Poly(lactic-co-glycolic acid) (PLGA) Services

Browse by

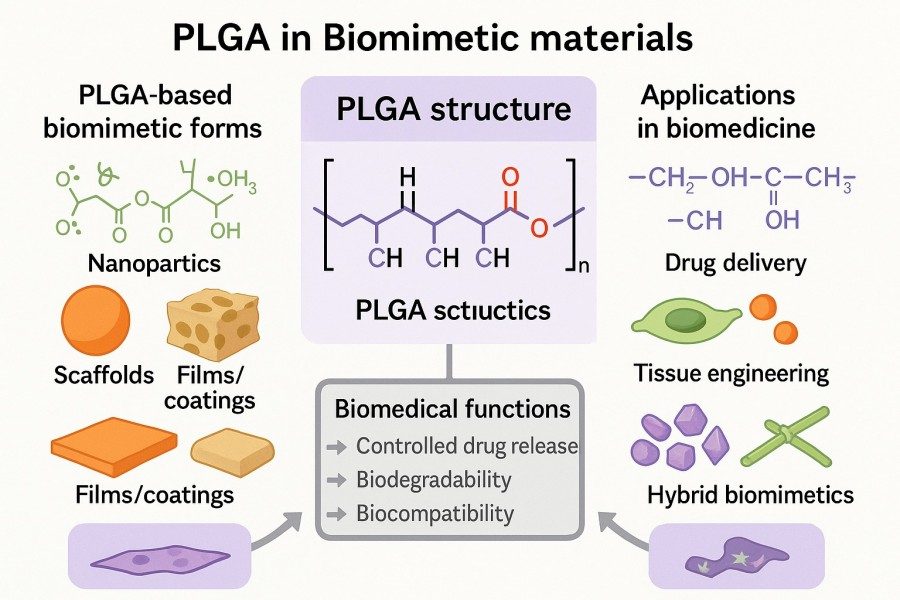

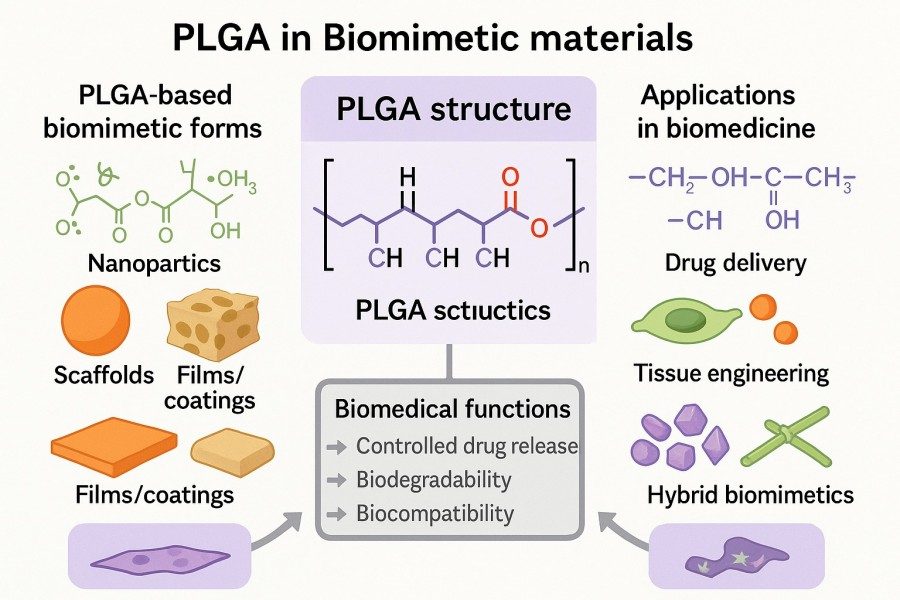

Polylactic-co-glycolic acid (PLGA) is a synthetic biodegradable polymer copolymerized from lactic acid (LA) and glycolic acid (GA). It features excellent biocompatibility, controllable degradation rates, and versatile processing adaptability, making it widely used in biomimetic materials, tissue engineering, drug delivery, and regenerative medicine. With the rapid development of biomimetic material research and industrial applications, the demand for PLGA as a core material is increasing. BOC Sciences is dedicated to providing professional PLGA services to global research institutions and industrial clients, covering customized polymer synthesis, analysis and characterization, modification design, and the development of materials in various forms. Leveraging advanced production platforms and comprehensive quality control systems, we deliver high-quality PLGA products and solutions that meet international standards, supporting researchers, developers, and manufacturers in accelerating innovation and translation.

