Gelatin Microsphere/Nanoparticle Preparation

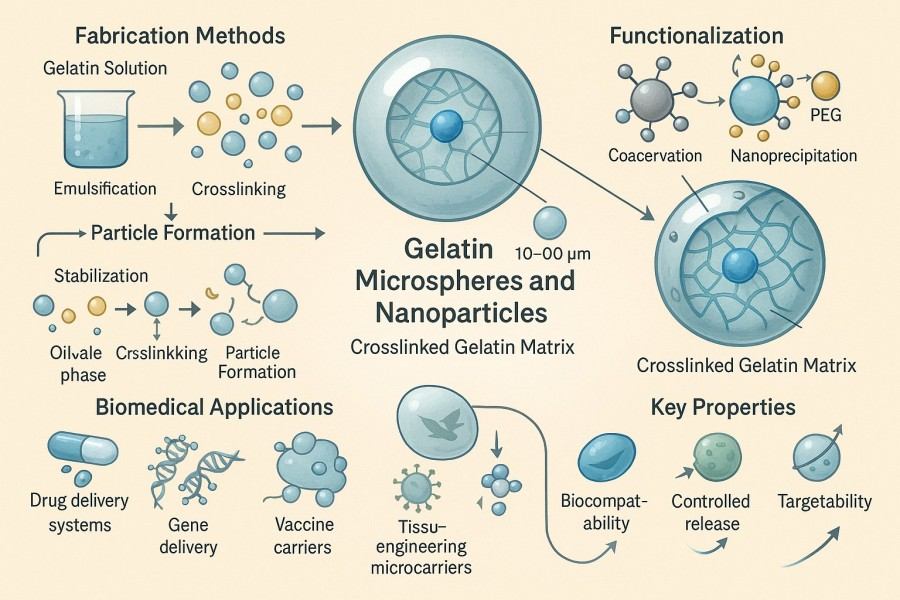

Gelatin microspheres typically refer to spherical particles with diameters ranging from 1–1000 μm, while nanoparticles generally range from 1–1000 nm in size. They are mainly composed of natural gelatin or chemically modified gelatin and can be formed into various sizes and morphologies through crosslinking, solution polymerization, emulsification, or spray-drying methods. In modern biomaterials and bioinspired material research, gelatin has become an ideal material due to its biocompatibility, biodegradability, and rich potential for functional modifications. Specifically, gelatin microspheres and nanoparticles, with their unique structural and dimensional advantages, play a significant role in drug delivery, tissue engineering, bioinspired scaffolds, and targeted release systems. BOC Sciences offers professional gelatin microsphere and nanoparticle preparation services covering the entire process from basic design and process development to functional modification. Our team combines advanced emulsification, crosslinking, and nanofabrication techniques to precisely control particle size, distribution, and surface characteristics, meeting the needs of drug delivery, tissue engineering, bioinspired materials, and nanomedicine. Through flexible customization and strict quality control, BOC Sciences helps clients develop and apply high-performance particulate materials, enhancing the success of both research and industrial projects.

What We Offer

Gelatin Microsphere/Nanoparticle Categories Offered by BOC Sciences

BOC Sciences provides a wide range of gelatin microsphere and nanoparticle preparation and development services to meet diverse research and industrial application needs. Our services cover multi-level customization, including particle size, crosslinking method, functional modification, and payload type, offering tailored solutions for drug delivery, tissue engineering, bioinspired materials, and nanomedicine. By precisely controlling particle structure, surface properties, and functionalization capabilities, BOC Sciences helps clients achieve high-performance, reproducible, and controlled-release microspheres/nanoparticles, providing solid technical support for biomimetic material development.

Natural Gelatin Particles

- Pure gelatin microspheres/nanoparticles: Prepared from unmodified natural gelatin, retaining intrinsic biocompatibility and biodegradability.

- Mild preparation process: Physical crosslinking and gentle emulsification methods preserve the stability of natural bioactive molecules.

- Broad applicability: Suitable for drug delivery, tissue engineering scaffolds, and basic research in bioinspired materials.

- Tunable size and porosity: Particle size and porous structure can be adjusted according to application needs, enhancing drug loading and cell adhesion.

Modified Gelatin Particles

- Functionalized gelatin: Includes PEGylation, aldehyde modification, acylation, or other chemical modifications to improve water solubility, circulation time, or drug-loading capacity.

- Targeted modification: Surface conjugation with peptides, antibodies, or sugars for specific cell or tissue recognition.

