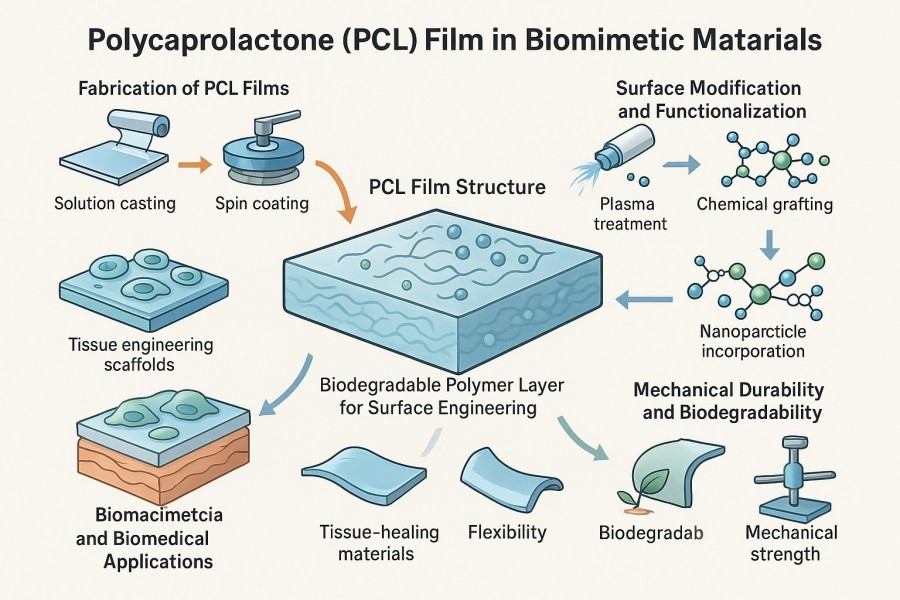

PCL film, made from polycaprolactone, is a biodegradable and versatile material. It offers excellent flexibility, ease of processing, and controllable degradation rates, making it ideal for applications in packaging, biomedical, and drug delivery systems.

- Home

-

Products

-

Monomers

- Acrylic Monomers

- Alcohol Monomers

- Allyl Monomers

- Amide & Imide Monomers

- Amine Monomers

- Anhydride Monomers

- Biodegradable Polymer Monomers

- Carboxylic Acid Monomers

- Cycloolefin

- Dendrimer Building Blocks

- Epoxide Monomers

- Halide Monomers

- Isocyanate Monomers

- Mercaptan Monomers

- Other Monomers

- Silicone Monomers

- Styrenic Monomers

- Vinyl Monomers

- Polymer Standards

-

Polymers

- Acid Functional Polymers & Salts

- Acrylic Polymers

- Alkene & Vinyl Polymers

- Amide and Imide Polymers

- Amine Functional Polymers & Salts

- Biodegradable Polymers

- Copolymers

- Dendrimers

- Epoxy Polymers

- Halogenated Polymers

- Natural Polymers & Derivatives

- Other Polymers

- Poly(ethylene glycol)s (PEGs) & Derivatives

- Polyester

- Polyether

- Silicones

- Styrenic Polymers & Derivatives

- π-Conjugated Polymers

- Reagents for Polymerization

-

Monomers

-

Custom Services

- Polymer Characterization Services

- Polymer Isolation and Purification

-

Custom Synthesis

- Copolymer Synthesis Services

- Polymer Additive Synthesis Services

- Polymer Initiator Synthesis Services

- Polymer Nanoparticle Synthesis

- Polymer Microsphere Synthesis

- Monomer Synthesis Services

-

Polymer Synthesis Services

- Atom Transfer Radical Polymerization Technology

- Reversible Addition-fragmentation Chain Transfer Polymerization Technology

- Nitroxide-mediated Polymerization Technology

- Ring-opening Polymerization Technology

- Ring-opening Metathesis Polymerization Technology

- Free Radical Polymerization Technology

- Living Cationic Polymerization (LCP) Technology

- Living Anionic Polymerization Technology

- Polymer Hydrogel Synthesis

- Polymer Micelle Synthesis

-

Polymer Modification Services

- Side/End Group Functionalization

- Side/End Group Protection

- Polymer Bioconjugation Services

- Biomimetic Materials

- Support

- About Us

- Contact Us