Browse by

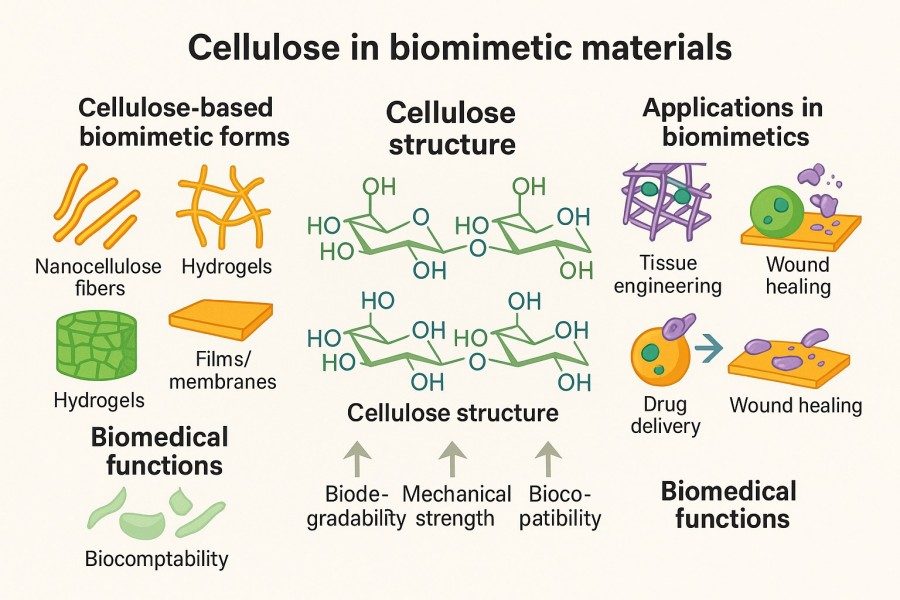

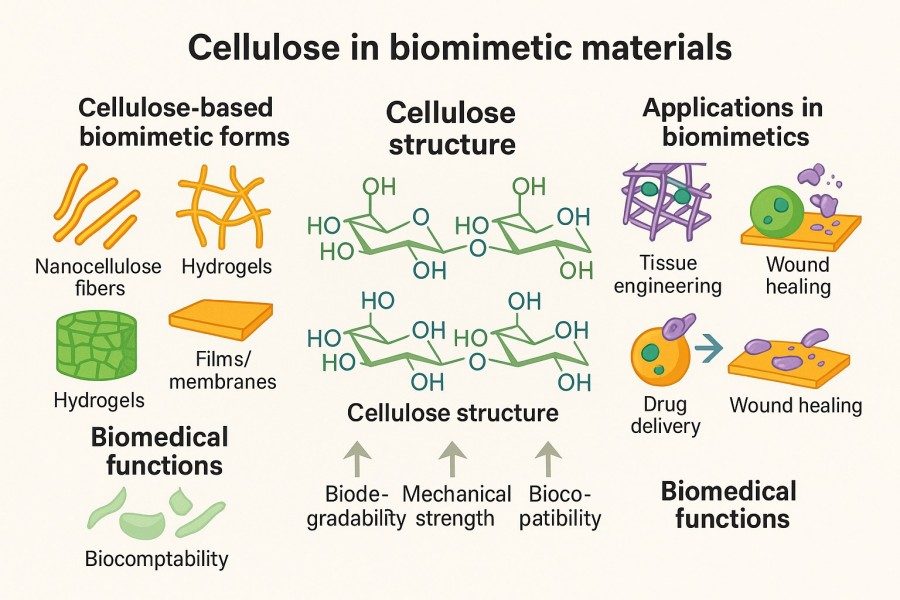

Cellulose is a linear polymer composed of β-1,4-linked glucose units and serves as the primary component of plant cell walls. Its molecular chains form microfibrils through hydrogen bonding, which further aggregate into cellulose fibers. This hierarchical structure provides cellulose with excellent mechanical strength and stability while offering abundant hydroxyl sites for chemical modification and functionalization. The unique linear polysaccharide structure of cellulose endows it with superior mechanical properties, chemical modifiability, and biocompatibility, making it highly promising in the field of biomimetic materials. BOC Sciences is committed to providing comprehensive cellulose services, covering raw material selection, custom synthesis, analytical characterization, and functional modification, fully supporting R&D and production in biomimetic materials. Whether it is nanocellulose, cellulose films, hydrogels, or composite materials, we provide tailored solutions to help clients efficiently translate innovations from the laboratory to industrial applications.

