Polylactic Acid Fiber Preparation

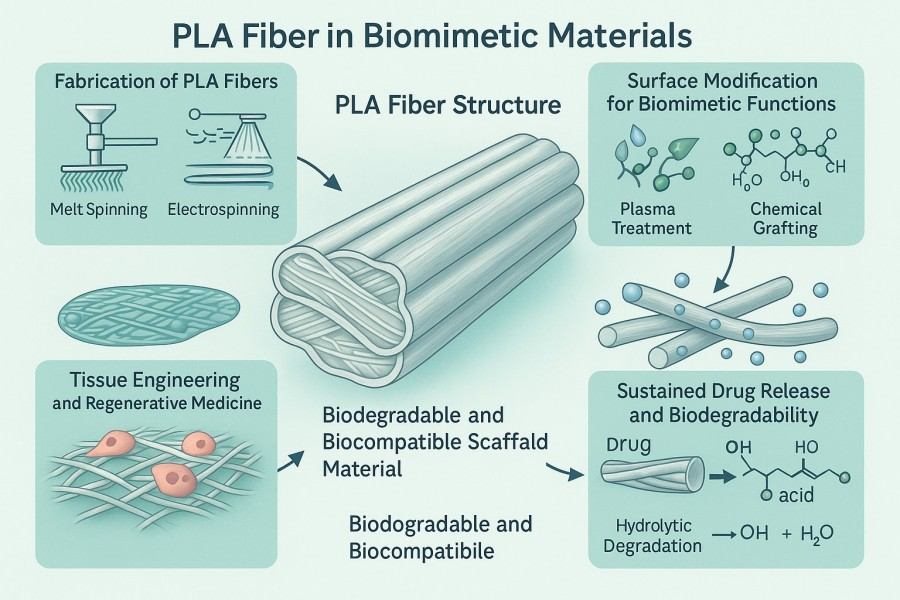

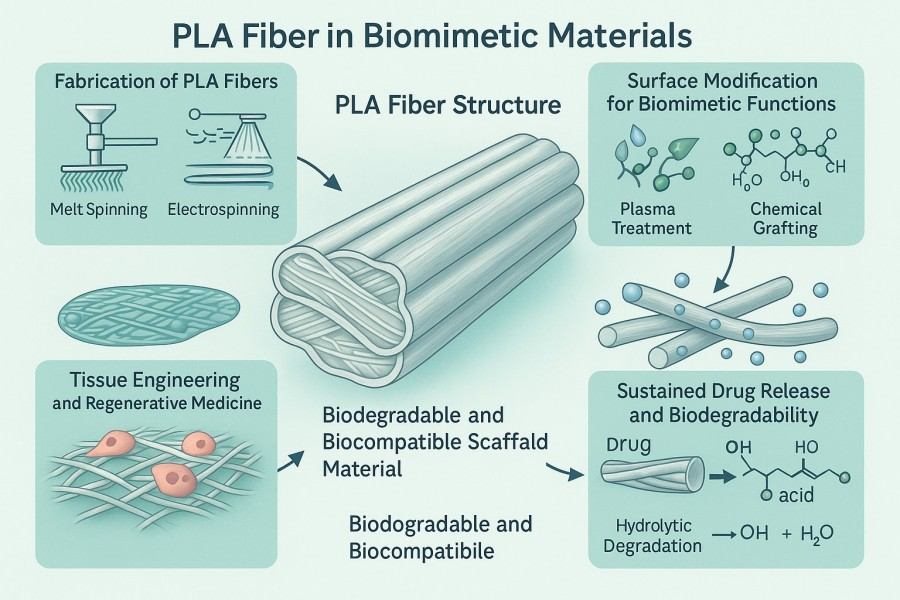

Polylactic acid (PLA) fiber is a biodegradable polymer fiber derived from renewable plant resources. It is produced by fermenting natural starches such as corn or sugarcane to obtain lactic acid, which is then polymerized through condensation or ring-opening polymerization to form polylactic acid. Finally, the fibers are fabricated via melt spinning, solution spinning, or electrospinning. PLA fibers offer advantages including light weight, high strength, good moisture absorption, and biodegradability. Moreover, through fiber morphology, surface modification, and composite material techniques, PLA fibers can achieve functional and biomimetic applications. In the field of biomimetic materials, PLA fibers can be processed into nanofiber scaffolds, microfiber meshes, layered or aligned fibers, biodegradable medical dressings, and functional composite fibers for applications in tissue engineering, drug delivery, smart textiles, and cartilage and tendon regeneration. BOC Sciences provides full-process support from high-purity raw material customization and fiber structure design to functional modification and scalable production. We focus on meeting the stringent performance requirements of biomedical and biomimetic materials, enabling tailored high-performance PLA fibers with controlled fiber diameter, porosity, and mechanical properties to advance tissue regeneration, drug delivery, and functional biomimetic material development.

