Polymer Hydrogel Synthesis

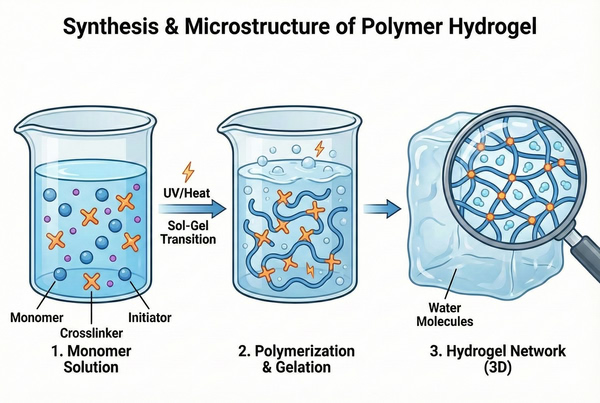

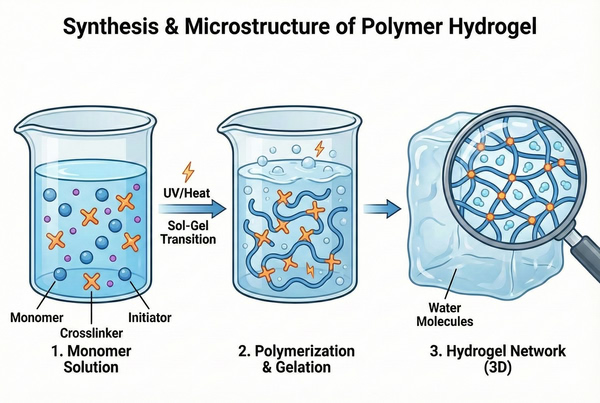

Polymer hydrogels, or polymer gels, are a class of three-dimensional network materials formed by hydrophilic polymers through physical or chemical crosslinking. They can absorb and retain large amounts of water in aqueous or physiological environments while maintaining structural stability. With highly tunable chemical structures, excellent biocompatibility, and adjustable mechanical and transport properties, polymer hydrogels have been widely applied in biomedicine, drug delivery, tissue engineering, cosmetics, environmental remediation, and advanced functional materials. Leveraging extensive expertise in polymer chemistry and biomaterials development, BOC Sciences provides polymer hydrogel synthesis and custom development services to global research institutions and industry clients. We support diverse needs from basic research to application development, enabling precise design and scalable production of hydrogels with tailored composition, structure, performance, and functionality according to client-specific applications.

Services

Precision Polymer Hydrogel Synthesis Services You Can Rely On

BOC Sciences offers highly customizable polymer gel synthesis services covering the full process from molecular design and synthetic route selection to network structure modulation. We systematically design and precisely control polymer composition, crosslinking methods, physicochemical properties, and functional characteristics of hydrogels to meet the high standards of reproducibility, stability, and scalability required for research and industrial translation.

-

Custom Synthesis of Various Polymer Hydrogels

-

Synthetic polymer hydrogels: PEG, PVA, PAAm, PAA, PNIPAM, and other systems.

-

Natural polymer hydrogels: gelatin, alginate, chitosan, hyaluronic acid, etc.

-

Support for natural and semi-synthetic hydrogel systems with chemical modification to enhance stability and tunable functionality.

-

Design of single-component or multi-component composite hydrogels to meet complex application requirements.

-

Crosslinking Strategies and Network Structure Design

-

Chemically crosslinked hydrogels (covalent bonds).

-

Physically crosslinked hydrogels (hydrogen bonds, ionic interactions, hydrophobic interactions).

-

Double Network (DN) hydrogels.

-

Dynamically reversible crosslinked hydrogels (for self-healing and stimulus-responsive systems).

-

Optimization of Key Gel Properties

-

Water content and swelling ratio.

-

Mechanical properties (tensile strength, compressive modulus, toughness).

-

Pore structure and distribution.

-

Degradation rate and stability.

-

Stimuli-responsive behavior (pH, temperature, light, ionic strength, etc.).

-

Biocompatibility and cellular interaction performance.

-

Functional Modification and Composite Material Design

-

Introduction and targeted modification of functional groups (e.g., carboxyl, amino, thiol, azide).

-

Regulation of bioactivity and interfacial functionality.

-

Nanofiller-reinforced composite design.