- Controlled degradation: Degradation rate can be tuned via crosslinking density and modification methods to suit different applications.

- Custom preparation schemes: Multi-functional particle designs, including sustained release and tracking functions, can be provided according to client requirements.

Composite Material Particles

- Gelatin-polysaccharide composites: Such as gelatin-chitosan or gelatin-hyaluronic acid composites, improving bioactivity and mechanical properties.

- Gelatin-polymer composites: Combined with degradable synthetic polymers (e.g., PLGA) to enhance structural stability and controlled-release performance.

- Multi-component functionalization: Supports co-loading of multiple molecules for combination drug delivery or multifunctional bioinspired scaffolds.

- Custom composite ratios: Optimized formulations for particle size, drug loading, and degradation rate.

Special Functional Particles

- Fluorescently labeled gelatin particles: Facilitate imaging and in vitro tracking, supporting research and diagnostic applications.

- Magnetic or conductive gelatin particles: Incorporating magnetic nanoparticles or conductive materials for controllable responses or biosensing functions.

- Smart responsive particles: Sensitive to pH, temperature, or enzymatic stimuli, enabling drug release or structural changes under specific conditions.

- Multifunctional design: Combines targeting, controlled release, and tracking capabilities for complex application requirements.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Gelatin Microsphere/Nanoparticle Preparation and Development Capabilities

BOC Sciences has a mature technology platform and extensive experience in the preparation and development of gelatin microspheres and nanoparticles, offering comprehensive support to research institutions and corporate clients. From particle design and process optimization to functional modification, we focus on creating high-performance, highly controllable microspheres/nanoparticles to meet the needs of drug delivery, tissue engineering, bioinspired materials, and nanomedicine. Through flexible customization and strict quality control, we help clients optimize material performance and achieve innovative applications.

1Particle Design and Process Development

- Precise particle size control: Design of micro- to nanoscale particles through emulsification speed, solution concentration, and crosslinking conditions.

- Morphology regulation: Fabrication of smooth, hollow, or porous particles to meet diverse drug loading and tissue engineering requirements.

- Crosslinking strategy optimization: Physical and chemical crosslinking options balancing stability and degradation rates.

- Optional functionalization: Introduction of surface-active groups or ligands during preparation for early-stage functionalization.

2Functional Modification and Targeted Design

- PEGylation and surface modification: Enhance water solubility and prolong in vivo circulation time.

- Targeting ligand conjugation: Modification with peptides, antibodies, or sugars for specific recognition and delivery.

- Fluorescent/magnetic labeling: Support imaging probes and biosensing applications.

- Multifunctional customization: Simultaneous targeting, sustained release, and tracking functions for complex applications.

3Drug Loading and Release Development

- Multi-molecule loading: Supports small molecules, proteins, peptides, and nucleic acid loading.

- Controlled and sustained release design: Regulate release rate via particle structure and crosslinking density.

- Drug stability optimization: Ensure the stability of bioactive molecules during preparation and storage.

- Multi-component composite loading: Enable co-delivery of combination drugs or multifunctional active molecules.

4Characterization and Quality Control

- Particle size and distribution analysis: Precise measurement using laser particle sizing (DLS), SEM, and TEM.

- Surface and chemical structure analysis: FTIR, NMR, and Zeta potential assessments ensure structural control.

- Functional verification and release evaluation: HPLC and UV-Vis determine drug loading and in vitro release profiles.

- Process reproducibility assurance: Strict control of particle consistency from laboratory, pilot, to bulk production.

Advantages

Leading Features of Our Gelatin Microsphere Preparation Services

- Highly uniform particle preparation: Precise control of emulsification, crosslinking, and process parameters ensures uniform particle size and stable distribution, guaranteeing consistency for research and industrial applications.

- Controllable release and degradation: Adjust particle crosslinking density and structure to achieve sustained, controlled release and degradability, optimizing drug or bioactive molecule delivery.

- Multifunctional surface modification: Supports PEGylation, targeting ligands, and fluorescent/magnetic labeling to enhance delivery, imaging, and multifunctional applications.

- Adaptable to multiple payload types: Can load small molecules, proteins, peptides, and nucleic acids, meeting diverse drug delivery, tissue engineering, and bioinspired material requirements.

- Strict analysis and quality control: Equipped with DLS, SEM, TEM, FTIR, NMR, HPLC, and other analytical techniques to ensure particle size, structure, drug loading, and functionality are controlled and reliable.

