Polylactic Acid Coating Preparation

Polylactic acid (PLA) is a biodegradable polymer derived from renewable resources such as corn starch, sugarcane, or cassava. It is produced via fermentation to lactic acid, followed by ring-opening polymerization or condensation reactions. In the field of surface engineering, PLA not only serves as a base material but can also be fabricated into coatings to enhance or impart specific surface functions, such as biocompatibility, corrosion resistance, controlled release, anti-fouling, or protective degradable layers. PLA coatings are functional layers based on renewable PLA materials, featuring excellent biocompatibility, biodegradability, and tunable properties. They are widely applied in biomedical, biomimetic, food packaging, and industrial protection fields. BOC Sciences provides comprehensive PLA coating preparation services, covering the entire process from formulation design, molecular weight and copolymer ratio control, to coating functionalization, micro/nanostructure optimization, and multilayer composite strategy development. Combining techniques such as spin coating, spray coating, electrospinning, melt coating, and solvent-free processes, we offer customized, high-performance, and controllable degradable PLA coating solutions, supporting R&D, pilot, and large-scale production, enabling clients to quickly realize functionalization and practical application of their coating products.

What We Offer

Enhance Material Performance with Our Custom PLA Coating Solutions

BOC Sciences offers complete custom development and preparation services for PLA coatings, ranging from basic pure PLA coatings to copolymers, composite functional coatings, antimicrobial coatings, nanocomposites, and biomimetic coatings. We provide tailored solutions with precise control of film thickness, surface structure, and functional performance for various applications. Whether for biomedical research, biomimetic materials, food packaging, or industrial protection, BOC Sciences delivers one-stop technical support from laboratory development and process optimization to pilot and mass production.

Pure PLA Coating

- Preparation of PLA coatings with different molecular weights to meet laboratory, pilot, and small-scale production needs.

- Precise control of film thickness, surface roughness, and crystallinity for biomedical and packaging applications.

- Basic functional optimization, including adhesion enhancement, uniform film formation, and controlled degradability.

PLA Copolymer Coating

- Custom development of PLA copolymer coatings, including ε-caprolactone, glycolic acid, propylene carbonate, and others.

- Tunable coating flexibility, degradation rate, and drug release properties.

- Compatible with solution casting, electrospinning, or melt processing for a variety of substrates.

PLA Composite/Functional Coating

- Doping with minerals, nanoparticles, or bioactive molecules to achieve multifunctional coatings.

- Custom services for antimicrobial, anti-corrosion, controlled release, and smart-responsive coatings.

- Support for multilayer composite design and gradient functional coatings to meet complex application requirements.

PLA Antimicrobial Coating

- Incorporation of silver nanoparticles, ZnO, or antimicrobial peptides to create highly effective antimicrobial surfaces.

- Suitable for medical devices, food-contact materials, and protective equipment coatings.

- Custom antimicrobial coating solutions that balance degradability and functionality.

PLA Nanocomposite Coating

- Development of nanofiller-reinforced coatings, such as graphene oxide or TiO₂ composites.

- Enhances mechanical strength, wear resistance, barrier properties, and functionalization capability.

- Supports multilayer or gradient nanocomposite coatings for biomimetic and industrial applications.

