Polycaprolactone (PCL) Services

Browse by

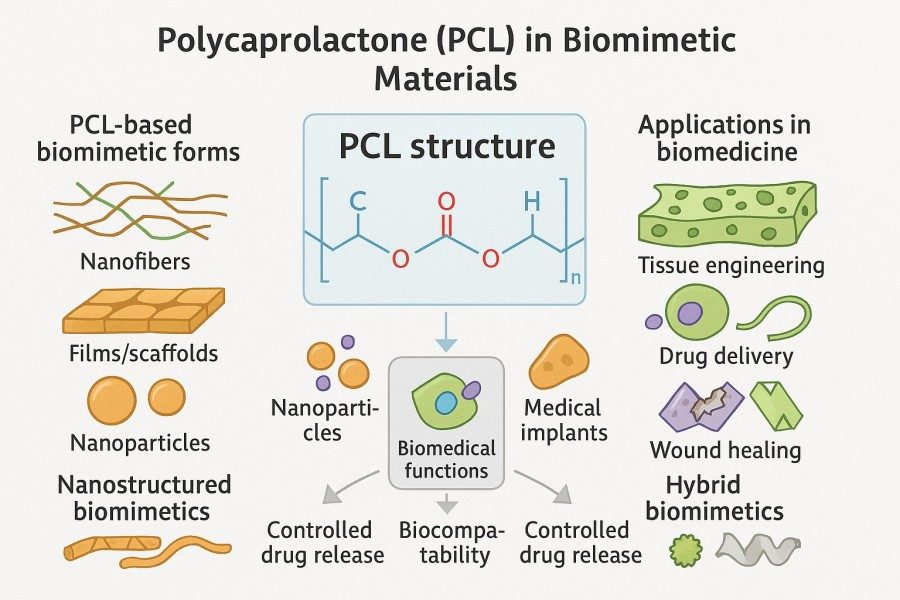

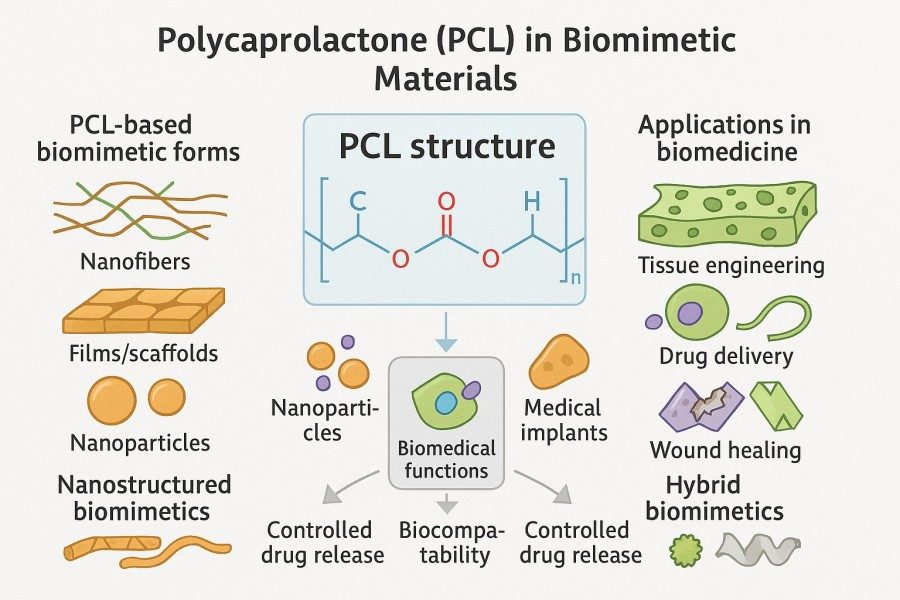

Polycaprolactone (PCL) is a synthetic linear aliphatic polyester. It is typically obtained through the ring-opening polymerization of ε-caprolactone monomers and is a semi-crystalline polymer. Initially, PCL was primarily studied as a biodegradable plastic material. In recent years, due to its biodegradability, excellent biocompatibility, tunable mechanical properties, and ease of blending with other polymers, it has become an important candidate in biomimetic material research. BOC Sciences has long focused on the custom synthesis, modification, and analysis of polymer chemicals and monomers, providing high-quality PCL products and technical support for customers engaged in biomimetic material research, development, and production. Through tailored solutions, we help research institutions, pharmaceutical companies, and material developers achieve breakthroughs in cutting-edge applications.

