Natural Polymers & Derivatives

- Molecular Formula: (C13H17O10Na)m(C6H7O7Na)n

- Molecular Formula: (C40H59N11O13)n

- Molecular Formula: (NaC20H28NO15)n

Introduction

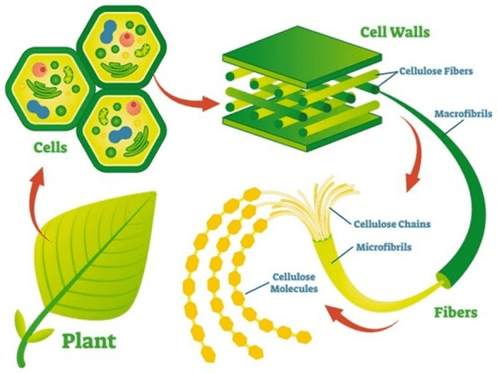

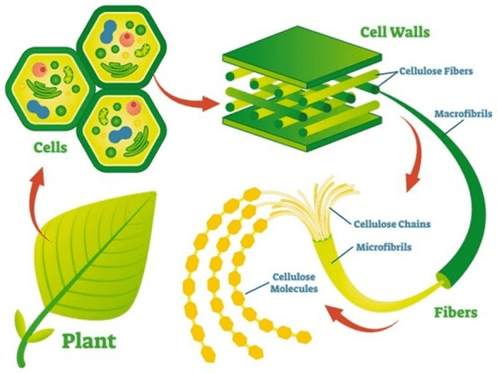

Polymers are divided into natural polymers and synthetic polymers. As the name implies, natural polymers refer to a class of macromolecules derived from nature, including animal sources, plant sources, and microbial sources. Common natural polymers include cellulose, starch, chitin, lignin, natural rubber, and fungal polysaccharides. As a well-known environmentally friendly chemical, natural polymers are easily degraded and the degradation products are non-polluting. In addition, natural polymers also contain a variety of functional groups, which can be transformed into new derivative materials through physical or chemical modification, and various functional materials can also be prepared in combination with emerging nanotechnology. Based on the above advantages, natural polymers and their derivatives have applications in green packaging, tissue engineering, energy production and storage, environmental cleaning, and sensing.

Cellulose is an important branch of natural polymers, not only from a wide range of sources, but also has many advantages, such as good renewability and biocompatibility. However, due to poor thermoplasticity and insufficient mechanical strength, it is difficult to directly use cellulose for production, and it is necessary to make up for the above-mentioned defects through physical or chemical modification techniques. Modification technology can effectively expand the application scope and application potential of cellulose. Some cellulose derivatives are covered in our product list.

Research and Development

Compared with synthetic polymers, natural polymers have the advantages of low toxicity, good reproducibility, flexible modification, and biodegradability. Therefore, they are widely used in many fields.

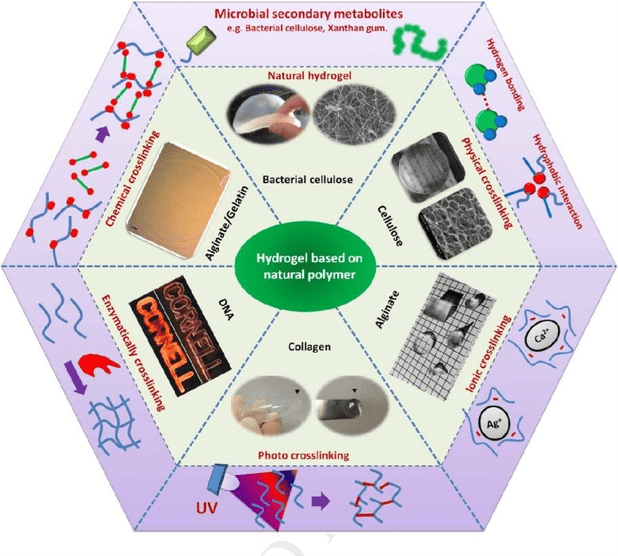

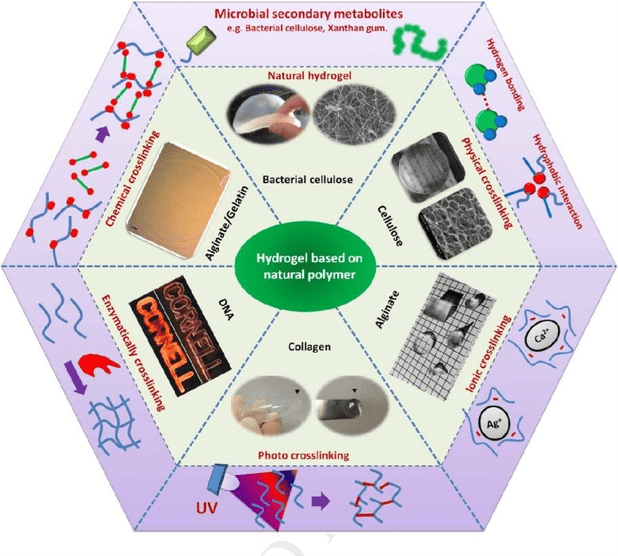

Fig. 1 Various types of natural polymer-based hydrogel. [1]

Fig. 1 Various types of natural polymer-based hydrogel. [1]

Natural polymers have been widely used as carriers for the encapsulation and delivery of drugs and other bioactive molecules. At the heart of drug delivery systems, natural polymers provide excellent biocompatibility, good sustained release, and stability. For example, the colonic drug delivery systems constructed by grafting graphene oxide with sodium alginate and carboxymethyl cellulose showed significant antitumor activity and achieved long-term controlled release effect.

- Gene delivery and tissue engineering

Natural polymers have unique intrinsic properties that help advance the field of non-viral gene therapy. Collagen, for example, has broad utility as a matrix for gene activation, enabling the delivery of large amounts of DNA in a direct, localized manner. In addition, natural polymers often have good cytocompatibility, making them popular choices for tissue engineering scaffold applications.

Technological innovations in materials engineering have led to the development of various membrane processes in water treatment methods. Using natural polymers as membrane materials can effectively improve membrane performance, improve anti-fouling and mechanical strength. In particular, membrane materials based on natural polymers can also specifically adsorb target pollutants.

If you are interested in our natural polymer & derivative products, please contact us immediately!

References

- Shi Z, et al. Electroconductive natural polymer-based hydrogels. Biomaterials. 2016:40-54.

- Ngwuluka N, et al. Naturapolyceutics: The Science of Utilizing Natural Polymers for Drug Delivery. Polymers. 2014, 6(5):1312-1332.

- Dang J M, et al. Natural polymers for gene delivery and tissue engineering. Advanced Drug Delivery Reviews. 2006, 58(4):487-499.

- Mansoori S, et al. Membranes based on non-synthetic (natural) polymers for wastewater treatment. Polymer Testing. 2020.

Fig. 1 Various types of natural polymer-based hydrogel. [1]

Fig. 1 Various types of natural polymer-based hydrogel. [1]