Polylactic Acid Scaffold Preparation

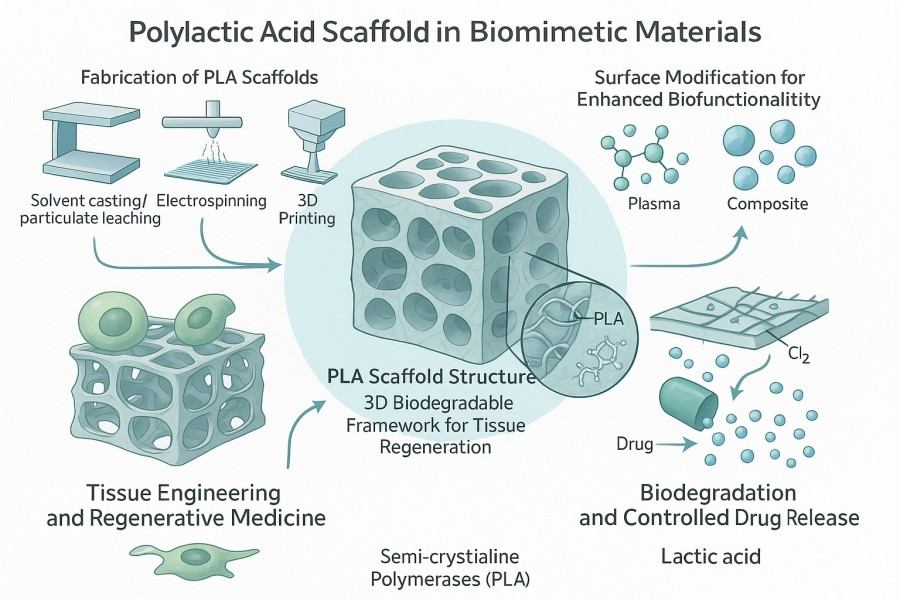

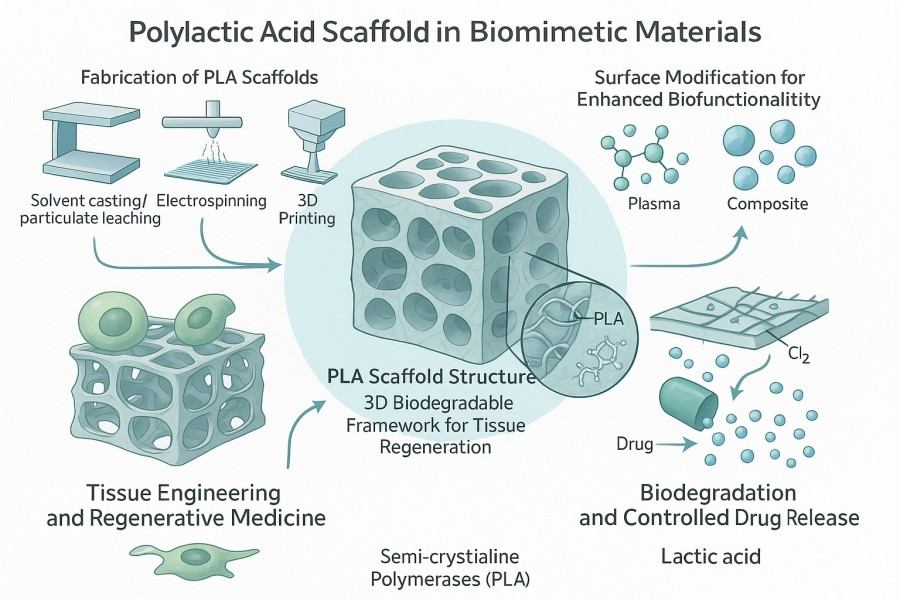

Polylactic acid (PLA) scaffold is a three-dimensional porous material primarily made from polylactic acid and fabricated through various processing and molding techniques. As a typical biodegradable polymer scaffold, PLA scaffolds can gradually degrade in vivo into non-toxic small molecules of lactic acid, which are ultimately metabolized into carbon dioxide and water. By modulating parameters such as molecular structure, porosity, and surface properties, these scaffolds enable precise control over tissue regeneration. With excellent biodegradability, biocompatibility, and tunable mechanical properties, PLA scaffolds have attracted widespread attention in tissue engineering, regenerative medicine, drug delivery, and biomimetic materials. BOC Sciences provides scaffolds in multiple forms (porous, fibrous, film), compositions (pure PLA, copolymers, composites), and functionalized modifications. Our services cover the full process from material selection and structural design to fabrication optimization and performance validation, ensuring each scaffold meets specific requirements in mechanical performance, degradation rate, and biocompatibility, thereby accelerating research and translation in biomimetic materials and tissue engineering.

