Alginate Film Preparation

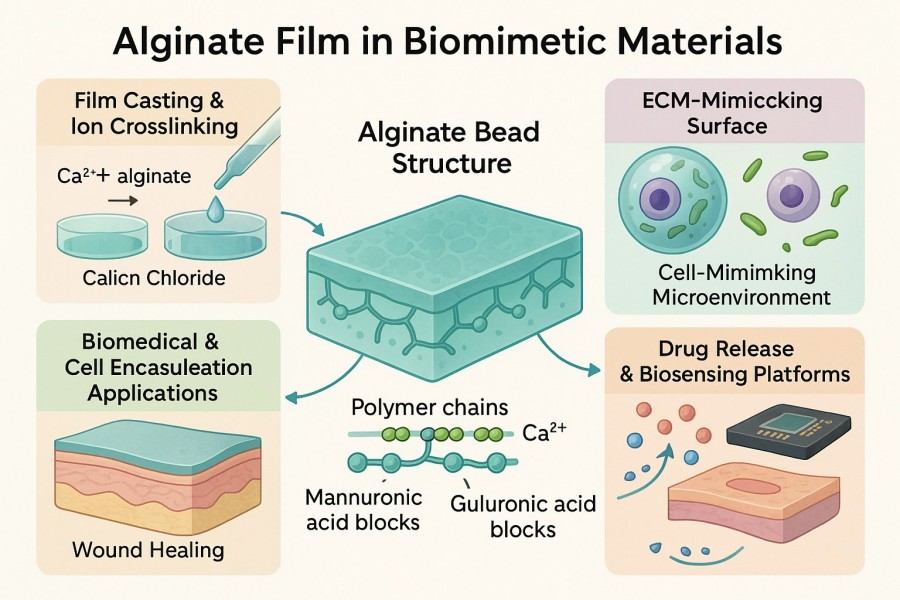

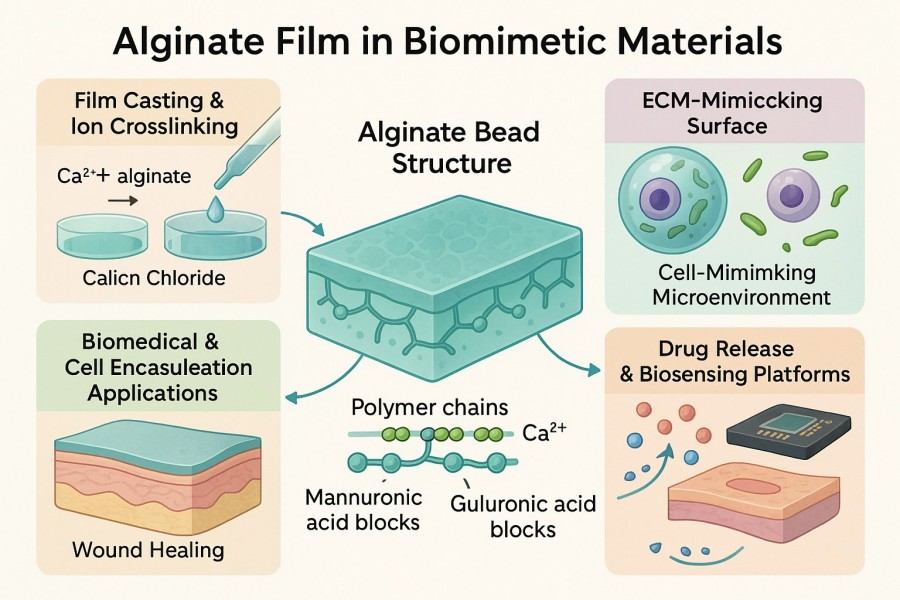

Alginate films/membranes are continuous films or membrane-like materials primarily composed of alginate, formed through physical or chemical methods. As a two-dimensional functional material derived from natural polysaccharides, alginate films have achieved significant advances in the field of biomimetic materials due to their biocompatibility, tunable physical properties, and multifunctional potential. From tissue engineering scaffolds and drug carriers to smart sensing membranes and medical dressings, alginate films demonstrate broad application value across diverse use cases. BOC Sciences is dedicated to providing high-quality alginate films and customized development services for research institutions, development laboratories, and manufacturing enterprises worldwide. From raw material selection, film formulation design, and structural control, to functional modification and large-scale production, BOC Sciences offers end-to-end customized services. We cater to both small-scale laboratory samples for basic research and large-scale membrane materials for production validation, meeting customer needs at every stage.

