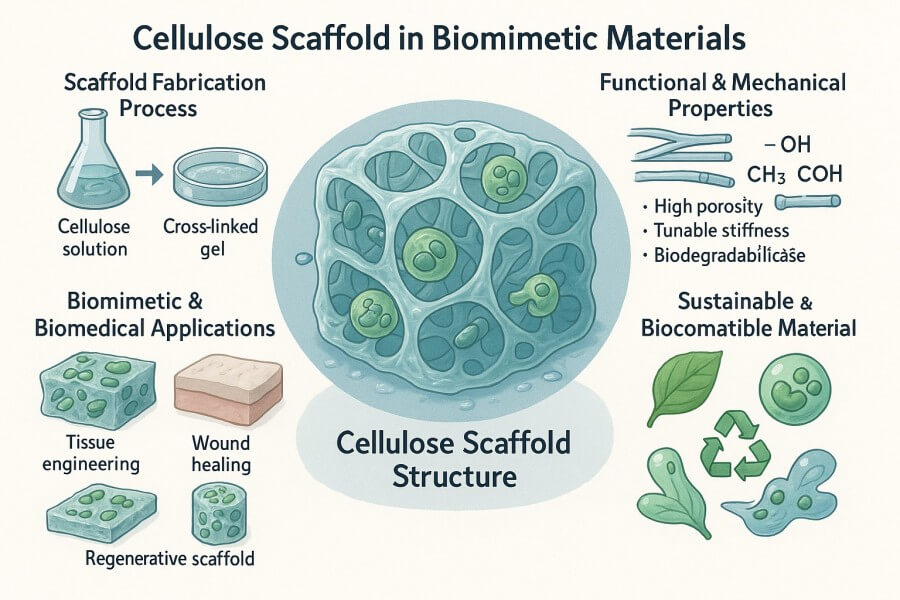

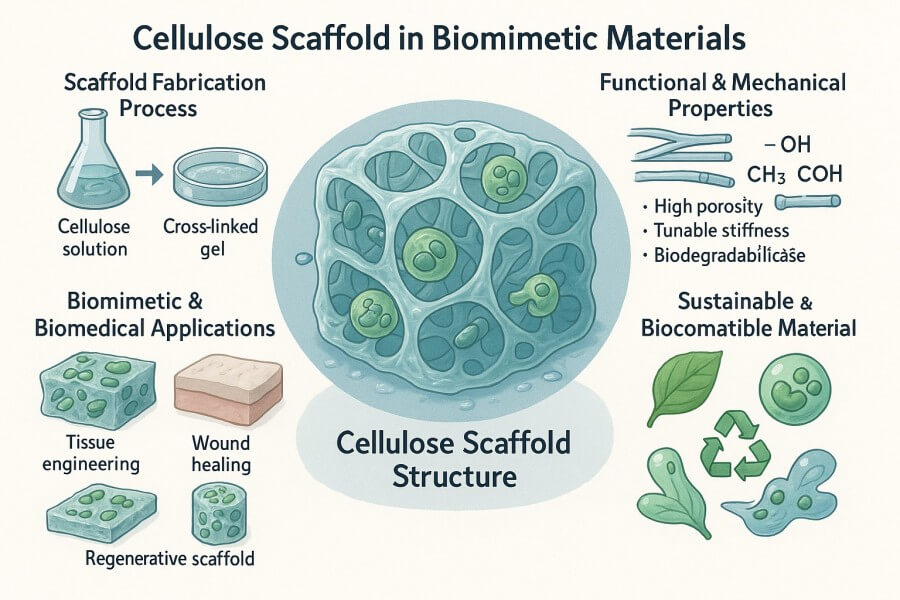

Cellulose Scaffold Preparation

Cellulose scaffolds are three-dimensional porous materials based on natural or modified cellulose, formed through physical or chemical methods. Their primary function is to provide a microenvironment for cell attachment, growth, and differentiation. They are widely used in tissue engineering, regenerative medicine, drug delivery, and biomimetic materials. The unique advantages of cellulose scaffolds lie in their biocompatibility, tunable pore structure, and flexible chemical modification, making them ideal as biological support materials. BOC Sciences is committed to providing high-quality cellulose scaffold fabrication and development services to global clients, focusing on biomimetic materials and tissue engineering. Our services cover the entire workflow—from raw material selection, scaffold design, and fabrication method optimization to performance evaluation—helping research and industrial clients efficiently obtain controllable cellulose scaffolds and providing a solid foundation for cell culture, tissue engineering, and high-performance polymer composite development.

