Polymer Nanoparticle Synthesis

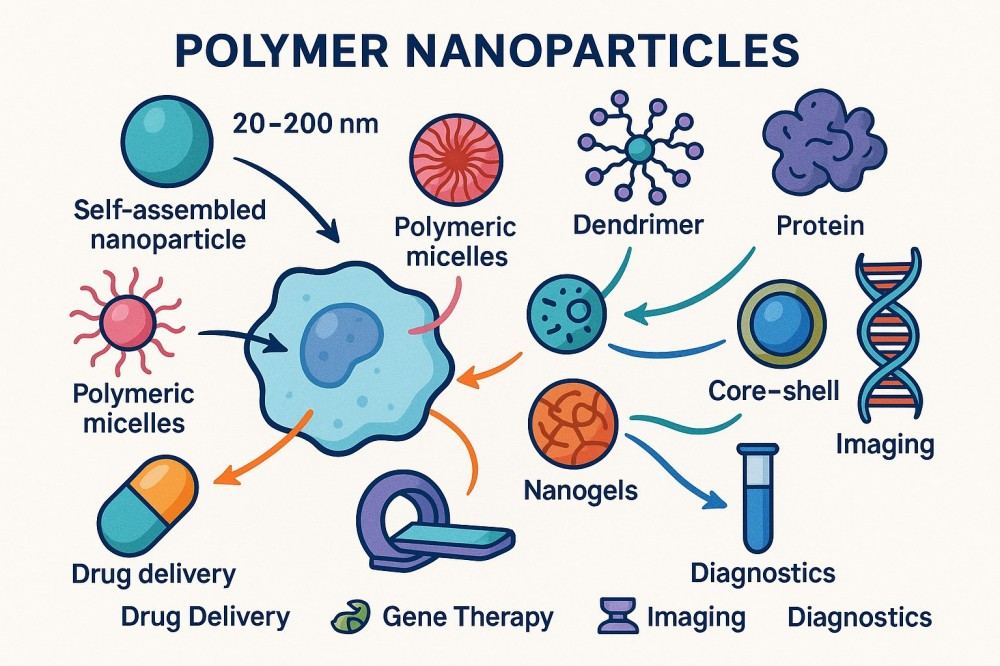

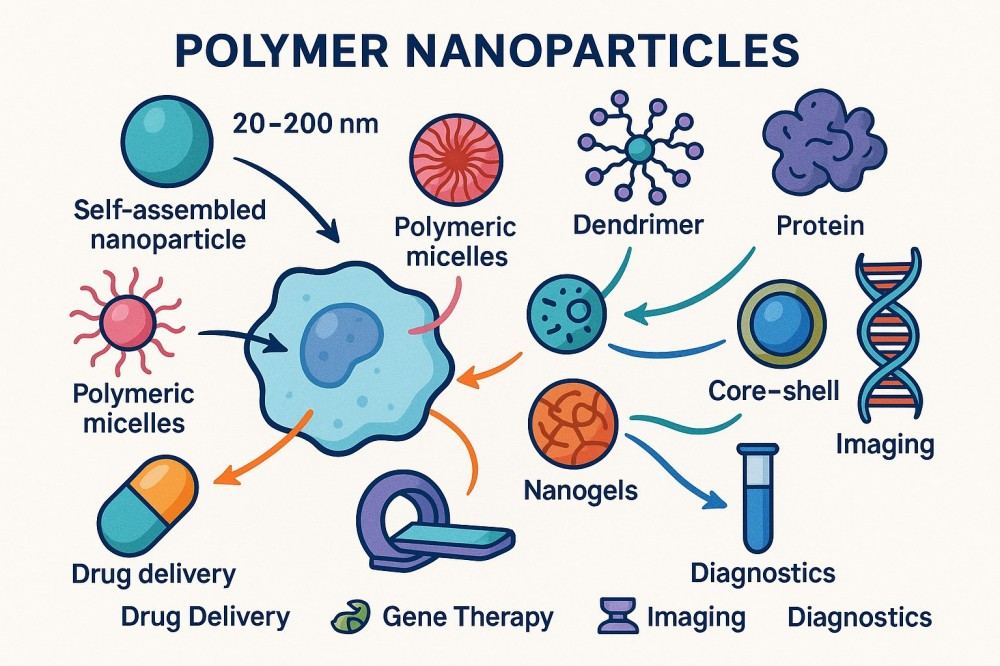

Polymeric nanoparticles are a class of nanoscale particulate systems based on natural or synthetic polymeric materials, typically ranging in size from 10 to 1000 nanometers. They are widely applied in drug delivery, diagnostic imaging, tissue engineering, agriculture, and environmental fields. Leveraging its strong foundation in polymer chemistry, materials engineering, and characterization analysis, BOC Sciences has established a comprehensive polymer nanoparticle synthesis platform capable of providing one-stop services—from design, synthesis, modification to characterization—for customers such as research institutions, biopharmaceutical companies, and new materials enterprises.