What We Offer

Alginate Films Offered by BOC Sciences for Biomimetic Materials

In the field of biomimetic material development, different applications demand diverse performance characteristics from alginate films. With extensive experience in alginate membrane development, BOC Sciences provides multiple categories of alginate films to meet functional, structural, and performance optimization requirements. The main categories include:

Pure Alginate Films

- Made solely from alginate, these films are formed via solution casting or ionic cross-linking.

- Features: Excellent biocompatibility, transparency, and flexibility, though mechanical strength is limited.

- Applications: Edible packaging, drug carriers, and basic research membranes.

Composite Alginate Films

- Prepared by combining alginate with other natural polymers (e.g., gelatin, chitosan, collagen, hyaluronic acid) or synthetic polymers (e.g., PVA, polylactic acid).

- Features: Enhanced mechanical performance, tunable degradation rate, and functional properties (antibacterial, moisturizing, sustained release, etc.).

- Applications: Tissue engineering scaffolds, controlled-release drug films, high-performance food packaging films.

Functionalized Alginate Films

- Special functional groups or bioactive molecules (e.g., drugs, enzymes, antibacterial agents, nanoparticles) are introduced onto alginate molecules.

- Features: Imparts specific functions such as targeted drug release, antibacterial activity, sensing, or responsiveness.

- Applications: Smart membranes, medical functional films, environmental monitoring membranes.

Composite Gel Films

- Formed through synergistic gelation of multiple polysaccharides or proteins.

- Features: Combines flexibility and strength, with tunable pore structures.

- Applications: Biomedical scaffolds, cell culture substrates, biomimetic membranes.

Ionically Cross-Linked Films

- Formed by interactions between alginate carboxyl groups and divalent/trivalent ions such as calcium, magnesium, or zinc, creating "egg-box" structures.

- Features: Good mechanical strength and moderate water resistance.

- Applications: Drug carriers, food films, tissue engineering scaffolds.

Chemically Cross-Linked Films

- Covalent bonds are formed using chemical cross-linkers such as glutaraldehyde or EDC/NHS.

- Features: Excellent water resistance and mechanical properties, suitable for long-term use.

- Applications: High-strength functional films, controlled-release membranes, biomimetic materials.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Alginate Film Preparation and Development Services

BOC Sciences understands the challenges faced by researchers and manufacturers during development. Leveraging an advanced polymer chemistry platform and a professional technical team, we provide efficient and reliable customized alginate film development services. Whether enhancing mechanical performance, tuning functional properties, or supporting small-scale validation and industrial scaling, we deliver end-to-end solutions to facilitate research innovation and industrial implementation.

1End-to-End Customized Support

- Precisely select alginate raw materials of different sources, G/M ratios, and molecular weights;

- Customize film thickness, porosity, and mechanical properties;

- Design specific functionalities such as sustained drug release, antibacterial activity, smart responsiveness, or biodegradability.

2Multi-Type Alginate Film Development Capability

- Pure alginate and composite films;

- Ionically cross-linked, chemically cross-linked, and composite gel films;

- Functionalized films, such as drug carrier films, smart responsive membranes, and edible films.

3Customized Biomimetic Material Development

- Micro-porous network designs simulating natural biological membranes;

- Smart-responsive functional film development;

- Multi-layer or composite film structures to meet requirements for biomimetic sensing, drug delivery, and tissue engineering applications.

4Industrial Support and Large-Scale Production

- Batch production planning to ensure consistent film performance;

- Process optimization to reduce production costs and improve yield;

- Quality control and standardized testing to meet industrial production and regulatory requirements.

Characterization

Professional Alginate Film Analysis and Testing Platform

To ensure high performance and stability of alginate films in biomimetic research and applications, BOC Sciences has established a dedicated analysis and testing platform. Combining advanced instrumentation with a skilled technical team, the platform provides comprehensive evaluation of film structural characteristics, mechanical properties, biocompatibility, and functionality. We deliver reliable data support and customized optimization plans for each batch of films, whether for basic research, functional development, or production quality control, ensuring that material performance meets the expected requirements.

