Alginate Bead Preparation

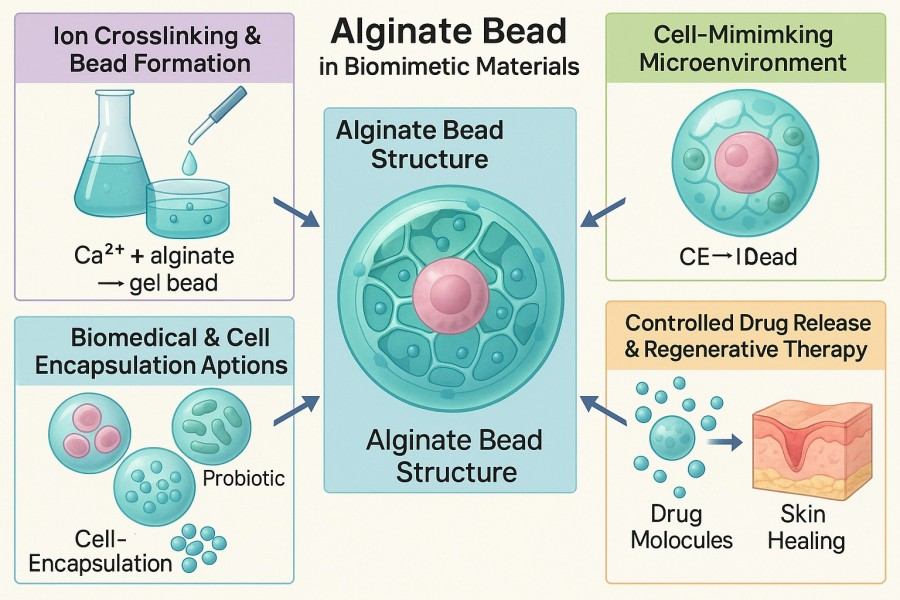

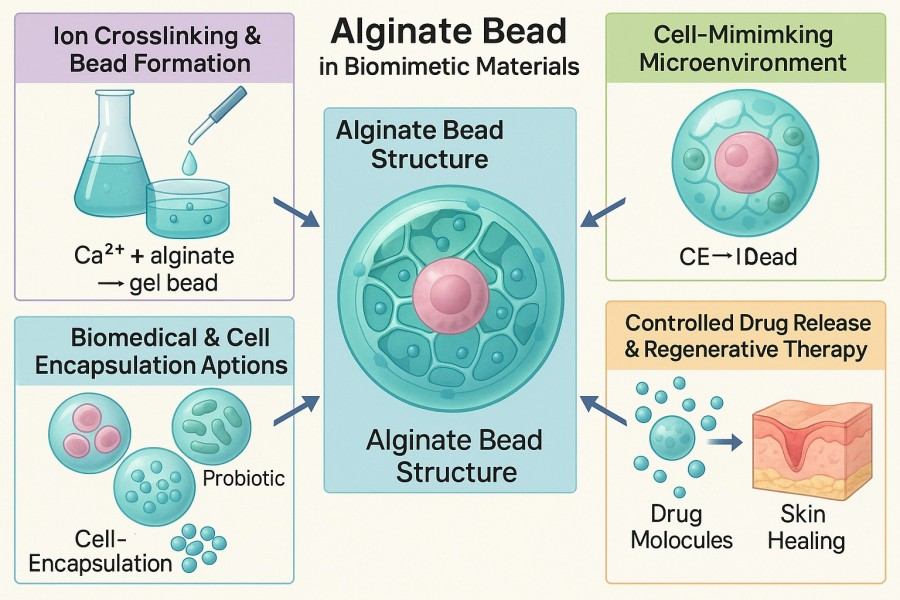

Alginate beads refer to hydrogel particles in which alginate molecular chains form a three-dimensional gel network through crosslinking reactions, resulting in spherical or near-spherical structures. Their size typically ranges from a few micrometers to several millimeters and can be precisely controlled by adjusting preparation parameters. Due to their tunable physical structure, mild fabrication conditions, and excellent biocompatibility, alginate beads have demonstrated significant application potential in drug sustained release, cell encapsulation, enzyme immobilization, three-dimensional cell culture, and environmental remediation. Leveraging its strong polymer chemistry platform and custom synthesis capabilities, BOC Sciences provides comprehensive alginate bead preparation, development, and production services, covering the entire workflow from basic formulation optimization and bead formation to composite material construction and application validation, helping clients achieve innovative breakthroughs in biomimetic materials and functional carriers.

