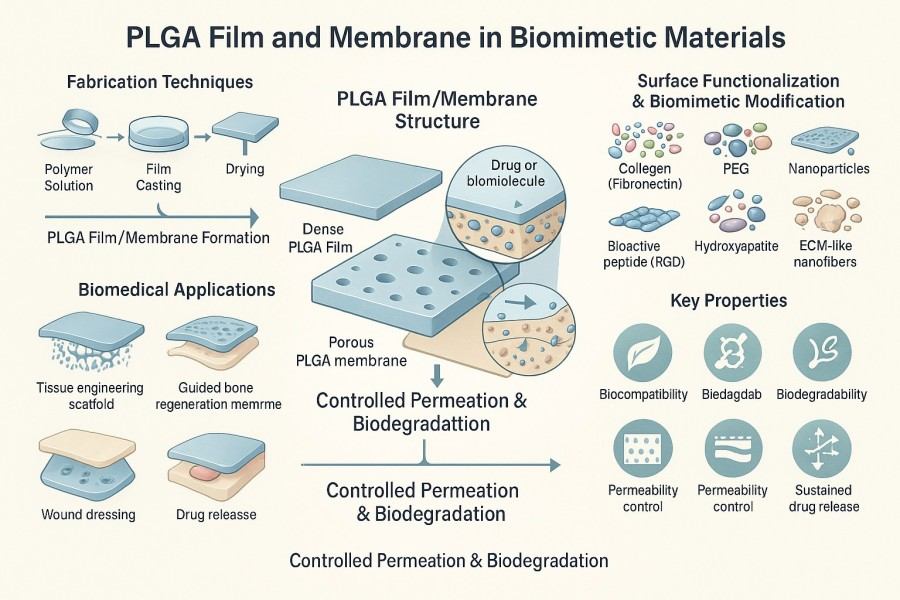

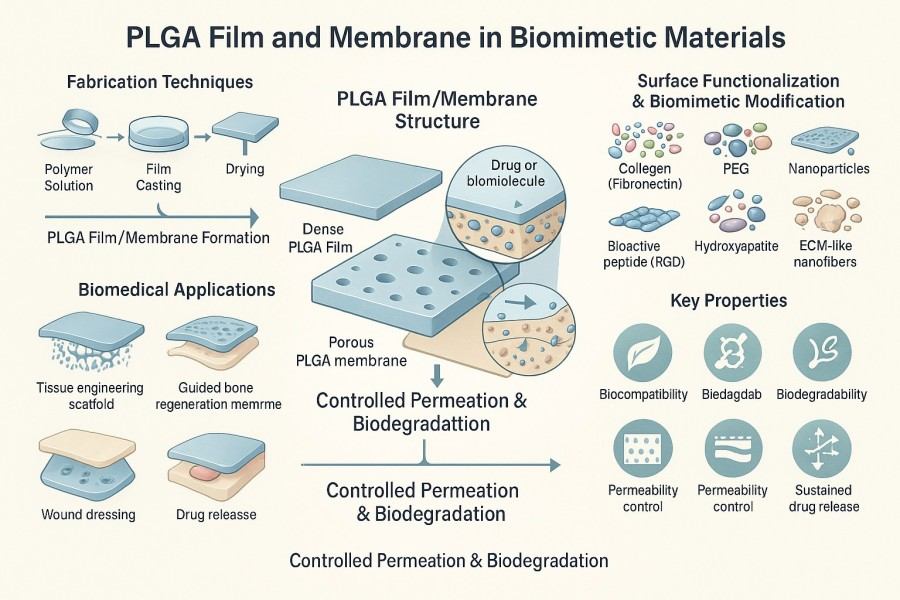

PLGA Film/Membrane Preparation

PLGA films or membranes are thin-film materials prepared from poly(lactic-co-glycolic acid) (PLGA). PLGA is a biodegradable and biocompatible polymer whose degradation products are lactic acid and glycolic acid, which can naturally break down into carbon dioxide and water through metabolic pathways. This property makes PLGA widely used in biomedical applications, tissue engineering, and drug delivery. PLGA films/membranes offer excellent mechanical strength, flexibility, and controllable degradation properties and can be fabricated with varying thicknesses and pore structures. These films can serve as drug carriers, tissue scaffolds, protective barriers, or biomedical materials, meeting diverse research and clinical needs. BOC Sciences provides professional PLGA film/membrane preparation and development services, dedicated to delivering high-performance biomimetic material solutions for research institutions and industrial clients. We can customize PLGA copolymer ratios, film thickness, porosity, and functional design, enabling a wide range of applications from drug-controlled release films to tissue engineering scaffolds. By precisely controlling film structure, surface properties, and degradation rate, our services support research innovation and industrial applications, ensuring every batch of PLGA film materials is consistent, reliable, and performance-controlled, providing solid support for biomimetic material development.

What We Offer

PLGA Films/Membranes Offered by BOC Sciences

We provide multi-category, high-precision film and composite film development services tailored to different application requirements. From dense non-porous films to porous films, nanofibrous membranes, drug-releasing films, and composite functional films, we offer precise customization of structure, thickness, porosity, and functionality. Whether for research exploration or industrial development, our professional team delivers full-process technical support, ensuring that every type of PLGA film achieves optimal mechanical performance, biocompatibility, and functional properties.

PLGA Dense/Non-porous Film

- Customizable thickness and molecular weight to meet specific mechanical strength and degradation cycle requirements.

- Smooth, uniform, and dense surfaces suitable for drug release patches and anti-adhesion films.

- Functional modifications such as drug loading or antibacterial coatings to support research and industrial applications.

