Ring-opening Polymerization Technology

Ring-opening polymerization (ROP) is a chain-growth polymerization where one end of the polymer chain carries a reactive center for cyclic monomers addition. The resulting polymer will contain end groups depending on the applied initiator and occurring termination reactions. With rich experience and extensive professional knowledge in polymerization reactions, BOC Sciences provides our customers with the most competitive polymer products and custom synthesis services to support the unique needs of our clients in polymer development projects.

Introduction of Ring-opening Polymerization (ROP)

Ring-opening polymerization (ROP) is a chain-growth polymerization in which the terminus of a polymer chain attacks cyclic monomers to form a more extended polymer (Fig. 1). The reactive center can be radical, anionic, or cationic, and reactions can be performed in bulk or solution. Specific cyclic monomers such as norbornene or cyclooctadiene can be polymerized to high molecular weight polymers using metal catalysts. In these addition polymerizations, the ring form of a molecule is converted into the open form through addition to a growing polymer chain. There is no change in bonding or bond order in typical polymerization forms in going from the ring to the chain form. These reactions are isodesmic and the driving force for polymerization relief ring strain. Furthermore, the relief of ring stain provides the enthalpy of polymerization needed to overcome the typical loss of translational entropy that accompanies most polymerizations. Thus, rings with high strain degrees are more susceptible to ring-opening polymerization (thermodynamically and kinetically).

Fig. 1. Biodegradable glycopolymers micelles obtained by ring-opening polymerization (Macromolecules 2016, 49(11): 4136-4146).

Fig. 1. Biodegradable glycopolymers micelles obtained by ring-opening polymerization (Macromolecules 2016, 49(11): 4136-4146).

Similar to radical chain polymerization, the common feature of all ring-opening polymerization (ROP) is the presence of at least two elementary reactions required for macromolecule formation: initiation and chain growth. Chain transfer and termination could be avoided, but if present, transfer (irreversible) and/or termination would lower molar mass. Further common features of ionic polymerizations, including ROP, is the interconversion and/or equilibrium between various kinds of active growing species. Covalent ion pairs of several types and "free" ions could simultaneously be present. However, it may also happen that only one or various kinds are present, and only one kind (due to its highest reactivity and/or dominating proportion) is eventually responsible for the product formation.

Applications of Ring-opening Polymerization (ROP)

- Copolymers Synthesis. Ring-opening polymerization is superior for making copolymers with tailored properties to support specific applications, such as coatings, fibers, elastomers, adhesives, and composites.

- Biomedical Materials. Ring-opening polymerization can be applied to synthetic biomedical polymer materials for drug delivery of therapeutic agents, such as small molecules, plasmid DNA, siRNA, etc.

- Degradable Materials. Ring-opening polymerization is commonly used to produce polycaprolactone (PCL), among other notable polyester biopolymers such as polylactic acid (PLA), polyglycolide (PGA), and the copolymer poly(lactic-co-glycolic acid) (PLGA), which are biodegradable structures approved for humans use by regulatory authorities.

- Cellulose Nanocrystals. Ring-opening polymerization has been one of the major routes to graft polymer chains from cellulose substrate surfaces due to surficial hydroxyl groups that act as polymerization initiation sites.

What Can We Do For You?

As a leading supplier for polymer customized synthesis, BOC Sciences offers ring-opening polymerization (ROP) methods for various monomers, including radical, anionic, or cationic. We can also apply radical ROP to synthesize polymers with functional groups incorporated in the backbone chain that cannot otherwise be synthesized via conventional chain-growth polymerization of vinyl monomers. For example, our researchers utilize radical ROP to produce polymers with ethers, esters, amides, and carbonates as functional groups along the main chain. Moreover, we monitor our products according to strict quality control standards during synthesis and characterization processes to ensure our customers receive first-class services and products.

Representative Ring-opening Polymerization (ROP) Monomers (Include but are not limited to the followings):

- Ethylene Oxide (EO)

- Poly (tetrahydrofuran)

- Polyacetals (Formaldehyde and 1,3,5-Trioxane)

- Polyesters (Polyglycolide and Polylactide)

- Polyamides

- Polysiloxanes (Silicones)

- Polycyclopentenes

- Polycyclooctenes

- Polycyclopentadienes

- Polyoxazolines

- Cyclic Phosphorus

- etc.

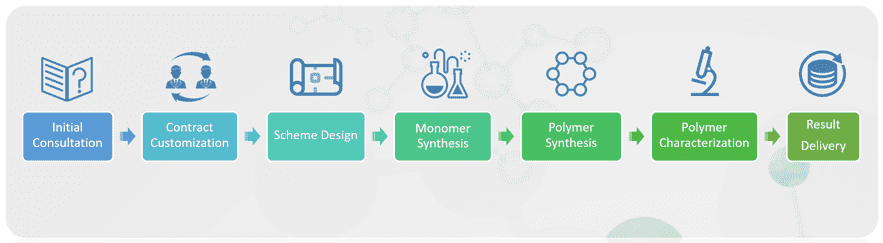

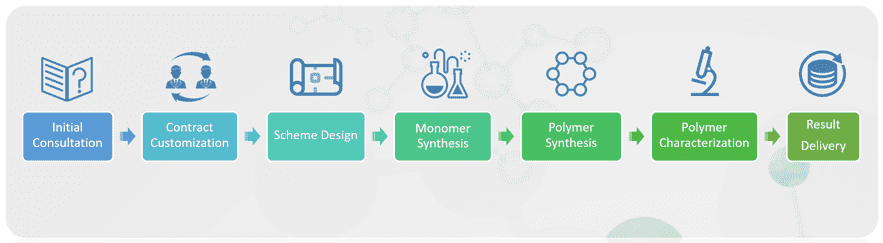

Workflow of Ring-opening Polymerization (ROP)

References

- Penczek S., et al. Ring-Opening Polymerization. Reference Module in Chemistry, Molecular Sciences and Chemical Engineering. Elsevier. 2016.

- Hillmyer, M.A. Polymer Science: A Comprehensive Reference, Polymer Synthesis. 2012 (1): 31-45.

Fig. 1. Biodegradable glycopolymers micelles obtained by ring-opening polymerization (Macromolecules 2016, 49(11): 4136-4146).

Fig. 1. Biodegradable glycopolymers micelles obtained by ring-opening polymerization (Macromolecules 2016, 49(11): 4136-4146).