| Test Category | Test Item | Purpose & Description |

|---|

| Structural Analysis | FTIR (Fourier Transform Infrared Spectroscopy) | Analyze chemical composition and functional groups of alginate films. |

| NMR (Nuclear Magnetic Resonance) | Confirm molecular structure, monomer ratio, and uniformity of composite films. |

| XRD (X-ray Diffraction) | Evaluate crystallinity and structural arrangement of the film. |

| Microscopic Morphology | SEM (Scanning Electron Microscopy) | Observe surface morphology and pore structure of the film. |

| AFM (Atomic Force Microscopy) | Analyze surface roughness and nanoscale morphological features. |

| Mechanical Properties | Tensile Strength | Measure resistance to pulling and assess mechanical robustness. |

| Elongation at Break | Evaluate flexibility and extensibility of the film. |

| Elastic Modulus | Determine elasticity and deformation capacity of the film. |

| Water Content & Swelling | Water Absorption | Assess water uptake and moisture retention capability. |

| Swelling Test | Analyze swelling behavior in different media. |

| Functional Performance | Drug Loading & Release | Measure drug loading capacity and controlled release behavior. |

| pH/Temperature Responsiveness | Test smart response of the film under different environmental conditions. |

| Biocompatibility | Cell Adhesion & Proliferation | Evaluate suitability of the film for cell attachment and growth. |

| In Vitro Degradability | Determine degradation rate and products of the film in biological environments. |

Advantages

Key Advantages of Our Alginate Film Solutions

- End-to-End Technical Support: From raw material selection and film formulation design to functional modification and batch production, we provide one-stop technical guidance to ensure efficient project progression.

- Multi-Type Film Development Capability: Customizable single-layer, composite, multi-layer, and microporous alginate films, enabling multifunctional design to meet diverse biomimetic material application requirements.

- High-Precision Analysis and Testing Platform: Equipped with advanced instruments such as FTIR, NMR, XRD, SEM, and AFM, providing comprehensive evaluation of film structure, mechanical properties, and functionality to ensure material reliability.

- Controlled Functional Modification: Supports drug loading, smart responsiveness, and antibacterial functionalization, offering targeted solutions to meet specific research and application needs.

- Strict Quality Control System: From laboratory-scale trials to kilogram-level production, quality monitoring is implemented throughout the process to ensure consistent, stable, and reliable film performance.

- Professional Customer Technical Support: Provides application guidance, experimental optimization, and performance evaluation to assist clients in overcoming R&D challenges and accelerating project implementation.

- Flexible Customization and Collaboration Models: Offers R&D collaboration, customized production, and technical consulting based on client needs, enabling highly personalized service and rapid response.

Service Process

Alginate Film Development Service Workflow

To ensure projects are efficient, controllable, and meet expectations, BOC Sciences provides systematic, end-to-end services for alginate film development. From requirement analysis to batch production, we combine advanced fabrication technology, a professional analysis and testing platform, and extensive material development experience to provide comprehensive support for research institutions, biomimetic material developers, and manufacturers.

1Requirement Communication and Feasibility Assessment

During project initiation, clients provide target applications, performance requirements, and functional design needs for the film material. BOC Sciences' expert team conducts in-depth analysis and feasibility evaluation, including:

- Selection and assessment of alginate raw materials (natural seaweed extracts or high-purity industrial sources);

- Feasibility analysis of film structure, including thickness, porosity, mechanical performance, and functional potential;

- Identification of process challenges and preliminary solutions, such as cross-linking methods, composite material ratios, and film formation techniques;

- Prediction of development timelines and milestone achievements to ensure R&D and application schedules are controllable.

2Raw Material and Formulation Customization

During the material selection and formulation design phase, BOC Sciences provides highly customized services:

- Select alginate type and purity according to client requirements, supporting single alginate or composite formulations;

- Introduce chitosan, collagen, gelatin, or nanoparticles for composite designs according to functional needs;

- Design controlled cross-linking methods and ratios to optimize mechanical properties, swelling behavior, and functional loading capacity;

- Provide specialized functional modification plans, such as smart responsiveness, drug loading, or enhanced antibacterial performance.

3Laboratory Development and Small-Scale Trials

Under laboratory conditions, BOC Sciences completes preliminary film fabrication and performance validation:

- Film formation methods: casting, spraying, or layer-by-layer self-assembly, ensuring controllable thickness and pore structure;

- Preliminary performance testing: mechanical strength, flexibility, pore structure, and functional verification;

- Functional verification: drug loading, pH/temperature responsiveness, or composite uniformity testing.

4Process Optimization and Functional Modification

After small-scale trials, we perform process optimization and functional modification based on experimental data:

- Adjust cross-linking methods, composite ratios, and film thickness to meet target mechanical and functional requirements;

- Optimize degradation rates to ensure controllable biodegradation or sustained performance in biological environments;

- Complete functional modifications, such as enhanced drug loading, optimized smart responsiveness, or improved antibacterial properties.

5Batch Production and Quality Control

BOC Sciences provides customized services from gram-scale laboratory samples to kilogram-level batch production:

- Supports pilot and small-scale production for process validation and application testing;

- Implements strict quality control, including mechanical performance testing, functionality verification, and structural consistency evaluation;

- Ensures each batch maintains consistent performance, uniform composition, and stable functional characteristics to meet research, development, or production needs.