What We Offer

PCL Biomimetic Materials Offered by BOC Sciences

In biomimetic material research and applications, the physicochemical properties of PCL allow it to be processed into various structures and forms to meet diverse research and industrial needs. Leveraging advanced synthesis and modification platforms, BOC Sciences can provide not only high-purity, molecular weight-controlled PCL but also customize multiple application forms according to project objectives. We offer one-stop support for researchers, developers, and manufacturers, accelerating progress in tissue engineering, drug delivery, medical implants, and functional coatings.

- Can be prepared as transparent or semi-transparent films with uniform and controllable thickness.

- Supports modifications to enhance mechanical strength, breathability, and water stability.

- Suitable for wound dressings, barrier membranes, and biomimetic packaging research.

- Can form PCL coatings on metal, ceramic, or polymer surfaces.

- Improves the biocompatibility and durability of substrate materials.

- Commonly used in medical implants and protective biomimetic coatings.

- Provides nanoparticles and microspheres with controlled size distribution.

- Supports loading and sustained release of drugs, proteins, or nucleic acids.

- Widely applied in targeted drug delivery and controlled-release formulation research.

- Prepared via electrospinning or other techniques to produce ultrafine nanofibers.

- Large surface area suitable for cell adhesion and drug immobilization.

- Commonly used in wound healing, drug release, and biomimetic scaffolds.

- Can be designed as porous 3D structures to mimic the extracellular matrix.

- Pore size and porosity are controllable, facilitating cell proliferation and tissue regeneration.

- Widely applied in orthopedic, dental, and soft tissue engineering research.

Polycaprolactone Blends & Composites

- Can be blended with PLA, PEG, Gelatin, and other materials.

- Used to tune degradation rate, mechanical properties, and biocompatibility.

- Supports the development and customization of functional biomimetic materials.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Custom PCL Services for Biomimetic Materials

We understand the strict requirements for precise material performance in biomimetic research and applications, which is why we have developed a comprehensive one-stop service system for polycaprolactone. Whether the needs involve cutting-edge research, functional material development, or industrial-scale production, we provide efficient, flexible, and high-quality support. With an international R&D team, advanced laboratory and production facilities, and rigorous quality control, BOC Sciences has become a long-term partner for numerous research institutions and companies in PCL research and applications.

1Custom PCL Synthesis

- Synthesis of PCL with different molecular weight ranges (low, medium, high).

- Polymerization conditions can be tailored to ensure crystallinity and degradation rates meet intended applications.

- Supports scale-up from laboratory, pilot, to industrial production to meet both research and industrial demands.

2PCL Modification Services

- Offers diverse modification options, including copolymerization with PLA, PEG, and other polymers.

- Surface grafting of functional groups such as amino or carboxyl groups enhances cell affinity and bioactivity.

- Development of PCL composites with natural polysaccharides or proteins to improve biomimetic properties and application adaptability.

3PCL Analysis & Testing Services

- Provides molecular weight and distribution (GPC), structural characterization (NMR, FTIR, XRD), and more.

- Conducts systematic analysis of thermal properties (DSC, TGA), mechanical properties, and degradation behavior.

- Fully compliant with international standards, offering complete reports to support research and product registration.

4PCL Scale-Up Production

- Produces PCL from kilogram to ton scales, meeting both research and commercial needs.

