Polycaprolactone Coating Preparation

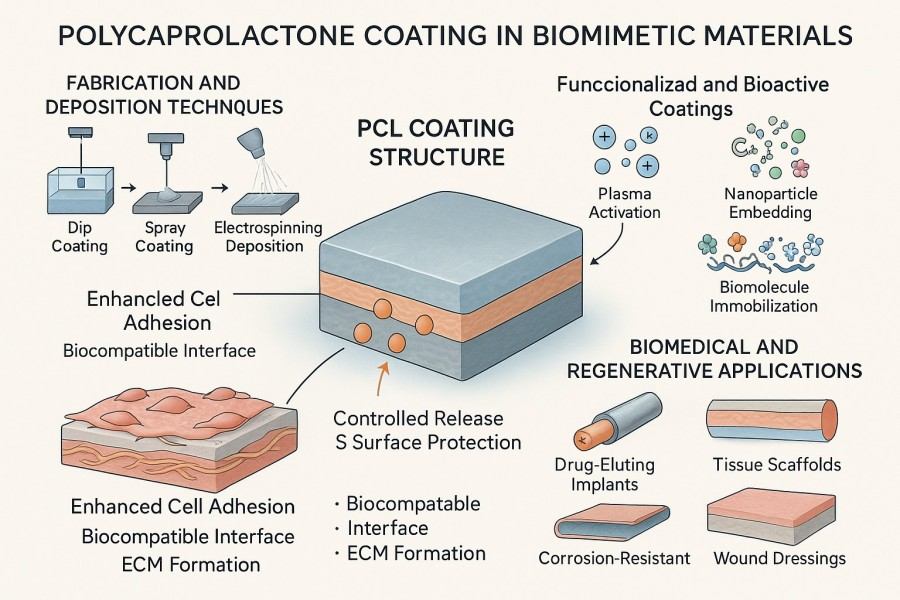

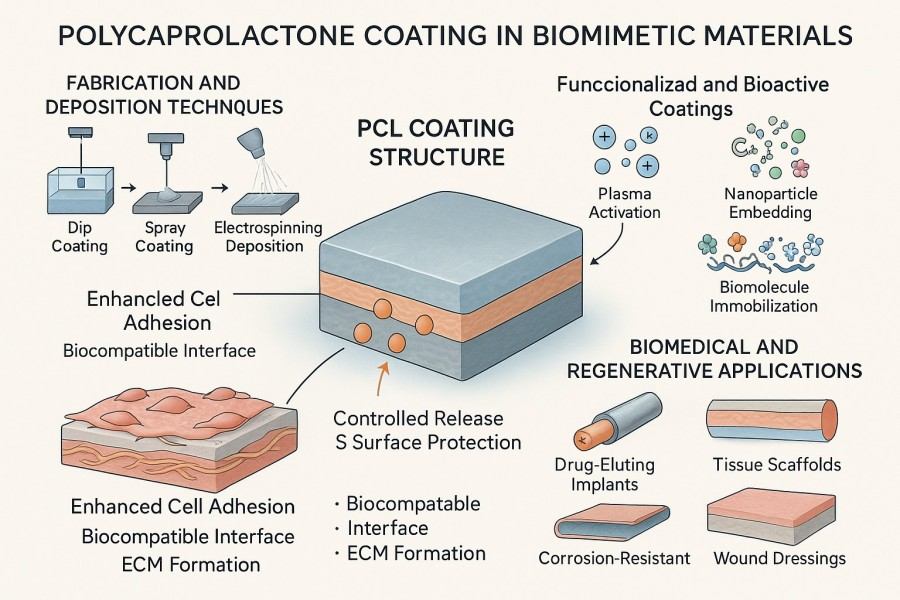

Polycaprolactone (PCL) coating refers to the process of uniformly applying polycaprolactone onto a material surface to form a film-like or layered structure, aiming to enhance material performance or impart specific functionalities. For example, coating medical implants with PCL can regulate degradation rates, improve biocompatibility, and reduce inflammatory responses; coating drug carriers with PCL can enable sustained or targeted drug release. These coatings are typically prepared using techniques such as solution casting, dip coating, spray coating, or electrospinning. In the field of biomimetic materials, PCL coatings are widely applied in tissue engineering scaffolds, drug delivery systems, antibacterial medical devices, and biodegradable implants. By forming a PCL coating on the material surface, it is possible to mimic the microenvironment of natural tissues, optimize surface properties, control degradation rates, and achieve controlled release of drugs or bioactive molecules, thereby significantly enhancing material performance and functionality. BOC Sciences' PCL coating preparation services focus on providing comprehensive technical support and customized solutions. We can design and produce uniform PCL films or fiber coatings with controlled thickness according to different substrates and application requirements. Our services cover formulation design, process development, functional modification, performance optimization, and scale-up from lab to pilot production, ensuring coating quality, functionality, and applicability for both research and industrial development.

What We Offer

Customizable PCL Coatings to Meet Your Specific Application Needs

BOC Sciences specializes in the preparation and development of PCL coatings, offering comprehensive solutions ranging from basic films to functional composites and multilayer hybrid coatings. With extensive experience in preparation techniques, precise analytical capabilities, and flexible customization services, we provide high-performance PCL coating solutions tailored to various material substrates and application scenarios, helping clients achieve biomimetic material performance optimization, functional integration, and innovative applications.

Pure PCL Coating

- Provides uniform and dense PCL films with customizable thickness.

- Supports multiple preparation methods, including solution dip coating and spray coating.

- Can serve as an initial drug-release layer or a base barrier coating in biomimetic materials.

PCL Composite Coating

