Biodegradable ABA Triblock Copolymers

Introduction

The biodegradable ABA triblock copolymer is a special polymer formed by linking three different polymer segments. It can combine the excellent properties of various polymers to obtain high-performance polymer materials. Biodegradable ABA triblock copolymers have specific structures that will exhibit different properties from simple linear polymers as well as from many random copolymers and even mixtures of homopolymers.[1] As a biodegradable polymer, ABA triblock copolymer can be gradually hydrolyzed under the action of enzymes or microorganisms in a water environment, and finally metabolized into CO2 and H2O. Therefore, ABA triblock copolymers can be used as thermoplastic elastomers, blending compatibilizers and interfacial modifiers, etc.

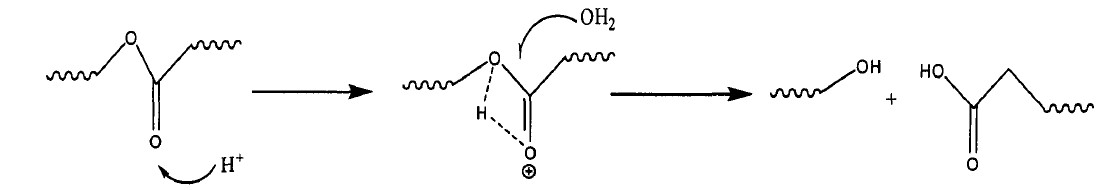

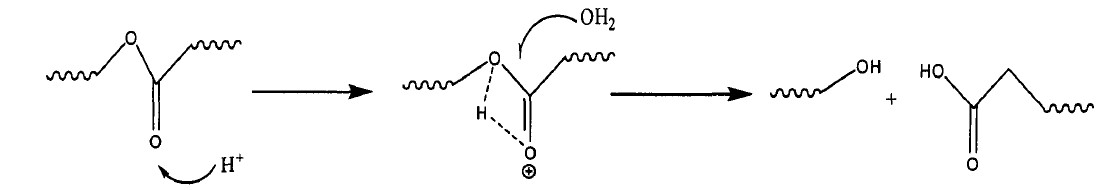

The biodegradation of biodegradable ABA triblock copolymers is essentially enzymatic or chemical catalyzed hydrolysis and microbial decomposition. Therefore, in addition to natural polymers such as starch, cellulose, protein, and chitosan, synthetic polymers can only be degraded when the polymer chain structure contains easily hydrolyzed groups such as aliphatic ester bonds and aliphatic carbonate bonds. The principle of acid catalytic hydrolysis degradation is shown in Fig. 1. Common biodegradable ABA triblock copolymers include polycaprolactone, polylactic acid, styrene-butadiene-3-propylene copolymer, etc.

Fig. 1. The principle of acid-catalyzed hydrolysis degradation (Polymers for Advanced Technologies. 2005, 16(8): 608-615).

Fig. 1. The principle of acid-catalyzed hydrolysis degradation (Polymers for Advanced Technologies. 2005, 16(8): 608-615).

Characteristics

- Biodegradability

- Hydrophiles

- Hydrophobic

- Chemical inertness

- High toughness

- Wide and high flexibility temperature range

Application

Biodegradable ABA triblock copolymers can be used in different industries, including medical, chemical, packaging industries, etc.

Biodegradable ABA triblock copolymers are widely used in the medical field. Due to the degradation that occurs in the human body, they are often used as drug carriers. ABA triblock copolymers can increase drug diffusion rate and achieve constant release. In addition, biodegradable ABA triblock copolymers can be used as surgical materials, such as surgical sutures, bone nails, etc., which can be removed without surgery after wound healing, reducing the pain of patients.[2]

The biodegradable ABA triblock copolymer has sufficient hardness and toughness. In addition, they have high physical strength and good impact resistance. Therefore, they can be mixed with other materials as reinforcing and toughening materials and are widely used as tires, pipes, engineering plastics, etc.

Packaging is very common in daily life. However, while the traditional polymer materials used for packaging provide convenience for people, they also cause serious environmental pollution because they are difficult to degrade. Therefore, biodegradable polymer materials are gradually becoming a new material for packaging. The biodegradable ABA triblock copolymer not only has biodegradable properties, but also has excellent heat resistance. Therefore, the biodegradable ABA triblock copolymer can be widely used in the food packaging industry.

If you are interested in our biodegradable ABA triblock copolymers, please contact us immediately!

References

- Nguyen, V.D. et al. A novel self-heat recuperative dividing wall column to maximize energy efficiency and column throughput in retrofitting and debottlenecking of a side stream column. Applied Energy. 2015, 159: 28-38.

- Sun, J. et al. Deepening Internal Mass Integration in Design of Reactive Distillation Columns, 1: Principle and Procedure. Industrial & Engineering Chemistry Research. 2009, 48(4): 2034-2048.

Fig. 1. The principle of acid-catalyzed hydrolysis degradation (Polymers for Advanced Technologies. 2005, 16(8): 608-615).

Fig. 1. The principle of acid-catalyzed hydrolysis degradation (Polymers for Advanced Technologies. 2005, 16(8): 608-615).