Browse by

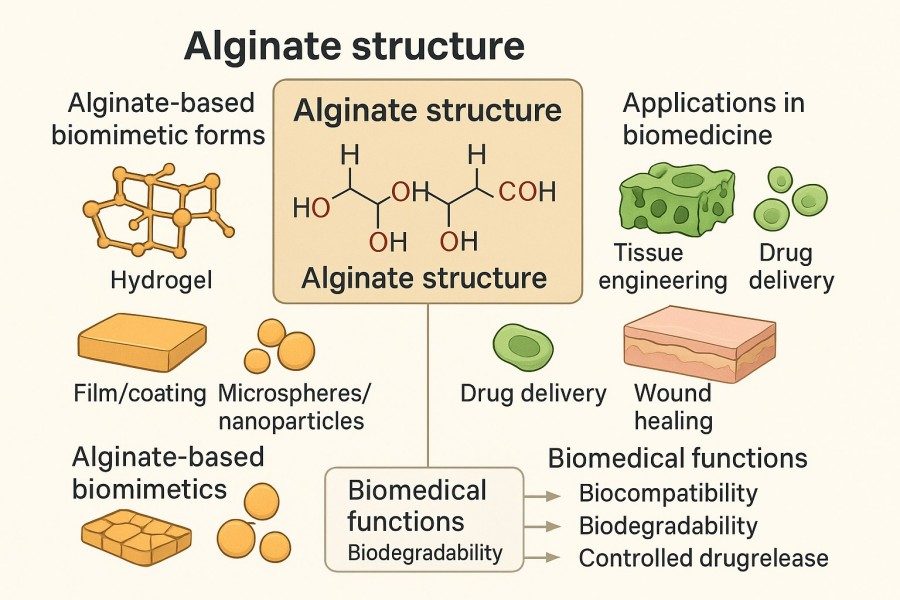

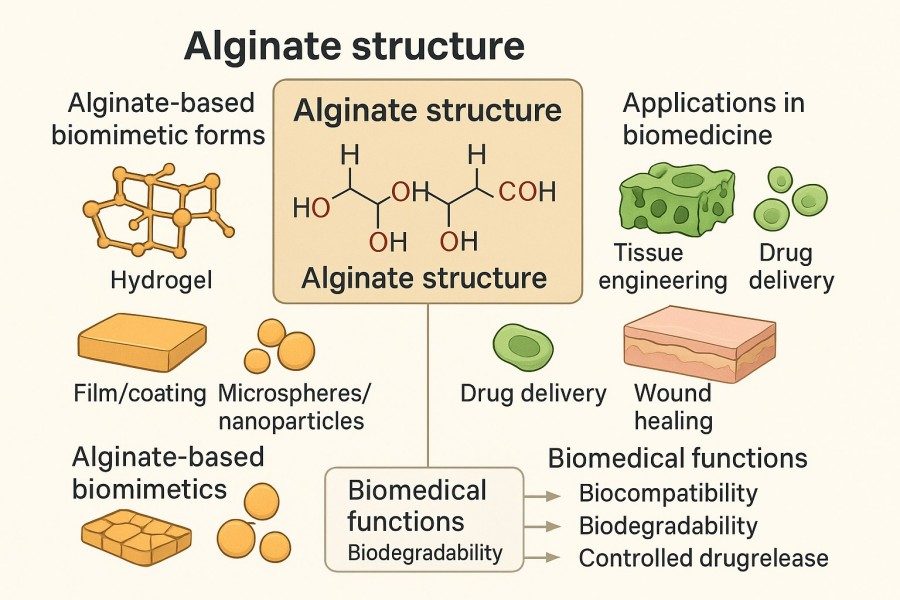

Alginate is a class of natural polysaccharides composed of β-D-mannuronic acid (M) and α-L-guluronic acid (G) arranged alternately in a linear copolymer. Its molecular structure endows alginate with excellent water solubility, controllable viscosity, and strong metal ion crosslinking capability. By adjusting the M/G ratio, molecular weight, and crosslinking method, gel systems with different mechanical properties and degradation rates can be prepared to meet diverse biomimetic material applications. Leveraging extensive experience in polymer chemistry and biomaterials, BOC Sciences provides comprehensive services, from raw material supply, molecular weight and M/G ratio customization, chemical modification, and composite material design, to analytical characterization, functional optimization, and application support. Whether it is aqueous solutions, gels, fibers, scaffolds, films, coatings, or microspheres, we offer highly controllable and traceable custom solutions to help research teams and enterprises efficiently advance biomimetic material development and applications.

