Polyurethane Coating Preparation

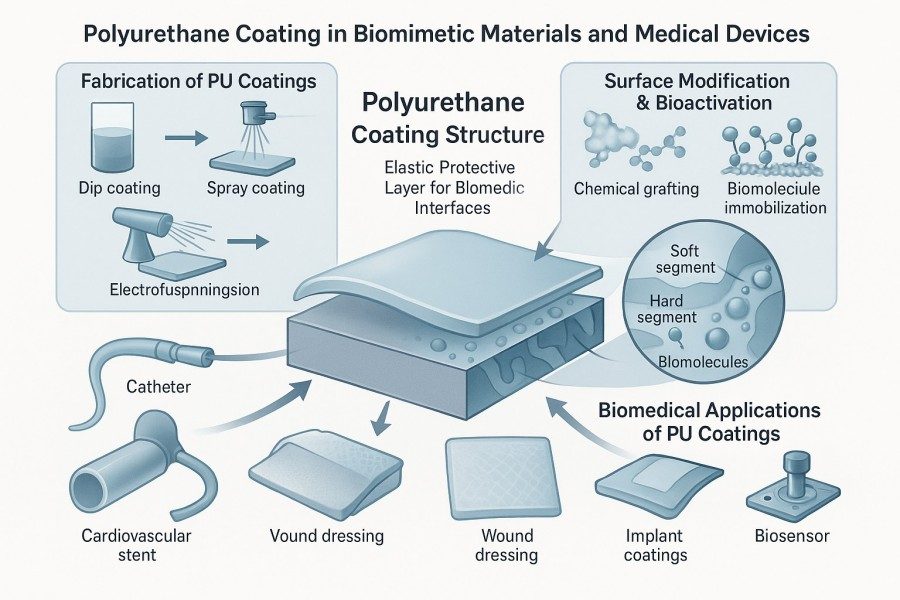

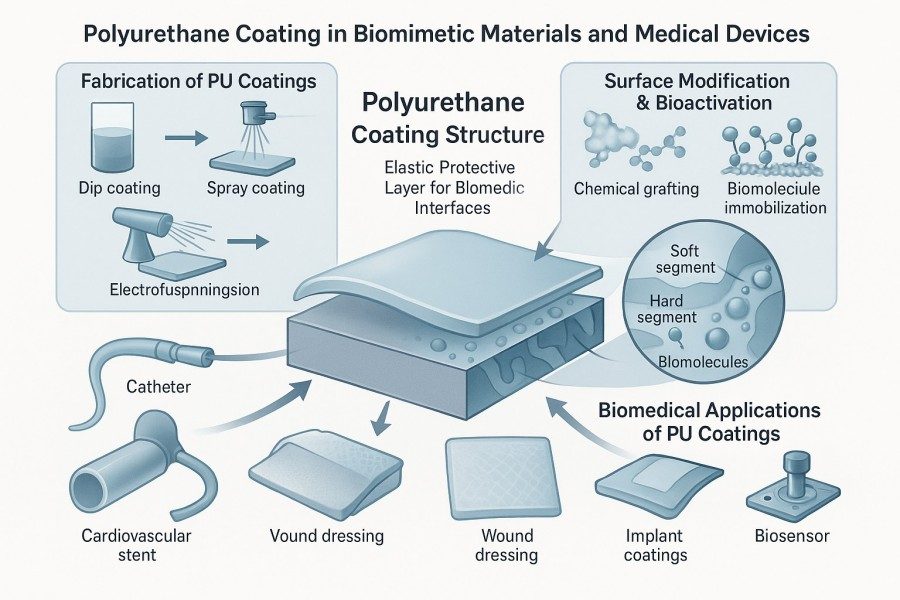

Polyurethane (PU) coatings are a class of polymer coating systems primarily formed from polyurethane resins. They are high molecular weight materials produced via addition polymerization of isocyanates with hydroxyl-containing compounds, such as polyols or polyamines. With excellent mechanical strength, flexibility, wear resistance, biocompatibility, and chemical stability, polyurethane coatings have become a key component of functional polymer materials. Compared with traditional epoxy or acrylic coatings, PU coatings offer the advantage of highly tunable structures. By adjusting the ratio of soft and hard segments, crosslink density, hydrophilicity/hydrophobicity, or introducing specific functional groups, their performance can be optimized across a wide range to meet diverse application needs. BOC Sciences provides end-to-end services for the preparation, development, and manufacturing of polyurethane coatings for global clients, covering the full technical chain from molecular design, formulation optimization, surface modification, performance evaluation, to industrial-scale production. We are committed to helping clients in the medical and materials fields achieve high-performance, biocompatible, and functionally intelligent products.