What We Offer

Explore High-Performance Cellulose Scaffold Materials for Research & Industry

BOC Sciences offers a variety of cellulose scaffold materials to meet diverse application needs, including tissue engineering, cell culture, and polymer composite development. We provide customized fabrication, modification, and performance optimization for each type of scaffold, ensuring that the structure, functionality, and applications meet client requirements.

Natural Cellulose Scaffolds

- Available from plant cellulose and bacterial cellulose, offering high purity and stable sourcing.

- Crystallinity, molecular weight, and pore structure can be optimized according to application requirements.

- Custom pre-treatments are supported, such as impurity removal or solubility enhancement.

- Suitable for in vitro cell culture and tissue engineering matrices.

Cellulose Derivative Scaffolds

- Includes derivatives such as carboxymethyl cellulose (CMC) and cellulose acetate.

- Solubility, mechanical strength, and chemical modifiability can be tailored to functional requirements.

- Surface modification and composite treatments are supported to enhance bioactivity or functional performance.

- Suitable for drug delivery, polymer composites, and functional scaffold development.

Cellulose Hydrogel Scaffolds

- Forms a flexible 3D porous network with uniform pores, suitable for soft tissue engineering.

- High water absorption and nutrient permeability support cell proliferation and migration.

- Can load drugs or bioactive molecules for controlled release.

- Supports pore structure regulation and mechanical property optimization for customized needs.

Fibrous Cellulose Scaffolds

- Nanofiber or microfiber networks that mimic the microstructure of natural extracellular matrices.

- High surface area promotes cell attachment, migration, and differentiation.

- Fabricated via electrospinning or template methods with excellent pore interconnectivity.

- Supports surface functionalization to enhance bioactivity or polymer composite performance.

Sponge-like Cellulose Scaffolds

- Porous and soft structure with high porosity, suitable for soft tissue engineering.

- Tunable pore size and interconnectivity optimize cell growth and nutrient transport.

- Supports chemical or physical modification for functional scaffold development.

- Can incorporate drugs or biomolecules for controlled release applications.

Film Cellulose Scaffolds

- Thin-film scaffolds suitable as substrates for cell culture or tissue coverage.

- Pore size and thickness can be customized for different experimental and application needs.

- Supports surface chemical modification to improve cell attachment or drug loading.

- Can serve as intermediate layers or functional films in polymer composite materials.

Composite Cellulose Scaffolds

- Combines cellulose with polymers or inorganic materials to enhance mechanical performance.

- Can achieve conductivity, magnetism, or optical functionality to expand application fields.

- Supports customized functionalization, such as drug carriers or bioactive modifications.

- Suitable for high-performance biomimetic materials, tissue engineering, and polymer composite development.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Customized Cellulose Scaffold Development Services

BOC Sciences offers full-process customized cellulose scaffold development services, covering raw material selection, scaffold fabrication, functional modification, and performance evaluation. We help research and industrial clients obtain high-quality cellulose scaffolds tailored to specific requirements. Our services provide flexible solutions for cell culture, tissue engineering, and polymer composite development.

1Cellulose Raw Material Selection and Optimization

- Offers a variety of natural cellulose raw materials, including plant cellulose, bacterial cellulose, and cellulose derivatives.

- Optimizes raw material purity, crystallinity, and molecular weight distribution based on scaffold applications to ensure stable performance.

- Supports pre-treatment of raw materials, such as impurity removal, solubility adjustment, or uniform gel formation.

- Custom raw material combinations are available to meet specific pore structure or mechanical performance requirements.

2Cellulose Scaffold Fabrication Techniques

- Freeze-drying: Forms highly porous, uniform networks suitable for hydrogel scaffolds.

- Electrospinning: Produces nanofiber networks that mimic natural extracellular matrix microstructures.

- Phase separation and template methods: Precisely control pore size, shape, and connectivity for complex scaffold structures.

- 3D printing and digital fabrication: Enables personalized 3D scaffold design for customized tissue engineering models.

3Surface Functionalization and Chemical Modification

- Hydroxyl modification and grafting chemistries enhance hydrophilicity, hydrophobicity, or bioactivity.

- Surface grafting of active molecules or peptides supports cell attachment, migration, and differentiation.

- Functionalized scaffolds can serve as drug carriers, controlled release systems, or polymer composite development platforms.

- Composite modification is supported by combining cellulose with polymers or nanoparticles to achieve multifunctional properties.

4Analysis and Performance Evaluation

- Pore structure analysis: Assess pore size, porosity, and connectivity via SEM or micro-CT.