What We Offer

Alginate Materials Offered by BOC Sciences

With rich expertise in polymer chemistry and biomaterials, BOC Sciences provides full-range services from raw material supply, custom synthesis, functional modification, to analytical characterization. We can tailor molecular weight, M/G ratio, and chemical functionalities according to customer needs, producing aqueous solutions, gels, films, microspheres, and composite materials. We also provide application support to facilitate research in tissue engineering, drug controlled release, functional coatings, and 3D printing, ensuring controlled material properties and efficient application outcomes.

- Applications: Form 3D network structures through ionic crosslinking (e.g., Ca²⁺, Ba²⁺) or chemical crosslinking.

- Features: Tunable mechanical properties, good biocompatibility, suitable for tissue engineering scaffolds, controlled-release systems, and biomimetic soft tissue materials.

- Examples: Stem cell scaffolds, injectable gels, wound dressings.

- Applications: Prepared by solution casting or drying, used for coatings, packaging, or cell culture surfaces.

- Features: Controllable thickness, high transparency, biocompatible, and chemically modifiable for special functions.

- Examples: Biodegradable packaging films, functional drug carrier films, cell culture substrates.

- Applications: Applied by coating or spraying onto material surfaces to form functional protective or biomimetic layers.

- Features: Uniform, strong adhesion, enhancing substrate biocompatibility, protection, and functionality.

- Examples: Medical device coatings, food packaging coatings, sensor and biomimetic surface modifications.

- Applications: Produced by wet spinning or electrospinning for cell scaffolds, tissue engineering, and functional composite materials.

- Features: Controllable fiber diameter, good mechanical performance, flexible, and biocompatible, supporting cell adhesion and proliferation.

- Examples: Neural tissue engineering fiber scaffolds, functional spun composites, degradable fiber networks.

- Applications: Formed by molding, freeze-drying, or 3D printing into 3D porous scaffolds for tissue engineering and biomimetic material research.

- Features: Adjustable pore structure, controllable scaffold mechanics, excellent cell adhesion and nutrient transport.

- Examples: Bone tissue engineering scaffolds, 3D stem cell culture scaffolds, soft tissue biomimetic scaffolds.

- Applications: Created by droplet or spray techniques, followed by crosslinking to form microspheres or microcapsules.

- Features: Can encapsulate cells, drugs, or nutrients for controlled release and protection.

- Examples: Drug release microspheres, cell carriers, enzyme or bioactive substance encapsulation.

Alginate Composite Materials

- Applications: Blended or combined with gelatin, collagen, chitosan, nanoparticles, etc.

- Features: Enhanced mechanical properties, tunable degradation, or new functions such as conductivity or fluorescent labeling.

- Examples: Composite tissue engineering scaffolds, functional biomimetic materials, smart responsive materials.

- Applications: Formed through ionic gelation or emulsion methods, alginate beads serve as versatile carriers for biomolecules, cells, and drugs in pharmaceutical, food, and biotechnological applications.

- Features: Offer biocompatibility, gentle encapsulation conditions, and adjustable porosity for controlled release and enhanced stability of sensitive actives.

- Examples: Used for drug delivery beads, probiotic encapsulation, enzyme immobilization, and nutrient protection systems.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Customized and Functional Alginate Solutions

In biomimetic material research, standard alginate products may not fully meet specific performance requirements. BOC Sciences leverages its extensive polymer chemistry and biomaterials expertise to provide one-stop services, from custom synthesis and analytical characterization to functional modification, helping research institutions and developers precisely design and optimize alginate materials for controlled properties, diverse functionality, and efficient application.

1Alginate Custom Synthesis Services

- Molecular Weight Control: Achieve specific molecular weight ranges through precise hydrolysis or polymerization, tailoring viscosity and mechanical performance.

- M/G Ratio Optimization: Provide customized M/G ratios based on desired gel hardness, elasticity, and degradation rate.

- Chemical Modification and Functionalization: Conduct amination, esterification, sulfation, etc., to enhance adhesion, crosslinking, or bioactivity.

- Combination Strategies: Blend with other natural or synthetic polymers to create multifunctional composite biomaterials.

2Alginate Modification Services

- Crosslinking Optimization: Support various metal ion or chemical crosslinking to enhance gel mechanics and stability.

- Composite Material Fabrication: Combine with collagen, gelatin, chitosan, etc., to improve biocompatibility and mechanical properties.

- Drug and Cell Carrier Applications: Provide alginate systems for controlled drug release or cell carrier design.

- Biomimetic Material Functionalization: Chemical modifications to achieve antibacterial, conductive, or fluorescent properties, expanding application scenarios.

3Alginate Analysis and Characterization Services

- Molecular Weight and Distribution Analysis: GPC, viscometry, etc.