- PCL can be combined with inorganic materials (e.g., silica, hydroxyapatite) or organic nanoparticles.

- Offers customized composites to enhance hardness and improve substrate adhesion.

- Supports functional design for drug-controlled release and precise delivery.

PCL Copolymer Coating

- Can be copolymerized or blended with biodegradable polymers such as PLA, PEG, or PGA.

- Enables tuning of coating degradation rate and hydrophilicity to optimize material properties.

- Functional coatings can be designed to meet drug release or tissue engineering requirements.

PCL Hybrid Coating

- PCL coatings can be layered or blended with other coatings (e.g., PEO layer, silane layer).

- Enhances adhesion of PCL to metals or other substrates.

- Multi-functional coatings can be designed to integrate corrosion resistance, biocompatibility, and drug-controlled release.

PCL Blend Coating

- Offers physical blending with other polymers (e.g., PLA, PET).

- Combines the advantages of two polymers to improve mechanical performance or flexibility.

- Supports customized coating structures to suit various application scenarios.

PCL Antibacterial Coating

- Combines PCL with antibacterial agents or nanoparticles for long-term protection.

- Customizable in terms of agent type, concentration, and release rate to meet application needs.

- Applicable to medical devices, catheters, wound dressings, and biomimetic implant surfaces.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

PCL Coating Development and Preparation Support Services

BOC Sciences is committed to providing comprehensive support for the development, preparation, and manufacturing of PCL coatings. Whether for laboratory research, biomimetic material development, or pilot and small-scale production, we provide full-process technical support from concept design to performance validation, ensuring the quality, functionality, and applicability of PCL coatings meet various research and industrial requirements.

1PCL Material and Formulation Development

- Design PCL molecular weight and functionality (Diol, Triol, Tetraol) to suit specific systems or biomedical scaffolds.

- Provide coating design solutions tailored to different substrates and application scenarios, including thickness, porosity, and fiber structure customization.

- Support functional modifications such as drug loading, antibacterial properties, cell guidance, or integration of bioactive molecules.

- Support composite formulations with bioactive ceramics (e.g., hydroxyapatite), metal nanoparticles, or drug carriers.

2PCL Coating Preparation Techniques

- Offer multiple preparation methods, including solution dip coating, spray coating, melt coating, and electrospun fiber coatings.

