PLGA Hydrogel Preparation

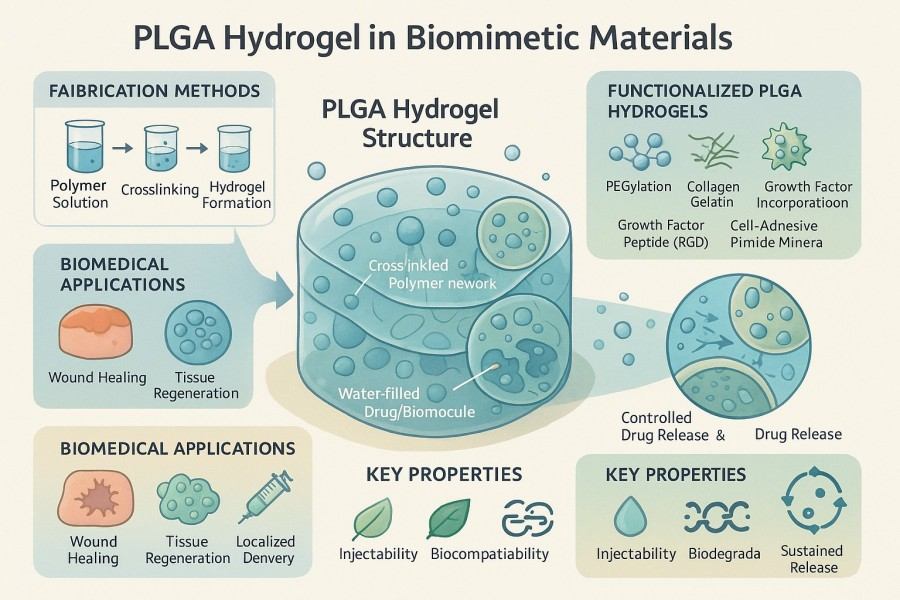

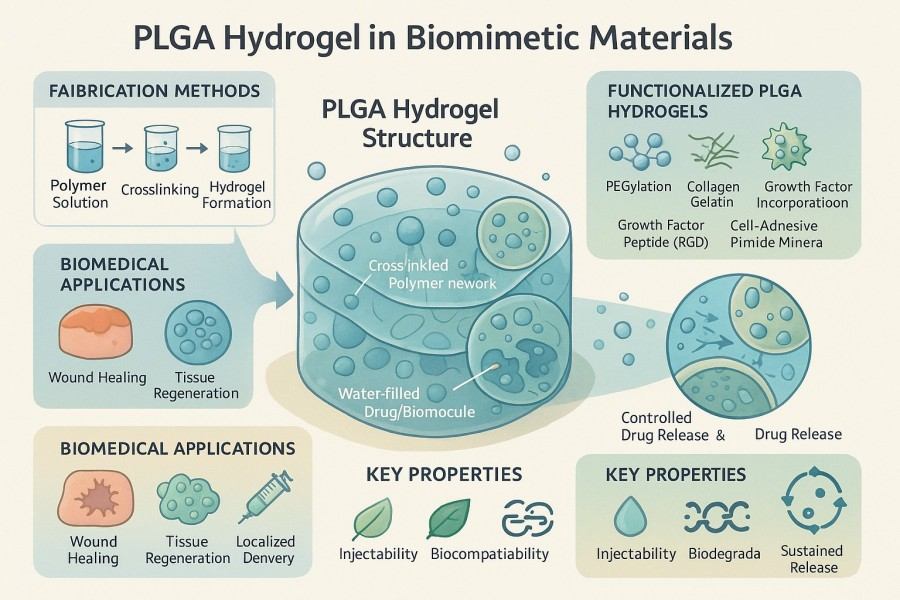

PLGA hydrogel is a biodegradable polymer material forming a three-dimensional crosslinked network based on poly(lactic-co-glycolic acid) (PLGA) and water. It combines the excellent biocompatibility and controllable degradability of PLGA with the high water content, flexibility, and biomimetic properties of hydrogels. Therefore, it has broad research and application value in drug delivery, tissue engineering, regenerative medicine, and wound healing. Compared with conventional natural polymer hydrogels (such as gelatin, alginate, chitosan), PLGA hydrogel offers superior mechanical tunability, controlled degradation, and stability. Compared with other synthetic polymers (such as PEG, PVA), its degradation products are more physiologically friendly, and its unique hydrophobic–hydrophilic synergistic properties allow flexible performance tuning through molecular design. Leveraging its extensive expertise in polymer chemistry and biomaterials, BOC Sciences provides PLGA hydrogel preparation, characterization, and development services, supporting clients throughout the entire process from experimental research to industrial translation with high-quality, customizable material solutions. We can precisely control PLGA ratios, molecular weight, crosslinking methods, and functional modifications according to specific application needs, enabling applications such as controlled drug release, tissue engineering scaffolds, and smart responsive materials. Whether for small-scale laboratory research or pilot-scale production, we provide full-process technical support to ensure stable and reliable product performance, accelerating your R&D and industrialization.

What We Offer

Unlock Custom PLGA Hydrogel Solutions for Your Research

BOC Sciences offers a diverse range of PLGA hydrogel types and customization services, including chemical crosslinking, physical crosslinking, copolymerization, composite, and smart responsive systems. Whether for drug delivery, tissue engineering scaffolds, or smart responsive material development, we provide tailored design and optimization solutions to meet research and industrialization requirements.

Chemically Crosslinked PLGA Hydrogel

- Offers multiple chemical crosslinking strategies, including ester bonds, amide bonds, and click chemistry reactions.

- Crosslinking density can be adjusted to achieve different mechanical properties and degradation rates.

- Supports custom development for drug carriers, tissue engineering scaffolds, and long-acting controlled-release systems.

