Gelatin Hydrogel Preparation

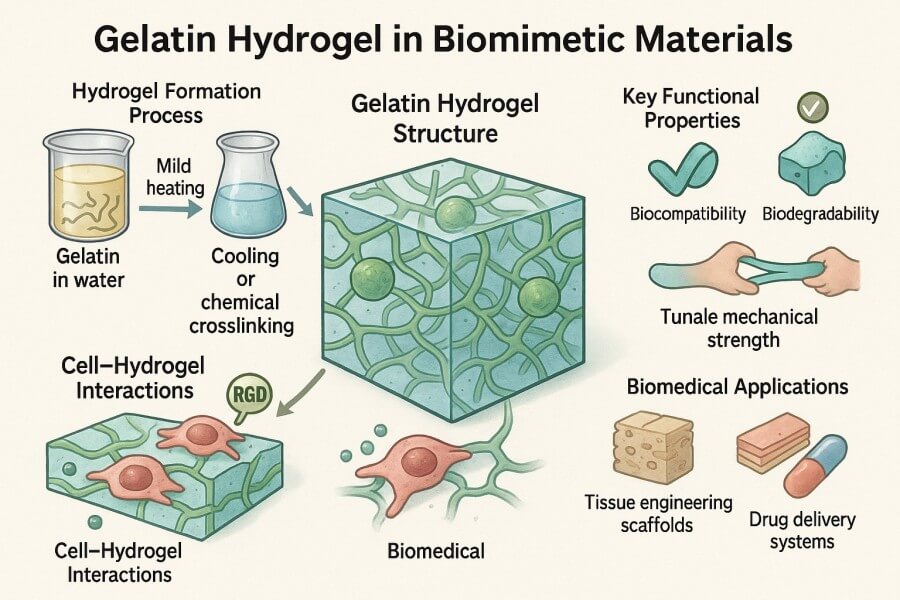

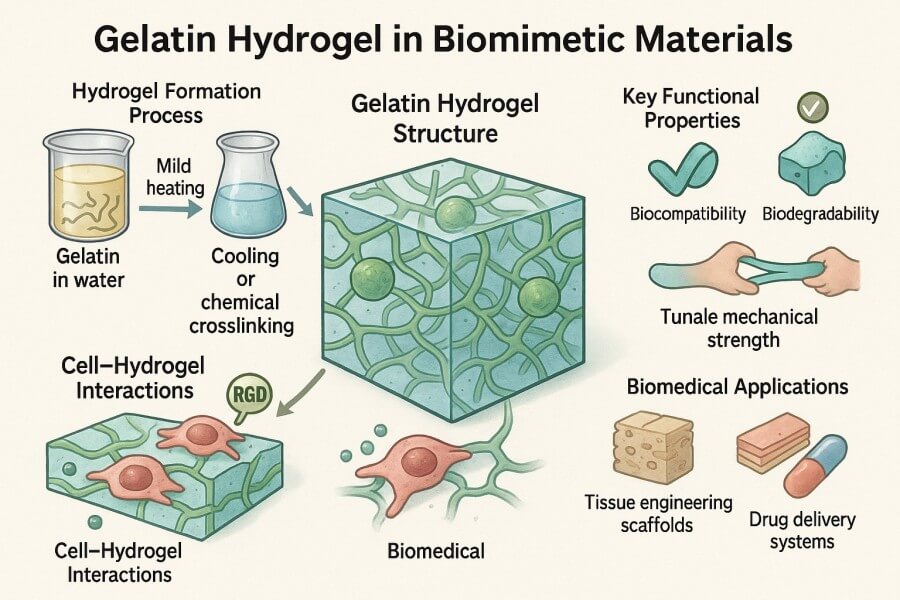

Gelatin-based hydrogels are a class of three-dimensional hydrogel materials primarily composed of gelatin, formed through physical or chemical crosslinking. Hydrogels are essentially hydrophilic polymer networks that can absorb water and swell without dissolving, creating elastic and flexible 3D structures. Gelatin hydrogels, building on traditional hydrogels, combine the natural bioactivity of proteins with excellent cell compatibility, mimicking the extracellular matrix (ECM) environment in vivo. This makes them ideal support carriers for cell growth, drug delivery, and tissue repair. BOC Sciences is dedicated to providing high-quality gelatin hydrogel synthesis and development services, supporting customers in innovative applications across drug delivery, tissue engineering, biomimetic materials, and functional coatings. We offer a variety of gelatin-based hydrogels and their derivatives, such as gelatin methacrylate hydrogel, agarose gelatin hydrogel, and gelatin graphene hydrogels, helping research institutions and enterprises achieve efficient development and experimental validation.

What We Offer

From Basic to Functional: Full Coverage of Gelatin Hydrogels

In the fields of biomimetic materials and tissue engineering, different types of gelatin hydrogels meet diverse research and industrial needs. BOC Sciences offers comprehensive services ranging from basic hydrogels to functional scaffolds, assisting clients in the design, preparation, and application optimization of high-performance hydrogels. Below are the main categories and service descriptions:

Pure Gelatin Hydrogel

- Provides gelatin raw materials of different molecular weights and concentrations to support custom gelatin-based hydrogel formulations.

- Physical crosslinking and temperature-controlled crosslinking processes ensure hydrogel stability and reproducibility.

- Capable of preparing basic scaffolds for in vitro cell culture and tissue engineering applications according to client needs.

Natural Polymer Composite Hydrogel

- Supports the design of composite materials such as chitosan gelatin hydrogel, gelatin alginate hydrogel, gelatin pectin hydrogel, and agarose gelatin hydrogel.

- Offers polysaccharide composite regulation to enhance hydrogel mechanical properties, water absorption, and biocompatibility.