PLGA Porous Film

- Adjustable pore size and porosity for optimized cell adhesion or drug release.

- Supports various fabrication methods, including gas foaming, solvent evaporation, and templating.

- Can incorporate bioactive molecules or drugs for tissue engineering and localized release applications.

PLGA Nanofibrous Membrane

- Fabricated via electrospinning, offering high porosity and large surface area, suitable as drug carriers or cell scaffolds.

- Adjustable fiber diameter, alignment, and thickness to meet diverse tissue engineering needs.

- Supports drug loading, natural polymer composites, or functional surface modifications for advanced customization.

PLGA Drug-Releasing Film/Patch

- Capable of loading small molecules, peptides, or proteins, with controlled release from days to months.

- Supports local patch designs for skin, oral, or surgical site drug delivery.

- Can incorporate responsive materials or composite structures for smart release functionality.

PLGA-Natural Polymer Composite

- Can be combined with gelatin, chitosan, cellulose, or other natural polymers to enhance bioactivity and cell adhesion.

- Supports porous or nanofibrous composite membrane fabrication for tissue engineering applications.

- Can integrate drugs or growth factors for multifunctional composite films.

PLGA-Inorganic Composite

- Can be combined with hydroxyapatite, silicates, or magnetic nanoparticles to enhance bone tissue engineering or magnetically controlled applications.

- Supports composite designs for porous or dense membranes, balancing mechanical properties and functionality.

- Can incorporate drugs, bone growth factors, or antimicrobial agents for advanced multifunctional applications.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

PLGA Film/Membrane Customization and Development Support

BOC Sciences has established a mature PLGA film/membrane preparation and functionalization platform. We provide full-process support for research institutions and enterprises, from material design and process optimization to functional development and performance evaluation, ensuring every PLGA film achieves optimal mechanical properties, biocompatibility, and functionality. Whether for fundamental research or industrial applications, we deliver efficient and reliable technical solutions to enable innovative applications.

1Formulation Design and Material Optimization

- Customized PLGA molecular weight, lactic/glycolic acid ratio (e.g., 50:50, 75:25, 85:15), and film thickness for different applications.