What We Offer

PLGA Materials Supported by BOC Sciences

With mature polymer preparation processes and advanced processing technologies, BOC Sciences offers diversified PLGA product forms, ranging from nanostructures, microparticles, porous scaffolds, to composite materials, ensuring ideal material support in drug delivery, tissue engineering, and medical devices. We provide both standardized products and customized solutions according to specific requirements.

- Supports the preparation of PLGA nanoparticles and microspheres with controllable particle size for drug delivery and sustained-release carriers.

- Provides surface modification and functionalization strategies (ligand modification, composite drug carriers) to enhance targeting, controlled release, and biocompatibility.

- Widely applied in anticancer drug delivery, vaccine development, and gene delivery systems.

PLGA Fibers

- Supports the fabrication of PLGA nanofiber membranes with adjustable diameter and porosity.

- Offers composite modification strategies (with collagen, gelatin, or drugs) to improve cell adhesion, mechanical properties, and biomimetic features.

- Applied in tissue engineering scaffolds, wound dressings, and soft tissue repair.

- Supports the preparation of PLGA porous scaffolds with controllable pore size and structure.

- Provides composite and modification options (with inorganic materials or natural polymers) to enhance mechanical strength, bioactivity, and degradation rate.

- Applied in bone tissue engineering, cartilage repair, and nerve regeneration.

- Supports the fabrication of PLGA hydrogel composites with tunable mechanical properties and water absorption.

- Offers composite modification strategies (with hyaluronic acid, gelatin, or other natural materials) to improve flexibility, biomimetic characteristics, and drug release performance.

- Applied in skin repair, chronic wound treatment, and soft tissue engineering.

- Supports the production of highly transparent PLGA films or membranes with controllable thickness.

- Provides modification strategies (crosslinking, grafting, or composite formation) to enhance mechanical strength, water resistance, and biocompatibility.

- Applied in biomimetic skin repair, biodegradable packaging, and film layers for tissue engineering scaffolds.

- Supports uniform PLGA coating on metal, ceramic, or polymer substrates.

- Offers functionalization strategies (drug loading, antibacterial modification, or bioactive molecule incorporation) to improve targeting, controlled release, and surface bio-performance.

- Applied in degradable medical device surfaces, drug-controlled release devices, and scaffold surface coatings.

Surface-Modified PLGA Materials

- Supports surface functionalization of PLGA (plasma treatment, graft modification, or nanocoatings).

- Enhances cell adhesion, antibacterial properties, and targeting ability.

- Applied in tissue engineering scaffolds, biodegradable medical devices, and targeted drug carriers.

PLGA Composite Systems

- Supports the preparation of PLGA composite materials with inorganic nanoparticles or natural polymers.

- Provides material ratio optimization and functionalization strategies to improve mechanical properties, biocompatibility, and biomimetic characteristics.

- Applied in high-performance biomimetic scaffolds, medical implants, and smart drug delivery systems.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Tailored PLGA Services for Biomimetic and Regenerative Applications

With extensive experience in PLGA research and application services, BOC Sciences offers one-stop solutions from custom synthesis to performance optimization. We provide not only PLGA raw materials but also comprehensive technical support and solutions. Whether precise control of polymer molecular weight and composition or selection and modification of PLGA processing forms, we offer professional support tailored to your specific research goals, facilitating the translation of scientific findings into industrial applications.