Physically Crosslinked PLGA Hydrogel

- Provides hydrogels based on hydrophobic interactions, hydrogen bonding, and electrostatic interactions.

- Customizable temperature- or pH-responsive in situ gel systems suitable for injectable applications.

- Supports low-toxicity, reversible gelation, ideal for cell culture and soft tissue repair.

Copolymer PLGA Hydrogel

- Offers various block or random copolymer designs, such as PLGA–PEG–PLGA, PLGA–PHEMA, PLGA–PVP.

- Hydrophilicity, mechanical strength, and degradation cycles can be adjusted to meet diverse drug delivery and scaffold needs.

- Supports functional modifications, such as incorporating cell-adhesion peptides, drugs, or signaling molecules.

Composite PLGA Hydrogel

- Can be combined with natural polymers (gelatin, chitosan, hyaluronic acid) to enhance bioactivity and cell compatibility.

- Provides inorganic composite systems (hydroxyapatite, graphene oxide) to improve mechanical properties and functional response.

- Supports multi-component composite design for applications such as bone repair, nerve guidance, and smart release.

Responsive and Smart PLGA Hydrogel

- Customizable thermo-, pH-, enzyme-, and light/magnetic-responsive hydrogels.

- Enables triggered release of drugs or signaling molecules in response to environmental stimuli.

- Supports development of smart delivery systems and programmable biomaterials.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

From Lab to Scale-Up: Comprehensive PLGA Hydrogel Development Support

Performance design and functional development are crucial for PLGA hydrogel applications in various research scenarios. BOC Sciences offers end-to-end custom development services, from molecular design and material preparation to functional optimization, supporting clients in developing high-performance hydrogels. Whether for drug delivery, tissue engineering, or smart responsive materials, we provide professional technical solutions and experimental validation support.

1Molecular Design and Formulation Optimization

- Design lactic/glycolic acid ratios, molecular weight, and terminal groups according to application requirements to precisely control degradation rates.

- Offer copolymer and composite system designs, such as PLGA–PEG–PLGA, PLGA–PHEMA, and multi-component composite hydrogels.

- Optimize crosslinking methods and density to achieve desired mechanical properties and swelling behaviors.

- Provide material optimization solutions combining computational modeling and experimental data to enhance R&D efficiency.