- Optimizes pore structure and degradation rate based on application requirements, suitable for drug delivery and tissue engineering.

Chemically Crosslinked Gelatin Hydrogel

- Provides crosslinked hydrogels such as gelatin glutaraldehyde hydrogel, gelatin methacryloyl hydrogel, and gelatin norbornene hydrogel.

- Supports various crosslinking strategies, including EDC/NHS, photoinitiated crosslinking, and naturally low-toxicity crosslinkers.

- Customizable mechanical strength, degradation rate, and functional properties for tissue engineering scaffolds and controlled drug release.

Nanocomposite Gelatin Hydrogel

- Provides gelatin graphene hydrogels and composites with nano-hydroxyapatite or nanocellulose.

- Tunable mechanical properties, conductivity, and biomimetic functions support high-performance material development.

- Offers nanocomposite formulation optimization, characterization, and functionalization services to meet research and industrial application needs.

Gelatin Hydrogel Microspheres

- Capable of preparing biodegradable gelatin hydrogel microspheres and drug carrier microspheres.

- Supports particle size control, crosslinking strength optimization, and drug/protein loading functionalization.

- Provides drug release testing and functional customization, suitable for controlled drug release and precise delivery.

Functional Gelatin Hydrogel Film & Scaffold

- Offers design and preparation of gelatin hydrogel films and scaffolds.

- Customizable pore structure, thickness, and mechanical properties to meet different tissue engineering requirements.

- Supports intelligent and functional modifications, such as glycerol, PEG, or nanomaterial composites, enhancing flexibility and functional characteristics.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Custom Gelatin Hydrogel Services to Meet Research and Industrial Needs

With extensive experience in polymer chemistry and hydrogel development, BOC Sciences offers end-to-end custom development services—from material selection, formulation design, and crosslinking control to microsphere, film, and scaffold functionalization. We optimize the mechanical properties, bioactivity, and performance of gelatin-based hydrogels according to clients' research goals or industrial requirements, ensuring efficient implementation in tissue engineering scaffolds, controlled drug release systems, and biomimetic material development.