1Custom PLGA Synthesis & Scale-Up Production

- Precisely control the lactic acid/glycolic acid ratio according to client needs to achieve tunable degradation cycles.

- Flexibly adjust molecular weight distribution (low, medium, high) to meet diverse requirements in drug delivery and tissue engineering.

- Provide scalable support from laboratory trials to kilogram-scale production, ensuring seamless transition from research to industrialization.

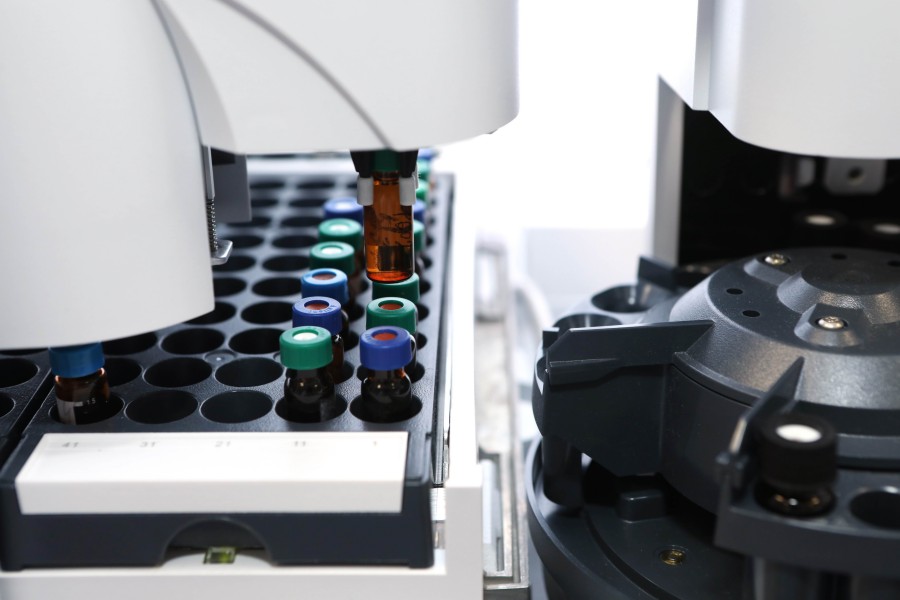

2Structural and Performance Characterization

- Employ advanced analytical techniques including GPC, NMR, FTIR, DSC, and TGA to comprehensively analyze molecular structure, thermal, and mechanical properties.

- Ensure batch-to-batch consistency in degradation rate and biocompatibility.

- Provide authoritative analytical reports and quality traceability documents to support research and product registration.

3Functional Modification & Composite Development

- Enhance PLGA cell adhesion and bioactivity via surface modification, block copolymerization, and grafting.

- Combine with natural polymers (e.g., collagen, chitosan) or inorganic materials (e.g., hydroxyapatite) to improve biomimetic properties and mechanical performance.

- Support the development of drug-loaded systems, smart responsive materials, and personalized biomimetic scaffolds.

4Technical Consultation & Solutions

- Offer expert-level technical consultation and process optimization for challenges in biomimetic material R&D.

- Develop customized synthesis routes and application solutions based on project-specific needs.

- Provide end-to-end support including material selection, process optimization, and application expansion to accelerate translation of results.

Advantages

Professional Advantages of Our Custom PLGA Services

- Professional Technical Platform: Equipped with advanced polymer synthesis and characterization instruments, including GPC, NMR, and FTIR, ensuring controllability and reliability of PLGA molecular structure, physicochemical properties, and batch stability.

- Highly Customizable: Flexible adjustment of lactic acid/glycolic acid ratio, molecular weight distribution, morphology, and processing methods, from nanoparticles to films, meeting both research exploration and industrial applications.

- Strict Quality Control: Adheres to international standards and quality systems, providing complete testing data and analytical reports, ensuring PLGA product safety and consistency for R&D, registration, and commercialization.

- Cross-Field Application Experience: Rich experience in drug delivery, tissue engineering, medical devices, and regenerative medicine, providing adaptable material solutions for multiple scenarios and supporting cutting-edge applications.