What We Offer

High-Performance PLA Scaffolds for Regenerative Medicine

BOC Sciences possesses an advanced platform for the design and fabrication of PLA scaffolds, offering a wide range of scaffold types tailored to different biomedical and biomimetic applications. From structural morphology to functional modification, we provide precise R&D support and customizable solutions for every scaffold type.

PLA Porous Scaffolds

- Fabricated via solvent casting, particulate leaching, or freeze-drying to achieve controlled pore size and high connectivity.

- Pore structures and mechanical strength can be optimized according to tissue type (bone, cartilage, skin).

- Degradation rate and pore distribution can be tailored to ensure cell infiltration and nutrient transport.

PLA Fibrous Scaffolds

- Produced by electrospinning to form nano/microscale fiber networks mimicking natural ECM structures.

- Customizable as single-layer, multi-layer, or aligned fibers to meet diverse tissue engineering needs.

- Surface activation or biomolecule modification can enhance cell adhesion and proliferation.

PLA Film Scaffolds

- Available as dense or microporous PLA films suitable for barrier membranes and soft tissue regeneration.

- Thickness, transparency, and flexibility can be adjusted for cell layer culture or biodegradable support membranes.

- Supports surface modification and multilayer film composites for functional interface control.

Pure PLA Scaffolds

- Made from high-purity PLLA, PDLA, or PDLLA, ensuring excellent biocompatibility.

- Suitable for applications requiring high purity and biodegradability in basic research and medical use.

- Offers raw materials with different molecular weights and crystallinity to meet specific mechanical requirements.

PLA Copolymer Scaffolds

- Copolymer systems combining PLA with PCL, PGA, PEG, etc., to adjust flexibility and degradation rate.

- Custom molecular design enables controlled mechanical and biological response properties.

- Optimal copolymer ratios and processing parameters can be selected for target tissue to achieve structural-functional synergy.

PLA Composite Scaffolds

- Inorganic composites: PLA/HA, PLA/β-TCP, PLA/BG for bone repair.

- Organic composites: PLA/collagen, PLA/chitosan for soft tissue regeneration.

- Functional composites: PLA/graphene, PLA/PPy for conductive biomimetic scaffolds.

PLA Functionalized Scaffolds

- Grafting of –COOH, –NH₂, –OH groups enhances hydrophilicity.

- Supports drug, protein, or peptide loading and controlled release system design.

- Offers functionalization strategies including plasma treatment, graft polymerization, and chemical modification.

PLA Biodegradable Scaffolds

- Degradation rates can be precisely controlled through stereochemistry adjustment, copolymer design, or structural optimization.

- Long-term, short-term, and gradient degradation systems are available to meet different regeneration timelines.

- All scaffolds comply with biodegradability standards to ensure in vivo safety and controlled metabolism.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Customizable PLA Scaffold Design for Your Specific Research Needs

BOC Sciences operates a comprehensive polymer synthesis platform and advanced biomaterials processing facilities, capable of customizing PLA scaffolds with varied forms, pore structures, mechanical properties, and degradation rates according to client requirements. Our services cover the following core aspects:

1Material Customization and Modification

- Supply high-purity PLA (PLLA, PDLA, PDLLA) raw materials.

- Perform copolymer modification (e.g., PLA/PCL, PLA/PEG) to tune flexibility and degradation rate.

- Surface grafting and bioactive group modification to enhance cell compatibility and adhesion.

2Structural Design and Process Development

- Design 3D scaffold architecture based on target application (bone, soft tissue, nerve, or skin engineering).

- Optimize porosity, pore size distribution, and connectivity.

- Use modeling and simulation to verify mechanical and fluidic performance.

3Multi-Process Fabrication Capabilities

- Supports solvent casting, hot pressing, electrospinning, 3D printing, gas foaming, freeze-drying, and other fabrication methods.

- Undertakes custom R&D projects, including drug-releasing scaffolds, cell culture scaffolds, and biomimetic composite scaffolds.

- Achieves multiscale control from microfibers to macroscopic structures.