What We Offer

Explore Tailored Polyurethane Coatings for Your Industrial Needs

BOC Sciences possesses an advanced platform for polyurethane material synthesis and modification, capable of customizing multiple types of coatings to meet different application requirements. Our R&D and preparation services cover the entire process from molecular design and raw material selection to film formation optimization and performance evaluation, ensuring optimal performance of coatings in medical devices, biomimetic structures, and smart materials.

Polyether-based PU Coating

- Offers diverse polyether polyol system designs, providing excellent flexibility and hydrolytic stability, suitable for medical device surfaces operating in long-term wet environments.

- Supports molecular weight and crosslink density regulation to achieve coatings with varying elasticity and mechanical strength.

- Available in wear-resistant, crack-resistant, and conductive modified versions for sensor-enabled biomaterials or flexible biomimetic devices.

Polyester-based PU Coating

- Utilizes polyester polyol structures to enhance chemical resistance and mechanical strength, ideal for high-durability medical components.

- Supports degradable and non-degradable systems to meet tissue engineering and absorbable device requirements.

- Can undergo copolymerization or composite modification to achieve a balance of adhesion and biocompatibility.

Polycarbonate-based PU Coating

- Uses high-purity polycarbonate polyols to provide excellent antioxidation and biological stability, suitable for long-term implantable devices.

- High transparency and superior mechanical properties can be achieved through soft/hard segment ratio design.

- Offers radiation-resistant and low-toxicity versions compatible with medical sterilization processes.

Bioinert Polyurethane Coating

- Features highly crosslinked and smooth surface designs to reduce cell and protein adhesion, preventing immune reactions at biological interfaces.

- Offers low-adhesion/low-thrombogenic surface solutions for blood-contacting devices, such as catheters and artificial vessels.

- Supports multilayer coating designs to provide dual protection via physical barriers and chemical inertness.

Bioactive Polyurethane Coating

- Capable of loading biomolecules (e.g., peptides, saccharides, proteins) or biomimetic groups to promote cell adhesion, proliferation, and tissue integration.

- Provides controllable functionalization technologies for long-term stable release of surface bio-signals.

- Supports functional design services for bone repair, vascular regeneration, and soft tissue integration.

Antimicrobial & Antifouling Polyurethane Coating

- Incorporates antibacterial components such as silver ions, quaternary ammonium salts, or graphene oxide to provide long-lasting antimicrobial effects.

- Offers hydrophilicity/hydrophobicity tuning to reduce extracellular matrix and protein adhesion, preventing biofouling.

- Supports surface modification services for antimicrobial and antifouling interfaces on medical tubing, artificial joints, and implants.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Polyurethane Coating Development & Preparation Services

In medical devices, biomimetic materials, and smart functional materials, the performance of polyurethane coatings directly determines product safety and functionality. BOC Sciences provides full technical support from molecular design, formulation optimization, surface functionalization, to coating preparation and process scale-up, ensuring clients obtain high-performance, customizable polyurethane coating solutions.

1Molecular & Material Design

- Design polyether-, polyester-, or polycarbonate-based PU systems according to client requirements, balancing flexibility, mechanical strength, and biocompatibility.

- Adjust soft/hard segment ratios, crosslink density, and molecular weight to optimize mechanical and chemical properties for specific applications.

- Offer functional monomer grafting solutions, such as PEGylation, antibacterial groups, or drug carrier integration, to meet diverse functional requirements.

- Support degradable and bio-based PU designs to improve environmental sustainability and implant material compatibility.

2Coating Formulation Development

- Optimize solvent-based, water-based, and solvent-free coating systems to ensure uniform film formation and adhesion.

- Provide multifunctional composite filler solutions, including nano-oxides, silver ions, conductive or fluorescent fillers, for enhanced functionality.

- Control solution viscosity, surface tension, and curing speed to meet requirements for spraying, dipping, spin-coating, and other processes.

- Customize chemical-resistant, wear-resistant, and antifouling coatings based on application environments (blood contact, wet conditions, or high abrasion).

3Surface Functionalization & Modification

- Offer chemical grafting, plasma treatment, and coating surface functionalization to provide anticoagulant, antibacterial, self-cleaning, or smart response properties.

- Support multilayer functional coating designs to achieve cumulative effects of protection, functionality, and signal responsiveness.

- Enable cell-recognition or tissue integration surface modifications for tissue engineering and bioactive coatings.

- Provide surface roughness, wettability, and interfacial energy regulation solutions to meet specific application needs.

4Coating Preparation & Process Optimization

- Support coating preparation from lab-scale samples to pilot and industrial-scale production, including spraying, dipping, spin-coating, and layer-by-layer assembly.