- Rapid Response & Delivery: Leveraging a complete production and supply chain system to significantly shorten R&D and delivery cycles, offering efficient and stable support for research projects and industrial processes.

- Global Service: Extensive international collaboration and compliance experience to provide PLGA products and solutions that meet regulatory requirements worldwide, helping partners maintain a competitive edge in the global market.

Service Process

PLGA Service Workflow from R&D to Delivery

At BOC Sciences, we have established a systematic and transparent service workflow to ensure that every PLGA project, from initial requirements to final delivery, is efficient, controllable, and compliant with international standards. Through the following six key steps, we provide comprehensive support to accelerate both research and industrial applications.

1Requirement Communication

We engage closely with clients to understand their research goals and application scenarios, clarifying specific requirements for PLGA formulation, molecular weight, morphology, and performance parameters. Our expert team conducts preliminary evaluation of the collected information to ensure the project is accurately directed.

2Solution Design

Based on client needs and application context, we develop personalized synthesis and modification plans. This includes setting the lactic acid/glycolic acid ratio, selecting molecular weight ranges, designing morphologies (e.g., particles, films, coatings), and outlining feasible process routes to ensure a scientifically sound solution.

3Experimentation & Optimization

During the laboratory-scale trial phase, synthesis and performance testing are conducted, followed by process optimization based on experimental results. This stage focuses on controlling reaction conditions and polymerization parameters to ensure controllable degradability, biocompatibility, and structural stability of the final material.

4Structural & Performance Characterization

Using advanced analytical techniques such as GPC, NMR, FTIR, DSC, and TGA, we perform comprehensive characterization of PLGA's molecular structure, thermal properties, mechanical properties, and degradation behavior, providing clients with complete and traceable technical reports.

5Scale-Up Production

After successful validation of the plan, pilot-scale and large-scale production are conducted. We offer production capabilities ranging from gram-scale to kilogram-scale, ensuring requirements at every stage are met while maintaining batch stability and product consistency.

6Delivery & Continuous Support

Upon completion of production and quality testing, products along with detailed reports are delivered to clients. Additionally, we provide ongoing technical support and optimization services to address application challenges, ensuring long-term reliability for research and industrial applications.

Applications

PLGA Applications in Biomimetic Materials

PLGA plays a crucial role in biomimetic material research. Its biodegradability, excellent biocompatibility, and tunable structure make it one of the most widely used polymers in current interdisciplinary medical and engineering studies. With flexible lactic acid/glycolic acid ratios, PLGA provides precise material solutions for various applications, including tissue engineering, drug delivery, medical devices, and regenerative medicine. Typical application areas include:

Tissue Engineering

- Bone tissue engineering: PLGA scaffolds combined with hydroxyapatite (HA) enhance mechanical strength and promote osteogenic differentiation.

- Cartilage repair: Electrospun PLGA nanofibers mimic cartilage matrix to support chondrocyte proliferation.

- Nerve regeneration: Tubular PLGA scaffolds guide axonal growth, showing potential in peripheral nerve repair.

Drug Delivery Systems

- Controlled & sustained release: Adjusting polymer composition and molecular weight can extend drug release from days to months.

- Targeted delivery: Ligands or antibodies can be attached to PLGA nanoparticles for precise targeting of tumors or inflamed tissues.

- Vaccine delivery: PLGA microspheres serve as antigen carriers to enhance immunogenicity and achieve prolonged immunity.

Regenerative Medicine & Biological Repair

- Vascular tissue engineering: PLGA/collagen composite scaffolds are used for artificial blood vessels, providing mechanical stability and endothelial cell compatibility.

- Skin repair: PLGA nanofiber membranes are used for burn and chronic wound healing.

- Dental applications: PLGA scaffolds support regeneration of periodontal ligament and dentin.

Medical Devices & Implants

- Biodegradable sutures: PLGA threads have controllable absorption rates, avoiding secondary suture removal.

