Cellulose-polymer Conjugation Technologies

The constitution and chemical composition of natural cellulose cannot be modified in the same ways as those that can be applied to a synthetic polymer because the features of cellulose are determined by biosynthesis. Introducing functional groups into cellulose molecules through chemical modification is one of the key ways of alleviating this problem. These functional groups can confer new properties to the cellulose without destroying its many desirable intrinsic properties. BOC Sciences is a chemical supplier dedicated to the development of various polymers. Our complete polymer modification services include protein-polymer conjugates, peptide-polymer conjugates, nucleic acids-polymer conjugates, carbohydrates-polymer conjugates, enzymes-polymer conjugates, viruses-polymer conjugates, and liposome-polymer conjugates to obtain polymer molecules with high purity and low dispersion. Furthermore, various side/end group functionalization services are also available.

Introduction of Cellulose-polymer Conjugates

Cellulose is the most abundant organic raw matcrial and finds applications in areas as diverse as composite materials, textiles, drug delivery systems and personal care products. Modification by graft polymerisation provides a means of altering the physical and chemical properties of cellulose and increasing its functionality. With the recent progresses in polymer synthesis, new routes are now available for the production of functional and sustainable cellulose-based materials. The chemical and physical properties of the cellulose biopolymer are largely dependent on its specific structure. The industrial history of the chemical modification of cellulose to impart new properties can be tracked back to 1870 with the production of the first thermoplastic polymeric material ‘‘celluloid’’ (cellulose nitrate plasticized with camphor). The formation of cellulose nitrate involves the esterification of cellulose with nitric acid in the presence of sulfuric acid, phosphoric acid or acetic acid. Currently, other commercially important cellulose esters are cellulose acetate, cellulose acetate propionate and cellulose acetate butyrate. Furthermore, the use of etherification reactions provides another important way of modifying the structure of cellulose chemically. Some commercially important cellulose ethers are methyl cellulose, carboxymethyl cellulose and thehydroxyalkyl celluloses. These cellulose esters and ethers have potential applications in coatings, laminates, optical films, sorption media, pharmaceuticals, foodstuffs and cosmetics.

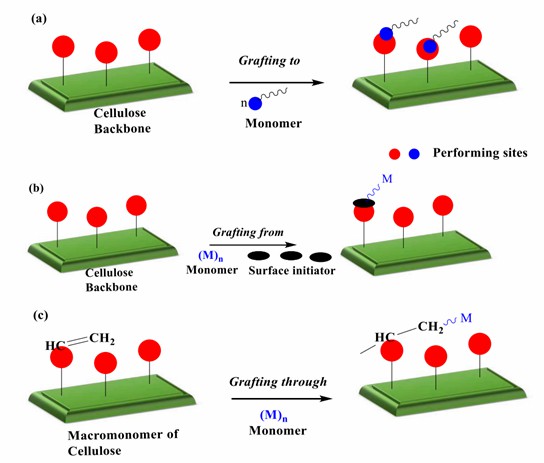

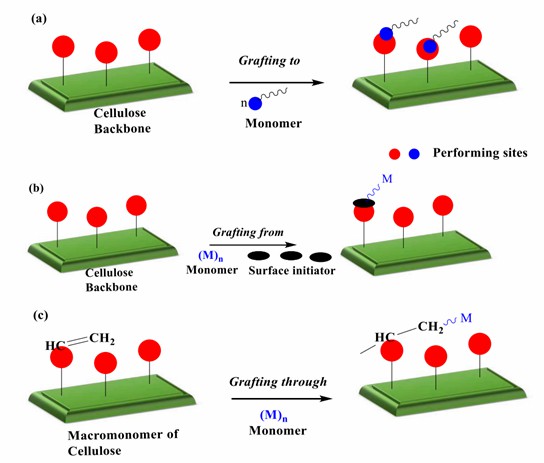

Fig. 1. Mechanism of (a) grafting to (b) grafting from (c) grafting through (European Polymer Journal. 2021, 152: 110448).

Fig. 1. Mechanism of (a) grafting to (b) grafting from (c) grafting through (European Polymer Journal. 2021, 152: 110448).

