- CAS: 9003-53-6

- Molecular Formula: (C8H8)x

Introduction

Polystyrene (PS) refers to the polymer synthesized by free radical polymerization of styrene monomer with the chemical formula (C8H8)n. It is a colorless and transparent thermoplastic with a glass conversion temperature higher than 100°C, which is widely used in the manufacture of various disposable containers and disposable foam lunch boxes that need to withstand boiling water temperatures. Polystyrene includes regular polystyrene, foaming polystyrene (EPS), high impact polystyrene (HIPS) and inter-gauge polystyrene (SPS).

Ordinary polystyrene materials are non-toxic, odorless, colorless and transparent particles with excellent electrical insulation, remarkable processing fluidity, especially high transparency with a light transmittance of more than 90%. The disadvantages of ordinary polystyrene are brittleness, low impact strength, susceptibility to stress cracking, and poor heat and boiling water resistance. HIPS is a copolymer of styrene and butadiene, where butadiene acts as a dispersed phase to increase the impact strength of the material, while the product is opaque. SPS is a new type of polystyrene, which uses metallocene catalysts to form a mutually homogeneous structure, and belongs to engineering plastics with excellent performance.[1]

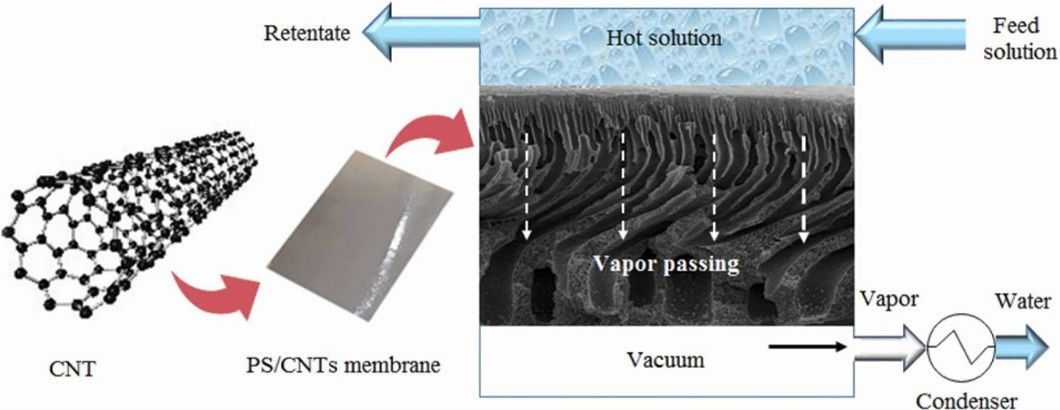

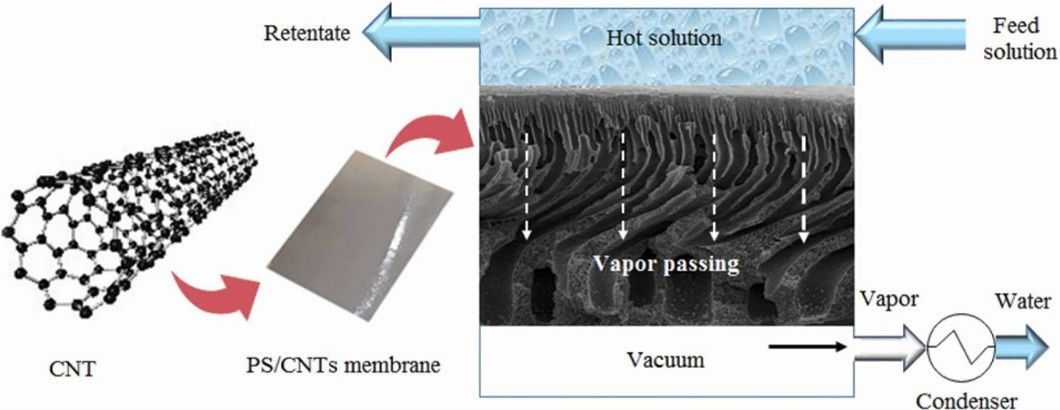

Fig. 1. Preparation of membranes by raw materials PS (Journal of Environmental Chemical Engineering. 2022, 10(4): 108175).

Fig. 1. Preparation of membranes by raw materials PS (Journal of Environmental Chemical Engineering. 2022, 10(4): 108175).