- Mechanical testing: Measure compressive modulus, tensile strength, and toughness to ensure application suitability.

- Biocompatibility evaluation: Supports in vitro testing of cell attachment, proliferation, and differentiation.

- Physicochemical property analysis: Includes water retention, swelling behavior, and degree of functionalization to ensure product stability and controllability.

Advantages

Top Reasons to Choose BOC Sciences for Cellulose Scaffold Development

- Professional R&D Team: Our team consists of experienced biochemistry and materials engineering experts, providing full-process technical support from design to fabrication, ensuring cellulose scaffolds meet both research and industrial application requirements.

- Diverse Fabrication Techniques: We master advanced processes including freeze-drying, electrospinning, phase separation, template methods, and 3D printing, enabling the production of cellulose scaffolds with various structures and functionalities.

- Customized Scaffold Design: Based on client application requirements, we offer tailored solutions for pore structure, fiber diameter, mechanical performance, and functionalized surfaces, meeting individualized research and production needs.

- Surface Functionalization and Chemical Modification: We provide hydroxyl modification, grafting chemistry, and composite material development services to achieve bioactivity, drug carrier functionality, or functional polymer composite scaffolds.

- Strict Quality Control: Multiple analytical tests, including pore structure, mechanical properties, biocompatibility, and degree of functionalization, ensure product stability and performance consistency.

- Efficient Customer Support: We offer technical consultation, process optimization, and project progress tracking, ensuring rapid response and professional guidance throughout research and production.

- Full-Process Solutions: From raw material selection, scaffold fabrication, and functional modification to performance evaluation and large-scale production, our end-to-end services support integrated solutions for research and industrial applications.

Service Process

How Our Cellulose Scaffold Services Workflow Works?

To help clients efficiently obtain high-quality and functionally controllable cellulose scaffolds, BOC Sciences provides a systematic, full-process custom service. Our offerings cover project requirement analysis, raw material optimization, scaffold fabrication, functional modification, performance evaluation, and scale-up production, ensuring each step meets research and industrial standards while supporting the development of cellulose hydrogel scaffolds, fibrous cellulose scaffolds, composite cellulose scaffolds, and more.

1Requirement Analysis

We first communicate extensively with clients to fully understand their application direction, target tissue type, scaffold pore structure, and mechanical property requirements. We also evaluate scaffold biocompatibility, degradation rate, and functionalization needs, providing a scientific basis for subsequent design.

2Material Selection and Preliminary Design

Based on the requirement analysis, we select suitable cellulose types for clients, including plant cellulose, bacterial cellulose, or chemically derived cellulose. Preliminary scaffold design is then conducted to determine porosity, mechanical performance, and potential functionalization strategies, providing precise parameters for the fabrication stage.

3Scaffold Fabrication

BOC Sciences employs advanced fabrication techniques including freeze-drying, electrospinning, phase separation, template methods, and 3D printing. We choose the most suitable method according to client requirements to form initial 3D porous scaffolds with precise control over pore size, structure, and mechanical properties.

4Performance Testing and Optimization

After initial scaffold fabrication, systematic performance evaluation is conducted, including porosity, pore size distribution, specific surface area, mechanical properties, and biocompatibility. Fabrication parameters and processes are optimized based on test results to ensure the scaffold achieves optimal structure, function, and biological compatibility.

5Surface Functionalization

To meet specific application requirements, scaffolds can undergo chemical or biological functionalization, such as surface grafting of drugs, proteins, or signaling molecules to achieve controlled release, targeting, or guidance of cell differentiation. Composite material development can also be performed to create intelligent biomimetic scaffold functions.

6Final Validation and Delivery

After functionalization and optimization, comprehensive validation is performed, including mechanical performance, biocompatibility, functional evaluation, and application simulation testing. Customized samples and complete technical reports are provided, ensuring scaffolds are ready for direct use in research experiments or industrial production, with ongoing technical support for subsequent applications.

Applications

Applications of Cellulose Scaffolds in Biomimetic Materials

With excellent biocompatibility, controllable pore structures, and chemical modifiability, cellulose scaffolds have become foundational materials in biomimetic materials and tissue engineering. Through careful design of pore size, mechanical performance, and surface functionality, cellulose scaffolds can mimic natural extracellular matrices, providing an ideal microenvironment for cell attachment, growth, and differentiation. They can also be combined with drug molecules or functional materials to achieve controlled release, targeted delivery, and smart responsive functions, making them widely applicable in tissue regeneration, drug delivery, in vitro cell culture, and the construction of biomimetic tissue models.