What We Offer

Alginate Beads Offered by BOC Sciences

BOC Sciences provides a wide variety of alginate beads, ranging from basic to functionalized and composite types. We focus not only on the physicochemical properties of the materials but also offer tailored solutions based on specific application scenarios and functional requirements, such as drug delivery, cell encapsulation, enzyme immobilization, tissue engineering, and environmental remediation. Our alginate bead classification system is based on functional composite strategies and material performance optimization, meeting multi-level needs from research exploration to industrial scale-up. The following is an overview of the main types we offer:

Calcium Alginate Beads

This is the most classic and widely used type of alginate bead. It is prepared by dropping a sodium alginate solution into a Ca²⁺-containing crosslinking solution, providing excellent mechanical strength and biocompatibility.

- Flexible size design from tens of micrometers to several millimeters using various bead formation techniques (dropwise method, spray gelation, microfluidic formation);

- Process options with different hardness and porosity for drug delivery systems, enzyme immobilization, and cell encapsulation;

- Complete physicochemical characterization, including swelling rate, release profiles, and crosslinking density analysis.

Sodium Alginate Beads

Based on sodium alginate, this type is typically used for precursor studies or as intermediates in composite material carriers.

- Optimized formulations of high-purity sodium alginate solutions with pH control;

- Customizable raw material systems with different viscosities and molecular weights for drug loading or composite studies;

- Full process development from sodium alginate bead preparation to calcium alginate bead conversion.

Alginate–Chitosan Beads

Layered composite structures are formed through electrostatic interactions between alginate and chitosan, combining the advantages of both natural polysaccharides.

- Optimized cation/anion ratios to achieve stable multilayer composite membranes;

- Charge-complex systems suitable for oral drug controlled release and protection of bioactive substances;

- Support for nanoparticle-level composites and surface functionalization, such as targeting ligands or fluorescent labeling.

Alginate–Gelatin Beads

Introducing gelatin, a natural collagen-derived material, into the alginate matrix significantly enhances bioactivity and cell adhesion.

- Customizable alginate-to-gelatin ratios to control gel stiffness and degradation rate;

- Low-temperature molding and temperature-sensitive crosslinking suitable for thermosensitive biomolecules;

- Long-term stability testing and parameter optimization for 3D cell culture and bioprinting applications.

Alginate–Collagen Beads

Collagen, a major component of the extracellular matrix, forms a hydrogel system closer to natural tissue when combined with alginate.

- Uniform mixing and gelation while maintaining bioactivity;

- Custom systems incorporating growth factors, peptide signals, or protein complexes;

- Dedicated material development services for tissue repair, skin substitutes, and cell proliferation research.

Alginate–Polyvinyl Alcohol (PVA) Beads

Co-crosslinking of PVA and alginate significantly improves bead thermal stability and mechanical strength.

- Crosslinking and freeze–thaw methods enhance bead mechanical strength and durability;

- Customizable dry and wet bead structures for long-term storage or continuous reaction systems;

- Scale-up process evaluation and quality verification for alginate–PVA bead production.

Nanocomposite Alginate Beads

Nanomaterials (e.g., SiO₂, Fe₃O₄, TiO₂, or nanoclays) are incorporated into the alginate matrix to create multifunctional composites.

- Uniform dispersion techniques for nanofillers (magnetic Fe₃O₄, SiO₂, TiO₂, graphene, or clay);

- Development of composite beads with adsorption, catalytic, magnetic, or antibacterial properties;

- Complete material design and validation support for environmental remediation, catalytic reactions, and targeted drug delivery.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Technical Platform and Custom Support for Alginate Beads

BOC Sciences not only offers standardized alginate bead production and preparation services but also customizes composite ratios, particle sizes, crosslinking methods, and surface modification strategies according to clients' research goals and functional needs. Whether exploring alginate bead drug delivery systems or developing new alginate hydrogel beads for biomimetic material research, we provide complete support for material development, characterization, and process optimization.

