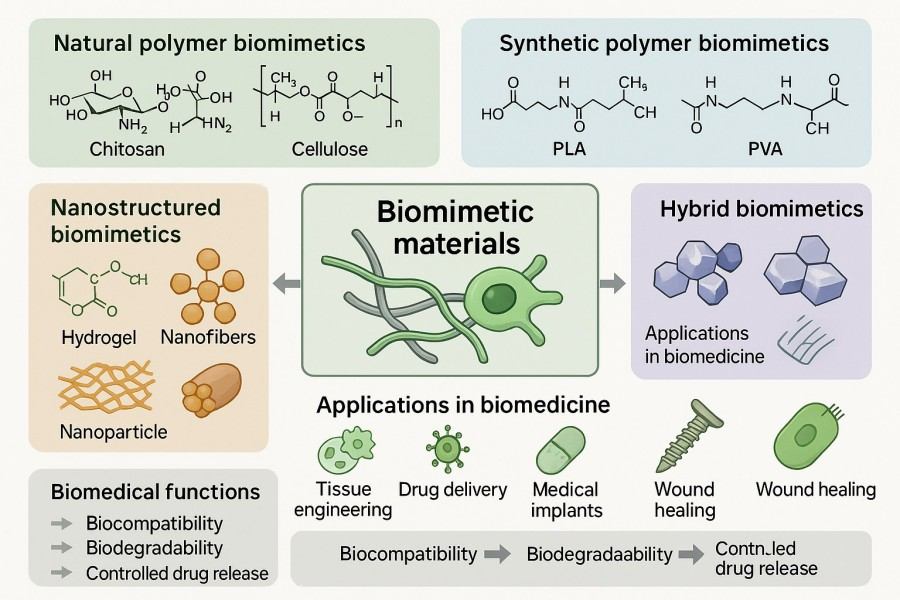

Biomimetic materials are designed to imitate natural biological structures, functions, or properties, enabling mechanical, chemical, or biological characteristics that mimic natural tissues. They are widely used in tissue engineering, regenerative medicine, drug delivery, and smart materials development to achieve high-performance and functional applications.

- Home

-

Products

-

Monomers

- Acrylic Monomers

- Alcohol Monomers

- Allyl Monomers

- Amide & Imide Monomers

- Amine Monomers

- Anhydride Monomers

- Biodegradable Polymer Monomers

- Carboxylic Acid Monomers

- Cycloolefin

- Dendrimer Building Blocks

- Epoxide Monomers

- Halide Monomers

- Isocyanate Monomers

- Mercaptan Monomers

- Other Monomers

- Silicone Monomers

- Styrenic Monomers

- Vinyl Monomers

- Polymer Standards

-

Polymers

- Acid Functional Polymers & Salts

- Acrylic Polymers

- Alkene & Vinyl Polymers

- Amide and Imide Polymers

- Amine Functional Polymers & Salts

- Biodegradable Polymers

- Copolymers

- Dendrimers

- Epoxy Polymers

- Halogenated Polymers

- Natural Polymers & Derivatives

- Other Polymers

- Poly(ethylene glycol)s (PEGs) & Derivatives

- Polyester

- Polyether

- Silicones

- Styrenic Polymers & Derivatives

- π-Conjugated Polymers

- Reagents for Polymerization

-

Monomers

-

Custom Services

- Polymer Characterization Services

- Polymer Isolation and Purification

-

Custom Synthesis

- Monomer Synthesis Services

-

Polymer Synthesis Services

- Atom Transfer Radical Polymerization Technology

- Reversible Addition-fragmentation Chain Transfer Polymerization Technology

- Nitroxide-mediated Polymerization Technology

- Ring-opening Polymerization Technology

- Ring-opening Metathesis Polymerization Technology

- Free Radical Polymerization Technology

- Living Cationic Polymerization (LCP) Technology

- Living Anionic Polymerization Technology

- Copolymer Synthesis Services

- Polymer Additive Synthesis Services

- Polymer Initiator Synthesis Services

- Polymer Nanoparticle Synthesis

- Polymer Microsphere Synthesis

- Polymer Hydrogel Synthesis

- Polymer Micelle Synthesis

-

Polymer Modification Services

- Side/End Group Functionalization

- Side/End Group Protection

- Polymer Bioconjugation Services

- Biomimetic Materials

- Support

- About Us

- Contact Us

Chitosan Services

Chitosan Services

Alginate Services

Alginate Services

Cellulose Services

Cellulose Services

Gelatin Services

Gelatin Services

Poly(lactic-co-glycolic acid) (PLGA) Services

Poly(lactic-co-glycolic acid) (PLGA) Services

Polycaprolactone (PCL) Services

Polycaprolactone (PCL) Services

Polylactic Acid (PLA) Services

Polylactic Acid (PLA) Services

Polyurethane (PU) Services

Polyurethane (PU) Services

Polyvinyl Alcohol (PVA) Services

Polyvinyl Alcohol (PVA) Services