- Optimized processes ensure high yield, low cost, and batch-to-batch consistency.

- Production systems adhere to strict quality control standards, ensuring reliable and traceable supply.

Advantages

Your Partner for Advanced PCL and Polymer Materials

- Expertise in Polymer Synthesis and Modification: Mastery of ring-opening polymerization, copolymerization, and graft modification, with molecular weight ranges from 2,000–200,000 Da. Precisely controls crystallinity and degradation rate to meet diverse biomedical and materials engineering applications.

- Comprehensive Analysis and Quality Control: Equipped with GPC, NMR, FTIR, DSC, and other characterization techniques to ensure purity, stability, and performance of every PCL batch.

- Flexible Scale-Up Support: Offers gram-scale experimental samples, kilogram-scale pilot materials, and hundred-kilogram industrial production, maintaining product performance across scales.

- Customized Solution Design: Beyond raw materials, we recommend optimal polymerization conditions and modification pathways for scaffolds, microspheres, and coatings, reducing R&D cycles and trial-and-error costs.

- Cross-Disciplinary Application Experience: Successful collaborations in tissue engineering, drug delivery, medical implants, and biodegradable packaging provide technical guidance and accelerate research translation.

- Efficient Communication and Responsiveness: Dedicated project managers and R&D teams respond within 24 hours, adjusting solutions according to client timelines to ensure efficient R&D and production.

Service Process

Comprehensive PCL Service Workflow for Research & Production

To ensure customers receive efficient and reliable support throughout PCL research and applications, BOC Sciences has established a systematic service workflow. Our process covers every stage from requirement communication and material design to industrial-scale delivery, emphasizing personalized customization, strict quality control, and rapid response. This ensures that scientific and industrial projects progress smoothly, minimizing trial-and-error costs and improving overall efficiency.

1Requirement Communication

BOC Sciences' professional project managers and technical teams work closely with clients to understand research goals, application scenarios, and material performance requirements. By integrating experimental conditions, scale needs, and expected outcomes, we develop preliminary technical solutions, ensuring a feasible path from the outset and laying a solid foundation for subsequent R&D and production.

2Solution Design

Based on requirement analysis, we design personalized PCL synthesis, modification, and application plans. This includes molecular weight selection, polymerization processes, modification strategies, and recommended application forms. The design balances scientific rigor and practicality, providing multiple options for client evaluation and decision-making, ensuring material performance aligns with application objectives.

3Lab-Scale Trials and Validation

Small-scale synthesis and performance validation are conducted in the laboratory to assess molecular weight, crystallinity, degradation rate, as well as mechanical and thermal properties. Results from these trials are used to optimize the plan, identify potential issues, and provide reliable data and process references for pilot-scale and industrial-scale production.

4Pilot-Scale Scale-Up

After confirming lab-scale feasibility, pilot-scale scale-up is performed to verify process stability and batch consistency. By optimizing reaction conditions and controlling temperature and stirring parameters, product performance is ensured to match lab-scale results, providing clients with scalable technology and samples while shortening the transition from R&D to production.

5Quality Testing and Validation

Every batch of material is rigorously tested before and after pilot or industrial-scale production, including molecular weight distribution (GPC), structural characterization (NMR, FTIR, XRD), thermal properties (DSC, TGA), and mechanical and degradation behavior assessments. Comprehensive validation ensures products meet client requirements and are suitable for research or commercial applications.

6Deliverables and Technical Support

Upon completion of production and testing, BOC Sciences delivers PCL products that meet standards along with complete analytical reports. Continuous technical support is provided, including material usage guidance, optimization of modification strategies, and assistance with further R&D, ensuring clients can successfully apply materials in experiments, development, or industrial projects.