1Flexible Customized Preparation Options

- Solid Alginate Beads

- Multi-layer or Core–Shell Beads

- Porous or Hollow Beads

- Composite Alginate Beads (with chitosan, PVA, gelatin, etc.)

- Magnetic or Smart Responsive Beads (Magnetic / pH-sensitive)

2Diverse Crosslinking and Modification Strategies

- Ionic crosslinking (Ca²⁺, Ba²⁺, Sr²⁺)

- Covalent crosslinking (EDC/NHS, ADH, glutaraldehyde)

- Endogenous release crosslinking (CaCO₃–acidification system)

- Nanocomposites (Fe₃O₄, SiO₂, Ag, ZnO, etc.) for magnetic or antibacterial properties

- Surface functionalization, such as amination, carboxylation, PEGylation, or nanocomposite enhancement

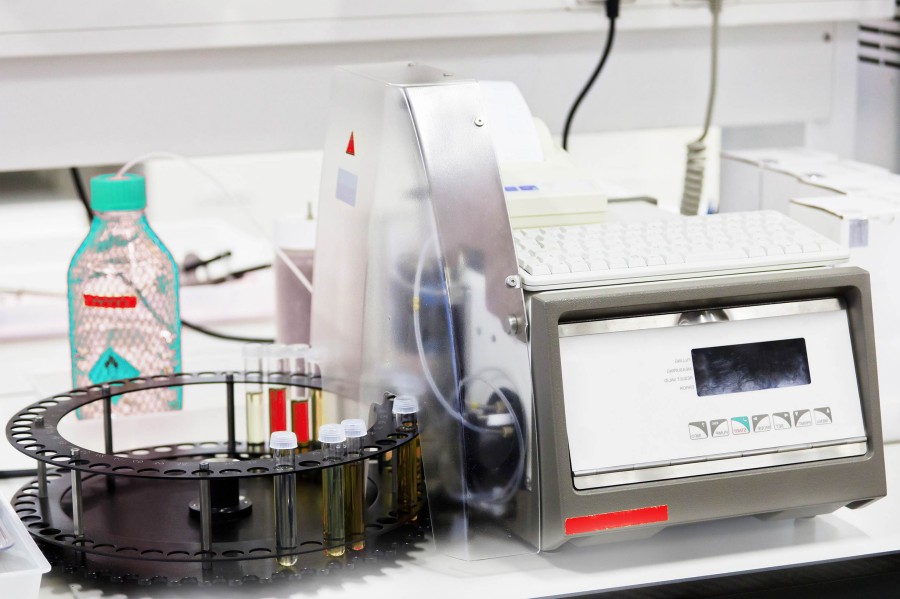

3High-Precision Preparation Platform

- Microfluidic chip systems (particle size controllable within ±5%)

- Spray-drying and electrospray systems (suitable for nano/microscale products)

- Batch dropping systems (suitable for pilot and scaled-up production)

4Alginate Beads Production

- Laboratory preparation (milliliter–liter scale) for formulation development and performance characterization

- Pilot and scale-up production (10–100 L scale) for process verification and material evaluation

- Customized large-scale production with automated control systems to ensure uniform particle size and batch consistency

Characterization

Analysis and Quality Assurance of Alginate Beads

We have established a comprehensive set of testing standards covering physical properties, chemical composition, mechanical performance, and biocompatibility to ensure each batch of beads meets client requirements for drug delivery, tissue engineering, and biomimetic material applications. Using multidimensional characterization methods, such as particle size analysis, infrared spectroscopy, and rheological testing, we provide full-process quality tracking and data support from raw material evaluation to final product inspection.