The synthesis of cellulose graft copolymers is one of the key ways of modifying the physical properties and chemical properties of cellulose. This is usually achieved by modifying the cellulose molecules through the creation of branches (grafts) of synthetic polymers that impart specific properties onto the cellulose substrate, without destroying its intrinsic properties. Indeed, depending on the polymer that is grafted onto the cellulose, it is possible to attain properties such as dimensional-stability, resistance to abrasion and wear, wrinkle recovery, oil and water repellence, elasticity, sorbancy, ionexchange capabilities, temperature responsiveness, thermal resistance and resistance to microbiological attack. The graft copolymerisation of many monomers onto cellulose and cellulose derivatives has been carried out by different methods that can be generally classified into three major groups: (i) free radical polymerisation, (ii) ionic and ring opening polymerisation and (iii) living radical polymerization.

Our Cellulose-polymer Conjugation Services

Free Radical Graft Copolymerization of Cellulose

In the free radical graft copolymerisation of cellulose, free radicals on the cellulosic backbone can be formed by chemical initiators, irradiation with ultraviolet light, irradiation with gamma rays, and exposure to plasma ion beams. The free radicals thus formed can add to monomers to form a covalent bond between the monomer and the cellulose. A free radical site is also formed on the newly formed branch. Many monomers may add subsequently to the free radical site of the branch. The propagation of the branch continues until termination occurs either by combination of two growing cellulose chains or by a disproportionation mechanism, where a hydrogen atom is abstracted by another growing polymeric chain. BOC Sciences has provided customized polymer synthesis services for our clients worldwide. We have established the most comprehensive free radical polymerization development process, including bulk polymerization, solution polymerization, suspension polymerization, emulsion polymerization, template polymerization, plasma polymerization, and sonication. Our cellulose free radical graft copolymerization services include:

Living Radical Polymerization of Cellulose

In recent years, living radical polymerization has been widely applied in cellulose grafting. Grafting from, that is, the synthesis of graft copolymers directly from surface-immobilized initiators, offers unique opportunities to tailor the surface properties, structure and composition of grafted polymers by controlling the graft length. BOC Sciences has accumulated abundant experience in custom polymer synthesis, and we are capable of providing our clients with the necessary scientific assistance in polymer modification. Our living radical polymerization services for cellulose include:

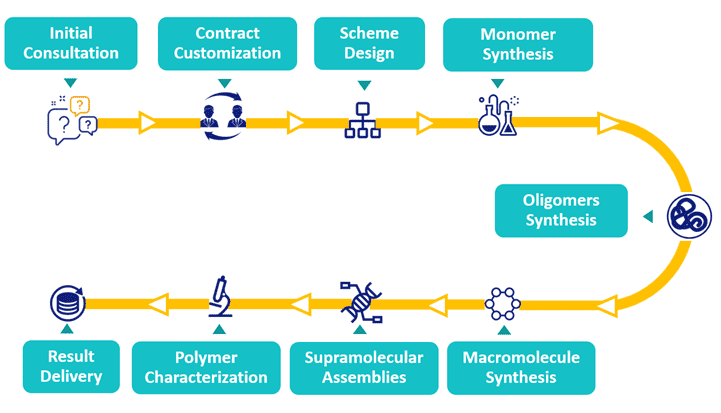

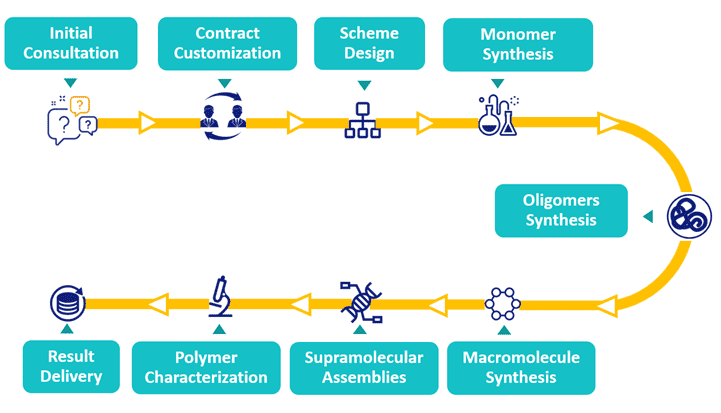

Our Polymer Bioconjugation Workflow

References

- Prasad, G. et al. Promising grafting strategies on cellulosic backbone through radical polymerization processes-A review. European Polymer Journal. 2021, 152: 110448.

- Perrier, S. et al. Cellulose modification by polymer grafting: a review. Chem. Soc. Rev. 2009, 38: 2046-2064.

Fig. 1. Mechanism of (a) grafting to (b) grafting from (c) grafting through (European Polymer Journal. 2021, 152: 110448).

Fig. 1. Mechanism of (a) grafting to (b) grafting from (c) grafting through (European Polymer Journal. 2021, 152: 110448).