What We Offer

High-Performance PLA Fibers Tailored to Your Research Needs

BOC Sciences offers comprehensive PLA fiber customization services ranging from nanoscale to microscale, and from functional modification to composite structures. Our expert technical team specializes in electrospinning, melt spinning, composite fiber development, and nonwoven technologies. Equipped with advanced performance analysis and characterization platforms, we optimize fiber structures, mechanical properties, and functional parameters according to client requirements, supporting the development of tissue engineering scaffolds, drug carriers, and smart biomimetic materials.

PLA Nanofiber

- Fabricated via electrospinning, with controllable fiber diameters from tens to hundreds of nanometers, mimicking extracellular matrix structures.

- Can be functionalized with drugs or bioactive molecules to support tissue engineering and regenerative medicine applications.

- Offers nanofiber mesh design and performance optimization services to meet specific biomechanical and porosity requirements.

PLA Microfiber

- Produced via melt spinning or solution spinning, suitable for biomimetic scaffolds for bone, cartilage, and tendon applications.

- Fiber crystallinity and mechanical properties can be tuned through stretching, thermal setting, and surface treatments.

- Supports customization of microfiber meshes and multilayer structures to optimize cell adhesion, proliferation, and tissue regeneration.

PLA Composite Fiber

- Can be combined with bioactive glass, hydroxyapatite, collagen, and other materials to enhance bone and soft tissue scaffold functionality.

- Supports loading of functional nanoparticles, drugs, or bioactive molecules for multifunctional composite applications.

- Provides end-to-end services for composite design, process development, and performance evaluation.

Functional PLA Fiber

- Can achieve antibacterial, drug delivery, conductive, or smart-responsive modifications.

- Functional carrier strategies can be customized to ensure biocompatibility and degradation performance.

- Offers surface modification, composite integration, and functional verification services to support biomimetic material development.

Nonwoven PLA Fiber

- Forms mesh structures through fiber entanglement or thermal bonding, with adjustable porosity, suitable for medical dressings and tissue engineering scaffolds.

- Can load drugs or bioactive molecules for localized degradable drug release.

- Supports optimization of nonwoven structures, performance testing, and custom-size production.

PLA Layered/Aligned Fiber

- Mimics the biological structure of tendons, ligaments, and cartilage, providing directional mechanical properties.

- Supports customization of multilayer distribution, fiber alignment angles, and porosity to optimize the cellular growth environment.

- Offers layered scaffold design, process development, and performance evaluation services to meet high-end biomimetic material requirements.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

PLA Fiber Solutions: From Design to Scalable Production

BOC Sciences is committed to providing full-process technical support from raw material customization to fiber fabrication, functional modification, and scalable production. With extensive experience in polymer chemistry and biomimetic material development, we design and manufacture high-performance PLA fibers tailored to tissue engineering, drug delivery, and smart biomimetic material applications. Our services cover not only the R&D stage but also pilot-scale and industrial-scale production, ensuring high consistency in performance, structure, and functionality for every batch.

1High-Purity Monomer and Polymer Customization

- Provides high-purity lactic acid monomers (L-lactic acid, D-lactic acid) and PLA polymers, ensuring raw materials meet biomedical application standards.

- Supports PLA polymer design with varying molecular weights and stereochemistry to meet fiber mechanical and degradation requirements.

- Offers polymer characterization and analysis, including molecular weight distribution, crystallinity, and thermal properties, to ensure raw material stability.

2Fiber Structure Design and Fabrication

- Designs and controls fiber microstructures, including crystallinity, orientation, and microporosity, to optimize strength and modulus.

- Can design nanofibers, microfibers, layered, or aligned fiber structures to replicate biomimetic scaffold properties.

- Supports melt spinning, solution spinning, electrospinning, and nonwoven processes, customizing fiber diameter, porosity, and mechanical performance.

3Surface and Functional Modification

- Functionalizes PLA fibers for antibacterial activity, drug delivery, conductivity, or smart responsiveness.

- Offers surface grafting, nanoparticle integration, and coating techniques to achieve multifunctional fiber properties.