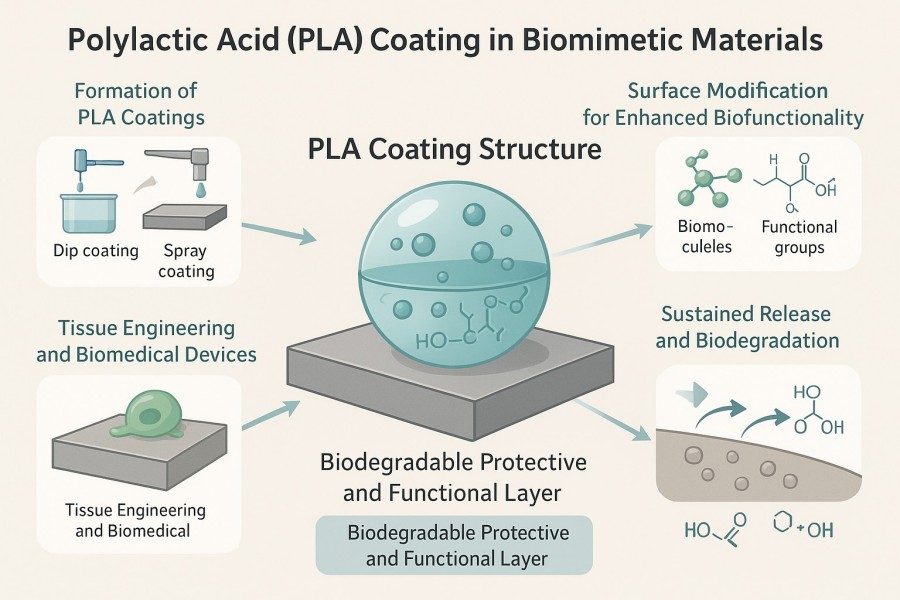

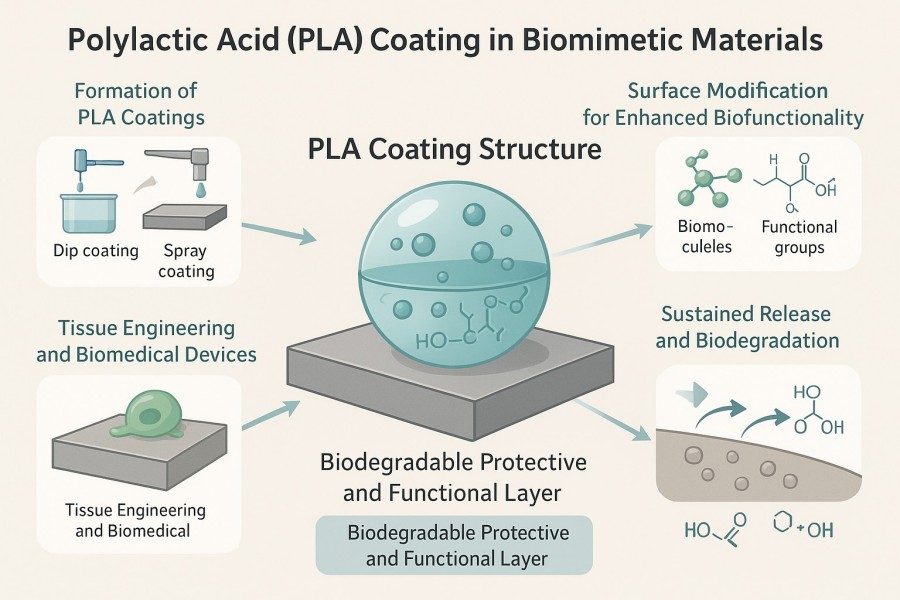

Biomimetic PLA Coating

- Mimics natural structures such as bone, blood vessels, or extracellular matrix for functional surface modification.

- Provides electrospun nanofibers, layer-by-layer assembly, and gradient structure coating services.

- Supports grafting of bioactive molecules to promote cell adhesion, proliferation, and differentiation, meeting biomimetic material requirements.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

PLA Coating Development and Biomimetic Material Customization

BOC Sciences offers full-process PLA coating design, preparation, and functionalization services, including molecular formulation optimization, micro/nanostructure control, and multilayer composite and gradient functionality implementation. Our team can adjust molecular weight, copolymer ratio, and additive formulation according to application requirements, achieving precise control of film thickness, surface roughness, and porosity through solution casting, spin coating, spraying, electrospinning, and solvent-free melt processes.

1PLA Coating Design and Formulation

- Design PLA molecular weight, copolymer ratio, and additive formulation based on target applications.

- Control micro/nano-porous structures to simulate natural tissue microenvironments.

- Implement multilayer composite functional gradients for staged release and responsive functionality.

- Visualize and control film thickness and surface roughness for various biomimetic design needs.

2PLA Coating Preparation Techniques

- Solution casting and spin coating: suitable for flat substrates and membrane materials.

- Spray coating and vapor deposition: ideal for complex shapes or large-area coverage.

- Melt coating and solvent-free processes: environmentally friendly, suitable for packaging and industrial coatings.

- Electrospinning and nanostructured coatings: for tissue engineering and biomimetic functional surfaces.

3Coating Modification and Functionalization

- Copolymerization or blending with PCL, PEG, or PDLA to improve flexibility and extensibility.

- Hydroxylation, amination, or small-molecule grafting to enhance hydrophilicity and adhesion.

- Immobilization of peptides, enzymes, or polysaccharides on PLA surfaces for bio-recognition, anticoagulant, or tissue-inductive functions.

- Incorporation of TiO₂, ZnO, graphene, or nanocellulose to enhance mechanical strength or antimicrobial performance.

4Biomimetic Material Support

- Bone-mimetic coatings: PLA/HA composite coatings simulating bone mineralization layers to promote osteoblast proliferation.

- Vascular-mimetic coatings: PLCL elastic coatings mimicking vessel flexibility and cell adhesion.

- Superhydrophobic and anti-fouling coatings: micro/nano-structured PLA coatings imitating lotus leaf self-cleaning effect.

