Browse by

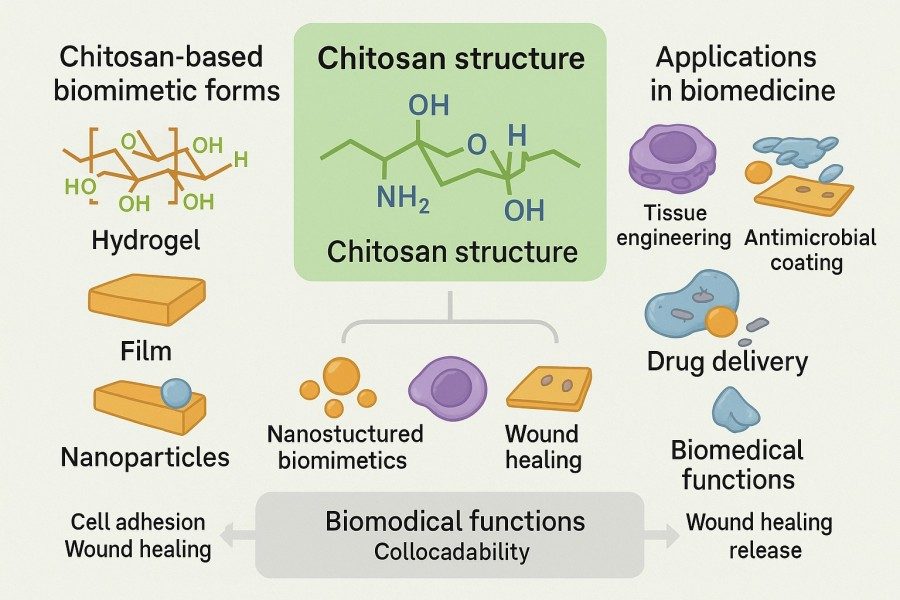

Chitosan is a natural cationic polysaccharide derived from the deacetylation of chitin found in the exoskeleton of crustaceans. As the only carbohydrate polymer with inherent cationic properties, chitosan exhibits unique biocompatibility, biodegradability, film-forming ability, and functionalization potential. It shows broad application prospects in bionic materials, pharmaceuticals, food, agriculture, and environmental engineering. BOC Sciences, as an international platform deeply engaged in polymer chemistry and monomer services, leverages strong capabilities in custom synthesis, analytical testing, structural modification, and technical consulting to provide one-stop chitosan services for global researchers and industrial users, helping accelerate the transition of bionic materials from basic research to industrial application.

What We Offer

Chitosan Materials Supported by BOC Sciences

As a multifunctional natural polysaccharide, chitosan can be prepared in various forms to meet the diverse application needs of bionic materials, pharmaceuticals, environmental fields, and functional materials. With profound expertise in polymer chemistry and monomer services, BOC Sciences offers customized chitosan development support for global clients, covering the entire process from raw materials to advanced derivatives.

- Support the development of transparent chitosan films with controllable thickness.

- Provide modification solutions (crosslinking, grafting, compounding) to improve antibacterial properties, mechanical strength, and water stability.

- Applied in bionic skin repair, biodegradable packaging, and antibacterial coatings.

- Deposition of chitosan layers on metal, polymer, or ceramic surfaces to provide antibacterial, anti-corrosion, and adhesive functions.

- Applications include medical device surface modification, food and pharmaceutical packaging, and functional films.

- Coating properties such as thickness, surface roughness, and functional group density can be tailored to meet specific application requirements.

- Offer hydrogels prepared through different crosslinking methods (chemical, physical, enzymatic).

- Adjustable water content, mechanical properties, and degradation rate according to client requirements.

- Widely used in tissue engineering scaffolds, drug-controlled release systems, and bionic soft tissues.

- Customizable chitosan particles at nano/micro scales with controllable particle size distribution and surface functionalization.

- Support for drug loading, gene delivery, and antimicrobial material development.

- Can be combined with metal ions or functional molecules to prepare efficient bionic drug delivery carriers.

- Prepared using electrospinning, freeze-drying, and other techniques to form porous or fibrous chitosan structures.

