization strategies. Both parties confirm before entering the R&D stage.

3Small-Scale Development and Process Optimization

Small-scale synthesis trials are conducted under laboratory conditions, adjusting reaction parameters to achieve precise control over particle size, structure, and function. Continuous process optimization ensures targets are met.

4Pilot Scale-Up and Preparation for Mass Production

Pilot scale-up validation is performed based on small-scale results, resolving technical issues during scaling, confirming process stability and production feasibility.

5Quality Testing and Characterization

Synthesized microspheres undergo multiple quality tests and characterization including particle size, morphology, chemical composition, and thermal properties to ensure products meet design specifications and customer requirements.

6Product Delivery and Technical Support

Products are packaged and delivered with related technical documentation and test reports. The project team continuously tracks feedback and provides follow-up technical support and services.

Applications

Key Application Areas and Industry Uses

Due to excellent controllability, functional diversity, and broad material options, polymer microspheres have become key technical carriers and functional materials across many industries. Polymer microspheres synthesized by BOC Sciences are widely applied in pharmaceuticals, biotechnology, materials science, environmental protection, and other fields, helping customers achieve innovation breakthroughs and industrial upgrades.

Biomedical Field

Polymer microspheres play vital roles as drug carriers in targeted delivery, sustained release, and vaccine adjuvants. Through precise size control and surface functionalization, microspheres achieve efficient drug loading and directed release, enhancing therapeutic effects and reducing side effects. Additionally, natural polymer microspheres and their composites are widely used in tissue engineering, cell carriers, and biomedical imaging.

Diagnostic and Analytical Technologies

Functionalized polymer microspheres are important components of biosensors and immunoassay systems. Specific surface modifications enable their use as highly sensitive molecular recognition carriers, applied in immunomagnetic bead separation, nucleic acid capture, and fluorescent labeling, serving clinical diagnostics, environmental monitoring, and food safety testing.

Materials Science and Industrial Applications

In coatings, adhesives, inks, and composites, polymer microspheres act as fillers and functional additives to improve mechanical properties, wear resistance, and optical characteristics. Porous and hollow microspheres are further used as catalyst carriers, adsorbents, and insulation materials to meet diversified industrial production demands.

Environmental Protection and Energy

Polymer microspheres serve as adsorbents and catalyst supports in environmental remediation, aiding water treatment, exhaust gas purification, and heavy metal removal. Their designable porosity and functional groups greatly enhance pollutant capture efficiency. Furthermore, microsphere materials are widely applied in new energy fields, such as lithium-ion battery separators and energy storage materials, promoting green energy technologies.

Cosmetics and Daily Consumer Products

In skincare, makeup, and personal care products, polymer microspheres are ideal carriers and fillers due to their stability and biocompatibility. Their unique structures help control active ingredient release, improve texture, and enhance sensory experience, meeting diverse demands of the high-end consumer market.

Medical Aesthetics

Polymer microspheres show broad application potential in medical aesthetics, primarily used as skin fillers, drug delivery systems, and carriers for sustained release of active ingredients. By precisely designing microsphere size, structure, and surface functionalization, the release rate of actives can be effectively controlled, improving their stability and bioavailability in skin, thus promoting skin repair and regeneration.

FAQs

Frequently Asked Questions

What types of polymer microsphere synthesis technologies does BOC Sciences provide?

We offer multiple technologies including emulsion polymerization, suspension polymerization, microemulsion polymerization, microfluidic synthesis, solvent evaporation, spray drying, and template-assisted synthesis to meet different particle size and structural requirements.

How precise can the control of polymer microsphere particle size be?

By optimizing process parameters, we can precisely control particle size ranging from 20 nanometers to 1000 micrometers, ensuring uniform size distribution to satisfy diverse customer needs.

Do you support the synthesis of functionalized microspheres?

Yes, we support introducing various functional groups and surface modifications during synthesis, including biomolecule conjugation, to achieve targeted delivery and intelligent responsive functions.

Can you synthesize microspheres based on customer-provided materials or formulations?

Absolutely. We can customize synthesis plans according to monomers, polymers, or special requirements provided by customers, ensuring personalized project needs are met.

How does BOC Sciences ensure microsphere quality and consistency?

We are equipped with advanced characterization equipment and conduct strict testing and quality control on particle size, morphology, chemical composition, and performance to guarantee stable and reliable products.