-

Construction of multiphase composite hydrogels.

-

Mechanical and functional synergy optimization.

-

Application-oriented composite system development.

Looking for Custom Polymer Hydrogel Solutions?

From synthetic to natural hydrogels, BOC Sciences delivers tailored polymer networks with precise mechanical, swelling, and functional properties to support your research and industrial projects.

Technology

Advanced Polymer Hydrogel Technology for Your Projects

BOC Sciences has established a complete technology platform for polymer hydrogel preparation, covering molecular design, process development, scale-up production, and technology transfer. We systematically design and continuously optimize hydrogel molecular structures, formulations, and production processes to ensure that materials meet research and industrialization requirements in terms of performance, stability, and manufacturability.

1Molecular Design and Formulation Optimization

-

Targeted design of polymer backbones, side chains, and functional groups according to application needs.

-

Optimization of monomer composition, copolymer ratios, and crosslinking systems to achieve precise performance matching.

-

Support for hydrogel formulation optimization to balance mechanical properties, swelling behavior, and stability.

-

Custom design for biomedical, delivery, and functional material applications.

2Core Hydrogel Preparation Technologies

-

Radical polymerization for controlled hydrogel network formation.

-

Physical gelation techniques for mild and biocompatible hydrogel formation.

-

Enzymatic reactions for selective and precise hydrogel construction.

-

Click chemistry for precise and functionalizable hydrogel structures.

3Smart Hydrogel Construction

-

Incorporation of functional monomers and side-chain modifications for targeted functionalities.

-

Development of temperature-, pH-, ion-, or other stimulus-responsive hydrogels.

-

Support for dynamic bonding and injectable in situ gelation strategies.

-

Optimization for drug delivery, biomedical, and functional material applications.

4Scale-Up Production and Technology Transfer Support

-

From lab-scale experiments to pilot-scale process development.

-

Adjustment of critical parameters and risk assessment during scale-up production.

-

Delivery of complete technical documentation and process schemes to support technology transfer.

-

Ensure consistent quality and performance during large-scale hydrogel production.

Characterization

Polymer Hydrogel Analysis and Validation Services

BOC Sciences offers comprehensive polymer hydrogel analysis and validation services covering the full range of physical, chemical, and functional performance evaluations. We systematically analyze hydrogel structural features, mechanical properties, swelling behavior, and application-specific functionality, providing reliable data for R&D optimization, process scale-up, and product validation. Through precise analysis and standardized validation, we ensure consistent performance and controllable specifications for every batch of hydrogel materials, supporting both research and industrial applications.

|

Testing Category

|

Detailed Test Description

|

Instruments / Methods

|

|

Physical Performance

|

Measure tensile strength, compressive modulus, and elasticity of hydrogels; assess network stability and load-bearing capacity; analyze the effect of formulation or crosslinking density on mechanical performance.

|

Universal testing machine, Dynamic Mechanical Analyzer (DMA)

|

|

Chemical & Structural Characterization

|

Analyze polymer chemical structure and functional groups; determine molecular weight distribution, crosslinking density, and polymer uniformity to support formulation optimization and functional modification.

|

FTIR, NMR, XRD, Gel Permeation Chromatography (GPC)

|

|

Swelling & Water Absorption

|

Measure swelling ratio and water absorption under different solution conditions; analyze swelling kinetics and volumetric changes to support drug delivery and controlled release systems.

|

High-precision balance, water bath/incubator, volumetric measurement devices

|

|

Microstructure & Morphology

|

Visualize network pore structure, 3D distribution, and surface morphology; evaluate pore uniformity and microstructure impact on mechanical and swelling performance.

|

Scanning Electron Microscope (SEM), Transmission Electron Microscope (TEM)

|

|

Thermal Properties & Stability

|

Analyze glass transition temperature, thermal degradation behavior, and thermal stability; assess material performance during processing, storage, and application.

|

Differential Scanning Calorimeter (DSC), Thermogravimetric Analyzer (TGA)

|

|

Functional Performance

|

Evaluate stimulus-responsive behavior (pH, temperature, ions), drug release profiles, biocompatibility, and cell interactions to ensure materials meet specific application requirements.

|

pH/temperature control equipment, drug release analysis system, cell culture and biocompatibility testing instruments

|

Advantages

Why Clients Choose Our Polymer Hydrogel Expertise?