Services

Advanced Polymer Nanoparticle Services

The BOC Sciences polymer nanoparticle service platform aims to provide customers with custom synthesis solutions that are structurally precise, functionally complete, and application-oriented. Our services cover the entire R&D process, from basic material selection and particle type customization to complex functional modifications and application testing. We categorize our services into the following major areas for clients to flexibly choose according to project requirements:

Synthesis Services for Diverse Polymeric Nanoparticles

BOC Sciences offers a wide range of custom polymeric nanoparticle synthesis services suitable for loading and releasing different molecules, drugs, or probes. By collaborating with customers to define target functions and loading requirements, we precisely adjust particle size, drug loading modes, release mechanisms, and shell structures to develop nanocarriers tailored to specific application scenarios. Common types include:

- Polymeric Micelles

- Nanospheres

- Nanocapsules

- Block Copolymer Particles

- Core-Shell Structured Particles

- Functionalized Stimuli-Responsive Nanoparticles (temperature/light/pH-responsive, etc.)

Material System Selection and Polymer Source Services

Material selection is a key factor influencing the performance of polymeric nanoparticles. BOC Sciences provides various natural or synthetic polymer materials suitable for different biocompatibility, degradation rates, and drug affinity applications. We also support customized synthesis of functional polymers based on customer needs, such as introducing responsive groups (pH-sensitive, thermo-sensitive, enzyme-sensitive, etc.), targeting units, or special conjugation sites to facilitate subsequent modification and conjugation.

- Natural polymers: chitosan, gelatin, sodium alginate, polysaccharide derivatives, etc.;

- Synthetic polymers: PLA, PLGA, PCL, PEG, PEI, polymethacrylic acid (PMAA), etc.;

- Functional polymers: block copolymers, graft copolymers, crosslinked polymers, etc.

Surface Modification and Conjugation Services

BOC Sciences specializes in polymeric nanoparticle surface modification technologies and can achieve functional design of particle surfaces through multiple conjugation strategies. We employ various conjugation methods, including active ester chemistry (NHS/EDC), click chemistry, thiol-maleimide reactions, etc., enabling precise modification with high efficiency and minimal side reactions.

- PEGylation (polyethylene glycol modification): enhances particle stability and prolongs circulation time;

- Targeting ligand modification: attaches folate, antibody fragments, carbohydrates, peptides, etc., to achieve tissue targeting;

- Fluorescent or magnetic labeling: enables multimodal imaging capabilities;

- Conjugation of functional groups such as carboxyl, amino, maleimide, azide, etc., facilitating further crosslinking or drug attachment.

Drug Loading and Release Control Services

For molecules with diverse therapeutic or functional properties, BOC Sciences provides flexible drug or probe encapsulation services. According to the physicochemical nature of drug molecules, we select appropriate drug loading methods (physical adsorption, hydrophobic embedding, covalent bonding) and release mechanisms (diffusion release, degradation control, stimulus-responsive release) for design and validation.

- Encapsulation of hydrophobic drugs or water-soluble molecules

- Loading via covalent bonding or physical adsorption

- Optimization of controlled release profiles

- Evaluation of encapsulation efficiency and drug loading content

- In vitro release behavior determination

Ready to Start Your Polymer Project?

BOC Sciences specializes in custom polymer synthesis, including block copolymers, functionalized polymers, and nanoparticle conjugates, tailored for drug delivery, diagnostics, and biomaterials research.

Technology

Polymeric Nanoparticle Synthesis Techniques

BOC Sciences possesses comprehensive synthetic strategies and flexible technical routes for constructing polymeric nanoparticles. We accurately select the most suitable preparation methods according to the physicochemical properties of different molecules, loading requirements, and customer application goals. We offer various mature and reliable synthesis techniques, which can be combined and optimized per project demands to ensure nanoparticles with uniform structure, controllable performance, and precise functions. The main synthesis strategies and their applicable scenarios are as follows:

1Self-Assembly Method

The self-assembly method utilizes amphiphilic block copolymers spontaneously forming nanostructures in selective solvents, commonly used to prepare micelles and vesicles. This method requires no surfactants and is suitable for encapsulating hydrophobic drugs or molecular probes. It features simple operation, controllable structure, and high biocompatibility. BOC Sciences achieves precise regulation of drug loading capacity, particle size, and stability via molecular structure design, adapting to various targeting and controlled-release scenarios.