- Customized technical solutions: Full-range professional customization from particle design, process development to functional modification for research, clinical, and industrial clients.

- Comprehensive customer support: End-to-end service from technical consultation, sample development, performance evaluation to bulk production, ensuring project success and optimal application outcomes.

Service Process

How We Prepare Gelatin Nanoparticles and Microspheres?

BOC Sciences provides a systematic, customizable service workflow for gelatin microsphere and nanoparticle preparation, covering all stages from requirement communication to bulk production. Through standardized operations and flexible customized solutions, we ensure particle quality, functionality, and application performance meet client expectations while providing continuous technical support and optimization guidance.

1Requirement Communication and Project Assessment

- Engage in in-depth discussions with clients to understand application goals and research needs, clarifying particle type (microsphere or nanoparticle).

- Define particle size range, morphology requirements, and surface functionalization needs.

- Assess payload type (drug, protein, nucleic acid, etc.) and release characteristics.

- Establish project timeline and feasibility evaluation to provide a foundation for subsequent development.

2Formulation Design and Process Development

- Design particle preparation formulations, including gelatin concentration, emulsification system, and crosslinking conditions.

- Optimize process parameters to control particle size, porosity, and morphology.

- Develop surface modification strategies such as PEGylation, targeted ligand conjugation, or fluorescent labeling.

- Ensure formulations balance drug-loading capacity, stability, and biocompatibility.

3Small-Scale Sample Preparation

- Prepare laboratory-scale particles to validate process feasibility.

- Analyze particle size distribution, surface morphology, and stability.

- Conduct preliminary evaluation of payload capacity and release characteristics, collecting data for optimization.

- Refine particle design and process conditions based on client feedback.

4Analysis and Performance Characterization

- Particle size and morphology analysis: Characterize size and distribution using laser particle sizing (DLS), SEM, and TEM.

- Chemical structure analysis: Use FTIR and NMR to evaluate crosslinking degree and surface functionalization.

- Functional verification: Determine payload content and release profiles using HPLC or UV-Vis spectroscopy.

- Stability assessment: Evaluate structural and functional integrity under storage or application conditions.

5Process Optimization and Pilot Scale-Up

- Optimize preparation processes based on analytical results to ensure particle performance meets design specifications.

- Adjust emulsification, crosslinking, and surface modification parameters to achieve batch-to-batch consistency.

- Conduct pilot-scale experiments to validate process feasibility for large-scale production.

- Provide technical reports documenting optimized parameters and key process control points.

6Bulk Production and After-Sales Support

- Perform large-scale production according to client requirements, ensuring stable and reproducible particle performance.

- Provide complete quality control and analytical reports to guarantee product compliance.

- Offer continuous technical support, including application guidance, performance improvement, and secondary functionalization.

- Assist clients in troubleshooting issues during research or industrial applications to ensure smooth project progress.

Applications

How Gelatin Microspheres and Nanoparticles are Used?

Gelatin microspheres and nanoparticles, with their biocompatibility, controllable structures, and functionalization potential, have become integral to biomimetic material research. By mimicking natural extracellular matrix (ECM) and enabling controlled delivery, these particles provide a reliable material foundation for tissue engineering, drug delivery, and functional biomimetic systems. BOC Sciences leverages advanced preparation technologies and customized services to support high-performance particle materials for both research and industrial applications.

Tissue Engineering Scaffolds and Cell Culture

- Gelatin microspheres can serve as 3D scaffold fillers, providing a microenvironment for cell adhesion, proliferation, and differentiation.

- Adjustable pore sizes and mechanical properties simulate natural ECM, enhancing tissue engineering outcomes.

- Nanoparticles reinforce scaffold mechanical strength and bioactivity, aiding the construction of biomimetic tissues.

- Support directed tissue regeneration and cellular function studies, providing a material basis for regenerative medicine.

Drug Delivery and Controlled Release Systems

- Nanoparticles can carry drugs and enable sustained or targeted release, improving bioavailability.

- Particle size and surface modification optimize tissue penetration and targeting efficiency.

- Support loading of diverse active molecules, including small-molecule drugs, proteins, and nucleic acids.

- Can be combined with biomimetic materials to construct multifunctional, controlled-release drug delivery systems.

Biosensors and Imaging Probes

- Functionalized gelatin nanoparticles can serve as fluorescent, magnetic, or multimodal imaging probes.

- Enhance biosensing sensitivity, enabling real-time monitoring and high-resolution imaging.