1Material Design & Formulation Optimization

- Provides gelatin raw materials of various molecular weights and concentrations, supporting custom hydrogel formulations.

- Designs natural composite hydrogels based on application requirements, such as gelatin alginate hydrogel or gelatin pectin hydrogel.

- Controls crosslinking methods and intensity to achieve tunable mechanical properties and degradation rates.

- Optimizes hydrogel pore structure and water absorption to meet tissue engineering and drug delivery requirements.

2Crosslinking & Functionalization Development

- Supports physical crosslinking, chemical crosslinking (e.g., gelatin glutaraldehyde hydrogel, gelatin methacryloyl hydrogel), and photoinitiated crosslinking techniques.

- Provides nanocomposite functionalization, such as gelatin graphene hydrogels or nanoparticle composites, enhancing mechanical and conductive performance.

- Customizes glycerol, PEG, or polysaccharide modifications for improved flexibility, smart responsiveness, or bioactivity regulation.

- Supports functional design of microspheres, films, or scaffolds, expanding hydrogel application diversity.

3Microsphere & Drug Carrier Development

- Prepares gelatin hydrogel microspheres capable of loading drugs or proteins.

- Offers particle size control, crosslinking density optimization, and drug release rate regulation.

- Supports precise delivery system design for controlled, targeted, and biodegradable applications.

- Provides drug compatibility testing and functional development to ensure stable performance.

4Scaffold & Film Customization Services

- Offers design and preparation of gelatin hydrogel scaffolds and films.

- Customizable pore structure, thickness, mechanical strength, and degradation rate to meet diverse tissue engineering needs.

- Supports intelligent and functional modifications, including nanomaterial composites, PEG, or glycerol modifications, enhancing application functionality.

- Provides one-stop custom development support from material selection and preparation to functional validation, ensuring efficient implementation in research and industrial applications.

Characterization

Gelatin Hydrogel Analysis & Characterization Services

BOC Sciences offers comprehensive gelatin hydrogel analysis and characterization services, covering mechanical properties, structural features, chemical composition, degradation behavior, and drug carrier performance. Through systematic testing and data analysis, we help clients validate material quality, optimize formulations, and ensure hydrogels meet expected performance in tissue engineering, drug delivery, and biomimetic material applications.

| Test Category | Test Item | Description & Purpose | Test Method/Instrument | Applicable Sample Types |

|---|

| Physical Properties | Swelling/Water Content | Measure hydrogel water absorption and retention, evaluate biocompatibility and application stability. | Gravimetric method, Dynamic Vapor Sorption (DVS) | Films, scaffolds, microspheres |

| Pore Structure Analysis | Analyze hydrogel pore size, porosity, and 3D structure using SEM or micro-CT, guiding tissue engineering scaffold design. | SEM/Micro-CT | Scaffolds, films, nanocomposite hydrogels |

| Mechanical Properties | Measure compression modulus, tensile strength, and elasticity to evaluate hydrogel load-bearing capacity and flexibility. | Tensile tester, Compression tester | Scaffolds, films, microspheres |

| Chemical Composition | FTIR Analysis | Confirm hydrogel functional groups and crosslinking efficiency, verify formulation and modification success. | FTIR Spectrometer | All types of Gelatin Hydrogel |

| Nuclear Magnetic Resonance (NMR) | Analyze crosslinking structure and functional modifications to ensure material stability. | ¹H-NMR/¹³C-NMR | Functionalized hydrogels, nanocomposite hydrogels |

| Elemental Analysis | Determine content of composite or nanomaterials to ensure accurate composition. | ICP-OES/XRF | Nanocomposite hydrogels, composite materials |

| Degradation & Stability | Enzymatic/Hydrolytic Degradation | Simulate in vivo degradation to evaluate biodegradation rate and controlled release capability. | Enzymatic assays, pH-controlled systems | Microspheres, scaffolds, hydrogel films |