4Performance Evaluation and Quality Control

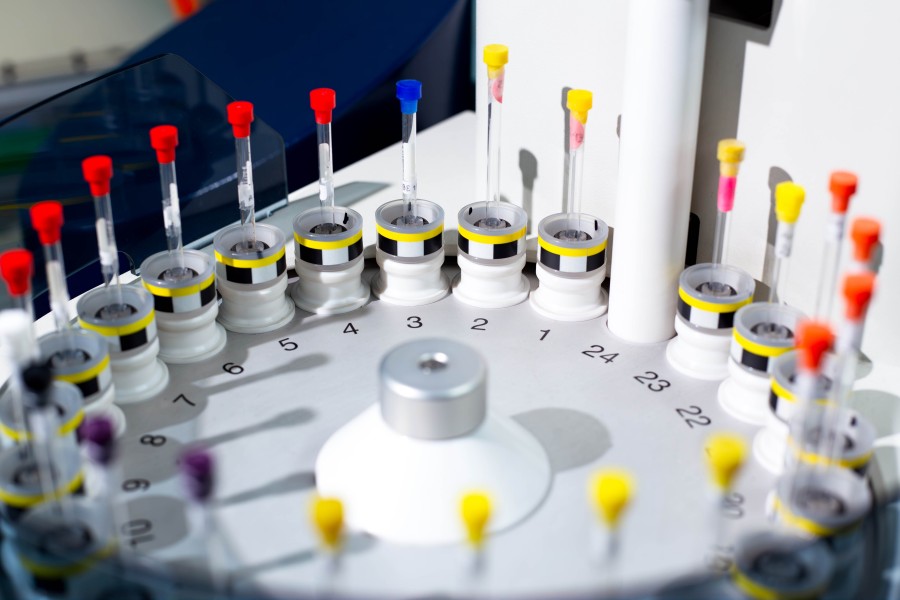

- Morphology and composition analysis using SEM, FTIR, DSC, GPC, etc.

- Provides mechanical testing, pore structure characterization, degradation profiling, and biocompatibility evaluation.

- Strict adherence to industry standards ensures stable quality from lab research to industrial production.

Advantages

Technical Advantages of Our PLA Scaffold Fabrication

- Expertise in Polymer Synthesis and Modification: Advanced polymerization control allows precise tuning of PLA molecular weight, stereoregularity, and crystallinity, providing a molecular foundation for scaffold performance design.

- Diverse Shaping and Microstructure Control Techniques: From solvent casting and electrospinning to 3D printing, scaffolds can be precisely controlled in pore size, thickness, interlayer structure, and surface roughness to meet diverse biological requirements.

- Tunable Degradation and Mechanical Performance: Stereochemical modification, copolymer design, or composite reinforcement enables degradation cycles ranging from weeks to years, ensuring synchronization with tissue regeneration.

- Biomimetic Design Guidance: Integrates biomechanical simulation and materials optimization to design scaffold microenvironment parameters for enhanced cell adhesion, migration, and differentiation.

- Comprehensive Characterization and Validation Platform: Equipped with complete analytical systems to verify chemical, thermal, mechanical, and biocompatibility properties, ensuring reliable experimental data.

- Flexible Project Collaboration Modes: Supports research collaborations, custom production, and joint development programs, responding quickly to different stages of client R&D needs.

Service Process

Workflow for Designing and Preparing PLA Scaffolds

BOC Sciences has established a comprehensive service system for the fabrication and development of PLA scaffolds. Our workflow is designed to ensure that every project, from proof of concept to sample delivery, is precise, efficient, and fully traceable. Whether your focus is tissue engineering, biomimetic structural design, or drug delivery systems, our team provides scientifically rigorous technical pathways and one-on-one project support to help you achieve research and industrialization goals quickly.

1Requirement Analysis and Project Assessment

- Conduct technical discussions with clients to clarify the scaffold's intended function, target tissue type (bone, soft tissue, neural, etc.), and desired degradation timeline.

- Evaluate project feasibility and technical challenges, developing an initial R&D plan and timeline aligned with application requirements to ensure precise project direction.

2Material Selection and Design Planning

- Select suitable PLA types (PLLA, PDLA, PDLLA) or copolymer systems (PLA/PCL, PLA/PEG) based on required mechanical properties and biodegradability.

- Determine pore structure, thickness, fiber alignment, and surface features through simulation and parameter optimization to achieve the optimal balance of mechanical stability and biocompatibility.

3Experimental Fabrication and Sample Development

- Employ multiple fabrication techniques such as solvent casting, electrospinning, 3D printing, gas foaming, and freeze-drying to meet different structural and dimensional requirements.

- Control pore size, porosity, and scaffold morphology according to design parameters, providing experimental samples and preliminary functional validation to support performance optimization.

4Structural and Performance Characterization

- Use SEM, FTIR, DSC, GPC, and other instruments to evaluate scaffold morphology, molecular composition, and thermal properties, ensuring material stability and reliability.

- Perform mechanical testing, degradation profiling, and biocompatibility evaluation to confirm that scaffolds exhibit safe and functional performance in practical applications.

5Optimization and Scale-Up Validation

- Adjust formulation ratios, processing temperatures, and molding parameters based on test results to enhance structural stability and performance consistency.

- Achieve scale-up validation from laboratory to pilot-scale under controlled conditions, ensuring uniform quality across batches.