- Composite with inorganic materials (hydroxyapatite) or natural polymers (silk fibroin, collagen).

- Typical applications include bionic bone repair, nerve conduits, and skin tissue engineering.

Chitosan Composites

- Development of composites combining chitosan with inorganic, natural, or synthetic polymers.

- Support structural enhancement (bone-like composites), functionalization (conductive composites), and more.

- Suitable for high-strength bionic structural materials, smart sensors, and environmental remediation materials.

Chitosan Derivatives

- Modification services including quaternization, carboxymethylation, and graft polymerization.

- Support development of derivatives with high solubility, enhanced antibacterial activity, or environmental responsiveness.

- Applied in intelligent drug delivery, bionic coatings, and eco-friendly bionic material design.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Professional Chitosan Services: Custom Synthesis and Modification Solutions

To help researchers and industrial users obtain high-quality chitosan materials tailored to their needs, BOC Sciences provides comprehensive chitosan services, including custom synthesis, precise analysis, structural modification, and technical consulting. Supported by an advanced polymer chemistry platform and an expert team, we can deliver complete solutions from laboratory scale to industrial production, accelerating the translation of bionic material innovations.

1Custom Chitosan Synthesis Services

- Molecular Weight Customization: Control the molecular weight range of chitosan (low, medium, high) according to client requirements to suit different applications.

- Degree of Deacetylation Control: Provide chitosan with low to high degrees of deacetylation to optimize solubility, mechanical properties, and bioactivity.

- Functional Modifications: Achieve antibacterial, targeted, or enhanced mechanical properties through chemical modifications such as esterification, graft copolymerization, crosslinking, or surface functionalization.

- Derivative Development: Support customized production of derivatives, including water-soluble chitosan, crosslinkable chitosan, and chitosan nanoparticles.

2Chitosan Analysis and Characterization Services

- Molecular Weight and Polydispersity Analysis: Accurately determine chitosan molecular weight and distribution using GPC, SEC, and related techniques.

- Chemical Structure Analysis: Verify chemical structure and degree of functionalization using FTIR, NMR, XPS, and other analytical methods.

- Physicochemical Property Testing: Evaluate parameters such as solubility, viscosity, thermal stability, mechanical strength, and film thickness.

- Functional Assessment: Test key properties including antibacterial activity, adsorption capacity, and biocompatibility.

3Chitosan Modification and Composite Material Development

- Bionic Composite Fabrication: Combine chitosan with nanoparticles, proteins, polysaccharides, or synthetic polymers to develop bionic composites with enhanced mechanical strength, conductivity, or bioactivity.

- Crosslinking and Physical Modification: Provide chemical or physical crosslinking, freeze-drying, and other treatments to optimize material mechanics and bioactivity.

- Processability Optimization: Customize different material forms such as films, gels, coatings, microspheres, and nanoparticles to meet research and industrial production needs.

4Industrial Support and Scale-Up Services

- Batch Production: Offer stable and controllable production from laboratory scale to pilot and industrial scale.

- Quality Control and Traceability: Strictly follow quality management systems, providing complete analytical data and certificates for each batch to ensure traceability.

- Technology Transfer and Process Optimization: Provide scale-up and process optimization solutions according to client requirements to accelerate industrialization.

Advantages

Why BOC Sciences Stands Out in Chitosan Development?

- Professional Research Team: BOC Sciences brings together multidisciplinary experts in polymer chemistry, materials science, and biomedicine, providing comprehensive technical support to ensure the scientific rigor and cutting-edge nature of chitosan and its derivative development.

- Advanced Analytical Instruments: Our laboratory platform is equipped with high-end analytical instruments, including NMR, FTIR, XRD, GPC, and HPLC-MS, ensuring precise and reliable data support for chitosan characterization from molecular structure to performance evaluation.

- Comprehensive Synthesis Facilities: Dedicated laboratories for organic synthesis, polymer modification, and nanomaterial preparation are equipped with reactors, electrospinning devices, and freeze dryers, enabling the customized development of chitosan materials at multiple scales.