What We Offer

Cellulose Materials Offered by BOC Sciences

BOC Sciences provides a wide range of cellulose forms to meet different biomimetic material development needs. We support the processing and customization of nanofibers, films, hydrogels, and composites, combined with modification techniques to optimize mechanical performance, functional response, and biocompatibility, offering comprehensive support for biomimetic material R&D and applications.

- High-strength, high-surface-area cellulose nanomaterials for composite reinforcement, drug delivery carriers, and flexible electronic devices.

- Surface modification or functionalization can enhance dispersion, interfacial bonding, and specific responsive properties.

- Applications include biomimetic bone scaffolds, soft tissue support, and smart sensors.

- Development of transparent, thickness-controllable cellulose films.

- Crosslinking, grafting, and composite modification options enhance mechanical strength, gas barrier properties, and humidity responsiveness.

- Applications include biomimetic skin, biodegradable packaging, and environmentally responsive smart films.

- Development of transparent, thickness-controllable cellulose coatings.

- Crosslinking, grafting, or composite modifications improve mechanical strength, water resistance, and surface activity.

- Applications include biomimetic skin surfaces, antibacterial coatings, biodegradable packaging, and smart responsive coatings.

- Physical or chemical crosslinked hydrogels with tunable pore structure and optimized mechanical properties.

- Functional modifications allow drug release, pH/temperature responsiveness, and cell-supportive functions.

- Applications include soft tissue engineering, controlled drug delivery carriers, and biomimetic tactile materials.

- Customizable microspheres/microcapsules with controllable particle size, drug loading, and release behavior.

- Functional applications include pharmaceuticals, environmental remediation, and food industry uses.

- Applications include biomimetic drug carriers, pollutant adsorption materials, and flavor or nutrient release systems.

- Customizable scaffolds with tailored pore size, porosity, and 3D structures.

- Mechanical strength and biocompatibility can be enhanced through nanocellulose reinforcement or chemical modification.

- Applications include soft tissue engineering, bone support, biomimetic organ models, and drug release scaffolds.

Cellulose Composites

- Can be combined with natural or synthetic polymers and inorganic nanoparticles for multifunctional design.

- Mechanical reinforcement, optical tuning, or smart response modifications are available.

- Applications include biomimetic bone/ shell structure materials, optical biomimetic devices, and intelligent material systems.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Custom Cellulose Services for Biomimetic Materials

BOC Sciences offers mature capabilities in custom cellulose synthesis, functional modification, analytical characterization, and industrial translation, providing full technical support to biomimetic material developers and manufacturers. We provide high-quality raw materials, flexible modification schemes, precise performance testing, and complete solutions from laboratory to industrial scale, helping clients efficiently realize material implementation and functional applications.

1Custom Cellulose Synthesis

- Molecular Weight Customization: Control high, medium, or low molecular weight cellulose according to client needs, meeting different mechanical performance requirements.

- Nanoprocessing: Nanocellulose and nanocrystal processing services for high-performance composites and biomimetic applications.

- Monomer and Polymerization Optimization: Adjust polymerization conditions and chain length to achieve optimal mechanical, thermal, and functional properties.

2Cellulose Functional Modification

- Chemical Modification: Grafting, esterification, etherification, oxidation, etc., to achieve hydrophobicity, hydrophilicity, smart responsiveness, or specific functionalization.

- Composite and Surface Modification: Combine with natural or synthetic polymers and inorganic nanoparticles to enhance mechanical, optical, and responsive properties.

- Functional Design: Meet biomimetic material requirements, achieving drug release, water/humidity responsiveness, antibacterial, conductive, and other functional extensions.

3Comprehensive Analytical Characterization

- Structural Analysis: FTIR, NMR, XRD, and other methods to analyze cellulose chemical structure and crystallinity.

- Morphology Characterization: SEM, TEM, AFM, and related techniques to observe microstructures.

- Mechanical and Thermal Testing: Tensile strength, modulus, thermogravimetric analysis (TGA), etc., ensuring material performance meets application needs.

4Industrialization and Scale-Up Support

- Raw Material Supply: Diverse cellulose sources ensure batch stability and traceability.

- Process Optimization: Assist clients in translating lab-scale processes to pilot and industrial scales.

- Technical Support: Provide process parameters, modification schemes, and application guidance to help clients rapidly implement materials.

Advantages

Why Choose BOC Sciences for Cellulose Solutions?