2Hydrogel Preparation and Process Development

- Provide chemical, physical, and smart responsive hydrogel preparation technologies.

- Support injectable, in situ gelation, molding, freeze-drying, and 3D printing processes.

- Develop small-batch experimental samples and pilot-scale production processes per client needs.

- Offer process optimization and reproducibility verification to ensure consistent product performance.

3Functional Modification and Composite Design

- Support surface functionalization, such as incorporating cell-adhesion peptides (RGD), growth factor binding sites, etc.

- Can composite with natural polymers (gelatin, chitosan, hyaluronic acid) or inorganic materials (hydroxyapatite, graphene oxide).

- Develop smart responsive hydrogels, including thermo-, pH-, enzyme-, and light/magnetic-responsive systems.

- Customize multifunctional composites for drug release, tissue repair, and signaling applications.

4Pilot and Scale-Up Production Evaluation

- Provide technical evaluation for scaling from gram-level experiments to kilogram-level pilot production, ensuring process scalability.

- Optimize raw material usage, reaction conditions, and mixing/crosslinking processes to achieve stable product performance and batch consistency.

- Verify physical properties, degradation behavior, and functional characteristics during scale-up to meet application requirements.

- Support industrial-scale production route design and technology transfer, shortening the timeline from R&D to manufacturing.

Characterization

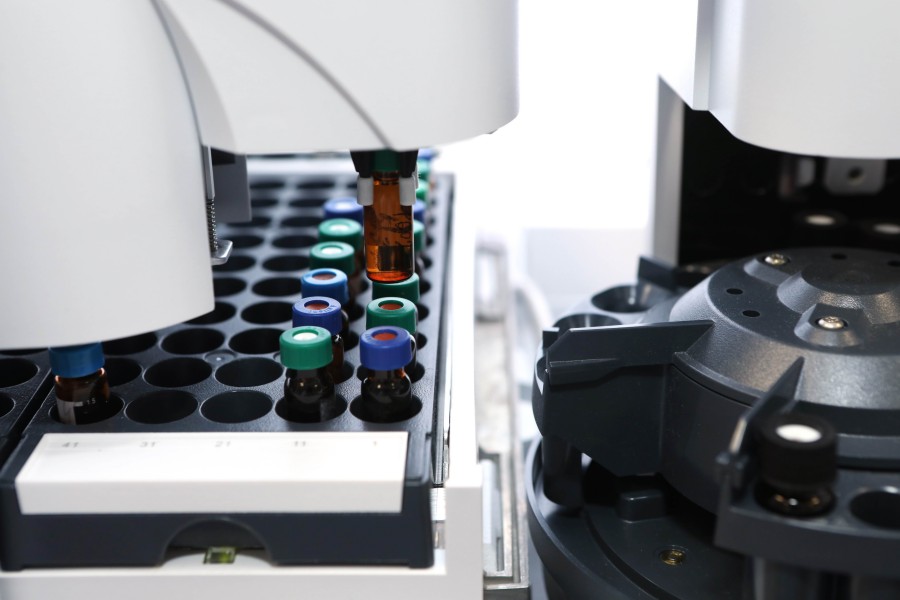

PLGA Hydrogel Analysis and Characterization Services

BOC Sciences is equipped with advanced polymer characterization and quality control platforms, conducting systematic testing for each batch of PLGA hydrogel to ensure structural, performance, and biocompatibility standards meet research and industrial needs. We provide full-process quality assurance from raw material validation and process monitoring to final product performance evaluation, supporting clients in smoothly advancing R&D and industrialization.