| Thermal Stability (TGA/DSC) | Assess thermal stability and thermodynamic properties, guiding processing and storage conditions. | TGA/DSC | All types of Gelatin Hydrogel |

| Drug Carrier Performance | Loading Capacity | Evaluate hydrogel or microsphere ability to load drugs, proteins, or nucleic acids. | UV-Vis/HPLC/Fluorescence assay | Microspheres, films, hydrogel scaffolds |

| Drug Release Behavior | Monitor controlled release performance to optimize drug delivery system design. | In vitro release study, HPLC | Microspheres, scaffolds, hydrogel films |

| Drug Compatibility | Verify stability and interaction of hydrogel with drugs or bioactive molecules. | Stability testing, solution analysis | Microspheres, films, nanocomposite hydrogels |

Advantages

Top Benefits of Professional Gelatin Hydrogel Solutions

- Professional Technical Team: Our team of experienced experts in materials science, biochemistry, and polymer chemistry provides end-to-end technical support for different types of gelatin hydrogels, from basic design to functional development, ensuring efficient project implementation.

- Customized Solutions: We offer personalized formulation design, crosslinking optimization, and functional development of microspheres and scaffolds based on client research or industrial application needs, supporting diverse applications in drug delivery, tissue engineering, and biomimetic materials.

- Comprehensive Analysis & Characterization Capabilities: Equipped with advanced instruments such as SEM, Micro-CT, FTIR, NMR, TGA/DSC, and HPLC, we systematically characterize hydrogel mechanical properties, microstructure, chemical composition, and drug carrier performance, ensuring reliable material quality.

- Efficient Client Support: We provide one-on-one technical consultation and project management, quickly responding to client needs, offering expert guidance on R&D challenges, and providing continuous support during hydrogel preparation, functionalization, and characterization.

- Strict Quality Control & Performance Assurance: From raw material sourcing to hydrogel preparation, we maintain rigorous quality control to ensure gelatin hydrogel mechanical properties, degradability, biocompatibility, and batch-to-batch consistency, providing reliable assurance for research and industrial applications.

- Flexible Collaboration & Scalable Services: We support full-cycle collaboration from small-scale R&D and functional verification to bulk production, with flexible project adjustments and follow-up services for application expansion and process optimization, meeting long-term research and industrial demands.

- Diverse Application Guidance: Drawing on our experience in tissue engineering scaffolds, controlled drug release systems, biomimetic films, and nanocomposite hydrogels, we provide material selection, structural optimization, and functional modification guidance to help clients achieve optimal performance and application outcomes.

Service Process

Gelatin Hydrogel Preparation & Development Process

BOC Sciences provides end-to-end gelatin hydrogel synthesis and custom development services, covering material design, preparation, functionalization, and application optimization to meet high standards for research and industrial applications. The main workflow is as follows:

1Requirement Analysis & Solution Design

- Conduct in-depth discussions with clients to define research direction, target tissue type, pore structure, and functional requirements.

- Select appropriate gelatin type, composite materials, and crosslinking strategies based on application goals (e.g., tissue engineering scaffolds, controlled drug release, or biomimetic material development).

- Provide multiple solution comparisons and recommendations to balance performance, degradation rate, and biocompatibility.

2Material Selection & Formulation Optimization

- Select high-quality gelatin raw materials to support gelatin-based or composite hydrogels such as agarose gelatin hydrogel and gelatin alginate hydrogel.

- Adjust hydrogel concentration, gelatin molecular weight, crosslinker type, and ratio to optimize mechanical properties and thermal stability.

- Optimize composite components and functional additives, such as polysaccharides, PEG, or nanoparticles, to enhance bioactivity and controllable degradability.

3Hydrogel Preparation & Crosslinking

- Physical Crosslinking: Induce hydrogel formation through temperature changes, ion concentration regulation, or pH control while maintaining natural biocompatibility.