Tissue Engineering and Regenerative Medicine

Cellulose scaffolds serve as matrices for cell culture and tissue regeneration:

- Skin Tissue Engineering: Bacterial cellulose scaffolds are used in wound dressings to accelerate healing and reduce scar formation.

- Cartilage and Bone Tissue Engineering: Composite scaffolds (cellulose + hydroxyapatite) provide mechanical support and promote osteogenic differentiation.

- Neural Regeneration: Scaffold pore structures guide nerve cell growth, enabling repair of neural defects.

Drug Delivery Systems

Cellulose scaffolds can act as drug carriers for controlled release or targeted delivery:

- Nanocellulose scaffolds can load small molecule drugs, proteins, or nucleic acids.

- Porous scaffolds can regulate drug release rates via pore control for long-term sustained release.

- Surface modifications enable specific targeting, such as tumor targeting or localized tissue delivery.

Biomimetic Materials and Tissue Models

Cellulose scaffolds are used to construct functional biomimetic materials and tissue models:

- Biomimetic Tissue Models: Adjusting pore size and mechanical properties allows the construction of in vitro models of soft tissue, bone, and neural tissue for drug screening and toxicology studies.

- Organ-on-a-Chip: Scaffold microstructures guide cell growth to create miniaturized functional tissues for drug screening and toxicology research.

- Soft and Smart Materials: When combined with functional materials, scaffolds can respond to temperature, pH, or magnetic fields, enabling the design and application of intelligent biomimetic materials.

Cell Culture and In Vitro Models

Cellulose scaffolds are suitable for in vitro cell culture and biomimetic model construction:

- In Vitro Cell Culture Models: Provide a 3D microenvironment that supports cell alignment, attachment, and functional expression, mimicking in vivo tissue environments.

- High-Throughput Screening: Scaffolds can be fabricated into microarrays and combined with microfluidics to observe cell behavior and evaluate drugs under multiple conditions.

- Functional Composite Models: By combining with optical, magnetic, or conductive materials, scaffolds enable external stimulus response and real-time monitoring in vitro.

FAQs

Frequently Asked Questions

-

What is a cellulose scaffold?

A cellulose scaffold is a three-dimensional structure made from natural or modified cellulose, providing mechanical support and a biocompatible environment for various applications. It serves as a framework in tissue engineering, drug delivery, and polymer composites, facilitating cell attachment, proliferation, and differentiation. Due to its renewable origin, biodegradability, and tunable properties, cellulose scaffolds are widely adopted in biomedical research and material science.

-

How is a cellulose scaffold used for cell culture?

Cellulose scaffolds for cell culture provide a porous, biocompatible matrix that mimics the extracellular environment. They support cell adhesion, growth, and differentiation, allowing researchers to study tissue development and drug responses in vitro. Hydrophilic cellulose and modified variants enhance nutrient diffusion and cell viability, making them ideal for advanced 3D culture systems and regenerative medicine studies.

-

What is a cellulose scaffold for polymer composite?

A cellulose scaffold in polymer composites acts as a reinforcing matrix to improve mechanical strength, thermal stability, and durability of the final material. Its fibrous or porous structure enables strong polymer integration, creating lightweight, sustainable, and high-performance composites. These scaffolds are increasingly used in biodegradable plastics, construction materials, and industrial engineering applications.

-

How are cellulose scaffolds used in tissue engineering?

Cellulose scaffolds in tissue engineering provide a biocompatible, porous structure that promotes cell attachment, proliferation, and differentiation. They serve as templates for regenerating tissues such as bone, cartilage, and skin. By tuning scaffold porosity, mechanical properties, and surface chemistry, researchers can optimize cell growth and tissue formation, offering promising solutions for regenerative medicine and 3D cell-based models.

-

What is a fibrous cellulose scaffold?

A fibrous cellulose scaffold is composed of interwoven cellulose fibers forming a porous, flexible network. Its high surface area and mechanical integrity support cell adhesion and proliferation, making it suitable for biomedical, tissue engineering, and filtration applications. Fibrous scaffolds can be produced via electrospinning, freeze-drying, or other fabrication methods, offering tunable porosity and structural properties.

-

What is a cellulose hydrogel scaffold?

A cellulose hydrogel scaffold is a water-swollen, three-dimensional network of cellulose that provides a hydrated and biocompatible environment. Its porous structure allows efficient nutrient and waste transport, supporting cell growth and tissue formation. These scaffolds are widely applied in regenerative medicine, drug delivery, and soft tissue engineering due to their tunable mechanical strength, biodegradability, and excellent cytocompatibility.