6Technical Support and Application Guidance

BOC Sciences not only provides high-quality materials but also offers comprehensive technical support:

- Offers functional design and application optimization advice for tissue engineering, drug delivery, sensor membranes, and medical dressings;

- Assists clients in experimental design, film performance evaluation, and functional testing;

- Provides full technical guidance from material usage to process improvement, accelerating project development and increasing R&D efficiency.

Applications

Application Support for Biomimetic Materials

Alginate films, due to their natural origin, biocompatibility, and highly controllable physicochemical properties, have become a key choice for biomimetic material research, development, and industrialization. In biomimetic applications, researchers focus not only on basic structure and mechanical performance but also on functional capabilities such as smart responsiveness, drug delivery, cell support, and microstructure simulation. BOC Sciences understands these needs and leverages advanced alginate film fabrication technology and comprehensive analysis platforms to provide full support.

Tissue Engineering and Regenerative Medicine

- Cell Culture Scaffolds: Provides controllable pore structures and bioactive surfaces to promote cell adhesion, proliferation, and differentiation.

- Skin and Soft Tissue Engineering Films: Maintains a moist environment to support wound healing.

- Biodegradable Scaffolds: For in vivo implantation, degrade over time while supporting tissue regeneration.

Drug Delivery and Smart Films

- Sustained-Release Drug Carriers: Controlled film thickness and cross-linking for continuous drug release.

- pH/Temperature-Responsive Films: Smartly regulate drug release location and rate.

- Functionalized Nanocomposite Films: Enhance drug loading and targeting efficiency.

Biomimetic and Microstructured Membranes

- Selective Permeation Films: For small molecule filtration and microbial isolation.

- Gradient Functional Films: Multi-layer films integrating multiple functionalities.

- 3D-Printed Microstructured Membranes: Custom scaffolds or bioreactor membranes.

Medical Dressings and Protective Films

- Moisture-Absorbing Hemostatic Dressings: Form a moist gel environment to promote hemostasis.

- Antibacterial Dressings: Incorporate silver ions or functional drugs to prevent infection.

- Wound Healing Membranes: Support cell proliferation and accelerate tissue repair.

FAQs

Frequently Asked Questions

-

What is sodium alginate film?

Sodium alginate film is a film material primarily made from sodium alginate, with excellent biocompatibility and film-forming properties. It is suitable for biomimetic materials, food packaging, and drug delivery systems. Its controllable thickness and flexibility make it ideal for functional films and scaffolds, and it can be easily cross-linked or composited to meet various application requirements.

-

How do you prepare sodium alginate film?

Sodium alginate film is typically prepared via solution casting or spraying. First, dissolve sodium alginate in deionized water to form a uniform solution, adding plasticizers or functional additives as needed. Then, pour or coat the solution onto a substrate, control the thickness, and dry to form a transparent, flexible film. Post-treatment with cross-linkers (e.g., calcium ions) can enhance mechanical strength and water resistance. The process is simple and allows control over thickness, porosity, and functional characteristics.

-

What is calcium alginate film?

Calcium alginate film is a gel-like film formed by cross-linking alginate with calcium ions, exhibiting stable mechanical performance and water resistance. It is widely used in tissue engineering, controlled drug release, and biomedical membranes, providing a moist environment and supporting cell adhesion. Cross-linking degree can be adjusted to control degradation rate and functional properties.

-

What are common methods for alginate film preparation?

Common alginate film preparation methods include casting, spraying, and layer-by-layer assembly. By controlling solution concentration, film thickness, and cross-linking conditions, single-layer, composite, or porous films can be fabricated. This allows tuning of mechanical properties, functional modifications, and drug loading, meeting both research and industrial requirements.

-

What are the characteristics of chitosan alginate film?

Chitosan alginate film is a composite film of chitosan and alginate, combining the advantages of both. It improves mechanical strength and stability while maintaining good biocompatibility and controllable degradation. These films are widely used in tissue engineering scaffolds, smart drug delivery, and antibacterial dressings, and their functional properties can be customized by adjusting the chitosan/alginate ratio.

-

What is sumatriptan alginate film?

Sumatriptan alginate film is a drug delivery carrier prepared by loading the analgesic sumatriptan into an alginate film. The film allows controlled and targeted drug release while maintaining alginate's biocompatibility and biodegradability. By adjusting film thickness, cross-linking degree, and drug loading, the release profile can be optimized, making it suitable for research and development of oral or sublingual fast-dissolving formulations.