- Chemical Crosslinking: Prepare hydrogels such as gelatin glutaraldehyde hydrogel and gelatin methacryloyl hydrogel to achieve tunable mechanical properties, degradation rates, and stability.

- Nanocomposite or polysaccharide copolymer modifications can be applied to enhance mechanical strength, conductivity, and functionalization, meeting advanced biomimetic material requirements.

4Functionalization & Modification

- Prepare gelatin hydrogel films, scaffolds, or microsphere carriers for drug delivery, cell culture, and tissue engineering.

- Modify hydrogels with glycerol, PEG, or nanomaterials to achieve flexibility, smart responsiveness, conductivity, or biomimetic functions.

- Support bioactive functionalization, such as growth factor or drug loading, enabling controlled release and targeted applications.

5Quality Testing & Characterization

- Systematically test hydrogel mechanical properties, water absorption, pore structure, degradation rate, and drug release characteristics to ensure performance meets application requirements.

- Verify hydrogel quality and reliability through microstructural analysis, chemical characterization, and functional testing.

- Provide detailed analytical reports to support R&D optimization, industrial scale-up, and application design.

6Custom Delivery & Technical Support

- Offer flexible delivery options from small-scale R&D samples to bulk production to meet research and industrial needs.

- Support gelatin hydrogel development for drug delivery systems and tissue engineering scaffolds, including functional design and process optimization.

- Provide one-on-one technical support and follow-up consultation to help clients maximize hydrogel performance and application potential.

Applications

Major Applications of Gelatin-Based Hydrogels

Gelatin-based hydrogels, with excellent biocompatibility, biodegradability, and tunable physicochemical properties, serve as essential materials in tissue engineering, drug delivery, and biomimetic materials. Hydrogels with different structures, crosslinking methods, and functional modifications can meet diverse research and industrial needs. Through precise design and preparation, gelatin hydrogels enable multifunctional applications ranging from cell scaffolds and controlled drug release systems to smart biomimetic materials.

Tissue Engineering & Regenerative Medicine

- Cell Scaffold Construction: Gelatin hydrogels can mimic the natural extracellular matrix (ECM), promoting cell adhesion, proliferation, and differentiation.

- Application Fields: Suitable for skin, cartilage, vascular, and bone tissue repair.

- High-Precision Scaffold Printing: Gelatin methacrylate hydrogel and gelatin norbornene hydrogel enable high-resolution 3D printing via photoinitiated crosslinking.

Drug Delivery Systems

- Microsphere Drug Loading: Gelatin hydrogel microspheres can carry anticancer drugs, proteins, or nucleic acids for controlled release.

- Delivery Optimization: Gelatin hydrogel drug delivery systems can prolong drug half-life and enhance therapeutic efficiency.

- Functional Development: Integration with nanomaterials or chemical modifications can improve hydrogel stability and drug delivery performance.

Biomimetic Materials & Functional Coatings

- Biomimetic Films & Porous Materials: Gelatin biomimetic hydrogels can be applied to films, porous materials, and functional coatings.

- Smart Functionalization: Combined with nanomaterials such as gelatin graphene hydrogels, hydrogels can achieve conductivity or smart responsiveness.

- Surface Coating Applications: Applicable to medical devices, implants, and functional surface coatings, enhancing biocompatibility and performance stability.

Injectable Hydrogels, Microspheres & Film Applications

- Injectable Microspheres: Gelatin hydrogel microspheres can be injected for soft tissue filling and local drug release.

- Films & Surface Materials: Gelatin hydrogel films can serve as wound dressings or medical implant covers, providing a moist environment and bioactive support.

- Multifunctional Integration: Functional modifications such as glycerol, PEG, or nanomaterials enhance flexibility, controlled drug release, or smart responsiveness.

FAQs

Frequently Asked Questions

-

Is gelatin a hydrogel?