6Delivery and Technical Support

- Provide detailed experimental data reports, performance test results, and process documentation to facilitate clients' subsequent applications and technical record-keeping.

- Continue offering material improvement advice, scale-up guidance, and product registration support after project delivery, ensuring long-term technical benefits for clients.

Applications

Applications of PLA Scaffolds in Biomedical and Biomimetic Materials

PLA scaffolds have become core support systems in biomimetic material development due to their excellent biocompatibility, controllable degradability, and structural design flexibility. By mimicking the microstructure and functional environment of natural tissues, PLA scaffolds provide cells with support similar to natural extracellular matrix (ECM), enabling multidimensional applications in tissue engineering, drug delivery, and biomimetic functional materials.

Bone Tissue Engineering

PLA scaffolds are commonly used biodegradable materials for bone regeneration. When combined with hydroxyapatite (HA) or β-tricalcium phosphate (β-TCP), they enhance osteoinductivity and mechanical strength while maintaining degradability. The scaffold provides a substrate for osteoblast attachment and is gradually replaced by newly formed bone tissue during degradation.

Cartilage Regeneration

PLA scaffolds can be blended with gelatin, chitosan, or polyglycolic acid (PGA) to create a microenvironment that supports cartilage cell growth. Adjustable pore structures promote chondrocyte differentiation and matrix secretion, suitable for repairing cartilage in joints such as the knee or auricle.

Vascular and Skin Tissue Engineering

PLA nanofiber scaffolds possess surface structures similar to natural collagen, suitable for skin repair or artificial vascular applications. Electrospun PLA/PCL composite scaffolds are flexible and breathable, facilitating keratinocyte and fibroblast adhesion, migration, and tissue reconstruction.

Neural Regeneration

PLA scaffolds can serve as nerve conduits or supporting structures, providing channels for axonal growth. When combined with neurotrophic factors, they promote Schwann cell proliferation and nerve fiber regeneration, enabling functional neural repair.

Drug and Growth Factor Delivery Systems

PLA scaffolds can act as carriers for drugs or growth factors, immobilizing them within or on the scaffold surface for controlled release. In bone repair, scaffolds are often used to release bone morphogenetic proteins (BMPs), promoting osteogenesis and tissue regeneration.

Biomimetic and Composite Structures

PLA scaffolds can be used to construct multilayer composite structures mimicking bone, cartilage, vascular, and other tissues. Through multilayer printing and functionalized design, mechanical and bioactive gradients can be achieved, replicating the zonal functions and hierarchical architecture of natural tissues.

FAQs

Frequently Asked Questions

-

What is a PLA scaffold?

A polylactic acid (PLA) scaffold is a biodegradable, biocompatible polymer framework used in tissue engineering and regenerative medicine. It provides structural support for cell attachment, growth, and tissue regeneration. PLA scaffolds can be fabricated in various forms, including porous structures, fibers, and 3D-printed matrices.

-

How is a PLA scaffold prepared?

PLA scaffolds can be prepared using methods such as solvent casting, electrospinning, 3D printing, and freeze-drying. Each method allows precise control over scaffold porosity, mechanical properties, and degradation rate to match specific biomedical applications.

-

What are the key advantages of PLA scaffolds?

PLA scaffolds offer excellent biocompatibility, controlled biodegradability, and mechanical strength suitable for tissue engineering. They can be customized to release growth factors or drugs and are compatible with various cells for regenerative applications.

-

What applications do PLA scaffolds have in biomedical research?

PLA scaffolds are widely used in bone tissue engineering, cartilage repair, wound healing, and drug delivery. Their biodegradable nature allows gradual replacement by natural tissue, promoting effective regeneration.

-

How can the properties of PLA scaffolds be modified?

Properties of PLA scaffolds can be tuned by adjusting molecular weight, copolymer composition, porosity, and surface functionalization. These modifications optimize mechanical strength, degradation rate, and cell interaction for specific tissue engineering needs.

-

What factors affect the degradation of PLA scaffolds?

Scaffold degradation is influenced by PLA molecular weight, crystallinity, porosity, and environmental conditions such as pH and temperature. Controlling these factors enables predictable degradation rates for controlled tissue regeneration.

-

Why is PLA a suitable material for tissue scaffolds?

PLA is a suitable material for tissue scaffolds due to its excellent biocompatibility, biodegradability, and mechanical properties. Its biodegradation into lactic acid allows gradual replacement by natural tissue without causing toxicity. PLA scaffolds can be easily fabricated into porous structures that support cell attachment, proliferation, and differentiation. Additionally, its tunable mechanical strength, degradation rate, and surface properties make it highly versatile for various tissue engineering applications, including bone, cartilage, and soft tissue regeneration.