- Monomer Composition Analysis: NMR, FTIR, HPAEC-PAD to assess M/G ratio.

- Purity and Impurity Testing: Endotoxins, heavy metal residues, ash content.

- Functionalization Assessment: Evaluate modification sites and chemical efficiency.

4Technical Support and Application Guidance

- Experimental Design Guidance: Assist customers in optimizing alginate usage and conditions.

- Process Scale-Up Support: Offer guidance from lab verification to small-scale production.

- Application Case References: Share successful examples in tissue engineering, drug release, 3D printing, and functional coatings.

- Full Consultation Services: Professional advice on raw material selection, modification strategies, and performance optimization.

Advantages

Why Choose BOC Sciences for Alginate Services?

- Molecular Weight Customization: Low, medium, and high molecular weight alginates to meet experimental research or large-scale production needs.

- M/G Ratio Control: Tailor mannuronic (M) and guluronic (G) acid ratios to adjust gel strength and flexibility, enabling functional material design.

- Functionalized Alginate: Support amination, sulfation, acrylation, and other modifications to enhance adhesion, crosslinking, or bioactivity.

- High Purity and Biocompatibility: Strict quality control with low endotoxin and heavy metal residues, suitable for biomedical and food applications.

- Expert R&D Team: Chemists and biomaterials specialists with extensive polymer synthesis and modification experience, providing reliable technical support.

- High Controllability and Customization: Fully customizable from molecular weight and M/G ratio to functional modification, meeting diverse R&D and application requirements.

- Strict Quality Management: Comprehensive quality control ensures purity, performance stability, and batch consistency, supporting research and production.

- One-Stop Service: From raw material supply, custom synthesis, functional modification, analytical characterization to application guidance, fully supporting biomimetic material research and industrialization.

Service Process

Alginate Custom Service Workflow – Efficient, Controllable, and Fully Traceable

In biomimetic material research, every step from concept design to material application requires precise and controllable support. BOC Sciences provides an efficient, transparent, and fully traceable alginate service workflow, covering requirement communication, solution design, small-scale verification, batch production, quality control, and technical support. Through scientific management and professional guidance, we ensure that each batch of alginate materials fully meets customer specifications in performance and functionality, providing reliable support for both research and industrial applications.

1Requirement Communication

We begin with in-depth communication with customers to fully understand the project background, application scenarios, and material performance requirements. Through detailed discussions, we clarify specific demands regarding molecular weight, M/G ratio, modification functionalities, and final application. This lays a solid foundation for subsequent customized services, ensuring that every design step precisely aligns with research objectives.

2Solution Design

Based on customer requirements, our professional team provides feasible solutions, including alginate molecular weight range, M/G ratio adjustment, functional modification strategies, and composite material recommendations. Each solution undergoes scientific analysis and technical evaluation to ensure that material performance meets expectations and to optimize experimental and production processes, enhancing R&D efficiency.

3Small-Scale Verification

Small-scale preparation and performance testing are conducted under laboratory conditions, including gel mechanical properties, solution viscosity, degree of modification, and biocompatibility assessment. This stage allows customers to directly evaluate whether the materials meet design requirements and provides reference data for batch production, reducing development risks and costs.

4Batch Production

Based on verification results, alginate production can be scaled up to small-scale or industrial production, ensuring consistency in molecular weight, M/G ratio, and functionalization across batches. Our production process strictly controls all parameters, achieving efficient, safe, and stable material supply to meet both research and industrial needs.

5Quality Control and Reporting

Each batch of alginate undergoes rigorous quality testing, including molecular weight, M/G ratio, purity, modification efficiency, and impurity content. BOC Sciences provides comprehensive QC reports, ensuring customers have a clear understanding of material performance. This guarantees reproducible experimental results and reliable applications, offering strong support for R&D and production.

6Technical Support and After-Sales

We provide not only materials but also full technical support, including experimental guidance, optimization of modification strategies, and application recommendations. Our expert team assists in resolving issues during use, ensuring maximum material performance and helping customers successfully advance biomimetic material R&D projects for rapid deployment and efficient applications.

Applications

Applications of Alginate in Biomimetic Materials

Alginate is widely recognized in biomimetic material research due to its excellent biocompatibility, tunable mechanical properties, and multifunctional modification potential. BOC Sciences provides high-quality alginate and customized services to help research teams and developers achieve innovative applications in tissue engineering, drug controlled release, biosensing, and functional materials. Below are typical application examples illustrating alginate's broad value in functional biomimetic material design.