- Control coating thickness, porosity, and fiber dimensions for customized structural design.

- Support composite or multilayer coatings for drug-controlled release, antibacterial function, or enhanced mechanical performance.

- Provide lab-scale and pilot-scale preparation services, ensuring scalable and reliable processes.

3PCL Coating Performance Optimization

- Perform surface morphology analysis (SEM, AFM) and chemical structure characterization (FTIR, NMR).

- Test coating mechanical properties, degradation behavior, and drug release kinetics to ensure functional stability.

- Adjust formulations or processes based on performance testing to optimize coating quality and function.

- Provide biocompatibility assessment and antibacterial testing to ensure material safety and practicality.

4PCL Coating Manufacturing and Scale-Up Support

- Full-process technical support from laboratory to pilot and small-scale production.

- Customizable batch preparation schemes according to client requirements, covering various coating types and composite materials.

- Strict quality control and traceable production records to ensure product consistency.

- Support subsequent process optimization and functional expansion, providing continuous technical assurance for biomimetic material applications.

Advantages

Key Advantages of Professional PCL Coating Services

- Professional Technical Team: Our team possesses extensive experience in polymer and biomaterials research, providing full-process technical support from PCL coating design and preparation to functional modification, ensuring efficient project execution and performance optimization.

- Customized Solutions: We offer personalized solutions for coating thickness, porosity, composite components, and drug loading based on client material types, application scenarios, and functional requirements.

- Multi-Process Preparation Capabilities: Supports various processes including solution dip coating, spray coating, melt coating, electrospun fiber, and multilayer composite coatings, enabling high-precision coatings on diverse substrates and structures.

- Advanced Analysis and Characterization: Provides comprehensive assessment of coating surface morphology (SEM, AFM), chemical structure (FTIR, NMR), mechanical properties, degradation behavior, and drug release kinetics.

- Functional Development Capabilities: PCL coatings can be integrated with drugs, antibacterial agents, nanoparticles, or other bioactive molecules to achieve drug release, antibacterial properties, cell guidance, and multifunctional biomimetic material development.

- Performance Optimization and Improvement: Based on coating performance test results, we provide formulation, process, and structural optimization solutions to enhance coating stability, mechanical performance, and functional effectiveness.

- Scale-Up and Production Capability: Laboratory processes can be smoothly scaled to pilot or small-scale production with strict quality control and traceable records to ensure consistent coating performance across batches.

Service Process

How Our PCL Coating Services Work?

BOC Sciences provides a systematic, modular PCL coating service workflow, delivering technical support and quality control from client requirement analysis to final product delivery, ensuring each project proceeds efficiently and meets performance and functional goals.

1Requirement Analysis

- Gain an in-depth understanding of client material types, application scenarios, and functional needs, and develop technical solutions aligned with project goals.

- Determine coating type, performance indicators, and potential applications to guide subsequent development scientifically.

2Solution Design

- Select suitable preparation processes, coating thickness, porosity, and functional modification strategies based on requirements to form an actionable plan.

- Design coating parameters and composite material combinations to ensure controllability and clearly defined performance optimization objectives.

3Small-Scale Experimental Development

- Conduct laboratory-scale preparation to validate process feasibility and preliminary coating performance stability.

- Perform initial tests and assessments on coating surface morphology, mechanical properties, chemical structure, and degradation behavior.

4Functional Optimization

- Optimize coating formulations and preparation processes to integrate drug loading, antibacterial functionality, or bioactive molecule features.

- Adjust coating structure and performance parameters to enhance biomimetic properties and biocompatibility.

5Pilot and Scale-Up Production

- Scale optimized laboratory processes to pilot or small-scale production, ensuring process controllability and stability.

- Ensure consistent performance across coating batches and enable functional adjustments per client requirements.

6Quality Control and Delivery

- Provide rigorous characterization, performance evaluation, and traceable production records to guarantee coating quality and functionality.

- Complete final product delivery with technical support to ensure smooth application in biomimetic material projects.