- Comprehensive Cellulose Product Line: High-purity cellulose, nanocellulose, films, hydrogels, and composites for biomimetic R&D and industrial applications.

- Customized Solutions: Tailored molecular weight, chemical modification, nanoprocessing, and composite design to precisely match material performance and functionality.

- Full Analytical and Characterization Support: Structure, morphology, and performance analysis ensure cellulose materials meet chemical, mechanical, and functional requirements.

- Technical and Industrial Support: Guidance and optimization from laboratory development to pilot and industrial-scale production for rapid material implementation.

- Rapid Customization and Flexible Delivery: Fast provision of custom cellulose products according to client R&D timelines, supporting both small-scale experiments and large-scale industrial delivery.

- High Quality and Traceability Assurance: Strict quality control ensures each batch of cellulose meets purity and performance standards with full traceable records.

Service Process

Complete Service Process for Cellulose Materials

BOC Sciences provides end-to-end cellulose services from requirement communication to product delivery, ensuring efficiency, control, and traceability at every step. Our workflow covers client needs analysis, custom synthesis, functional modification, characterization, application development, and industrialization support, helping clients quickly realize biomimetic material R&D and production.

1Requirement Communication and Project Evaluation

We engage deeply with clients to fully understand project objectives, application scenarios, and material performance needs, assess feasibility, and develop customized R&D plans. This ensures scientific and practical approaches that meet the specific functions and performance requirements of biomimetic materials, providing a clear direction for subsequent development.

2Custom Cellulose Synthesis

We provide custom synthesis of high, medium, and low molecular weight cellulose, as well as nanocellulose, tailored to project requirements. Polymerization conditions, chain length, and purity are strictly controlled to ensure that materials meet design specifications in mechanical properties, thermal stability, and dispersibility, providing a reliable foundation for biomimetic material research and development.

3Functional Modification Design

Based on client application needs, we offer a variety of chemical modification, grafting, composite, and surface functionalization strategies. These enable hydrophobicity, hydrophilicity, smart responsiveness, antibacterial, or conductive functionalities, enhancing material diversity and performance and providing technical assurance for advanced biomimetic material design.

4Analysis and Characterization

Using FTIR, NMR, XRD, SEM, TEM, AFM, and mechanical and thermal testing methods, we comprehensively evaluate the structure, crystallinity, morphology, and functional performance of cellulose materials. This ensures consistent and stable material performance during R&D and application, while providing clients with detailed technical reports and data support.

5Application Development and Validation

We assist clients with processing and performance validation of biomimetic materials such as films, hydrogels, composites, or microspheres/microcapsules. Formulations, pore structures, and mechanical properties are optimized to ensure that materials meet required functionality and reliability in target applications, accelerating the translation from research to practical use.

6Industrialization Support and Delivery

We provide pilot and large-scale production guidance, including process optimization, formulation adjustment, and batch production support. This ensures materials can be produced stably at scale, delivered on schedule, and backed by comprehensive technical consulting and problem-solving solutions, achieving seamless transition from laboratory development to industrial application.

Applications

Typical Applications of Cellulose in Biomimetic Materials

Cellulose is a crucial foundation for biomimetic material development due to its natural renewability, biodegradability, excellent mechanical properties, and ease of modification. Through nanoprocessing, chemical modification, and composite techniques, cellulose can mimic natural tissue structures, functional responses, and environmental adaptability. It is widely applied in artificial tissue scaffolds, biodegradable composites, smart responsive systems, and environmental biomimetic materials, providing innovative solutions for both research and industrial applications.

Artificial Tissue and Organ Scaffolds

Three-dimensional scaffolds can be constructed using cellulose nanofibers, nanocrystals, and hydrogels to precisely replicate the microstructure and mechanical properties of soft or bone tissues. For example, combining nanocellulose with gelatin or chitosan produces porous scaffolds that support cell adhesion, proliferation, and differentiation, aiding tissue engineering and artificial organ development.

Biodegradable Composite Materials

Cellulose can be combined with biodegradable polymers such as PLA (polylactic acid) or PHA (polyhydroxyalkanoates) to produce lightweight, high-strength, degradable packaging or structural materials. By mimicking the natural reinforcement mechanisms of plant fibers, cellulose composites achieve sustainable design while balancing mechanical performance and environmental friendliness.

Smart Responsive Materials

Chemically modified cellulose films or hydrogels can respond to external stimuli such as temperature, pH, or humidity through deformation or functional changes. For example, mimicking leaf curling and stretching behaviors, cellulose-based materials can be used to develop flexible sensors, smart actuators, and environmentally responsive biomimetic systems.