2Nanoprecipitation Method

Nanoprecipitation induces nanoparticle formation by dissolving polymers and drugs in water-miscible organic solvents and then adding them dropwise into an aqueous phase, causing precipitation. This method does not rely on high-energy mechanical forces, is simple to operate, and offers good particle size control, suitable for encapsulating hydrophobic drugs. BOC Sciences optimizes solvent choice, addition rate, and polymer concentration in this process to achieve high encapsulation efficiency and good size uniformity, suitable for laboratory development and process scale-up.

3Emulsification–Solvent Evaporation Method

This method forms polymeric nanoparticles by creating oil-in-water emulsions and evaporating organic solvents, suitable for fabricating nanospheres and nanocapsules. It is used for encapsulating hydrophobic drugs and can be extended to water-in-oil-in-water (W/O/W) double emulsions for loading water-soluble macromolecules. BOC Sciences provides full-process services from emulsifier screening, ultrasound condition control to solvent residue evaluation, ensuring encapsulation efficiency and system stability.

4Graft & Interfacial Polymerization

This strategy constructs nanoparticles through in-situ polymerization on polymer backbones or oil-water interfacial reactions, often used to develop core-shell structures or stimuli-responsive carriers. It is suitable for loading sensitive macromolecules such as proteins, vaccines, and nucleic acids, offering high stability and controlled release properties. BOC Sciences customizes monomer design and polymerization conditions according to targeting, pH responsiveness, or controlled release requirements to develop highly functionalized, multilayer polymer particles.

5Microfluidic Synthesis

Microfluidic technology controls microscale fluid mixing on chips to achieve continuous, highly consistent nanoparticle synthesis. This method precisely regulates particle size and composition, suitable for rapid screening and process scale-up of drug carriers, imaging probes, and multifunctional composite particles. BOC Sciences possesses advanced microfluidic platforms enabling rapid formulation iteration and high-throughput parameter optimization, making it ideal for projects demanding high precision and low batch-to-batch variation.

Characterization

Quality Control and Characterization Services

To ensure that polymeric nanoparticles meet customers' specific application requirements in structure, performance, and functionality, BOC Sciences has established a comprehensive and standardized quality control and analytical characterization system. Equipped with advanced characterization instruments and a professional technical team, we provide complete data support from particle size, morphology to drug loading capacity and release behavior, helping customers efficiently advance their R&D, registration, or industrialization processes.

| Category | Test Content | Technique/Instrument | Service Description |

|---|

| Particle Size & Distribution | Average particle size, PDI (Polydispersity Index) | Dynamic Light Scattering (DLS), Nanoparticle Tracking Analysis (NTA) | Particle size range controlled from 20 to 1000 nm, supports fine size control and uniformity analysis. |

| Morphology & Structure | Particle shape, surface structure, uniformity | Transmission Electron Microscopy (TEM), Scanning Electron Microscopy (SEM), Atomic Force Microscopy (AFM) | Provides high-resolution images and morphology reports, supports identification of core-shell, capsule structures. |

| Surface Charge | Zeta potential | Zeta Potential Analyzer | Evaluates colloidal stability, charge neutralization effect, and trends in cellular compatibility. |

| Molecular Structure Confirmation | Polymer structure, functional group analysis | Nuclear Magnetic Resonance (¹H NMR, ¹³C NMR), Fourier Transform Infrared Spectroscopy (FTIR) | Confirms polymer composition, copolymer ratio, and functional group modifications. |

| Molecular Weight Distribution | Polymer average molecular weight, dispersity | Gel Permeation Chromatography (GPC/SEC) | Analyzes polymerization degree and uniformity, used for synthetic quality assessment. |

| Drug Loading Capacity | Drug loading content, encapsulation efficiency (EE%) | High-Performance Liquid Chromatography (HPLC), UV-Vis Spectroscopy | Provides drug loading measurements for various drug types (small molecules, proteins, nucleic acids). |

| Release Profile | In vitro release curve, drug release mechanism | Dialysis method, enzyme degradation test | Evaluates controlled release under different buffer, enzyme, and pH conditions. |

| Stability Testing | Storage stability, size drift, component degradation | Particle size monitoring, turbidity test, HPLC analysis | Supports long-term stability tests and stability simulations in plasma or buffer solutions. |

| Functional Validation (Optional) | Targeting ability, biocompatibility, cellular uptake | Confocal microscopy, flow cytometry, cell viability assays | Provides preliminary functional evaluation to assist clients in assessing application potential. |