- Can be conjugated with targeting ligands for specific recognition and signal amplification.

- Support development of signal-feedback systems and smart responsive materials in biomimetic research.

Biomimetic Material Development

- Facilitate construction of biomimetic microenvironments, simulating in vivo tissue and organ physicochemical conditions.

- Particle structure and functional modification can regulate cell behavior and molecular interactions.

- Support drug screening, disease modeling, and functional material research.

- Aid in the development of intelligent biomimetic materials and tunable biointerface systems.

FAQs

Frequently Asked Questions

-

What are gelatin microspheres?

Gelatin microspheres are spherical particles primarily made of gelatin, typically at the micrometer scale. They offer excellent biocompatibility, biodegradability, and functionalizable surfaces capable of carrying drugs, proteins, or other active molecules. With controllable size and structure, they are widely used in tissue engineering scaffolds, drug release systems, and biomimetic materials to mimic natural ECM and provide a stable microenvironment.

-

How are gelatin microspheres prepared?

Gelatin microspheres are commonly prepared using emulsification–gelation or solution polymerization methods. Gelatin is dissolved in aqueous solution, formed into spherical particles via oil-phase emulsification, spray drying, or microfluidics, and then crosslinked physically or chemically to enhance stability and mechanical strength. Adjusting emulsification conditions, crosslinking concentration, and process parameters allows precise control over particle size, distribution, and surface functionality for drug delivery or tissue engineering applications.

-

What are acrylic gelatin microspheres?

Acrylic gelatin microspheres are functionalized particles with acrylic groups introduced onto gelatin molecules. These microspheres exhibit enhanced mechanical strength, controllable crosslinking, and specific chemical reactivity, allowing conjugation with other functional molecules for multifunctional drug carriers or biomimetic materials. Acrylic content and crosslinking conditions can be tuned to control particle performance for diverse research and industrial applications.

-

What are biodegradable gelatin microspheres?

Biodegradable gelatin microspheres gradually degrade in vivo or under specific conditions, releasing loaded molecules. By adjusting crosslinking density, particle size, and morphology, the degradation rate and payload release profile can be precisely controlled. These microspheres are widely used in drug delivery, tissue engineering scaffolds, and biomimetic material research, offering biocompatibility and controlled functional release for various biomedical applications.

-

What are crosslinked gelatin microspheres?

Crosslinked gelatin microspheres are stabilized and strengthened via chemical or physical crosslinking. Chemical crosslinking often uses glutaraldehyde or EDC/NHS, while physical crosslinking relies on temperature, pH, or ionic conditions. Crosslinking density can modulate degradation rate and release properties, making them suitable for controlled drug delivery, tissue engineering, and long-term storage in biomimetic material applications, ensuring reproducible performance.

-

What are gelatin hydrogel microspheres?

Gelatin hydrogel microspheres are soft particles formed through hydrogel crosslinking, with high water content and biocompatibility. Their soft, tunable structure mimics natural ECM, supporting cell adhesion and growth. Hydrogel microspheres can be used in tissue engineering scaffolds, drug delivery systems, and biomimetic material research. Crosslinking density and pore structure can be adjusted to control mechanical properties and molecular release behavior.

-

What are gelatin nanoparticles?

Gelatin nanoparticles are particles ranging from 1–1000 nm in size, offering high surface area and excellent controlled-release capabilities. Prepared by emulsification–gelation, solution polymerization, or spray drying, they can undergo surface modification and functionalization. Nanoparticles are suitable for drug delivery, targeted therapy, and biomimetic material applications, with size, surface characteristics, and payload customizable for specific research or industrial needs.

-

What are alginate-gelatin nanoparticles?

Alginate-gelatin nanoparticles are formed by combining gelatin with sodium alginate, integrating the biocompatibility and controlled-release properties of both materials. These composite particles can carry small molecules, proteins, or nucleic acids and enable targeted delivery via surface modification. They are widely used in drug delivery, tissue engineering, and biomimetic material research, providing an ideal platform for functionalized particles and multimodal applications.

-

How are gelatin nanoparticles prepared?

Gelatin nanoparticles are commonly prepared using emulsification–gelation, solution polymerization, or spray-drying methods. After uniform dispersion of gelatin solution, nanoparticles are formed through crosslinking or gelation. Particle size and surface properties can be optimized for application requirements. By adjusting process parameters, emulsification conditions, and crosslinking strategies, high stability, controlled release, and functionalization can be achieved for drug delivery, tissue engineering, and biomimetic material applications.