Alginate Scaffold Preparation

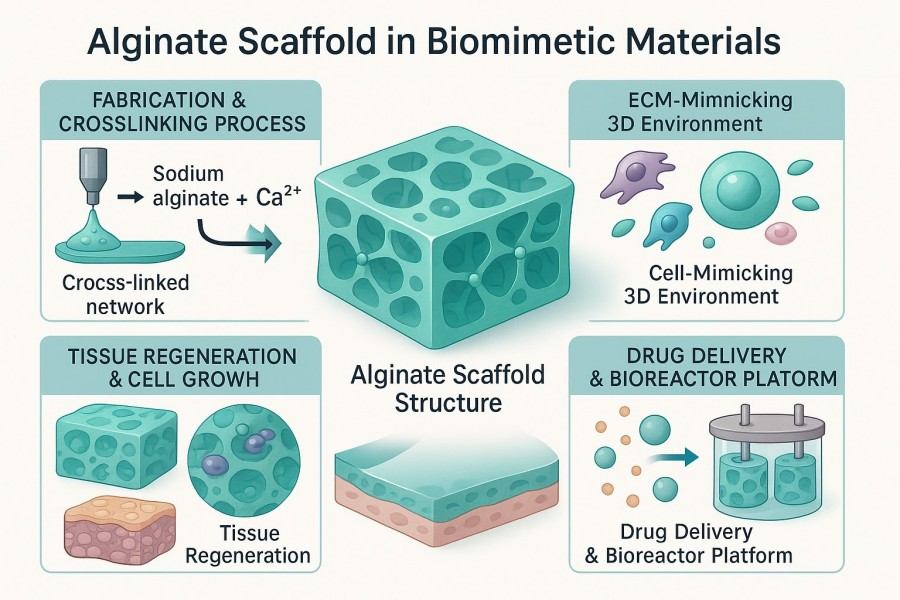

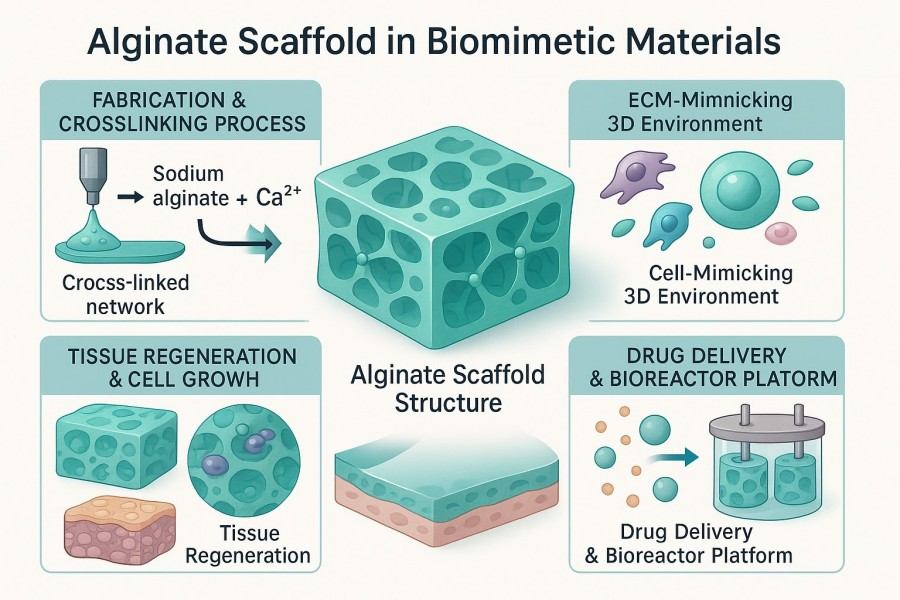

Alginate scaffold refers to a three-dimensional porous network primarily composed of alginate, constructed through techniques such as gelation, freeze-drying, electrospinning, or 3D printing. Its main function is to provide cells with physical support and a biochemical signaling environment, thereby promoting tissue formation and functional recovery. In the research and industrialization of tissue engineering and regenerative medicine, alginate scaffolds have become a key material for constructing biomimetic tissues, 3D cell culture systems, and drug delivery carriers due to their excellent biocompatibility, biodegradability, and tunable flexibility. BOC Sciences, specializing in polymer chemistry and biomaterials engineering, leverages a comprehensive synthesis and analytical platform to provide one-stop services—from custom alginate materials to scaffold fabrication, structural control, and performance optimization—helping clients achieve breakthroughs in tissue regeneration, cell carriers, biosensing, and drug delivery.

