Liposome-polymer Conjugates

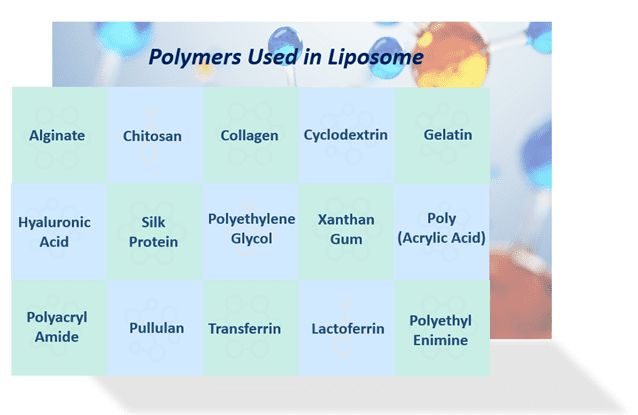

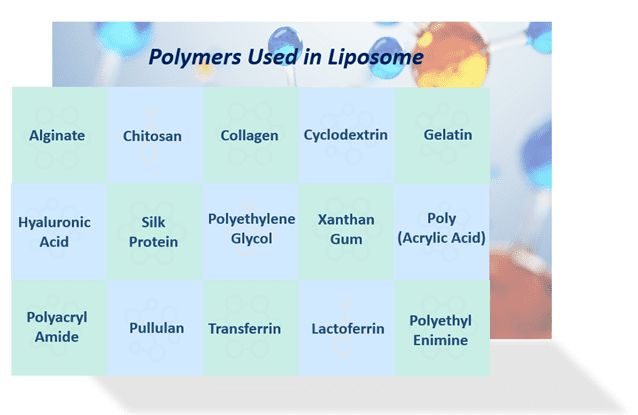

The complexation of the liposome-polymer is called a liposome complex. It is known that complexing liposomes using polymers can improve the physicochemical properties of liposome, so they can be explicitly used for targeted delivery and controlled release of drugs. BOC Sciences develops various polymers that conjugate with liposomes, such as alginate, chitosan, collagen, cyclodextrin, gelatin, hyaluronic acid, lactoferrin, transferrin, poly(acrylic acid), polyacrylamide, polyethylene glycol, etc. We take your needs as our responsibility and provide the best quality service.

Introduction of Liposome-polymer Conjugates

Liposomes have been used extensively as micro- and nanocarriers for hydrophobic or hydrophilic molecules. However, conventional liposomes are biodegradable and quickly eliminated, making it difficult to be used for delivery in specific routes, such as the oral and systemic routes. One way to overcome this problem is through complexation with polymers, which is referred to as a liposome complex. The use of polymers can increase the stability of liposome with regard to pH, chemicals, enzymes, and the immune system. The research indicated that both natural and synthetic polymers can be used in modifying the structure and physicochemical properties of liposomes to specify their use in targeted delivery, controlled release, and stabilizing drugs and vaccines. These properties are influenced by the type of polymer, crosslinker, interaction, and bond in the complexation process.

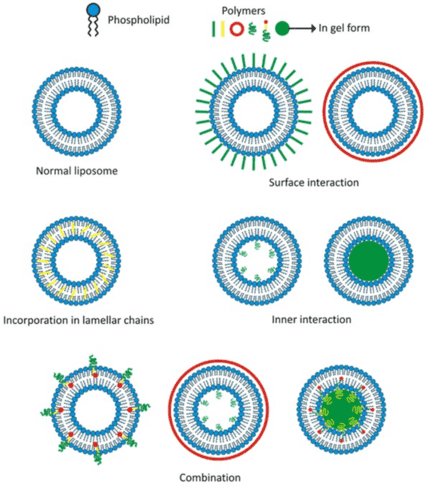

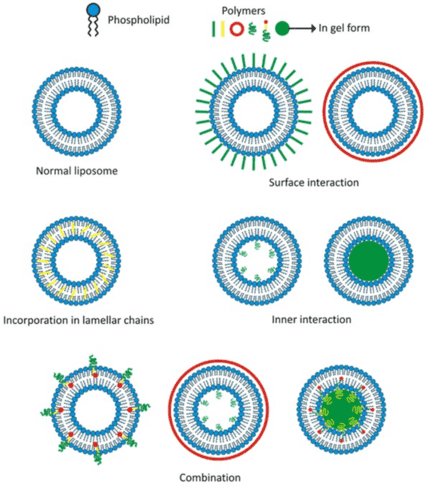

Fig. 1. The possible interaction of liposome-polymer (Heliyon. 2022, 8: e08934).

Fig. 1. The possible interaction of liposome-polymer (Heliyon. 2022, 8: e08934).

Liposome-polymer coupling is a method of modifying the structure of liposome to improve its physicochemical properties, stability, and pharmacokinetic profile. Each type of polymer will produce different interactions and complex shapes with liposomes. The interaction is also influenced by the initial form of phospholipids (ring form or not). Generally, polymers mixed with a proliposome material will create a fusing interaction on the lamellar chain or inside of the liposome. Whereas, the polymer added after the formation of the liposome bilayer membrane will form interactions on the surface. Some types of interactions between polymers and liposomes that can occur are physical adsorption or chemical reactions, such as electrostatic interactions, hydrogen bonds, disulfide bonds, covalent bonds, and others. Weak bonds, such as hydrogen, dipole, and disulfide, slowly release liposomes in a matter of hours to acouple of days. However, if the bonds formed are covalent or ionic, more energy or bioreagents (enzymes) are needed to break the bonds.