Tissue Engineering Scaffolds

By precisely controlling the M/G ratio and molecular weight, research teams can prepare 3D cell scaffolds with controllable mechanical properties. These scaffolds offer good elasticity and porous structures, supporting stem cell adhesion, proliferation, and differentiation, making them ideal carrier materials for tissue engineering and regenerative medicine.

Drug Controlled-Release Systems

Functionalized alginate can be chemically crosslinked to design drug release carriers, enabling controlled and precise drug delivery. Adjusting the molecular weight and crosslinking density of alginate can prolong drug action, improve therapeutic efficacy, reduce side effects, and enhance the performance of drug delivery systems.

Biosensor Materials

Functionalized alginate can combine with fluorophores, metal ions, or nanomaterials to create highly sensitive biosensors. These materials can accurately detect biological signals, such as pH, ion concentrations, or specific molecule levels, providing reliable material foundations for environmental monitoring, medical diagnostics, and bioanalysis.

3D Printing and Biomimetic Structures

Alginate can serve as bio-ink or a composite material base in 3D printing. By precisely controlling viscosity and crosslinking performance, complex three-dimensional structures can be printed. Such scaffolds and materials are suitable for artificial organ models, soft tissue biomimetics, and functional biomimetic material development, helping research teams quickly validate structural designs and application performance.

FAQs

Frequently Asked Questions

-

What is alginate used for?

Alginate is a natural polysaccharide widely used due to its biocompatibility, tunable mechanical properties, and hydrogel-forming ability. It finds applications in biomimetic materials, tissue engineering, drug delivery, food processing, and cosmetics. In tissue engineering, alginate is used for cell scaffolds and 3D culture systems; in drug delivery, it forms controlled-release microspheres or gel carriers; in industry, it acts as an emulsifier, stabilizer, or film material to support functional composites and biomimetic coatings.

-

How is alginate produced?

Alginate is primarily extracted from brown algae. First, the algae are dried and milled, then dissolved in an alkaline extraction solution. The alginate is subsequently precipitated, washed, and dried to obtain a powder. To meet different application needs, further processing can adjust molecular weight, hydrolysis degree, and M/G ratio. Additionally, alginate can be chemically modified or combined with other polymers to produce functional materials for tissue engineering, drug delivery, biomimetic materials, and the food industry, ensuring stable and controllable material performance.

-

How to prepare alginate beads?

Alginate beads are typically prepared using dropwise or spray methods. First, alginate solution is uniformly dissolved and then dropped into a solution containing crosslinking ions such as Ca²⁺ or Ba²⁺. Ionic crosslinking forms a 3D network, rapidly solidifying into beads. The bead size, porosity, and crosslinking density can be adjusted by controlling alginate concentration, dripping rate, and ion concentration. This method is commonly used for drug delivery carriers, cell carriers, and functional biomimetic material preparation.

-

Is alginate a natural biomaterial?

Yes, alginate is a naturally derived biomaterial mainly extracted from brown algae. It consists of polysaccharide chains of mannuronic (M) and guluronic (G) acids, exhibiting excellent biocompatibility, biodegradability, and low immunogenicity. Natural alginate is used in tissue engineering, drug delivery, food, and cosmetics. Its molecular weight, chemical modification, or composite processing can further produce functional biomimetic materials to meet various research and industrial needs.

-

What are alginate composite materials?

Alginate composite materials are functionalized materials formed by blending alginate with other natural or synthetic polymers, nanomaterials, proteins, or bioactive molecules. Composites enhance alginate's mechanical properties, stability, and bioactivity, and can impart additional functions such as conductivity, fluorescence, or antibacterial properties. These materials are widely used in tissue engineering scaffolds, drug delivery carriers, biosensors, and biomimetic coatings, enabling multifunctional, high-performance material design.

-

Are alginate hydrogels biodegradable?

Yes, alginate hydrogels are biodegradable. Their polysaccharide chains can be gradually degraded by enzymes or hydrolysis in vivo or under environmental conditions, producing natural monomers that are low in toxicity and easily absorbed. By controlling molecular weight, crosslinking density, and functional modification, degradation rates can be tuned. Alginate hydrogels are widely applied in tissue engineering scaffolds, drug delivery carriers, and biodegradable biomimetic materials, providing safe and controllable material systems for research and medical applications.

Alginate Hydrogel Preparation

Alginate Hydrogel Preparation

Alginate Bead Preparation

Alginate Bead Preparation

Alginate Film Preparation

Alginate Film Preparation

Alginate Coating Preparation

Alginate Coating Preparation

Alginate Scaffold Preparation

Alginate Scaffold Preparation

Alginate Microsphere Preparation

Alginate Microsphere Preparation

Alginate Fiber Preparation

Alginate Fiber Preparation