What We Offer

Alginate Scaffolds Supported by BOC Sciences

BOC Sciences is committed to offering high-quality, customizable alginate scaffold solutions to meet both research and industrial needs. With extensive materials expertise and process technology, we provide a wide range of alginate scaffolds tailored to various applications—from traditional hydrogels to advanced 3D-printed scaffolds—while supporting functional modifications and composite material development. Whether for fundamental research or industrial-scale production, BOC Sciences delivers comprehensive alginate scaffold solutions, covering material selection, fabrication processes, and functionalization, enabling efficient R&D and product translation.

Alginate Hydrogel Scaffold

- Alginate hydrogels crosslinked with ions such as Ca²⁺, Ba²⁺, and Sr²⁺.

- Supports cell encapsulation, drug delivery, and growth factor carrier design.

- Adjustable porosity and gel mechanics to meet diverse tissue engineering needs.

- Typical systems: Ca²⁺-alginate hydrogel, alginate-gelatin blended hydrogel, Ba²⁺-crosslinked alginate microsphere hydrogel.

Alginate Sponge-like Scaffold

- Prepared via freeze-drying or gas foaming to form highly porous 3D structures.

- Supports cartilage and bone tissue repair, as well as tissue filling applications.

- Amenable to surface functionalization and multi-layer composite modifications.

- Typical systems: alginate sponge, alginate-gelatin composite sponge, alginate-hydroxyapatite composite bone scaffold.

Alginate Fibrous Scaffold

- Micro/nanofiber networks produced by electrospinning or wet-spinning.

- Can be combined with gelatin, silk fibroin, or polycaprolactone (PCL) to enhance mechanical properties and cell adhesion.

- Suitable for skin, nerve guidance, and vascular tissue engineering.

- Typical systems: alginate-gelatin electrospun fibers, alginate-PCL nanofibers, alginate-silk fibroin fiber scaffolds.

Alginate Microsphere/Particle Scaffold

- Spherical or porous particles with controllable diameters.

- Supports controlled release and targeted delivery of drugs, proteins, and cells.

- Surface modification or multi-layer composites can enhance functionality.

- Typical systems: Ca²⁺-crosslinked alginate microspheres, alginate-chitosan microspheres, alginate-PLGA composite particles.

Alginate Film Scaffold

- Single or multi-layer alginate films with adjustable thickness and porosity.

- Can be combined with chitosan or gelatin to form multifunctional membranes.

- Suitable for wound dressings, barrier membranes, and controlled-release membranes.

- Typical systems: alginate films, alginate-chitosan composite films, alginate-gelatin multilayer films.

Alginate 3D-Printed Scaffold

- Supports printing of alginate and composite bioinks.

- Enables personalized structures with precise control over porosity and geometry.

- Compatible with co-printing of living cells for customized tissue engineering applications.

- Typical systems: alginate-GelMA bioink, alginate-collagen composite scaffolds, alginate-PEG 3D-printed scaffolds.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Full-Process Support for Alginate Scaffold Development

BOC Sciences offers end-to-end, customized support from raw material selection to scaffold performance verification, helping clients build high-performance alginate scaffolds for tissue engineering, drug delivery, and biomimetic material research. By integrating expertise in polymer chemistry, materials engineering, and biology, we provide traceable and scalable R&D and production solutions.

1Custom Alginate Materials and Functionalization

- Select high-G, high-M, or composite alginate raw materials to meet mechanical and biological requirements of different tissue scaffolds.

- Achieve precise control of gelation rate and pore structure via molecular weight control, carboxyl substitution degree adjustment, and solution viscosity optimization.

- Introduce active functional groups such as amino, thiol, or methacrylate to expand crosslinking reactions and functionalization pathways.

- Provide material purity and structural characterization services to ensure consistency and reproducibility in scaffold construction.

2Scaffold Fabrication and Structural Design

- Diverse scaffold fabrication platforms including freeze-drying, electrospinning, 3D printing, microfluidic molding, and ionic crosslinking.