Application

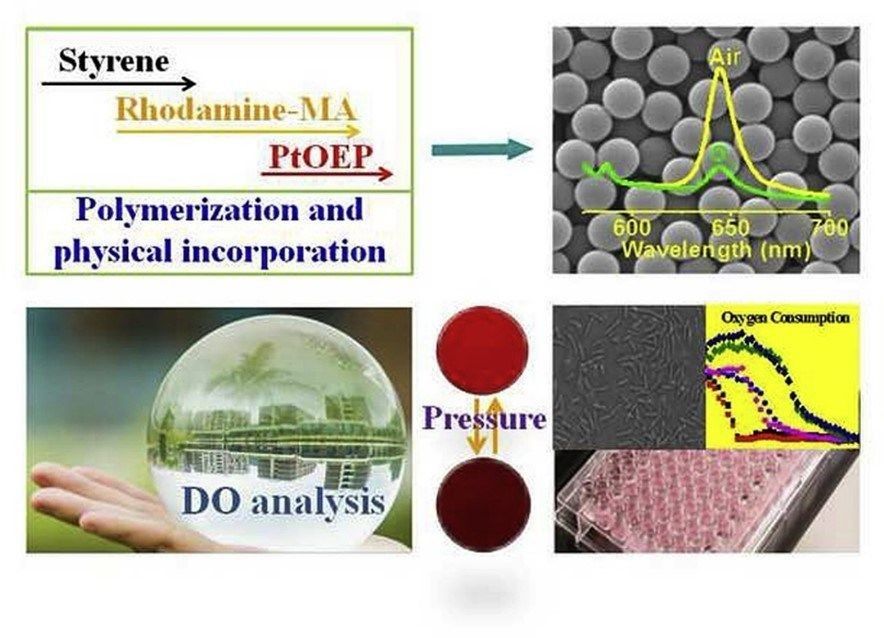

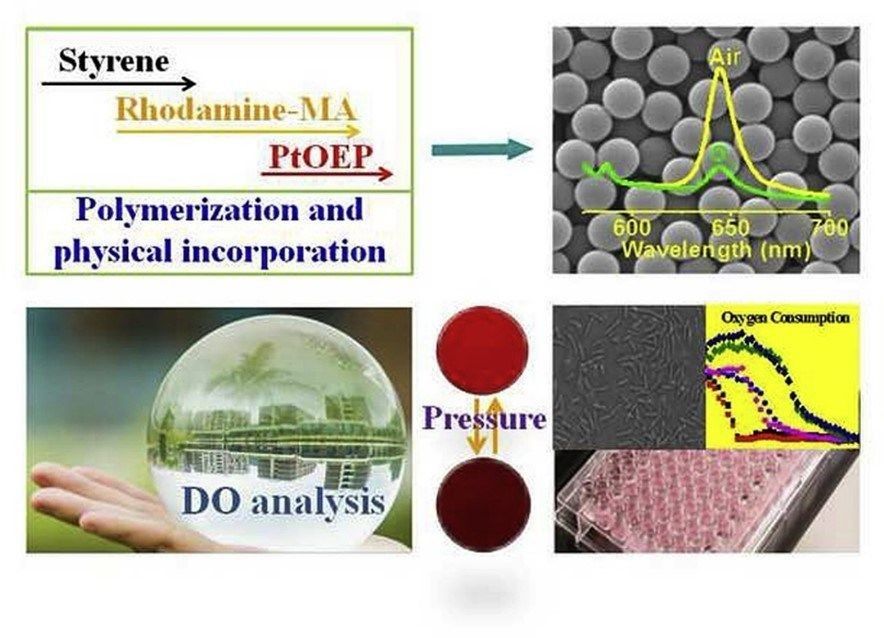

Due to its advantages of transparency, cheapness, rigidity, insulation, and good printability, polystyrene is widely used in the light industry market, daily decoration, lighting instructions and packaging. PS is also a raw material for membranes with high porosity, average pore size and mechanical properties.[2] In addition, PS can be used in powder and emulsion cosmetics because of its perfect compressibility, which enhances powder adhesion. As an advanced filler, PS can replace talc and silica to impart radiance and lubrication to the skin. At the same time, polystyrene is an excellent electrical insulating material and thermal insulating material, which can be made into various instrument housings, lamp covers, photochemical instrument parts and capacitor dielectric layers. Furthermore, polystyrene-based microspheres can be used as oxygen sensors for precise analysis of dissolved oxygen in certain liquids and for monitoring cellular respiration.[3]

Fig. 2. The preparation and application of polystyrene-based microspheres (Analytica Chimica Acta. 2018, 1030: 194-201).

Fig. 2. The preparation and application of polystyrene-based microspheres (Analytica Chimica Acta. 2018, 1030: 194-201).

Polystyrene is known as one of the five most widely used general-purpose plastics in the world. Currently, the development of polystyrene has the following characteristics: large-scale production equipment, intelligent production control, and product specialization. If you are interested in our polystyrene standards, please contact us immediately!

References

- Chaukura, N. et al. Potential uses and value-added products derived from waste polystyrene in developing countries: A review. Resources, Conservation and Recycling. 2016, 107: 157-165.

- Bahrami E.M. et al. Fabrication of polystyrene (PS)/cyclohexanol-based carbon nanotubes (CNTs) mixed matrix membranes for vacuum membrane distillation application. Journal of Environmental Chemical Engineering. 2022, 10(4): 108175.

- Liang, L. et al. Preparation and application of ratiometric polystyrene-based microspheres as oxygen sensors. Analytica Chimica Acta. 2018, 1030: 194-201.

Fig. 1. Preparation of membranes by raw materials PS (Journal of Environmental Chemical Engineering. 2022, 10(4): 108175).

Fig. 1. Preparation of membranes by raw materials PS (Journal of Environmental Chemical Engineering. 2022, 10(4): 108175). Fig. 2. The preparation and application of polystyrene-based microspheres (Analytica Chimica Acta. 2018, 1030: 194-201).

Fig. 2. The preparation and application of polystyrene-based microspheres (Analytica Chimica Acta. 2018, 1030: 194-201).