| Test Category | Specific Test | Service Features & Capabilities |

|---|

| Chemical Structure Analysis | FTIR (Fourier Transform Infrared Spectroscopy), NMR (Nuclear Magnetic Resonance) | Accurately confirms polymer chemical structure, end groups, and copolymer ratios |

| Molecular Weight & Distribution | GPC/SEC (Gel Permeation Chromatography/Size Exclusion Chromatography) | Measures average molecular weight and dispersity, guiding degradation performance optimization |

| Morphology & Microstructure | SEM/TEM (Scanning/Transmission Electron Microscopy), Pore Size Analysis | Observes hydrogel pore structure, network distribution, and micro-morphology |

| Thermal Properties | DSC (Differential Scanning Calorimetry), TGA (Thermogravimetric Analysis) | Evaluates thermal stability, melting behavior, and degradation characteristics |

| Mechanical Properties | Compression, Tensile, and Shear Testing | Quantitatively measures elastic modulus, strength, and deformation resistance |

| Swelling & Degradation Behavior | Water Absorption Measurement, In Vitro Degradation Tests | Controls swelling ratio and degradation period to suit different application needs |

| Drug Loading & Release Performance | Drug Encapsulation Efficiency, In Vitro Release Profile | Evaluates controlled release performance and drug stability |

| Biocompatibility Assessment | Cell Viability, Adhesion, and Proliferation Tests | Ensures material safety and compatibility for cells and tissues |

Advantages

Why Choose BOC Sciences PLGA Hydrogel Services?

- Professional Technical Team: Rich experience in polymer and hydrogel R&D, providing full-process technical support from polymer design to functional hydrogel development.

- Customized Development Capability: Design lactic/glycolic acid ratios, molecular weight, and crosslinking strategies according to client application needs to achieve personalized material solutions.

- Advanced Analysis and Characterization: Equipped with FTIR, NMR, GPC, SEM, DSC, and other instruments for comprehensive testing of hydrogel structure, mechanics, degradation, and functional performance.

- Multi-Process Preparation Capability: Supports laboratory preparation, pilot-scale production, and process optimization for chemical/physical crosslinked, copolymer, composite, and smart responsive hydrogels.

- High-Quality Assurance: Full traceable quality control system ensures batch consistency and stable performance, meeting research and industrial requirements.

- Customer Technical Support: Provides comprehensive support in material selection, process optimization, performance verification, and data analysis, helping clients accelerate R&D progress.

- Industrialization Service Capability: From lab-scale preparation to kilogram-level pilot-scale production, we provide feasibility assessment and process transfer to support industrial implementation.

Service Process

Custom PLGA Hydrogel Synthesis and Preparation Service Workflow

To help clients efficiently develop high-performance PLGA hydrogels, BOC Sciences offers a systematic service workflow, covering everything from requirements analysis to pilot-scale production and technical support. Our workflow balances flexibility and standardization, supporting customized R&D and functional optimization to provide clients with complete solutions.

1Requirements Analysis & Project Evaluation

- Understand client application scenarios, performance requirements, material specifications, and R&D goals, including drug delivery, tissue engineering, or smart responsive systems.

- Conduct comprehensive feasibility assessments and propose preliminary technical solutions covering material composition, preparation methods, performance indicators, and project timelines.

- Provide project risk analysis and optimization recommendations to ensure a scientifically sound and sustainable R&D plan.

2Molecular Design & Formulation Development

- Design lactic/glycolic acid ratios, molecular weight, and terminal groups to control hydrogel degradation cycles and mechanical properties.

- Select the most suitable crosslinking strategy (chemical, physical, or composite) to balance material stability and biocompatibility.

- Offer copolymer and composite designs, including PLGA–PEG–PLGA, PLGA–PHEMA, and multi-component composite solutions for specific functional requirements.

- Customize functionalization for client applications, such as bioactive groups, cell-adhesion peptides, or drug-loading capability.

3Laboratory Preparation & Process Optimization

- Provide multiple preparation methods, including chemical crosslinking, physical crosslinking, copolymerization, and composite systems, ensuring laboratory feasibility.

- Optimize key process parameters such as temperature, pH, crosslinking time, and concentration to ensure hydrogel performance stability and reproducibility.

- Supply small-batch experimental samples for client performance verification and preliminary application testing.

- Adjust processes according to client needs, supporting rapid iterative optimization and seamless transition from experiment to application.