Advantages

Technical Advantages of BOC Sciences

- Diverse synthesis strategies: covering conventional and advanced methods such as self-assembly, emulsification–solvent evaporation, nanoprecipitation, interfacial polymerization, and microfluidics;

- Precise particle size control: nanoparticle size typically controlled within 20–1000 nm, with low polydispersity index (PDI) capability;

- Customized surface functionality: supports various functional modifications (e.g., PEGylation, targeting ligand conjugation, introduction of responsive groups);

- Rigorous quality characterization system: equipped with instruments including DLS, TEM, SEM, FTIR, NMR, GPC, Zeta potential analysis, drug loading/encapsulation efficiency evaluation, etc.;

- Flexible customer-customized workflows: supports scale synthesis from laboratory to pilot scale, meeting R&D and industrialization needs.

Service Process

Polymeric Nanoparticle Project Execution Process

BOC Sciences is committed to providing efficient, transparent, and traceable service experiences to research and industry clients worldwide. We have established a comprehensive workflow for customized polymer nanoparticle services, covering the entire process from initial requirement analysis to final project delivery, ensuring each stage is precisely aligned with the client's objectives.

1Requirement Communication and Project Evaluation

Upon receiving project requirements, our scientific consultants conduct one-on-one discussions to understand key details such as the intended application, carrier specifications, particle size range, payload characteristics, and delivery format. We then assess technical feasibility and recommend preliminary synthesis strategies and service solutions based on material-process compatibility.

2Solution Design and Technical Planning

Based on a thorough understanding of the client's goals, we design a detailed synthesis plan. This includes selecting appropriate polymers, choosing synthesis methods (e.g., self-assembly, precipitation, emulsification), determining encapsulation strategies, particle size control techniques, and functional modification approaches—ensuring that the proposed solution is both scientifically sound and tailored to the client's needs.

3Sample Preparation and Process Optimization

During the experimental phase, we carry out small-scale synthesis according to the design plan. We fine-tune formulation parameters such as polymer concentration, solvent system, and stirring speed to optimize particle size, encapsulation efficiency, and system stability. Multiple rounds of iterative experiments may be conducted to ensure product performance meets expectations.

4Quality Testing and Data Analysis

After sample preparation, we perform comprehensive characterization using standardized techniques such as DLS, TEM, zeta potential analysis, and HPLC. We provide key data including particle size distribution, encapsulation efficiency, drug loading, and release profile in a full analytical report, ensuring results are accurate and traceable.

5Sample Delivery and Usage Instructions

All nanoparticle samples undergo strict quality control and are packaged according to customer requirements. Each delivery includes raw data, storage recommendations, and usage guidelines. We can customize parameters such as concentration, buffer system, and drug load to support seamless integration into subsequent experiments or functional validation.

6Ongoing Technical Support and Project Expansion

Following delivery, we offer continuous technical support, including troubleshooting, particle size adjustment recommendations, encapsulation efficiency improvements, or surface modification guidance. Upon request, we can also assist with formulation scale-up, pilot production, functional enhancements, or long-term collaborative projects.

Applications

Application Support for Polymeric Nanoparticles

BOC Sciences' polymeric nanoparticle synthesis services not only focus on the preparation and functionalization of materials but also commit to providing industry customers with application-oriented comprehensive solutions. We understand the value of polymeric nanoparticles lies not only in their physical structure and drug-loading ability but also in how they improve efficiency, overcome bottlenecks, and create commercial potential in specific applications. Therefore, we offer full support from fundamental particle design and efficient drug/molecule loading to biological evaluation and functional testing, comprehensively aiding customers in research and translation within the following key application areas:

Drug Delivery Systems

Polymeric nanoparticles serve as advanced drug delivery carriers capable of effectively encapsulating hydrophobic and hydrophilic drugs, improving drug stability and bioavailability. Their controllable size and surface functionalization promote targeted accumulation and sustained release in vivo, significantly enhancing therapeutic outcomes and reducing systemic toxicity. Particularly in tumor treatment and chronic disease management, polymeric nanoparticles enable precise drug delivery regulation and represent a critical platform for intelligent drug delivery.