Applications

Application Support of PCL in Biomimetic Materials

Polycaprolactone's excellent biocompatibility, biodegradability, and processing versatility make it a key polymer in the field of biomimetic materials. It can be fabricated into films, fibers, scaffolds, microspheres, and coatings to meet diverse applications in tissue engineering, drug delivery, degradable implants, and functional coatings. Leveraging advanced synthesis, modification, and shaping technologies, BOC Sciences provides PCL materials and technical support tailored for various application scenarios, helping clients accelerate research and explore innovative uses.

Tissue Engineering Scaffolds

Tissue engineering is one of the most prominent fields for biomimetic materials. PCL, with its 3D processability and structural stability, is a crucial material for scaffold fabrication.

- Bone Tissue Engineering: PCL scaffolds can mimic the porous structure of bone, providing moderate load-bearing capacity and, when combined with bioceramics (e.g., hydroxyapatite), enhancing mechanical strength and osteoconductivity.

- Cartilage Repair: PCL/collagen composite scaffolds produced via 3D printing or electrospinning can mimic the fiber network of cartilage matrix, promoting chondrocyte adhesion and differentiation.

- Skin and Nerve Repair: PCL nanofiber membranes mimic extracellular matrix (ECM) morphology, supporting keratinocyte and neuron adhesion and growth.

Drug Delivery and Controlled Release Systems

PCL is widely used in drug delivery due to its slow and controllable degradation.

- Microspheres and Nanoparticles: PCL micro/nanoparticles can be prepared via emulsion-solvent evaporation or self-assembly for controlled release of small molecules, proteins, peptides, or nucleic acids.

- Long-Acting Formulations: For example, contraceptive drug release or anticancer sustained-release systems utilize PCL's degradation properties for prolonged and stable drug delivery.

- Surface Modification: Grafting hydrophilic molecules (e.g., PEG) improves drug release behavior and biocompatibility.

Medical Biomimetic Implants

PCL's plasticity and biocompatibility make it suitable for degradable implants:

- Sutures and Surgical Clips: PCL gradually degrades and is absorbed after tissue fixation, eliminating the need for secondary removal surgery.

- Vascular Stents: PCL composites can form degradable vascular stents that mimic natural blood vessel flexibility and mechanical properties.

- Dental and Craniofacial Repair: PCL bone substitutes act as fillers, gradually degrading while promoting bone cell ingrowth.

Biomimetic Functional Membranes

PCL membranes are commonly used to mimic biological membranes or barriers, offering breathability and flexibility.

- Cell Culture Membranes: Mimic natural extracellular matrix, supporting stem cell differentiation studies.

- Barrier Membranes: In periodontal regeneration or guided bone regeneration (GBR) surgeries, PCL membranes act as barriers to prevent premature fiber tissue invasion of bone defects.

- Skin-Mimicking Applications: Porous membranes composed of PCL and natural polysaccharides serve as wound dressings, simulating skin barrier function.

FAQs

Frequently Asked Questions

-

What is polycaprolactone (PCL) used for?

Polycaprolactone (PCL) is widely applied in biomimetic materials, tissue engineering, drug delivery, degradable implants, and functional coatings. Its biodegradability and processing versatility allow fabrication into films, fibers, microspheres, and 3D scaffolds, making it a key polymer for research and industrial development.

-

Is polycaprolactone (PCL) thermoplastic?

Polycaprolactone (PCL) is a thermoplastic polymer that can be melt-processed under heat and solidifies upon cooling. Its thermoplastic properties allow it to be shaped via injection molding, extrusion, electrospinning, and other techniques, suitable for producing films, fibers, and scaffolds.

-

What are the biomedical applications of polycaprolactone?

PCL is extensively used in biomedical applications, including degradable implants, tissue engineering scaffolds, drug delivery carriers, and wound dressings. Its controllable degradation and excellent biocompatibility support cell adhesion and proliferation, long-term drug release, and tissue repair, meeting diverse medical device and regenerative medicine needs.

-

Is polycaprolactone biocompatible?