- Optimized film structure and porosity to balance dense, porous, or nanofibrous membrane performance.

- Integration with natural polymers (e.g., collagen, gelatin) or inorganic materials (e.g., HA) to enhance bioactivity and functional performance.

2Film Fabrication and Process Development

- Various preparation techniques including solution casting, hot-press molding, and electrospinning to meet structural requirements.

- Supports development of porous, nanofibrous, and multilayer composite films for customized performance.

- Process parameter optimization improves uniformity, mechanical performance, and controllable degradation.

3Functionalization and Composite Development

- Development of multifunctional PLGA films such as drug-loaded, antibacterial, or smart responsive films.

- Supports PLGA-natural polymer and PLGA-inorganic composite film design to enhance tissue engineering and drug delivery performance.

- Surface modification, coating, or incorporation of bioactive molecules for advanced functional films.

4Characterization and Performance Evaluation

- Molecular weight determination, mechanical testing, and porosity analysis to ensure controlled material performance.

- Drug release profiling and biocompatibility assessment to support application development and translational studies.

- Custom performance testing solutions to provide reliable data for different application scenarios.

Advantages

Technical Advantages of BOC Sciences in PLGA Film/Membrane Services

- Personalized Customization: Tailored PLGA copolymer ratios, film thickness, porosity, and functional design to match specific application needs.

- Advanced Analysis and Characterization: Comprehensive testing of thickness, pore size, mechanical properties, degradation rate, and surface chemistry to ensure stable and controllable performance.

- Multifunctional Film Design: Development of antibacterial, anticoagulant, and cell-adhesion-modulating films to support tissue engineering and biomimetic research.

- One-Stop R&D to Mass Production Service: Solutions for small-scale, pilot-scale, and industrial production covering research verification, clinical trials, and commercialization.

- Strict Quality Control: All PLGA films undergo rigorous quality control, meeting research and industrial standards for reliable and reproducible performance.

- Flexible Customization: Supports development from small research samples to large-scale production to meet diverse research and manufacturing needs.

- Leading Technical Expertise: Rich experience in film fabrication, functional modification, and composite membrane development to provide innovative solutions and technical support.

Service Process

Workflow for PLGA Film and Membrane Development Services

BOC Sciences leverages extensive experience in polymer chemistry and biomaterials development to establish a complete R&D and production workflow for PLGA films/membranes. From requirement analysis to functionalized film preparation, performance validation, and application optimization, we provide full-process technical support to ensure each film achieves optimal mechanical performance, biocompatibility, and functional properties. Our standard service workflow includes:

1Requirement Analysis and Project Design

- Engage in detailed discussions with clients to define application goals, film types, and functional requirements.

- Provide material selection recommendations based on application scenarios, including PLGA molecular weight, LA/GA ratio, and film structure design.

- Develop a customized R&D plan, providing a technical blueprint for subsequent preparation and functionalization.

2Formulation Development and Optimization

- Design formulations according to film type (dense, porous, or nanofibrous) and adjust solvent systems and processing parameters.

- Optimize drug loading, composite materials, and functional factors to meet controlled release or bioactivity requirements.

- Conduct small-scale laboratory trials to ensure formulation feasibility and scalability.

3Film Fabrication and Processing

- Offer solution casting, electrospinning, hot-press molding, and other preparation techniques.

- Control film thickness, porosity, and fiber diameter to meet client specifications for mechanical properties and degradation rate.

- Support multilayer or composite film processing to enhance functional performance.

4Functionalization and Composite Development

- Provide drug loading, antibacterial agent incorporation, and smart responsive functionality.

- Support PLGA-natural polymer and PLGA-inorganic material composite development.

- Achieve multifunctional films tailored for drug release, tissue engineering, and biomimetic material applications.

5Characterization and Performance Validation

- Conduct mechanical testing, porosity and thickness measurement, and molecular weight analysis.