Vaccine and Immunoadjuvant Systems

Polymeric nanoparticles encapsulate antigens and adjuvants to enhance vaccine immunogenicity and stability. They mimic pathogen particle structures, facilitating antigen delivery to lymph nodes and immune cells to activate robust immune responses. The size and surface modification of nanoparticles enable efficient uptake by immune cells, widely applied in novel subunit and mRNA vaccine platforms, advancing vaccine technology innovation and immunotherapy development.

Nucleic Acid Drug Delivery

Nucleic acid drug delivery faces challenges such as rapid degradation and poor cellular membrane penetration. Polymeric nanoparticles protect nucleic acids via electrostatic complexation or covalent conjugation, improving stability and transfection efficiency. Specifically designed stimuli-responsive polymer carriers enable targeted release, enhancing treatment precision. This technology is widely applied in gene therapy, RNA interference, and vaccine fields, greatly expanding clinical potential for nucleic acid drugs.

Tissue Engineering and Regenerative Medicine

Polymeric nanoparticles act as functional components of cell scaffolds in tissue engineering, promoting cell adhesion, growth, and differentiation. They also serve as carriers for growth factors or signaling molecules, achieving localized delivery and sustained release to enhance tissue repair. By regulating nanoparticle biodegradation rates and mechanical properties, they meet regeneration requirements of different tissues (e.g., bone, cartilage, skin), advancing regenerative medicine technologies.

Molecular Imaging and Diagnostics

Fluorescent, magnetic, or photoacoustic polymeric nanoparticles serve as imaging probe carriers, enhancing sensitivity and specificity of molecular imaging. Their structures can be designed as multimodal imaging platforms to enable combined detection by MRI, CT, fluorescence imaging, and other techniques. Polymer carriers improve probe stability and targeting in vivo, supporting early disease diagnosis and therapeutic monitoring.

Agricultural and Environmental Applications

In agriculture, polymeric nanoparticles are used as controlled-release carriers for pesticides and fertilizers, improving nutrient utilization efficiency and reducing environmental pollution. Their precise release properties decrease pesticide amounts and prolong efficacy, supporting sustainable agriculture development. In environmental fields, nanoparticles are applied for heavy metal adsorption, organic pollutant degradation, and water purification, promoting innovative green and environmentally friendly technologies.

FAQs

Frequently Asked Questions

What are polymer coated nanoparticles?

Polymer coated nanoparticles refer to nanoparticles whose surfaces are covered with a polymer film or shell, formed by physical adsorption, chemical bonding, or in situ polymerization. The coating layer improves nanoparticle stability, dispersibility, biocompatibility, and imparts specific functions such as targeting, responsiveness, or drug protection against degradation.

What are polymer grafted nanoparticles?

Polymer grafted nanoparticles refer to nanoparticles with polymer chains covalently grafted directly onto their surfaces, forming stable core-shell structures or brush-like surfaces. Such grafted structures enhance particle dispersion stability and interface interactions with environments or biological systems and can be designed as responsive or functionalized materials.

What are fluorescent polymer nanoparticles?

Fluorescent polymer nanoparticles are polymer-based nanoparticles containing fluorescent dyes or fluorescent monomers that emit detectable fluorescence signals. They are widely used in bioimaging, disease diagnosis, and sensors, valued for their high brightness, photostability, and excellent biocompatibility.

What types of polymeric nanoparticle synthesis services does BOC Sciences provide?

We offer multiple polymeric nanoparticle synthesis services, including polymeric micelles, nanospheres, nanocapsules, core-shell structures, and stimuli-responsive nanoparticles. Particle size, drug loading capacity, and surface functionalization can be customized according to customer needs.

How to choose the appropriate synthesis method?

We recommend self-assembly, nanoprecipitation, emulsification–solvent evaporation, interfacial polymerization, etc., based on drug properties, loading goals, and application scenarios, and design optimal technical routes tailored to customer requirements.

Does BOC Sciences support functional modification and targeting ligand conjugation?

Yes. We provide PEGylation, antibody, peptide, and other targeting ligand conjugation services to realize directional targeting and immune evasion functions on particle surfaces.

What is the achievable particle size and distribution for polymeric nanoparticles?

We achieve particle size control within 20–1000 nm using dynamic light scattering (DLS) and nanoparticle tracking analysis (NTA), with uniform distribution and coefficient of variation as low as 5%.

Can drug-loaded nanoparticles be customized? What types of drugs are supported?

Yes. We support efficient encapsulation and stable release of various drugs or functional molecules, including hydrophobic small molecules, hydrophilic proteins, peptides, and nucleic acids.