Living Cationic Polymerization (LCP) Technology

Living cationic polymerization (LCP) can realize macromolecular engineering polymerization with active cationic propagating species. With rich experience and extensive professional knowledge, BOC Sciences provides different polymer synthesis solutions and customized synthesis programs according to customers' research needs. Our first-class experimental capabilities and advanced experimental platforms allow us to provide customers with high-quality polymer products.

Introduction of Living Cationic Polymerization (LCP)

Living cationic polymerization (LCP) has become a typical method for obtaining precisely synthesized polymers with controlled molecular weights, weight distribution, as well as complex architectures and sequences. The critical foundation of LCP is to lower the concentration of active species during polymerization through a reversible degeneration process. Similar to conventional radical polymerization, the step of initiation, propagation, chain transfer, and termination all occur in LCP as well. In order to obtain polymers of controlled molecular weight, narrow dispersity, and precise chain-end functionality, elimination or inhibition of chain transfer or chain termination are essential. During LCP, the equilibrium between active substance and dormant polymer chain has become the key factor. Because active substances and dormant substances are exchanged rapidly, thus only a small amount of active substance is provided to the system to keep dispersity low. Factors such as temperature, solvent polarity, the concentration of active initiating species, and the nature of counterion play a decisive role in controlling the equilibrium of the overall mechanism.

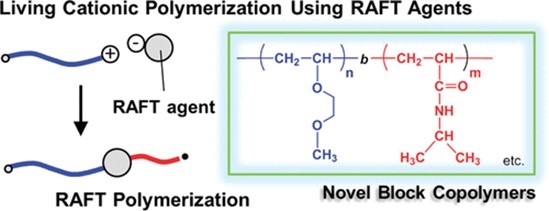

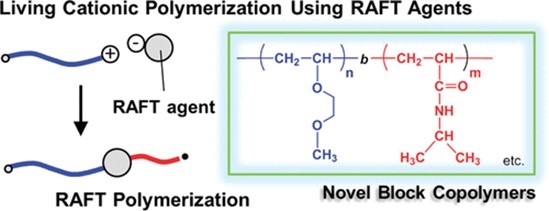

Fig. 1. Example of living cationic polymerization (Macromolecules 2012, 45(2): 794-804).

Fig. 1. Example of living cationic polymerization (Macromolecules 2012, 45(2): 794-804).

The key to accomplishing living cationic polymerization (LCP) is to control initiation and propagation. Polymer chemists have developed a variety of novel initiation systems. For example, external stimuli (i.e., photon and electron) have been exploited to offer temporal control and sequence regulation; organic catalysts have been employed to facilitate propagation without metal-contamination concern; chiral ligands have extended the usage of Lewis acid/base pairs and endowed the tacticity for polymers. Recent advances in LCP with emerging initiation/controlling systems include stereoselective LCP, thionyl/selenium halide-initiated LCP, photoinitiated/controlled LCP, organic acid-assisted LCP, electrochemical-controlled LCP, and chemical-initiated/controlled cationic reversible addition-fragmentation chain transfer (RAFT) polymerization. These strategies can design and synthesize macromolecules, such as functionalized polymers, block polymers, grafted polymers, branched and hyperbranched polymers, etc.

Applications of Living Cationic Polymerization (LCP)

- Antibacterial Polymeric Materials. Living cationic polymerization can develop antimicrobial polymers, including peptidomimetics, synthetic antimicrobial polymers with nondegradable backbones, and biodegradable polymers, which possess potent antimicrobial activity and excellent biocompatibility.

- End-functionalized Polymers. End-functionalized polymers such as macromonomers and telechelic polymers are of great interest due to their potential in many important application areas, and a variety of end-functionalized polymers have been successfully prepared using living/controlled polymerizations.

- Block Copolymers. Block copolymers can form different ordered phases at nanoscopic length scales, such as nanostructured polymer materials and thin films. Living cationic polymerization enables the synthesis of block copolymers and star polymers and is therefore of commercial and academic interest.

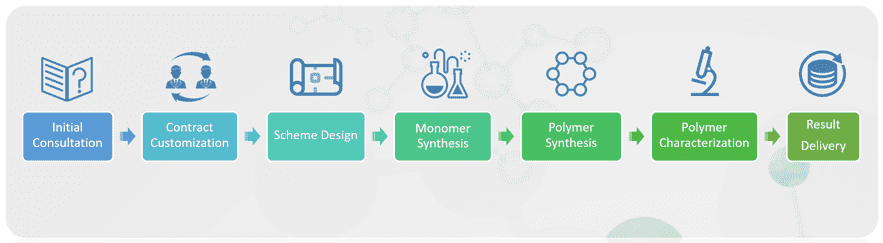

What Can We Do For You?

As a leading service provider in polymer development and synthesis, BOC Sciences is fully qualified and committed to providing advanced and comprehensive living cationic polymerization and development services. Besides undertaking custom synthesis of related products, we also provide polymerization method development and scheme design. We possessed vast experience producing monomers and polymers through various process routes, supported by sensitive analytical tools for product characterization.

Representative Living Cationic Polymerization (LCP) Monomers (Include but are not limited to the following):

- Vinyl Ether

- α-Methyl Vinyl Ether

- Isobutene

- Styrene

- Methylstyrene

- N-vinylcarbazole

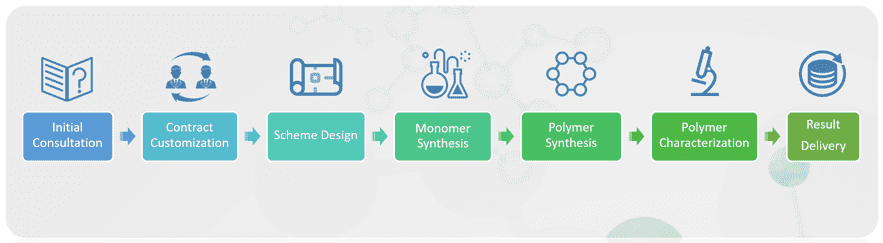

Workflow of Living Cationic Polymerization (LCP)

References

- De, P. et al. Block copolymer synthesis by the combination of living cationic polymerization and other polymerization methods. Frontiers in Chemistry. 2021, 9: 2296-2646.

- Zhu, J. et al. Living cationic polymerization of vinyl ethers initiated by electrophilic selenium reagents under ambient conditions. Polym. Chem. 2021, 12: 983.

- Chen, M. et al. Recent advances in living cationic polymerization with emerging initiation/controlling systems. Macromol. Rapid Commun. 2021, 2100148.

Fig. 1. Example of living cationic polymerization (Macromolecules 2012, 45(2): 794-804).

Fig. 1. Example of living cationic polymerization (Macromolecules 2012, 45(2): 794-804).