- Customize pore size distribution, porosity connectivity, and mechanical properties based on target applications (e.g., bone, cartilage, skin, vascular).

- Design multi-layered, gradient, or composite structures to achieve biomimetic interfaces of multiple tissues.

- Optimize fabrication parameters and structural simulation to balance mechanical stability and biological performance.

3Performance Optimization and Functionalization Strategies

- Material composites: Blend with gelatin, collagen, or chitosan to enhance bioactivity and mechanical strength.

- Biomolecular modification: Introduce RGD peptides, growth factors, or polysaccharides via EDC/NHS chemistry or photopolymerization to improve cell adhesion and differentiation signaling.

- Nano-enhancement: Incorporate hydroxyapatite (HAp), graphene oxide (GO), or silver nanoparticles to enhance osteoconductivity, conductivity, or antimicrobial properties.

- Controlled release design: Achieve sustained release of drugs, proteins, or nucleic acids through multi-layer structures or gradient crosslink density.

4Scale-Up and Bulk Production Support

- Provide process scale-up from lab-scale to pilot and industrial production.

- Optimize crosslinking conditions and freeze-drying procedures to ensure batch-to-batch consistency.

- Offer bulk stability analysis and quality traceability to ensure long-term supply and project sustainability.

- Assist clients in establishing standardized scaffold fabrication workflows and technical documentation to improve experimental efficiency and comparability of results.

Characterization

Characterization and Quality Control of Alginate Scaffolds

To ensure consistency and reliability in scaffold structure, performance, and biological function, BOC Sciences has established a comprehensive characterization and quality control system. By systematically testing physical, chemical, and biological properties, we deliver high-standard, reproducible scaffolds that support smooth execution of research and biomimetic material development. This system covers the full process, from raw material analysis and scaffold formation quality to bioactivity evaluation, providing reliable data support for every batch.

| Test Item | Measured Parameter | Method / Technique |

|---|

| Chemical Composition Analysis | M/G ratio, molecular weight, functional group content | ¹H NMR, FTIR, GPC |

| Scaffold Pore Structure | Pore size distribution, porosity, connectivity | SEM, Micro-CT |

| Mechanical Properties | Compression modulus, tensile strength, elasticity | Universal testing machine |

| Water Absorption & Swelling | Water uptake capacity, volumetric change | Immersion method |

| Degradation Behavior | Degradation rate under physiological conditions | PBS immersion, mass loss measurement |

| Biocompatibility | Cell adhesion, proliferation, and viability | MTT/CCK-8 assay, Live/Dead staining |

| Drug/Protein Release Profile | Controlled release performance and kinetics | UV-Vis spectroscopy, ELISA |

| Surface Chemistry | Surface charge, chemical composition | XPS, contact angle measurement |

| Functionalization Verification | Efficiency of RGD peptide or growth factor immobilization | Fluorescent labeling, immunoassay |

Advantages

Technical and Service Advantages of BOC Sciences

- Full-Process Technical Capability: From raw material design and scaffold fabrication to functional modification, all processes are controllable, efficiently supporting client R&D needs.

- Multi-Process Fabrication Platform: Covering freeze-drying, electrospinning, 3D printing, and microfluidic molding, enabling scaffold development for diverse structures and application scenarios.

- Specialized Performance Optimization: Offers material composites, biomolecular modification, nano-enhancement, and controlled-release design to achieve customized scaffold functions.

- Strong Structural Controllability: Precisely regulates pore size distribution, porosity, and multi-layer structures to enable biomimetic design and multi-tissue interface construction.

- Characterization and Quality Monitoring: Provides comprehensive testing of chemical, mechanical, pore structure, and biological properties to ensure batch-to-batch consistency.

- Customized R&D Support: Develops personalized scaffold solutions according to client requirements, offering experimental design guidance and technical consultation.

- Rapid Response and Technical Support: Professional team delivers timely communication and problem-solving solutions to ensure efficient R&D progress.

Service Process

One-Stop Alginate Scaffold Development Workflow

BOC Sciences offers a one-stop alginate scaffold development workflow, providing end-to-end technical support from concept design to sample delivery, ensuring efficient project execution and reproducibility. Our service process covers all stages—from requirement analysis, material selection, scaffold fabrication, and performance verification to scale-up production—offering a systematic solution for research and industrialization.