- Flexible Service Models: Based on customer needs, we offer solutions ranging from milligram-level research samples to kilogram- or ton-level industrial production, covering the entire process from R&D and validation to scale-up, ensuring efficient project progression.

- Strict Quality Control: Following GMP standards and international quality systems, combined with batch traceability and multiple testing steps, we provide chitosan products and services with high purity, stability, and reproducibility.

- Global Client Base: With long-term service to research institutions and enterprises in Europe, the United States, Asia-Pacific, and beyond, we have accumulated extensive cross-disciplinary collaboration experience, enabling us to quickly understand and meet the specific needs of diverse application scenarios.

- One-Stop Solutions: From custom synthesis and analytical characterization to functional modification and application consulting, we deliver full-chain services for chitosan, helping customers save R&D time and accelerate the transformation of research achievements into industrial value.

Service Process

Service Workflow for Efficient and Reliable Chitosan Development

At BOC Sciences, we recognize that the research and application of chitosan and its derivatives require scientific, standardized processes and professional support. To ensure that every customer receives efficient, reliable, and application-specific solutions, we have established a systematic service workflow. From initial communication to custom synthesis, performance validation, and follow-up support, every step reflects our professionalism and rigorous approach, accelerating both scientific research and industrialization.

1Requirement Communication

Engage in in-depth communication with clients regarding research objectives and application scenarios, defining the required molecular weight, degree of deacetylation, or modification type of chitosan. Considering project budgets and timelines, we develop a preliminary technical route.

2Solution Design

Our multidisciplinary expert team designs practical experimental and development plans tailored to client requirements, selecting appropriate synthesis routes, modification strategies, and analytical methods to ensure scientific feasibility.

3Custom Synthesis

Implement customized preparation on our advanced synthesis platform, covering basic chitosan, functional derivatives, and composite materials. We support everything from small-scale laboratory synthesis to pilot-scale production, meeting diverse demands.

4Performance Characterization

Conduct structural and performance analysis using advanced instruments, including molecular weight, degree of substitution, thermal properties, and biological evaluations, providing complete testing data to support R&D and applications.

5Process Optimization

Based on analytical results and client feedback, we further refine processes and improve material performance, ensuring that chitosan products meet target application requirements while enhancing stability, functionality, and controllability.

6Delivery and Support

Deliver high-quality chitosan materials and detailed data reports on schedule, while providing continuous technical consulting and application guidance to ensure smooth project progression through to industrial implementation.

Applications

Applications of Chitosan in Bionic Materials

Chitosan is obtained by the deacetylation of chitin, with a backbone composed of repeating β-(1→4)-linked D-glucosamine and N-acetyl-D-glucosamine units. Unlike other polysaccharides, chitosan contains abundant amino groups, which endow it with flexibility for chemical modification and functionalization. This molecular structure provides tunable properties such as molecular weight, degree of deacetylation, and solubility. In the field of bionic materials, chitosan is widely used in the preparation of tissue engineering scaffolds, drug delivery carriers, and functional coatings due to its structural similarity to the natural extracellular matrix. Its reactive functional groups (–OH and –NH2) offer versatile possibilities for structural modification and performance optimization.

Biomedical Bionic Materials

- Tissue Engineering Scaffolds: Chitosan hydrogels or porous scaffolds simulate the natural extracellular matrix, widely applied in cartilage and bone regeneration.

- Medical Dressings: Chitosan films, acting as bionic skin, maintain a moist environment and promote wound healing.

- Drug Delivery Systems: Chitosan nanoparticles enable sustained release and targeted delivery of drugs via oral, injectable, and transdermal routes.

Functional Bionic Materials

- Antibacterial Coatings: Chitosan coatings on devices and packaging mimic natural antibacterial mechanisms.

- Bionic Sensors: Chitosan films with conductive polymers enable flexible electronics and wearable devices.

- Stimuli-Responsive Materials: Chitosan derivatives respond to pH, temperature, or moisture for smart applications.

Structural Bionic Materials

- Bone Substitutes: Chitosan/hydroxyapatite composites mimic natural bone, improving mechanical strength.

- Fiber-Reinforced Composites: Combined with silk fibroin or collagen to enhance toughness and stability.