4Analysis, Characterization & Performance Verification

- Conduct comprehensive characterization of chemical structure, molecular weight, mechanical properties, microstructure, and thermal behavior to ensure material meets design objectives.

- Test swelling behavior, degradation profile, and drug release performance to validate reliability in practical applications.

- Conduct biocompatibility and cell interaction assessments, providing scientific support for drug delivery or tissue engineering applications.

- Deliver complete data reports to assist clients in material selection and performance optimization.

5Functionalization & Custom Modification

- Introduce functional molecules or bioactive groups based on client application requirements to enhance hydrogel bioactivity and specific functionality.

- Develop composite materials with natural polymers (gelatin, chitosan, hyaluronic acid) or inorganic materials (hydroxyapatite, graphene oxide).

- Support smart responsive hydrogel development, enabling customized thermo-, pH-, enzyme-, and light/magnetic-responsive designs.

- Optimize composite ratios and functionalization strategies based on experimental results to achieve optimal performance of multifunctional hydrogels.

6Pilot-Scale Production & Technology Transfer

- Evaluate lab-scale processes for pilot-scale production, ensuring smooth transition from gram-level experiments to kilogram-scale production.

- Optimize raw material ratios, reaction conditions, and crosslinking processes to maintain batch consistency and meet industrial requirements.

- Provide production feasibility analysis and process parameter standardization to support clients in industrial-scale manufacturing.

- Support technology transfer and process guidance to help clients rapidly convert R&D outcomes into mass-producible products.

Applications

Exploring the Versatile Applications of PLGA Hydrogels

With tunable degradation, excellent biocompatibility, and strong drug-loading capacity, PLGA hydrogels have become important materials in biomedicine and tissue engineering. Their versatile performance allows key roles in drug delivery, tissue repair, smart responsive materials, and bioimaging. From controlled drug release and 3D cell scaffolds to injectable minimally invasive therapies and diagnostic platforms, PLGA hydrogels meet diverse research and clinical needs, supporting the development and application of innovative biomimetic materials.

Drug Delivery Systems (DDS)

PLGA hydrogel has attracted attention as a controllable release carrier. Due to its tunable degradation rate and good loading capacity, it can be applied in:

- Small molecule controlled release: By adjusting PLGA ratios and crosslinking density, drug release cycles can be precisely tuned.

- Protein and peptide delivery: The hydrogel's high water content protects large biomolecules from denaturation.

- Local chemotherapy and anti-infection treatment: Enables in situ drug release at tumor or bone infection sites, reducing systemic toxicity.

- Vaccine and nucleic acid delivery: Controlled release enhances antigen exposure and immune response.

Tissue Engineering & Regenerative Medicine

PLGA hydrogel mimics the structure and softness of natural extracellular matrix (ECM), making it an ideal 3D cell culture scaffold.

- Bone tissue engineering: Composite with hydroxyapatite or β-TCP to form scaffolds with good mechanical performance and bioinductivity.

- Cartilage repair: Suitable elastic modulus supports chondrocyte differentiation and matrix formation.

- Skin and nerve repair: High water content and permeability facilitate nutrient transport and cell migration.

- Vascular and muscle regeneration: Sustained release of growth factors (VEGF, bFGF) enables microenvironment modulation.

Injectable & In Situ Gel Systems

PLGA-based thermosensitive hydrogels (e.g., PLGA-PEG-PLGA) are liquid at room temperature and rapidly gel upon body temperature increase.

- Drug sustained release: Provides continuous local drug delivery and reduces administration frequency.

- Cell encapsulation and tissue repair: Creates supportive microenvironment for cell survival, migration, and tissue regeneration.

- Minimally invasive applications: Avoids trauma from conventional surgical implantation, suitable for hard-to-access tissues.

- Smart diagnostic carriers: Embedding sensors in hydrogels enables real-time monitoring of pathological or metabolic changes.

Smart Responsive Biomaterials

PLGA can be copolymerized with thermo- or pH-sensitive monomers to create hydrogels responsive to external stimuli.