1Requirement Communication and Project Evaluation

- Engage in in-depth discussions with clients to clarify target tissue type, application scenario, and scaffold performance specifications.

- Evaluate project feasibility, including structural requirements, functionalization needs, and material selection range.

- Develop a research timeline and key milestones to ensure orderly project progress.

2Solution Design and Material Selection

- Provide selection of various alginate types (high-G, high-M, and composite) and functionalization strategies.

- Design crosslinking strategies, pore structures, and multi-layered or gradient scaffold schemes based on application needs.

- Offer feasibility recommendations for material composites, nano-enhancement, or biomolecular modification.

3Laboratory Fabrication and Parameter Optimization

- Conduct scaffold fabrication under laboratory conditions, optimizing concentrations, crosslinker amounts, and gelation parameters.

- Precisely control porosity, pore size distribution, and mechanical properties to achieve biomimetic structures.

- Validate functional modifications to ensure desired bioactivity and controlled-release performance.

4Characterization and Verification

- Provide comprehensive testing of scaffold physical properties, chemical composition, pore structure, and mechanical performance.

- Conduct biocompatibility assessments, including cell adhesion, proliferation, and functional response tests.

- Deliver complete characterization reports to support subsequent application development and provide technical references.

5Scale-Up Fabrication and Delivery

- Supply laboratory-scale, pilot-scale, or pre-industrial scaffold samples to meet different stages of R&D.

- Optimize fabrication processes to ensure batch-to-batch consistency and material stability.

- Support client customization of scaffold parameters to meet specific application requirements.

6Ongoing Technical Support

- Provide continuous technical consultation and optimization solutions during subsequent R&D or application development.

- Assist clients in establishing standardized scaffold fabrication workflows and operational documentation to improve R&D efficiency.

- Offer professional advice on new application requirements or structural adjustments to ensure long-term scaffold performance stability.

Applications

Applications of Alginate Scaffolds in Various Fields

BOC Sciences' alginate scaffolds and technologies are widely applied across cutting-edge research and industrial fields. With highly controllable structures, excellent biocompatibility, and functionalization capabilities, they provide reliable support for tissue engineering, drug delivery, 3D cell culture, and biomimetic device development.

Tissue Engineering and Regenerative Medicine

- Alginate/hydroxyapatite composite scaffolds mimic bone matrix structures, supporting osteoblast adhesion, proliferation, and mineralization, enhancing bone and cartilage regeneration efficiency.

- Alginate-gelatin scaffolds replicate dermal layer structures, providing 3D support for wound sites and promoting keratinocyte and fibroblast growth.

- Conductive alginate scaffolds support neuron extension and synapse formation, providing electrical signal pathways for neural tissue repair.

- 3D-printed alginate scaffolds allow precise control of vascular network morphology and branching structures for vascular tissue engineering and vascularization studies.

3D Cell Culture and Biological Model Construction

- Alginate scaffolds provide a stable 3D microenvironment for stem cells, tumor cells, and various primary cells, supporting natural spatial growth and differentiation.

- Facilitate organoid and micro-tissue model construction, offering reliable platforms for drug screening, toxicology assessment, and disease mechanism studies.

- Adjustable pore structures and mechanical properties help simulate diverse tissue environments, improving physiological relevance in vitro.

Drug and Growth Factor Delivery

- Multi-layer or gradient crosslink designs enable controlled, sustained release of drugs, proteins, or siRNA molecules.

- Functional modifications enhance targeting and biological stability, improving therapeutic efficiency and reducing side effects.

- Can be integrated with tissue engineering scaffolds to simultaneously promote tissue regeneration and drug therapy.

Biosensing and Flexible Biomimetic Devices

- Alginate/conductive polymer composite scaffolds can be used in flexible biosensors, supporting development of in vivo and wearable monitoring devices.

- High biocompatibility and tunable conductivity make them suitable for smart biomimetic electronics, neural interfaces, and implantable sensor platforms.

- Functional modifications enable detection and response to specific biomolecules, providing technological support for precision medicine and intelligent monitoring.

FAQs

Frequently Asked Questions

-

What is an alginate scaffold?