Applications

Key Applications of PCL Coatings in Biomimetic Materials

Polycaprolactone coatings, with excellent biodegradability, biocompatibility, and high functionalization potential, are widely applied in biomimetic materials. Forming a PCL coating on substrates can mimic the microenvironment of natural tissues, control degradation rates, enable drug release, and integrate functional modifications, supporting medical, tissue engineering, and biomimetic material development.

Surface Modification of Tissue Engineering Scaffolds

Forming a PCL coating on bone, soft tissue, or vascular scaffolds improves surface roughness and hydrophilicity, promoting cell adhesion and proliferation. Fibrous or porous structures can mimic natural extracellular matrices, enhancing tissue repair efficiency.

Drug Delivery Systems

PCL coatings enable localized drug release, including antibiotics, anti-inflammatory drugs, or growth factors. By adjusting coating thickness, porosity, and composite composition, precise and controlled drug release kinetics can be achieved.

Antibacterial Biomimetic Materials

Integrating antibacterial agents or nanoparticles into PCL coatings forms long-term protective layers. Applications include catheters, wound dressings, and implants to reduce infection risk while maintaining tissue compatibility.

Multifunctional Composite Biomimetic Materials

PCL can be layered or combined with other coatings or materials to create multilayer functional coatings. Simultaneously achieves mechanical reinforcement, drug release, antibacterial effects, and cell guidance, suitable for complex medical devices or high-performance biomimetic scaffolds.

Biodegradable Implants

The slow degradation of PCL coatings is ideal for resorbable implant surfaces, reducing the need for secondary surgeries. Degradation products are non-toxic and safely break down in vivo while maintaining structural support and functional release.

Wound Repair and Dressings

Applying PCL coatings to biodegradable wound dressings provides a moist protective environment and promotes healing. Drug or growth factor loading enables both antibacterial function and accelerated tissue repair.

FAQs

Frequently Asked Questions

-

What is a polycaprolactone coating?

A PCL coating is a film or fiber structure formed by covering a substrate surface with polycaprolactone. It significantly improves the substrate's physical and chemical properties, such as enhancing mechanical strength and regulating surface hydrophilicity or roughness. PCL coatings have controllable biodegradability and can enable drug or bioactive molecule release, supporting applications in tissue engineering, medical devices, and biomimetic materials.

-

What are the applications of PCL coatings in biomimetic materials?

PCL coatings have wide applications in biomimetic materials, including surface modification of tissue engineering scaffolds to improve cell adhesion and proliferation, local drug delivery systems, antibacterial coatings on medical devices, biodegradable implants to reduce secondary surgeries, and multifunctional biomimetic materials integrating mechanical reinforcement, drug release, antibacterial, and bioactive functions.

-

What PCL coating preparation methods does BOC Sciences provide?

We provide multiple PCL coating preparation processes tailored to substrate type and functional needs, including solution dip and spray coating for flat or complex structures, electrospun fiber coatings for biomimetic fiber networks or porous structures, porous coatings to regulate cell growth and drug diffusion, and melt coating for high uniformity and controllable thickness, suitable for both research and industrial production.

-

Can PCL coatings carry drugs or antibacterial agents?

Yes, PCL coatings can effectively integrate drug molecules, antibacterial agents, or nanoparticles to achieve local sustained release or antibacterial functionality. By controlling coating thickness, porosity, and composite ratios, release rates or antibacterial duration can be precisely tuned. PCL's excellent biocompatibility ensures safe in vivo application, making it suitable for wound dressings, implants, and medical device surface functionalization.

-

How is the degradation rate of PCL coatings controlled?

The degradation rate of PCL coatings can be precisely controlled through strategies such as selecting different PCL molecular weights, copolymer modification (e.g., PCL-PEG or PCL-PLA), and adjusting coating thickness, porosity, and composite ratios. Optimizing these parameters enables controllable degradation from weeks to months or longer, supporting customized applications in tissue engineering, drug delivery, and biomimetic materials.