- Evaluate drug release profiles, biocompatibility, and functional performance.

- Optimize formulations and fabrication processes based on testing results to ensure reliable performance.

6Technical Support and Application Optimization

- Offer end-to-end technical consultation, supporting film applications in research, clinical, or industrial contexts.

- Adjust film performance and functional design based on client feedback.

- Provide scale-up process optimization guidance to facilitate efficient translation and industrial implementation.

Applications

Exploring the Applications of PLGA Films and Membranes

With controllable degradation, biocompatibility, and functional potential, PLGA films are widely applied in drug delivery, tissue engineering, and biomimetic materials. Leveraging extensive material development experience, BOC Sciences provides tailored PLGA film design and customization solutions to ensure optimal mechanical, bioactive, and functional performance.

Drug Delivery and Controlled Release Systems

- Sustained Release Patches: Embed drugs in PLGA films for localized slow release.

- Oral or Transdermal Patches: Controlled release enhances efficacy and reduces dosing frequency.

- Targeted Drug Delivery: Combine with nanoparticles or drug molecules for localized high-concentration release, minimizing systemic side effects.

Tissue Engineering and Regenerative Medicine

- Bone Tissue Engineering: Serve as defect-filling membranes, support osteoblast growth, and deliver bone growth factors (BMPs).

- Soft Tissue Repair: Cover wounds to promote skin healing.

- Vascular Stent Linings: Provide degradable support to prevent restenosis.

Biomedical Protective Membranes

- Anti-adhesion Membranes: Reduce tissue adhesion post-surgery.

- Isolation Membranes: For cell culture or graft separation, improving experimental or clinical success rates.

- Barrier Membranes: Provide mechanical protection and functional support in biomimetic or tissue engineering applications.

Functionalized Membrane Materials

- Antibacterial Membranes: Incorporate silver nanoparticles or antibiotics to reduce infection risk.

- Smart Responsive Membranes: Sensitive to pH, temperature, or enzymes for controlled degradation and drug release.

- Magnetic Membranes: Incorporate magnetic nanoparticles for magnetically controlled targeting.

FAQs

Frequently Asked Questions

-

What is a PLGA film/membrane?

PLGA films/membranes are thin-film materials made from PLGA copolymers, composed of lactic acid and glycolic acid in varying ratios. They offer tunable degradation rates and excellent mechanical properties and are used for drug delivery, tissue engineering scaffolds, biomimetic material development, and medical device coatings. Films are generally uniform and continuous, suitable for drug release or coverage, while membranes emphasize porosity and mechanical support for tissue engineering.

-

What is the typical degradation time for PLGA membranes?

Degradation is highly tunable depending on the LA/GA ratio and molecular weight, ranging from several days to months. Higher LA content slows degradation for long-term support, while higher GA content accelerates degradation for short-term applications.

-

What types of drugs can PLGA membranes carry?

PLGA membranes can load small molecules, peptides, proteins, and nucleic acids for localized or targeted delivery. Optimizing structure, porosity, and composites allows controlled release and protects drug activity.

-

How is membrane porosity controlled?

Porosity can be regulated via fabrication method, solvent type, fiber diameter, or gas foaming techniques to achieve dense, porous, or nanofibrous structures. High porosity facilitates drug diffusion and cell adhesion, while low porosity enhances mechanical strength and controlled release.

-

Can PLGA membranes be combined with other materials?

Yes, they can be combined with natural polymers (gelatin, chitosan, PEG) or inorganic materials (hydroxyapatite, growth factors). Composite membranes enable drug release, antibacterial properties, or enhanced cell adhesion, improving bioactivity and performance.

-

Does BOC Sciences provide functionalized customization?

Yes, we offer customized functional PLGA membranes including antibacterial, smart responsive, porous tissue engineering, and drug-loaded films. We tailor structure, porosity, degradation rate, and functional design according to client needs, providing full technical support and performance validation for research and industrial applications.