An alginate scaffold is a three-dimensional scaffold structure primarily made of alginate, featuring high porosity and tunable mechanical properties. It can mimic the cellular microenvironment in vivo, providing support for tissue engineering, drug delivery, and regenerative medicine research. Alginate scaffolds can also be functionalized to meet specific biological application requirements. Due to their excellent biocompatibility and adjustable pore structure, they serve as an important material platform in both research and industrial development.

-

How is alginate scaffold preparation performed?

Alginate scaffold preparation refers to the process of fabricating alginate scaffolds, including raw material selection, solution formulation, crosslinking, and functional modification. Common methods include ionic crosslinking, freeze-drying, electrospinning, and 3D printing. By controlling scaffold pore structure, mechanical properties, and bioactivity, the scaffolds can meet diverse needs in tissue engineering, cell culture, and drug delivery applications.

-

What is an alginate beads hydrogel scaffold?

An alginate beads hydrogel scaffold is a three-dimensional hydrogel scaffold formed from alginate microspheres as the basic unit. Using ionic crosslinking or composite gelation techniques, it creates spherical pore structures whose internal network can carry cells, proteins, or drug molecules, enabling 3D culture, controlled release, and tissue regeneration. Its advantages include uniform porosity, high water content, tunable mechanical properties, and ease of functional modification.

-

What is an alginate chitosan scaffold?

An alginate chitosan scaffold is a three-dimensional scaffold composed of alginate and chitosan. Through ionic crosslinking between cationic chitosan and anionic alginate, the scaffold achieves enhanced mechanical strength, biological stability, and cell adhesion. This composite scaffold is widely used in tissue engineering, stem cell culture, and drug delivery, mimicking the natural extracellular matrix and supporting functional modifications.

-

What is an alginate hydrogel scaffold?

An alginate hydrogel scaffold is a 3D scaffold material made from alginate hydrogels, featuring high porosity and adjustable physicochemical properties. The hydrogel network provides water and nutrient transport channels while supporting cell adhesion, proliferation, and differentiation. Through crosslinking methods and structural design, it can achieve controlled release of drugs or proteins, nano-enhancement, and functional surface modification.

-

What is a gelatin-alginate scaffold?

A gelatin-alginate scaffold is formed by combining alginate and gelatin through physical blending or crosslinking. Gelatin provides excellent bioactivity and cell adhesion sites, while alginate offers mechanical support and controllable pore structures. This composite scaffold can be used for tissue engineering, cell culture, and controlled drug release, offering both mechanical stability and biocompatibility, suitable for various biomimetic applications.

-

What are the applications of alginate scaffolds in tissue engineering?

In tissue engineering, alginate scaffolds serve as support and templates to promote cell adhesion, proliferation, and differentiation, simulating the natural tissue microenvironment. Their tunable porosity and mechanical strength make them suitable for repairing cartilage, skin, vasculature, and other tissues. Combined with growth factors or other functional materials, alginate scaffolds can enable controlled drug release and tissue regeneration. They are also used for in vitro tissue models and bioprinting, advancing regenerative medicine and tissue engineering research.

-

What are the applications of alginate scaffolds in cell culture?

In cell culture, alginate scaffolds primarily provide 3D support and mimic the in vivo microenvironment. Their porous, hydrated 3D network promotes cell adhesion, proliferation, and differentiation while allowing efficient nutrient and waste exchange. Common applications include:

Stem cell culture: Supporting maintenance of pluripotency or directed differentiation in a 3D environment.

Tumor models: Building 3D in vitro tumor models for drug screening and mechanistic studies.

Tissue engineering: Serving as in vitro culture templates for cartilage, vasculature, or skin.

Co-culture systems: Supporting the growth of multiple cell types on the same scaffold to enhance physiological relevance.

Advantages include high biocompatibility, tunable pore structures, and gentle ionic crosslinking, making them ideal for research and regenerative medicine studies.

-

How to choose alginate scaffold manufacturers?

When selecting alginate scaffold manufacturers, consider raw material quality, technical capability, customization services, and ongoing support. BOC Sciences leverages extensive experience in alginate material R&D and multiple fabrication platforms to provide full-process services, from material selection and scaffold fabrication to performance optimization and characterization. Choosing BOC Sciences ensures controllable pore structures, stable mechanical properties, and professional technical support, guaranteeing smooth progress for research and industrial applications.