- Antimicrobial biomimetic coatings: PLA/nanosilver coatings simulating shark-skin anti-adhesion properties.

Characterization

PLA Coating Analysis and Characterization Services

BOC Sciences provides comprehensive PLA coating analysis and characterization services, covering physical, chemical, and functional performance testing. Our technical team employs advanced instruments and methods to accurately assess film thickness, porosity, surface morphology, mechanical properties, and functional characteristics, ensuring each batch of coatings meets clients' R&D and application requirements.

| Analysis Category | Test Item | Description & Application |

|---|

| Physical Properties | Coating Thickness | Measured by profilometer or microscopy to ensure uniform thickness across the coating. |

| Surface Roughness | Evaluated using atomic force microscopy (AFM) or profilometry to assess micro- and nano-scale surface topography. |

| Porosity & Microstructure | Observed with scanning electron microscopy (SEM) to examine coating porosity and layered structure. |

| Chemical Properties | Composition Analysis | FTIR, XPS, or NMR used to determine chemical composition and confirm surface modification. |

| Copolymer Ratio | Analysis of monomer ratio and molecular weight for PLGA, PLCL, and other copolymer coatings. |

| Thermal Properties | Thermogravimetric Analysis (TGA) | Measures thermal stability and degradation temperature range of the coating. |

| Differential Scanning Calorimetry (DSC) | Assesses glass transition temperature, melting point, and crystallinity to guide performance optimization. |

| Mechanical Properties | Tensile & Peel Strength | Evaluates coating adhesion, flexibility, and resistance to mechanical stress. |

| Functional Properties | Contact Angle Measurement | Determines hydrophilicity/hydrophobicity and effectiveness of surface modifications. |

| Antimicrobial Performance | Tests antibacterial coatings for inhibition rate and colony count. |

| Degradation Performance | Monitors degradation rate and controlled release properties under simulated physiological or environmental conditions. |

Advantages

Why Choose Our PLA Coating Services: Benefits & Capabilities

- Professional Technical Team: Our experts in polymer chemistry, materials science, and nanotechnology provide one-stop technical support and solutions, covering everything from molecular design to functionalized coatings.

- Full-Process Customization: Services include formulation design, film thickness control, porosity regulation, and functional modification, enabling end-to-end customization from laboratory development to pilot and industrial-scale production.

- Diverse Preparation Techniques: We support spin coating, spray coating, solution casting, electrospinning, and melt coating, meeting coating requirements across different substrates, shapes, and application environments.

- Functionalization and Modification Capabilities: Through copolymerization, grafting of biomolecules, or nanoparticle incorporation, we enable precise customization of antimicrobial, controlled-release, anticorrosion, and biomimetic functionalities.

- Biomimetic Material Support: Development of bone, vascular, soft tissue, and superhydrophobic anti-fouling coatings that mimic natural structures and functions to enhance material performance.

- Controllable Degradation and Eco-Friendly Design: Utilizing renewable PLA materials with safe, non-toxic degradation products, supporting water-based or solvent-free processes to reduce environmental impact.

- Customer Support and After-Sales Service: Providing technical consultation, sample development, process optimization, and production guidance to ensure smooth implementation and successful application from R&D to commercialization.

Service Process

PLA Coating Service Workflow – From Design to Production

Our workflow covers needs assessment, formulation development, functional modification, process optimization, pilot testing, and large-scale production, complemented by comprehensive analysis and characterization services. Each batch is ensured to meet customer standards in performance, functionality, and quality for fast, reliable coating development and deployment.

1Needs Assessment and Concept Design

- Collect customer application scenarios, substrate types, and specific functional requirements to guide precise coating development.

- Preliminary design of PLA molecular weight, copolymer ratio, and additive formulation, with recommendations for functionalization and biomimetic structures.

- Communicate feasibility plans with clients to ensure designs align with final application goals.

2Formulation Development and Optimization

- Scientific design and optimization of PLA molecular weight, copolymer ratios, and additive combinations based on target applications.

- Small-scale testing to verify film thickness, porosity, adhesion, and uniformity, ensuring stable formulation performance.

- Adjust formulation parameters to meet degradation rate, flexibility, and functional requirements, creating a scalable production plan.

3Coating Functionalization and Modification

- Introduce bioactive molecules via copolymerization, grafting, or blending to achieve antimicrobial, controlled-release, or tissue-inductive functions.

- Incorporate nanofillers (e.g., TiO₂, ZnO, graphene, nanocellulose) or surface modifications to enhance mechanical strength, adhesion, and functionality.

- Design multilayer or gradient structures for staged release and biomimetic functional responses.