Gelatin itself is a protein derived from collagen, which can absorb water and form a gel-like structure. While gelatin in its dry form is not a hydrogel, it can be transformed into a hydrogel under suitable conditions, such as dissolution in water followed by cooling or chemical modification. Gelatin hydrogels are widely used in biomedical and tissue engineering applications due to their biocompatibility, biodegradability, and ability to mimic the natural extracellular matrix. This makes gelatin an ideal material for hydrogel formation and various bioengineering applications.

-

What is gelatin hydrogel?

Gelatin hydrogel is a three-dimensional network of gelatin molecules that can retain large amounts of water while maintaining structural integrity. It combines the natural biocompatibility and biodegradability of gelatin with the unique properties of hydrogels, such as flexibility, porosity, and tunable mechanical strength. Gelatin hydrogels are commonly used in tissue engineering scaffolds, drug delivery systems, wound healing, and regenerative medicine, where they provide a supportive environment for cell growth and controlled release of bioactive molecules.

-

How to make gelatin hydrogel?

Gelatin hydrogels can be prepared by dissolving gelatin in warm water or buffer and then cooling it to induce gelation. The gelation process can be enhanced or stabilized using crosslinking agents such as genipin, glutaraldehyde, or enzymatic methods. Temperature, gelatin concentration, and pH can influence the gelation rate and final mechanical properties. Advanced methods, like photopolymerization of modified gelatin derivatives, allow precise control of hydrogel structure for specific biomedical or tissue engineering applications.

-

What is crosslinking gelatin hydrogels?

Crosslinking gelatin hydrogels is the process of chemically or physically connecting gelatin chains to enhance stability, mechanical strength, and resistance to degradation. Common crosslinking methods include chemical agents (glutaraldehyde, genipin), enzymatic reactions, or physical methods like UV irradiation of methacrylated gelatin. Crosslinking improves the hydrogel's durability, maintains its 3D structure under physiological conditions, and allows customization of porosity and elasticity for applications such as scaffolds, drug delivery, and tissue regeneration.

-

How does gelatin hydrogel synthesis work?

Gelatin hydrogel synthesis involves dissolving gelatin in water or buffer, optionally adding crosslinkers or chemical modifications, and inducing gelation through cooling, enzymatic reaction, or photo-crosslinking. The synthesis parameters, such as gelatin concentration, crosslinking density, and environmental conditions, determine the hydrogel's mechanical strength, porosity, and biodegradability. Proper synthesis allows production of gelatin hydrogels tailored for biomedical applications, including cell culture, drug delivery, wound healing, and tissue engineering scaffolds.

-

Can gelatin hydrogels be used for drug delivery?

Gelatin hydrogels are widely used in drug delivery systems because their three-dimensional network can encapsulate drugs and enable controlled release. By adjusting gelatin concentration, crosslinking density, or chemical modification, the drug release rate and loading capacity can be tailored. Their biocompatibility and biodegradability make them suitable for in vivo drug delivery, wound dressings, and localized therapies in tissue engineering, improving efficacy while minimizing side effects.

-

What is the pore size of gelatin hydrogels?

The pore size of gelatin hydrogels can be controlled by gelatin concentration, crosslinking method, and preparation conditions, typically ranging from tens of nanometers to several hundred micrometers. Pore size affects mechanical properties, drug release rates, and cell adhesion or migration. Proper pore design can mimic natural extracellular matrix structures, providing an ideal environment for tissue engineering scaffolds and drug carriers.

-

How are gelatin hydrogel scaffolds used in tissue engineering?

Gelatin hydrogel scaffolds mimic the natural extracellular matrix, providing support, adhesion, and proliferation environments for cells. By controlling pore structure and mechanical properties, they can be applied in skin, cartilage, vascular, and bone tissue repair. These scaffolds not only support tissue regeneration but can also deliver drugs or growth factors locally, facilitating functional recovery and making them ideal 3D materials in regenerative medicine and tissue engineering.