Applications of Liposome-polymer Conjugates

- Drug Delivery. A liposome is a drug delivery system composed of phospholipids and forms a bilayer membrane in an aqueous system. Liposomes have been used extensively as a drug delivery system to increase the solubility and permeability of hydrophilic or hydrophobic drugs.

- Vaccine Delivery. Liposome-polymer derivatives, cationic liposomes, and liposome protein complexes have been identified as novel adjuvants and vaccine delivery platforms due to some of their distinct potentialities over non-functional nanocarriers as well as traditional carrier proteins on immunogenic stimulation.

Our Polymers of Liposome-polymer Conjugates

Our Services of Liposome-polymer Conjugates

Surface Modification of Liposome

Surface modification of liposomes can be used to avoid bonding or adsorption of liposomes on some proteins during circulation. Besides, surface modification is intended for targeted drug delivery using ligands, receptors, or polymers that can stimulate the destruction of liposomes through pH, enzymes, or specific bonds on the cell matrix to initiate endocytosis and drug release. BOC Sciences has the world's leading polymer bioconjugation technology platform, which can provide efficient lipid-bioconjugation services for various targets or research needs, including magnetic responsive, thermal, pH, and enzymatic responsive, tumor targeted delivery and controlled release.

Lamellar Chains Incorporation of Liposome

The incorporation of polymers into lipid bilayers can strengthen bonds in the membrane of the liposome, so it becomes more sturdy and stable in chemical, enzymatic, and immune reactions. Polymers that are incorporated in the lamellar chain are hydrophobic, so they easily bind to the aliphatic chains of phospholipids. Furthermore, this type of interaction can also provide controlled drug release from the liposome via thermal, enzyme, or pH triggers. In BOC Sciences, we tailor-made integrated lipid-polymer conjugates services based on the type and structure of polymers, crosslinkers and lipids. Our professional technicians and good equipment are the keys to make you choose us.

Inner Incorporation of Liposome

This interaction usually occurs when the matrix system of a hydrophilic polymer that has been formed is used as an aqueous medium in proliposome wetting. These interactions include those that are easily made and reliable. Therefore, this system can be used as a drug delivery system that is easily degraded chemically or that is photode-gradable. Moreover, this internal interaction also affects the strength of the bonds among the lipids in the lamellar chain. In addition to selecting the most suitable polymers, crosslinkers and lipids based on customer research needs, BOC Sciences also can perform standard evaluations to observe interaction patterns and their effects on the physicochemical properties of liposome complexes.

Polymer Combination of Liposome

Combinations of several polymer and liposome interactions can be obtained using a combination of polymers or the addition of a cross-linker. The mixture can be in the form of hydrophilic and hydrophobic polymers to streamline drug loading and give trigosable properties to the liposome. Therefore, the right complexation method can even deliver multiple drugs with different release profiles for synergistic purposes. BOC Sciences' advanced platform technology improves the physicochemical properties of liposomes through the lipid-polymer conjugates process, thus supporting research programs for targeted drug delivery and controlled release of drugs.

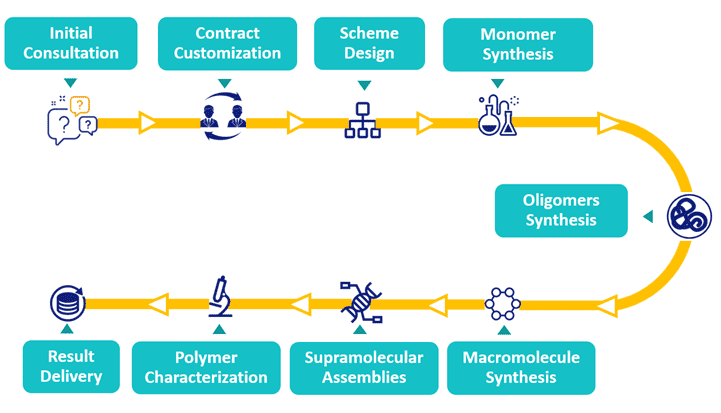

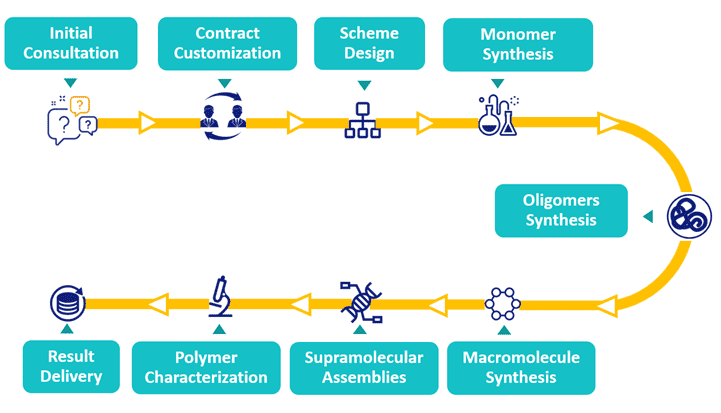

Our Polymer Bioconjugation Workflow

References

- Weil, T. et al. Polymer bioconjugates: Modern design concepts toward precision hybrid materials. Progress in Polymer Science. 2020, 105: 101241.

- Sriwidodo. et al. Liposome-polymer complex for drug delivery system and vaccine stabilization. Heliyon. 2022, 8: e08934.

Fig. 1. The possible interaction of liposome-polymer (Heliyon. 2022, 8: e08934).

Fig. 1. The possible interaction of liposome-polymer (Heliyon. 2022, 8: e08934).