-

Extensive Polymer and Biochemistry Expertise: With over 15 years of experience in polymer and biomaterials research, our team has completed more than 200 polymer projects, providing clients with scientifically reliable design and technical solutions.

-

One-Stop Service from Design to Performance Evaluation: Covering molecular design, synthesis, network structure control, and performance validation across 50+ monomer systems, our end-to-end service supports integrated solutions from proof-of-concept to application evaluation.

-

Support for Lab-Scale to Pilot-Scale Scale-Up: Laboratory production ranges from 1 g to 500 g, with pilot-scale batches up to 5 kg, ensuring consistent hydrogel performance at all production stages to meet research and industrialization needs.

-

Strict Quality Control and Batch Consistency: Our systematic quality management system and standardized experimental procedures ensure over 95% consistency in mechanical properties, swelling ratio, and functional response between batches, guaranteeing material reliability and reproducibility.

-

Highly Customizable Technical Capabilities: We support functional group modification, composite material development, and multi-functional responsive system customization, offering 10+ hydrogel formulation optimization solutions to meet diverse application requirements.

-

Advanced Laboratory and Analytical Facilities: Equipped with 30+ high-end instruments, including FTIR, NMR, XRD, SEM/TEM, DMA, DSC/TGA, etc., we can perform comprehensive hydrogel characterization and functional validation.

-

Comprehensive Customer Support and Technical Collaboration: We provide full support from technical consultation, solution design, and experimental guidance to project delivery. Data analysis reports, technical training, and R&D collaboration services are also available to help clients achieve their research or industrial goals quickly.

Service Process

Partner with BOC Sciences to Fast-Track Your Hydrogel Research

We provide a systematic and transparent collaboration process for every polymer hydrogel project, ensuring efficiency and control from project initiation to final deliverables. A typical six-step collaboration process includes:

1Requirement Communication and Goal Confirmation

Engage in detailed discussions with clients to understand project background, performance targets, functional requirements, and timelines, while assessing technical feasibility. Professional analysis and preliminary discussions establish clear project goals and R&D directions, laying the foundation for experimental design and planning.

2Technical Solution Design

Based on project objectives, we provide comprehensive plans covering hydrogel molecular design, formulation selection, synthesis route planning, and crosslinking strategy optimization. Plans include experimental design, raw material selection, key parameter recommendations, and feasibility analysis to ensure organized and efficient R&D progression.

3Lab-Scale R&D and Sample Preparation

Perform small-scale hydrogel synthesis and preparation in the lab, optimizing monomer ratios, crosslinking conditions, and process parameters. Preliminary performance testing verifies mechanical properties, swelling behavior, and functional characteristics, providing reliable data and optimization directions for subsequent evaluation and scale-up.

4Performance Evaluation and Iterative Optimization

Analyze physical, chemical, and functional performance of prepared hydrogel samples, including mechanical strength, swelling behavior, microstructure, and functional responses. Formulation and process are iteratively optimized based on results to ensure materials meet specific client application requirements.

5Pilot-Scale Scale-Up and Process Optimization

Expand lab-scale formulations and process conditions to pilot scale, optimizing reaction conditions, batch consistency, and production efficiency. Systematic process validation ensures hydrogel performance remains stable during scale-up, laying a solid foundation for transitioning R&D results to industrial applications.

6Technical Delivery and Ongoing Support

Upon project completion, provide complete technical documentation, performance data, and process operation manuals. Continued technical support, experimental guidance, and optimization recommendations are available to help clients advance research projects or industrial applications and maximize material development value.

Applications

Tailored Application Support for Your Polymer Hydrogel Projects

BOC Sciences offers comprehensive polymer hydrogel preparation and application support across biomedical, cosmetic, and industrial fields. We customize designs for different applications to optimize hydrogel performance and functionality, ensuring materials meet research, development, and industrialization needs.

Biomedical and Tissue Engineering

-

Cell Culture and 3D Scaffold Materials: Hydrogels with tunable pore size and mechanical properties, suitable for 3D cell culture and scaffold construction.

-

Wound Healing and Dressing Hydrogels: High water-absorbing, biocompatible hydrogels designed for wound repair and protection.

-

Regenerative Medicine and Soft Tissue Substitutes: Biodegradable, flexible hydrogels developed for soft tissue replacement and regenerative applications.