- Optimize film formation conditions, curing temperature, and crosslinking reaction rates to ensure uniform thickness, strong adhesion, and stable performance.

- Provide coating performance testing and quality control services, including mechanical testing, wear resistance, surface morphology, and biocompatibility evaluation.

- Customize process solutions according to client product geometry and usage environment to enable rapid transition from R&D to mass production.

Characterization

Polyurethane Coating Performance Characterization & Analysis Services

Through precision instrumentation, systematic experimental methods, and customized analytical solutions, we comprehensively evaluate the physical, chemical, and biological properties of coatings, providing scientific support and quality assurance for R&D and industrial applications. Our services cover structural analysis, surface performance assessment, biocompatibility, and environmental response testing, with tailored reports and technical recommendations to meet diverse application requirements.

| Test Category | Test Item | Service Capabilities & Description |

|---|

| Mechanical Properties | Tensile Strength/Elastic Modulus | Measures coating performance under stress to evaluate flexibility and durability. |

| Abrasion/Scratch Resistance | Evaluates the coating's surface durability under friction and wear conditions. |

| Compression & Bending Performance | Assesses stability and elastic recovery of the coating under complex deformation. |

| Surface & Microstructure | Surface Morphology (SEM/AFM) | Analyzes microstructure, roughness, and pore distribution of the coating surface. |

| Contact Angle Measurement | Determines surface hydrophilicity or hydrophobicity for antifouling and wettability optimization. |

| Adhesion/Bond Strength | Tests coating adhesion to substrates to ensure long-term stability. |

| Chemical Structure & Composition | FTIR/NMR Analysis | Confirms chemical structure and functional groups of the coating for formula verification. |

| XPS/EDS Analysis | Analyzes surface elemental composition and chemical states for functionalization or doping verification. |

| Thermal Analysis (TGA/DSC) | Measures thermal stability, glass transition temperature, and thermodynamic properties. |

| Biological & Environmental Performance | Cell Compatibility Testing | Evaluates coating effects on cell adhesion, proliferation, and cytotoxicity. |

| Blood Compatibility | Tests anticoagulant performance and blood contact response for vascular device coatings. |

| Antimicrobial/Antifouling Performance | Assesses surface antibacterial activity and protein adsorption behavior, supporting anti-infection design. |

| Degradation & Release Performance | Evaluates hydrolysis, solubility, and drug release for degradable or drug-eluting coatings. |

Advantages

Technical Advantages of Our Polyurethane Coatings

- Customized Molecular Design Capability: By precisely controlling the structure of isocyanates and polyols, we achieve comprehensive optimization of coating flexibility, adhesion, and wear resistance.

- Multi-System Coating Customization: Supports development of polyether-, polyester-, polycaprolactone-based, and multiphase composite systems, enabling multidimensional performance tuning.

- Cross-Disciplinary Expert Team Support: Polymer chemists, biomaterials scientists, and medical engineering experts collaborate to ensure coatings meet the functional requirements of medical devices and biomimetic applications.

- Multifunctional Surface Modification Platform: Combines chemical grafting, plasma treatment, and nanocomposite technologies to realize multifunctions such as antifouling, antibacterial, and self-healing.

- Comprehensive Quality and Performance Testing System: Relies on internationally standardized testing equipment to validate both biocompatibility and physical performance of coatings.

- Green and Sustainable Material Systems: Prioritizes waterborne or bio-based polyurethanes to minimize solvent emissions and environmental impact, meeting modern medical and environmental standards.

- Rapid Response and Collaborative Development: Provides one-stop custom services from concept verification to mass manufacturing, accelerating the realization of clients' innovative solutions.

Service Process

Stepwise Polyurethane Coating Service Process

BOC Sciences offers full-process services from concept design to industrial production, ensuring each stage meets client functional and quality requirements. Our workflow integrates technical R&D, performance validation, and process optimization for rapid, efficient, and controllable product development.

1Requirement Analysis & Solution Design

- Communicate closely with clients to define coating functionality, mechanical performance, degradation cycle, and biocompatibility requirements.

- Assess product environment and usage conditions to provide a scientific basis for coating system selection.

- Provide preliminary molecular design and functional proposals, establishing a feasible technical route.

2Polyurethane System Design & Synthesis

- Design polyether-, polyester-, or polycarbonate-based PU structures according to application requirements, adjusting soft/hard segment ratios and crosslink density.

- Support functional monomer grafting, such as antibacterial, PEGylation, or drug carrier integration.

- Offer degradable or bio-based system options to meet environmental and absorbable material needs.

3Coating Formulation Development

- Optimize solvent-based, waterborne, and solvent-free formulations to ensure uniform film formation and adhesion.

- Adjust viscosity, surface tension, and curing conditions to accommodate different coating processes (spraying, spin-coating, dipping).