- Provides modification effect analysis and validation, including biocompatibility, degradation performance, and functional release assessment.

4Quality Control and Scalable Manufacturing

- Each batch undergoes strict quality control, including mechanical properties, fiber diameter, porosity, and functional index testing.

- Provides process design from lab-scale R&D to pilot-scale and industrial-scale production.

- Supports custom specifications and batch production to meet the demands of high-end biomimetic materials and pharmaceutical research.

Advantages

Customized PLA Fiber Services: Key Benefits for Research and Applications

- Professional Technical Team: We possess extensive experience in polymer and biomaterial research and development, with expertise in PLA fiber fabrication, spinning technologies, nanofiber electrospinning, and composite modification. We provide full-process technical support from experimental design to process optimization.

- Customized Solutions: We offer tailored PLA fiber design solutions based on clients' biomimetic material applications, including scaffold mechanical properties, drug release rates, or functional composites. Customization parameters include fiber diameter, crystallinity, porosity, surface functionalization, and composite material optimization.

- Diverse Spinning Technologies: We support a wide range of fabrication processes, including melt spinning, solution spinning, dry–wet spinning, and electrospinning. We can produce filaments, staple fibers, nonwoven fabrics, and nanofibers to meet structural requirements for various biomimetic applications.

- Advanced Analysis and Characterization: Our facilities include high-precision fiber diameter measurement, scanning electron microscopy (SEM), X-ray diffraction (XRD), mechanical testing, and thermal analysis. We comprehensively evaluate PLA fiber crystallinity, mechanical properties, porosity, and surface modification effects.

- Functional Modification Capability: PLA fibers can be functionalized on the surface or internally for antibacterial activity, moisture absorption, conductivity, or drug delivery, enabling the development of high-performance, application-specific biomimetic materials.

- Quality and Traceability Assurance: Each batch of PLA fibers undergoes strict quality control. Materials and finished products are fully traceable, ensuring stable performance that meets the requirements of medical, biomimetic scaffold, and high-end textile applications.

Service Process

Step-by-Step PLA Fiber Service Workflow for Biomedical Applications

BOC Sciences ensures efficient progress for every PLA fiber project through a systematic and traceable service workflow, from requirements analysis to mass production. Leveraging extensive polymer R&D experience and biomimetic material expertise, we provide full-process support including fiber design, functional modification, performance evaluation, and scalable manufacturing, offering reliable solutions for tissue engineering, drug delivery, and smart biomimetic material applications.

1Requirements Analysis and Application Assessment

- Engage in detailed communication with clients to define PLA fiber application goals, functional requirements, and performance indicators.

- Analyze fiber structural, mechanical, and degradation requirements for biomimetic or biomedical applications.

- Provide feasibility assessments and preliminary technical solution recommendations.

2Raw Material Customization and Polymer Selection

- Customize high-purity PLA monomers or polymers according to performance requirements, controlling molecular weight and stereochemistry.

- Provide polymer characterization and analysis to ensure raw material stability and consistency.

- Recommend optimal polymer specifications to meet fiber fabrication and functionalization objectives.

3Fiber Structure Design and Fabrication

- Design fiber diameter, porosity, alignment, and hierarchical structures to meet biomimetic material requirements.

- Support melt spinning, solution spinning, electrospinning, and nonwoven fabrication techniques.

- Conduct small-scale sample preparation and process parameter optimization to ensure controllable fiber performance.

4Functional Modification and Composite Design

- Enable antibacterial, drug delivery, conductive, or smart-responsive functionalization.

- Support surface grafting, nanoparticle integration, and coating technologies for multifunctional fibers.

- Provide modification effect validation and biocompatibility testing to ensure safe biomimetic applications.

5Performance Analysis and Validation

- Conduct comprehensive evaluation of fiber structure, mechanical properties, porosity, degradation behavior, and functional effects.

- Utilize SEM, XRD, mechanical testing, and thermal analysis to ensure each batch meets design standards.

- Deliver detailed performance reports to support client R&D and project decision-making.

6Scalable Production and Post-Sales Technical Support

- Provide pilot-scale and industrial-scale production solutions, ensuring batch-to-batch consistency and traceability.

- Support customized specifications and large-scale production with specialized functionalities.

- Offer ongoing technical support, including process optimization, functional improvements, and recommendations for new functionalities.