- Porous Scaffolds: Chitosan-based porous structures support tissue growth and nutrient exchange efficiently.

Environmental and Sustainable Bionic Materials

- Separation Membranes: Chitosan-based membranes mimic the selective permeability of biological membranes, used in water treatment and wastewater recovery.

- Adsorbents: Modified chitosan materials efficiently adsorb heavy metal ions and organic pollutants.

- Green Packaging: Biodegradable chitosan films serve as eco-friendly bionic packaging materials.

FAQs

Frequently Asked Questions

-

What is chitosan?

Chitosan is a natural cationic polysaccharide obtained by the deacetylation of chitin, which is commonly found in the exoskeletons of crustaceans such as shrimp and crabs. It has a unique chemical structure containing amino and hydroxyl functional groups, making it suitable for modification and customized development. Due to its excellent biocompatibility, biodegradability, and antibacterial properties, chitosan has been extensively studied and applied in bionic materials, medicine, food, agriculture, and environmental engineering. It serves as an important raw material for many biomedical and novel functional materials.

-

What is chitosan used for?

Chitosan has a very wide range of applications. In biomedicine, it is commonly used in tissue engineering scaffolds, drug delivery systems, and wound dressings. In environmental engineering, chitosan membranes and microspheres can be used for heavy metal adsorption and wastewater purification. In agriculture, it serves as a natural fungicide and plant growth promoter. In the food industry, chitosan films are applied in biodegradable packaging. With its multifunctionality and eco-friendly nature, chitosan is considered one of the core polysaccharides in bionic materials research and sustainable applications.

-

What is the best source of chitosan?

The primary source of chitosan is the exoskeleton of crustaceans such as shrimp shells, crab shells, and lobster shells, which represent the most common and economically feasible route for industrial production. By deacetylating chitin, chitosan with different molecular weights and degrees of deacetylation can be obtained to meet diverse application requirements. With the development of biotechnology, microbial fermentation is also emerging as a novel and green source of chitosan. Both traditional marine crustacean sources and innovative microbial synthesis serve as essential raw material bases for customized chitosan services.

-

What is another name for chitosan?

Chitosan, a naturally occurring polysaccharide derived from chitin, is commonly referred to as deacetylated chitin due to the chemical process that removes acetyl groups from chitin. It is also sometimes called polyglucosamine, reflecting its structure composed of glucosamine units linked together. These alternative names emphasize its origin and chemical composition, highlighting its biocompatibility, biodegradability, and versatility in applications ranging from biomedical materials and drug delivery systems to water treatment and food preservation. The terminology varies depending on scientific, industrial, or commercial contexts.

-

Is chitosan a natural material?

Yes, chitosan is a naturally derived functional polysaccharide. It is mainly obtained from chitin in the exoskeletons of crustaceans through deacetylation processes. As a natural material, chitosan offers excellent biocompatibility, biodegradability, and non-toxicity, making it widely applied in bionic materials, medicine, food packaging, and environmental treatment. Its natural origin and green characteristics make it an important candidate in sustainable development research. Therefore, chitosan services are attracting increasing attention and demand in both scientific and industrial applications.

-

What are the biomedical applications of chitosan?

Chitosan has extremely broad applications in the biomedical field. It can be used to prepare tissue engineering scaffolds that mimic the extracellular matrix environment, promoting cell adhesion and tissue regeneration. In drug delivery systems, chitosan nanoparticles and hydrogels enable controlled release and targeted transport of drugs. As wound dressings, chitosan films provide excellent hemostatic and antibacterial properties. In addition, it is used in gene delivery, bionic coatings, and the surface modification of medical implants. With these advantages, chitosan has become a core focus of biomedical chitosan services in both research and application.

Chitosan Hydrogel Preparation

Chitosan Hydrogel Preparation

Chitosan Film/Membrane Preparation

Chitosan Film/Membrane Preparation

Chitosan Coating Preparation

Chitosan Coating Preparation

Chitosan Microsphere Preparation

Chitosan Microsphere Preparation

Chitosan Scaffold Preparation

Chitosan Scaffold Preparation