- Incorporate functional fillers to achieve antibacterial, conductive, fluorescent, or controlled-release properties.

4Surface Functionalization & Modification

- Provide chemical grafting, plasma treatment, and surface functionalization solutions to achieve anticoagulant, antibacterial, self-cleaning, and smart response functionalities.

- Enable multilayer functional stacking designs to combine protection and bioactivity.

- Support cell-recognition or tissue-integration surface modifications for tissue engineering and bioactive coatings.

5Coating Preparation & Process Optimization

- Provide laboratory sample preparation, pilot testing, and industrial-scale production solutions.

- Optimize film formation conditions, curing temperature, and reaction rates to ensure uniform thickness, strong adhesion, and stable performance.

- Offer customized processes based on product geometry and application environment, enabling rapid transition from R&D to mass production.

6Performance Validation & Technical Support

- Conduct comprehensive testing of mechanical properties, surface morphology, chemical structure, and biocompatibility.

- Adjust coating formulations and processes based on test results to ensure final products meet application requirements.

- Provide technical reports and application recommendations to support regulatory compliance and industrial deployment.

Applications

Top Applications of Polyurethane Coatings in Modern Materials

With excellent biocompatibility, chemical resistance, and tunable flexibility, polyurethane coatings are widely applied for functional treatment and protection of medical device surfaces and biomimetic materials. Key applications include:

Medical Catheter & Vascular Stent Coatings

PU coatings improve blood compatibility of vascular stents, urinary catheters, venous catheters, and dialysis tubing, reducing platelet adhesion and thrombosis. Incorporation of heparin, PEG, or fluorinated segments further enhances anticoagulant and antifouling properties.

Protective Layers for Implantable Medical Devices

Applied on pacemakers, artificial joints, dental implants, and other devices, PU coatings isolate against body fluid corrosion, prevent metal ion leaching, and regulate surface properties for tissue compatibility and controlled cell adhesion.

Drug-Controlled Release Carriers & Implant Coatings

PU coatings act as controlled-release membranes, enabling sustained or environment-responsive drug delivery. By tuning coating porosity and hydrophilicity/hydrophobicity, the release rates of antibiotics or anticancer drugs can be precisely controlled for infection-resistant implants or localized chemotherapy systems.

Biosensors & Wearable Medical Devices

Flexible PU coatings in wearable sensors and implantable electronics provide waterproofing, abrasion resistance, and biological isolation while maintaining signal conductivity and skin comfort. Conductive or ion-conductive modifications enable sensing functionalities.

Surface Modification for Tissue Engineering Scaffolds

PU coatings on porous scaffolds regulate surface roughness and wettability to control cell adhesion, proliferation, and differentiation, creating ideal microenvironments for bone, cartilage, skin, and neural tissue engineering.

Biomimetic Wetting & Antifouling Surfaces

By incorporating fluorinated segments or micro/nanocomposite structures, PU coatings mimic the superhydrophobic properties of lotus leaves, achieving self-cleaning, anti-protein adsorption, and anti-bacterial adhesion. Such coatings are widely used in artificial skin, medical protective films, and implantable devices.

FAQs

Frequently Asked Questions

-

What is a polyurethane coating?

A polyurethane (PU) coating is a polymer layer applied to medical devices and biomaterials to improve surface performance. It provides biocompatibility, flexibility, and chemical resistance, protecting implants, catheters, and wound dressings while maintaining material integrity. PU coatings can also be tailored for anti-bacterial or controlled-release functionalities.

-

What is polyurethane coating used for?

In medical and biomaterial applications, PU coatings protect devices from wear, corrosion, and biological reactions. They are applied to catheters, stents, wound dressings, and implants. PU coatings also improve blood compatibility, reduce friction, and enable functional surfaces for drug delivery or tissue engineering scaffolds.

-

Is PU coating toxic?

Properly cured PU coatings used in medical devices are generally biocompatible and non-toxic. During manufacturing, uncured PU may release isocyanates, requiring controlled environments and protective measures. Fully processed coatings are safe for use in implants, catheters, and other biomaterials.

-

Is the PU coating biodegradable?

Most standard PU coatings are not biodegradable, ensuring long-term durability in medical devices and implants. Bio-based or modified PU coatings can be engineered to degrade in the body or under specific conditions, allowing applications in resorbable implants or controlled drug delivery systems.

-

What are the medical uses of polyurethane?

Polyurethane is used extensively in medical devices and biomaterials due to its flexibility, biocompatibility, and durability. Applications include catheters, vascular grafts, wound dressings, implantable devices, and drug delivery systems. PU can also be formulated for tissue engineering scaffolds, antibacterial surfaces, or controlled release of therapeutics.