Applications

PLA Fiber Applications in Biomimetic and Biomedical Materials

Due to their biodegradability, tunable mechanical properties, and functionalization potential, PLA fibers have broad applications in biomimetic materials. Through different spinning processes and composite modification technologies, PLA fibers can mimic natural tissue structures, control degradation rates, achieve drug or bioactive molecule release, and incorporate customized functional features to support tissue engineering, regenerative medicine, and smart biomimetic material development.

Tissue Engineering and Regenerative Scaffolds

- Nanofiber Scaffolds: Electrospun high-porosity fiber networks mimic the extracellular matrix (ECM), promoting cell adhesion, proliferation, and differentiation.

- Microfiber Meshes and Layered Scaffolds: Customizable microfiber alignment and layered structures replicate the directional mechanics of tendons, ligaments, and cartilage.

- Composite Scaffolds: PLA fibers can be combined with collagen, hydroxyapatite, and other materials to enhance biological functionality and mechanical performance of bone and soft tissue scaffolds.

Drug Delivery and Functional Carriers

- Drug-Loaded Fibers: PLA fibers can embed drugs for localized controlled release, supporting wound healing, antibacterial, and anti-tumor applications.

- Functional Composite Fibers: Surface modification or nanoparticle integration enables antibacterial, anti-inflammatory, or smart-responsive functionalities.

- Controlled Degradation Fibers: Fiber crystallinity and structure can be tuned to precisely control drug release timing and rates.

Medical Dressings and Biodegradable Protective Materials

- Nonwoven PLA Fiber Meshes: Highly breathable, suitable for medical dressings or biodegradable protective clothing.

- Smart-Responsive Materials: PLA fibers can release bioactive molecules in response to temperature, pH, or humidity changes, enabling intelligent biomimetic applications.

- Biodegradable Protective Materials: Ideal for disposable surgical barriers and eco-friendly medical protective materials, reducing residual contamination.

Functional Biomimetic and Smart Applications

- Conductive PLA Fibers: Combined with carbon nanotubes or graphene for flexible sensors and wearable biomimetic electronics.

- Antibacterial and Functional Fibers: Applied in wound care or biomimetic scaffolds, providing both biosafety and functionality.

- Smart Fiber Materials: PLA fibers can respond to external stimuli through structural and composite design, achieving intelligent biomimetic functions.

FAQs

Frequently Asked Questions

-

What is PLA fiber?

PLA fiber (Polylactic Acid fiber) is a biodegradable, bio-based polymer fiber derived from renewable resources such as corn starch or sugarcane. In biomedical and biomimetic applications, PLA fiber is widely used to create tissue engineering scaffolds, drug delivery carriers, and degradable medical materials due to its excellent biocompatibility, tunable mechanical properties, and controllable degradation rate. It is ideal for simulating extracellular matrix structures and supporting cell growth in regenerative medicine.

-

How to make PLA fiber?

PLA fiber can be produced using melt spinning, solution spinning, or electrospinning techniques, depending on the desired fiber diameter and structure. In biomimetic and biomedical applications, electrospinning is commonly used to create nanofiber scaffolds that mimic the extracellular matrix. Process parameters such as polymer molecular weight, spinning temperature, and solvent system are carefully controlled to achieve fibers with high uniformity, adjustable porosity, and optimal mechanical strength for tissue engineering and drug delivery applications.

-

What are the characteristics of PLA fiber?

PLA fiber is biodegradable, biocompatible, and derived from renewable resources, making it ideal for medical and biomimetic materials. Key characteristics include adjustable mechanical properties, controllable degradation rate, high surface area (especially in nanofibers), and compatibility with functional modifications such as drug loading, antibacterial treatment, or conductivity enhancement. These properties enable PLA fiber to support tissue scaffolds, drug delivery systems, and advanced biomimetic materials.

-

How can PLA fibers be modified?

Yes, PLA fibers can undergo chemical or physical modifications to improve hydrophilicity, mechanical strength, or bioactivity. Surface coating, copolymerization, and blending with natural polymers or nanoparticles enable enhanced cell adhesion, antimicrobial properties, and tailored degradation, making them suitable for advanced biomedical and biomimetic applications.

-

What affects PLA fiber degradation?

PLA fiber degradation is influenced by molecular weight, crystallinity, fiber diameter, and environmental conditions such as pH and temperature. Higher crystallinity and molecular weight slow degradation, while thinner fibers degrade faster. Controlled degradation allows precise timing for tissue regeneration or drug release, providing critical flexibility in biomedical and biomimetic material design.