Polycaprolactone (PCL) exhibits excellent biocompatibility, showing minimal toxicity or immune rejection in vivo. It supports cell adhesion, proliferation, and differentiation, commonly used in tissue engineering, degradable scaffolds, and medical implant development, making it a preferred biomimetic and biomedical material.

-

What are the benefits of polycaprolactone?

PCL offers biodegradability, thermoplasticity, processing flexibility, and superior biocompatibility. It can be fabricated into films, microspheres, fibers, or 3D scaffolds for drug release and tissue repair. Additionally, PCL blends easily with other polymers, meeting diverse research and industrial needs and enhancing material application potential.

-

What is PCL in tissue engineering?

In tissue engineering, polycaprolactone (PCL) is a key degradable polymer used to fabricate 3D scaffolds, fibers, and films. Its excellent biocompatibility, controllable degradation rate, and processing flexibility provide an ideal microenvironment for cell adhesion, proliferation, and tissue regeneration, making it a common material in regenerative medicine research.

-

Is polycarbonate good for 3D printing?

Polycarbonate (PC) has high strength, heat resistance, and toughness, making it suitable for 3D printing complex structures. Its thermoplasticity allows processing via melt extrusion, FDM, and other techniques, though temperature and shrinkage must be controlled. It is often used for high-performance engineering prototypes and durable parts.

-

Is polycaprolactone soluble in water?

Polycaprolactone (PCL) is insoluble in water but soluble in various organic solvents such as dichloromethane, tetrahydrofuran, and toluene. Its hydrophobicity enables slow degradation in vivo, suitable for drug release, tissue engineering scaffolds, and long-term implants, while allowing solution-based fabrication of films, microspheres, and fibers.

Polycaprolactone Scaffold Preparation

Polycaprolactone Scaffold Preparation

Polycaprolactone Fiber Preparation

Polycaprolactone Fiber Preparation

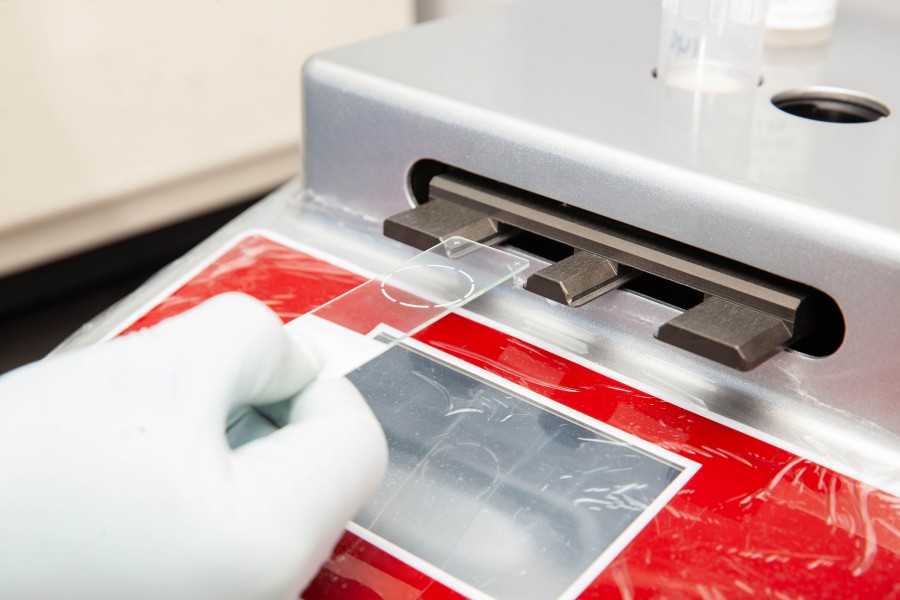

Polycaprolactone Film Preparation

Polycaprolactone Film Preparation

Polycaprolactone Coating Preparation

Polycaprolactone Coating Preparation

Polycaprolactone Microsphere Preparation

Polycaprolactone Microsphere Preparation