Drug Delivery and Controlled Release Systems

-

Small Molecule Sustained-Release Hydrogels: Construct controlled-release systems for stable and prolonged delivery of small-molecule drugs.

-

Protein and Peptide Delivery Systems: Biocompatible hydrogels for stable delivery of proteins and peptides.

-

Stimuli-Responsive Controlled-Release Platforms: Hydrogels responsive to temperature, pH, light, and other stimuli for smart release functionality.

Cosmetics and Personal Care Materials

-

High-Moisture Gel Matrices: Hydrogels with high water content, providing long-lasting hydration and soft skin feel.

-

Functional Facial Masks and Skincare Carriers: Hydrogels designed to deliver active ingredients, enhancing skincare efficacy and comfort.

-

Contact Lenses and Ocular Care Materials: Transparent, highly oxygen-permeable hydrogels suitable for contact lenses and eye care applications.

Industrial and Environmental Applications

-

Adsorption and Separation Hydrogels: Selective adsorption hydrogels for pollutant capture and optimized separation efficiency.

-

Water Treatment and Pollutant Removal: High-adsorption hydrogels for water treatment and removal of harmful substances.

-

Flexible Sensors and Functional Materials: Stimuli-responsive hydrogels designed for sensors and smart material applications.

FAQs

Frequently Asked Questions

-

What is polymer hydrogel?

A polymer hydrogel is a three-dimensional network of hydrophilic polymer chains that can absorb and retain large amounts of water while maintaining their structural integrity. Hydrogels are typically crosslinked either chemically or physically, which provides mechanical stability. They are widely used in biomedical applications, drug delivery, tissue engineering, and industrial applications due to their tunable properties, biocompatibility, and ability to mimic biological tissues.

-

Are hydrogels polymers?

Yes, hydrogels are a type of polymer material. They are composed of hydrophilic polymer chains that are crosslinked into a network structure. The polymer chains themselves provide the backbone, while crosslinking (chemical or physical) gives the hydrogel its three-dimensional structure, water absorption capacity, and mechanical stability. Essentially, all hydrogels are polymers, but not all polymers form hydrogels.

-

How to determine roughness of a polymer hydrogel?

The roughness of a polymer hydrogel can be evaluated using surface characterization techniques such as Atomic Force Microscopy (AFM), Scanning Electron Microscopy (SEM), or Profilometry. AFM is particularly useful, providing high-resolution 3D surface topography and quantitative roughness parameters (e.g., Ra, RMS). Sample preparation should preserve the hydrogel’s hydrated state if relevant, and measurements can be performed under dry or hydrated conditions depending on the application.

-

What types of polymer hydrogels can you synthesize?

We can synthesize a wide range of polymer hydrogels, including chemically crosslinked, physically crosslinked, stimuli-responsive, injectable, and composite hydrogels. We support customization in polymer composition, network structure, mechanical properties, and functional modifications, ensuring our hydrogels are suitable for biomedical research, drug delivery, tissue engineering, or industrial applications.

-

Can you customize hydrogels for my specific application?

Yes. We offer highly customizable hydrogel design, including molecular composition, crosslinking strategies, and functionalization. We work closely with our clients to optimize mechanical strength, swelling behavior, degradation rate, and bioactivity, ensuring the final hydrogel meets precise requirements for tissue engineering, drug delivery, cosmetics, or industrial use.

-

What scale of hydrogel synthesis do you support?

We support flexible scales from small laboratory batches (grams) to mid-scale pilot production (kilograms). Our process optimization ensures that key properties like mechanical strength, swelling ratio, and functional performance remain consistent across scales, making our services suitable for both R&D and early-stage industrial production.

-

How do you ensure quality and batch-to-batch consistency?

We apply strict quality control protocols, including standardized synthesis, characterization, and verification. Each batch undergoes comprehensive physical, chemical, and functional testing to ensure consistent mechanical properties, swelling behavior, and performance metrics. This guarantees reliable and reproducible hydrogels for research, product development, and industrial applications.

-

What analytical services do you provide for hydrogels?

We provide comprehensive hydrogel analysis, including mechanical testing, swelling and absorption measurements, chemical and structural characterization (FTIR, NMR, XRD), thermal stability analysis (DSC, TGA), microstructure observation (SEM, TEM), and functional performance evaluation such as drug release and stimulus response. These services help us optimize designs and confirm performance.