Environmental Biomimetic Materials

Cellulose-based composites demonstrate significant biomimetic functionality in water treatment, air purification, and degradable adsorption materials. For instance, cellulose microspheres can adsorb heavy metals, dyes, or pollutants, mimicking the adsorption capacity of natural algae or plant roots for efficient contaminant capture.

FAQs

Frequently Asked Questions

-

What is cellulose made of?

Cellulose is composed of β-D-glucose molecules linked through β-1,4-glycosidic bonds, representing a typical natural high-molecular-weight polysaccharide. Its repeated glucose units form long-chain polymers capable of hydrogen-bonding networks, giving cellulose unique mechanical properties and chemical stability. Primarily found in plant cell walls, cellulose can also be produced by bacteria, algae, and certain fungi. Its natural renewability and biodegradability make it widely used in biomimetic materials, food, pharmaceuticals, and environmental applications, serving as an important sustainable and bio-based polymer resource.

-

How is cellulose produced?

Natural cellulose is synthesized in plant cell walls via photosynthesis, where plants convert carbon dioxide and water into glucose, which is then enzymatically polymerized into β-1,4-glucose chains. Industrial production of artificial cellulose involves chemical or physical extraction from natural fibers such as cotton, wood, or recycled pulp, followed by alkali treatment, bleaching, and dissolution-spinning to produce regenerated cellulose materials. Bacterial cellulose can also be produced through microbial fermentation, forming highly pure nanostructured cellulose used in medical scaffolds and high-performance composites.

-

Is cellulose a biomaterial?

Cellulose is a natural, bio-based polymer and can be classified as a typical biomaterial. Sourced from plants, algae, and microbes, it is biodegradable, non-toxic, and renewable. Nanoprocessing and chemical modification techniques enable its extensive use in biomedical materials, biomimetic tissue scaffolds, drug carriers, and environmentally degradable materials. Its biocompatibility and functional versatility make cellulose a key focus in modern green biomimetic material and biomaterial research.

-

What are examples of cellulose-based materials?

Cellulose-based materials include various forms such as nanocellulose, cellulose films, hydrogels, composites, and microspheres/microcapsules. Nanocellulose is used in high-strength composites and flexible electronics; films are applied in biodegradable packaging and biomimetic skin; hydrogels serve for controlled drug release and tissue scaffolds; composites combined with inorganic nanoparticles enhance mechanical and functional performance; microspheres/microcapsules are used in environmental adsorption or controlled release systems. These materials highlight cellulose's versatile potential in biomimetic, pharmaceutical, and environmental applications.

-

What is the basic structure of cellulose?

The basic structure of cellulose is a linear polysaccharide formed by β-D-glucose units linked via β-1,4-glycosidic bonds. Interchain hydrogen bonding creates highly ordered crystalline regions and amorphous areas, giving cellulose excellent mechanical strength and stability. Its repeated glucose unit structure allows for nanoprocessing, chemical modification, and composite fabrication, forming the basis for films, fibers, hydrogels, and composites while supporting biomimetic structural design and functional applications.

-

How does cellulose provide structural strength?

Cellulose achieves mechanical reinforcement and structural stability through interchain hydrogen bonds and van der Waals forces, forming highly ordered crystalline regions. Closely packed β-1,4-glucose chains confer high tensile strength and toughness. Additionally, cellulose can form composites with other polymers or nanofiber networks to further enhance support and compressive resistance. This structural characteristic enables cellulose to provide reliable mechanical support in plant cell walls, biomimetic scaffolds, and composite materials.

-

What is the characteristic of cellulose?

Cellulose is naturally renewable, biodegradable, mechanically strong, and chemically stable. It can be chemically modified or processed into composites to achieve hydrophobic/hydrophilic tuning, smart responsiveness, or functionalization. In hydrogels, films, nanofibers, and composites, cellulose demonstrates diverse application potential, balancing environmental friendliness and performance optimization. It is a fundamental material for biomimetic materials, medical scaffolds, biodegradable packaging, and smart functional materials.

Cellulose Hydrogel Preparation

Cellulose Hydrogel Preparation

Cellulose Film Preparation

Cellulose Film Preparation

Cellulose Coating Preparation

Cellulose Coating Preparation

Nanocellulose Preparation

Nanocellulose Preparation

Cellulose Bead/Microsphere Preparation

Cellulose Bead/Microsphere Preparation

Cellulose Scaffold Preparation

Cellulose Scaffold Preparation