- CAS: 1478-61-1

- Molecular Weight: 336.23

- Molecular Formula: C15H10F6O2

- CAS: 25038-59-9

- Molecular Formula: (C10H8O4)n

Introduction

Polyester is a class of polymers containing ester functional groups on the main chain obtained by polycondensation of polyols and polyacids. Due to the differences in raw materials and intermediates, there are many types of polyesters. As a class of polymer materials with excellent performance and wide application, polyester includes polyester resin and polyester elastomer. Polyethylene terephthalate (PET), polybutylene terephthalate (PBT) and polyarylate (PAR) are all common polyester resins, while polyester elastomers generally refer to the thermoplastic elastomer including hard segment and soft segment, which is polymerized from dimethyl formate, 1,4-butanediol and polybutanol.

Polyesters are one of the most promising polymer families based on renewable resources, thanks to their unique and wide-ranging properties, such as fiber-forming ability, potential biodegradability, and biocompatibility.

Synthesis of Polyester

Polyesters can be developed by polycondensation of various combinations of diols and dicarboxylic acids, self-polycondensation of hydroxy acids, and ring-opening polymerization (ROP) synthesis of lactones and lactides. ROP, in particular, is very popular in polyester synthesis because it is highly efficient, produces no by-products (such as water during polycondensation), and requires relatively mild reaction conditions.

Applications

Polyester is widely used in biomedical field as a biodegradable soft material. For example, poly(lactic acid), poly(glycolic acid), and poly(caprolactone) and their series of copolymers have been extensively studied as synthetic biomaterial devices in sutures, plates, and fixation devices for fracture fixation, scaffolds for cell transplantation, and other clinical applications . In addition, surface-functionalized poly(lactic acid) and poly(caprolactone) films can also be used to enhance cell immobilization and protein delivery.

Compared to polyolefins and natural polymers, polyesters offer additional economic and environmental benefits to the packaging industry. Polyester has the same thermoplastic and water repellency properties as polyolefins, but also has the same biodegradability as natural polymers. Additionally, polyesters can be derived from petroleum and renewable sources. These unique properties of polyesters promote their broad prospects as green packaging materials. Poly(ethylene terephthalate) (PET) is the most commonly used polyester in the packaging industry. Recently, Poly(ethylene furanoate) has been developed as a 100% bio-based polyester and is widely regarded as a promising alternative to PET in the packaging industry.

- Electronic and electrical industry

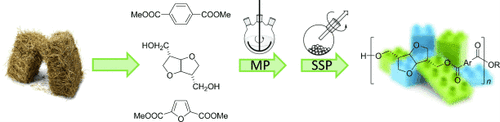

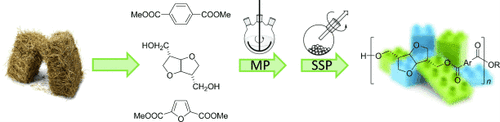

The rapid development of the electronics industry has further promoted the research and development of polyester engineering plastics. At present, many high-performance polyesters have been developed for the preparation of precision electronic components. For example, semi-aromatic polyesters based on carbohydrate-derived rigid diols as a new class of semi-aromatic polymers exhibit high melting points and glass transition temperatures and are promising engineering polyesters. Low pollution flame retardant glass fiber reinforced Poly (butylene terephthalate) can be widely used in relays, connectors, potentiometers, switches and other precision electronic components that require reliable contact.

Fig. 1 Semi-Aromatic Polyesters Based on a Carbohydrate-Derived Rigid Diol for Engineering Plastics.[3]

Fig. 1 Semi-Aromatic Polyesters Based on a Carbohydrate-Derived Rigid Diol for Engineering Plastics.[3]

If you are interested in our polyester products, please contact us immediately!

References

- Xing Z, et al. Biodegradable polyester shape memory polymers: Recent advances in design, material properties and applications. Materials science & engineering. C, Materials for biological applications. 2017, 92(NOV.):1061.

- Rabnawaz M, et al. A roadmap towards green packaging: the current status and future outlook for polyesters in the packaging industry. Green Chemistry. 2017, 19.

- Jing Wu, et al. Semi-Aromatic Polyesters Based on a Carbohydrate-Derived Rigid Diol for Engineering Plastics. ChemSusChem. 2015.

Fig. 1 Semi-Aromatic Polyesters Based on a Carbohydrate-Derived Rigid Diol for Engineering Plastics.[3]

Fig. 1 Semi-Aromatic Polyesters Based on a Carbohydrate-Derived Rigid Diol for Engineering Plastics.[3]