- pH-responsive hydrogels: Targeted release in specific gastrointestinal sites.

- Thermosensitive hydrogels: Injectable systems triggered by body temperature for controlled drug release.

- Enzyme-sensitive hydrogels: Enable precise degradation and drug release in specific tissue environments.

- Electromagnetic- and light-responsive PLGA hydrogels: Enable precise control of release and response.

FAQs

Frequently Asked Questions

-

What is PLGA Hydrogel?

PLGA hydrogel is a polymer hydrogel made from poly(lactic-co-glycolic acid) (PLGA), featuring tunable degradability, high biocompatibility, and excellent drug-loading capacity. It mimics the natural extracellular matrix, providing an ideal platform for drug delivery, tissue engineering scaffolds, and smart responsive materials, with functionality and performance adjustable through molecular design.

-

Is PLGA Hydrogel biocompatible?

PLGA hydrogel exhibits excellent biocompatibility and biodegradability, safely breaking down into lactic acid and glycolic acid in the body. Functional modifications or composites with natural polymers enhance cell adhesion and tissue compatibility, making it suitable for drug delivery, cell support, and tissue repair while minimizing immune rejection and toxicity.

-

What is PLGA-PEG-PLGA Hydrogel?

PLGA-PEG-PLGA hydrogel is a triblock copolymer-based thermosensitive hydrogel, composed of hydrophobic PLGA blocks and hydrophilic PEG blocks. It remains liquid at room temperature and gels at body temperature, making it ideal for minimally invasive injectable drug delivery, sustained release formulations, and tissue engineering applications. Its composition can be tailored to adjust gelation time, mechanical strength, and degradation rate for specific biomedical needs.

-

Is PLGA a hydrogel?

PLGA itself is a biodegradable polymer, not a hydrogel in its native form. However, PLGA can be formulated into hydrogels through chemical or physical crosslinking, copolymerization, or blending with hydrophilic polymers such as PEG. The resulting PLGA hydrogel retains PLGA's biocompatibility and degradability while providing a water-rich, three-dimensional network suitable for drug delivery, tissue scaffolds, and cell encapsulation applications.

-

What is PLA-PLGA hydrogel used for?

PLA-PLGA hydrogel is a biodegradable and biocompatible hydrogel made from poly(lactic acid) and poly(lactic-co-glycolic acid). It is widely used in controlled drug delivery, injectable scaffolds, tissue engineering, and localized therapeutic systems. Its degradation rate and mechanical properties can be tuned by adjusting PLA/PLGA ratios, molecular weight, and crosslinking density, making it suitable for applications requiring sustained release, cell support, or minimally invasive implantation.

-

How is PLGA hydrogel made porous?

Porous PLGA hydrogels can be prepared using techniques such as salt leaching, gas foaming, freeze-drying, or emulsion templating. These methods create interconnected pores, enhancing nutrient transport, cell infiltration, and tissue integration. Porosity and pore size can be precisely controlled by adjusting polymer concentration, porogen type, or processing conditions, enabling optimization for drug delivery, tissue scaffolds, or regenerative medicine applications.

-

How is PLGA hydrogel synthesized?

PLGA hydrogel can be synthesized through chemical crosslinking of PLGA derivatives, physical gelation of PLGA-PEG-PLGA triblock copolymers, or blending with hydrophilic polymers. Key synthesis steps include polymer selection, molecular weight adjustment, crosslinker addition, and control of reaction conditions to achieve desired gelation time, mechanical strength, and degradation profile. Post-synthesis characterization ensures reproducible and functional hydrogels for biomedical applications.

-

What is the difference between PLGA scaffolds and hydrogels?

PLGA scaffolds are typically solid, porous 3D structures providing mechanical support for tissue engineering, whereas PLGA hydrogels are water-rich networks offering injectable, flexible, and degradable environments. Scaffolds are suited for load-bearing applications, while hydrogels are ideal for minimally invasive drug delivery or cell encapsulation. Both leverage PLGA's biocompatibility and biodegradability but differ in physical form, porosity, and application strategies.