4Process Selection and Optimization

- Select spin coating, spray coating, solution casting, electrospinning, or melt coating based on substrate type and application environment to ensure compatibility.

- Optimize parameters such as temperature, speed, solution concentration, and layer number to achieve uniform film thickness, smooth surfaces, and precise micro/nanostructure control.

- Provide lab, pilot, and industrial-scale solutions to ensure scalability.

5Pilot Testing and Large-Scale Production Support

- Offer pilot-scale validation and process scale-up guidance to maintain consistent coating performance during batch production.

- Establish quality control systems for film thickness, structure, functionality, and degradation monitoring.

- Provide production training and technical support to help clients achieve successful industrial implementation.

6Analysis, Characterization, and Customer Feedback

- Comprehensive characterization using SEM, AFM, DSC, TGA, contact angle measurement, and mechanical testing.

- Optimize formulations and process parameters based on testing data to ensure expected coating performance and functionality.

- Provide detailed analytical reports and technical recommendations to support scientific decision-making during R&D, application, and production.

Applications

PLA Coating Applications in Biomimetic Materials

PLA coatings, with excellent biocompatibility, biodegradability, and tunable properties, are widely applied in biomimetic materials. Through micro/nanostructure design, functional modification, and multilayer composite strategies, PLA coatings can mimic natural tissue structures and functionalities, providing innovative solutions for bone tissue engineering, vascular biomimetics, anti-fouling surfaces, and smart controlled-release materials. BOC Sciences integrates polymer chemistry and nanotechnology to deliver customized PLA biomimetic coating development and preparation services, achieving high-performance and functionalized materials.

Bone-Mimetic Coatings

- PLA/HA composite coatings simulate bone mineralization layers, promoting osteoblast adhesion and proliferation.

- Tunable porosity and thickness allow gradient performance design for bone regeneration materials.

- Support multilayer composites and functional modification, such as antimicrobial activity or controlled release of growth factors.

Vascular and Soft Tissue-Mimetic Coatings

- PLA/PLCL elastic coatings mimic vascular flexibility and extracellular matrix environments.

- Surface grafting of bioactive molecules improves endothelial cell adhesion and function.

- Nanofiber or gradient structure design enhances tissue compatibility.

Superhydrophobic and Anti-Fouling Coatings

- Micro/nano surface structures mimic lotus leaf self-cleaning effects to achieve superhydrophobic and anti-fouling properties.

- Applicable to medical devices, industrial equipment, and packaging surfaces to reduce contamination and adhesion.

- Multilayer coatings enhance wear resistance and long-term functional stability.

Antimicrobial Biomimetic Coatings

- PLA/nanosilver or ZnO coatings mimic shark skin anti-adhesion features, providing long-term antimicrobial protection.

- Suitable for medical device surfaces, food-contact materials, and high-contamination environments.

- Can be combined with controlled degradation or drug release for multifunctional applications.

FAQs

Frequently Asked Questions

-

What is PLA coating?

PLA coating is a functional surface layer made from polylactic acid, a biodegradable and biocompatible polymer derived from renewable resources. It provides protective, barrier, or functional properties on various substrates, including medical devices, packaging materials, and biomaterials.

-

Is PLA coating biodegradable?

PLA coating is naturally biodegradable. It can break down into lactic acid under hydrolysis or microbial action, safely absorbed by the environment or organisms without harmful residues. By adjusting molecular weight, copolymer ratio, and coating structure, degradation rates can be precisely controlled to meet functional requirements while maintaining performance and sustainability.

-

What is the composition of PLA coatings?

PLA coatings are primarily composed of renewable PLA polymers and can use pure PLA or copolymers (e.g., PLGA, PLCL) to tune performance. Coatings may form uniform films, porous layers, or micro/nanostructures, sometimes doped with nanofillers, bioactive molecules, or functional additives to achieve antimicrobial, controlled-release, biomimetic, or enhanced mechanical properties.

-

How are PLA coatings manufactured?

PLA coatings can be prepared by solution casting, spin coating, spray coating, electrospinning, or melt coating. Single-layer or multilayer composites can be produced depending on substrate type and application requirements. Molecular weight, copolymer ratio, and additive formulations are adjusted to optimize performance.

-

What are the properties of PLA coatings?

PLA coatings exhibit excellent biodegradability and biocompatibility, safely degrading in vivo or in the environment. Performance is tunable, including flexibility, adhesion, surface roughness, and porosity, enabling micro/nano functionalization. Copolymerization or nanocomposite modification allows antimicrobial, anticorrosive, controlled-release, and biomimetic functions, suitable for bone tissue engineering, vascular biomimetics, food packaging, and industrial protection.