- Bone screws & pins: PLGA implants gradually degrade in vivo and are replaced by newly formed bone.

- Scaffolds & plates: Used in vascular and orthopedic treatments to reduce long-term complications.

FAQs

Frequently Asked Questions

-

What is poly lactic co-glycolic acid (PLGA)?

PLGA, or poly(lactic-co-glycolic acid), is a biodegradable synthetic polymer prepared via copolymerization of lactic acid and glycolic acid. It combines controllable degradability, biocompatibility, and tunable mechanical properties, making it suitable for tissue engineering scaffolds, drug-controlled release systems, and biomimetic materials. Adjusting the lactic acid/glycolic acid ratio and molecular weight enables different degradation rates to meet research, medical device, and drug delivery needs.

-

Is PLGA synthetic or natural?

PLGA is a synthetic polymer produced by chemically copolymerizing lactic acid and glycolic acid monomers. Compared with natural polymers, its molecular structure, molecular weight, and lactic acid/glycolic acid ratio can be precisely controlled, allowing adjustment of degradation rate and mechanical properties. This synthetic nature provides advantages in biomimetic materials, drug delivery, and tissue engineering, while ensuring material consistency and batch controllability.

-

Is PLGA biocompatible?

PLGA exhibits excellent biocompatibility and biodegradability, hydrolyzing into lactic acid and glycolic acid in vivo, which are naturally metabolized and excreted. Its non-toxic, non-inflammatory nature makes it ideal for drug delivery systems, tissue engineering scaffolds, and absorbable medical devices. Its biocompatibility also allows long-term contact with cells and tissues, supporting cell adhesion, growth, and tissue regeneration, and it is widely applied in biomimetic material development.

-

Is PLGA hydrogel?

PLGA itself is a solid polymer but can form hydrogel systems through modification or combination with natural polymers (collagen, hyaluronic acid), resulting in injectable or implantable PLGA hydrogels. These hydrogels feature controllable degradability, drug release capability, and good biocompatibility, widely used in soft tissue repair, wound healing, and controlled drug delivery, providing both structural support and drug-carrying functions.

-

How is PLGA manufactured?

PLGA is typically produced via ring-opening polymerization, copolymerizing lactic acid and glycolic acid monomers in the presence of a catalyst. The process allows control over lactic acid/glycolic acid ratio, molecular weight, and polymerization conditions, tuning degradation rate and mechanical properties. PLGA can be further processed into nanoparticles, microspheres, films, scaffolds, or coatings for tissue engineering, drug release, and biomimetic applications.

-

How does PLGA form nanoparticles?

PLGA nanoparticles can be prepared by emulsion solvent evaporation, nanoprecipitation, or microfluidic techniques. In the process, PLGA is dissolved in an organic solvent and emulsified in water. By controlling emulsification conditions, molecular weight, and lactic acid/glycolic acid ratio, nanoparticles with controllable size and uniform distribution are obtained. PLGA nanoparticles are widely used for drug-controlled release, targeted delivery, and vaccine carriers, exhibiting excellent biocompatibility and degradability.

-

What are PLGA microparticles for drug delivery?

PLGA microparticles are micron-sized particles made from PLGA polymers for drug sustained release and targeted delivery. By adjusting molecular weight, lactic acid/glycolic acid ratio, and particle preparation methods, controlled in vivo drug release can be achieved. They are widely applied in anticancer drugs, vaccines, protein, and gene delivery, protecting drug stability, extending half-life, and providing excellent biocompatibility and biodegradability.

PLGA Nanoparticle Preparation

PLGA Nanoparticle Preparation

PLGA Microsphere Preparation

PLGA Microsphere Preparation

PLGA Scaffold Preparation

PLGA Scaffold Preparation

PLGA Hydrogel Preparation

PLGA Hydrogel Preparation

PLGA Coating Preparation

PLGA Coating Preparation

PLGA Film/Membrane Preparation

PLGA Film/Membrane Preparation