| Category | Testing Item | Purpose |

|---|

| Physicochemical Properties | Particle Size Distribution | Evaluates the uniformity and dispersion of alginate beads to ensure consistent drug release and kinetic behavior. |

| BET Surface Area & Porosity Analysis | Determines the adsorption properties and pore structure of the beads, important for controlling drug loading and diffusion performance. |

| Moisture Content & Swelling Ratio | Measures the water absorption capacity and gel stability, essential for alginate hydrogel beads. |

| Chemical Composition & Crosslinking Structure | FTIR Spectroscopy | Confirms chemical bonding between alginate and crosslinkers (e.g., Ca²⁺, chitosan, gelatin, PVA, etc.). |

| Elemental Analysis (Ca²⁺, Na⁺ Content) | Quantifies ion composition in calcium alginate beads and sodium alginate beads to ensure formulation accuracy. |

| NMR Analysis | Characterizes alginate molecular integrity and the effects of chemical modifications. |

| Mechanical & Rheological Properties | Compressive Strength and Elastic Modulus | Evaluates bead stability under mechanical stress—particularly important for tissue scaffolds and cell encapsulation applications. |

| Rheological Testing | Analyzes the viscoelastic properties of alginate gels to optimize alginate beads protocol and processing conditions. |

| Morphological & Structural Characterization | Scanning Electron Microscopy (SEM) | Observes surface morphology, pore structure, and encapsulation homogeneity of alginate beads. |

| Optical Microscopy | Rapidly assesses shape and uniformity during making alginate beads processes. |

| Drug Delivery Performance | Drug Loading & Encapsulation Efficiency | Measures the efficiency of drug incorporation for alginate beads drug delivery applications. |

| In Vitro Release Profile | Studies drug release kinetics of alginate gel beads under various environmental conditions. |

| Biological Evaluation | Biodegradability Test | Assesses degradation behavior of alginate beads in biological or simulated environments. |

| Cytocompatibility & Cytotoxicity Evaluation | Ensures material safety and biocompatibility, critical for biomedical and drug delivery applications. |

Advantages

Custom Alginate Beads Solutions – Service Benefits

- Full-Process Customized Support: From alginate raw material selection to bead formation and functionalization, we provide end-to-end customization to meet research, development, and industrialization needs.

- Capability in Diverse Alginate Bead Development: Experienced in preparing multiple types of beads, including calcium alginate beads and sodium alginate beads, allowing flexible adaptation to different application scenarios.

- Strict Quality Control System: Leveraging advanced analytical platforms, we have established a comprehensive testing system covering particle size, chemical composition, crosslinking structure, and bioperformance to ensure batch stability and traceability.

- High Reproducibility and Scale-Up Capability: We have optimized the alginate beads production process to ensure laboratory-scale preparation conditions can be reliably scaled to pilot and industrial production.

- Flexible Project Collaboration and Rapid Response: One-on-one technical support and project management ensure fast response to client needs, enabling efficient project advancement and outcome translation.

- Comprehensive Technical Documentation and Data Reports: Detailed process records, analytical reports, and technical analyses are provided for each project to facilitate research, regulatory submission, and production documentation.

Service Process

BOC Sciences Alginate Beads Full-Service Process

During alginate beads preparation and development, BOC Sciences provides full-process services from concept design to deliverables. Combining advanced polymer chemistry, process development expertise, and strict quality control, we offer efficient, controllable, and traceable project implementation. A typical service workflow includes six main stages:

1Requirement Analysis and Project Evaluation

We communicate closely with clients to define bead application goals, functional requirements, and scale. Preliminary feasibility assessments enable the design of personalized R&D plans for different types of calcium alginate beads, sodium alginate beads, or composite beads, ensuring alignment with project objectives from the outset.

2Raw Material Selection and Formulation Design

High-purity sodium alginate, chitosan, gelatin, collagen, or PVA is selected based on project needs. Optimal ratios and crosslinking systems are designed, with laboratory validation of bead structure, particle size, and mechanical properties to ensure batch consistency and reproducibility.

3Bead Preparation and Process Optimization

Bead formation is performed via dropwise method, spray gelation, or microfluidic techniques. Particle size, pore structure, and crosslinking density are optimized according to client requirements to meet functional demands for alginate beads drug delivery or tissue engineering applications while ensuring process controllability and scalability.

4Functionalization and Composite Modification

For specific applications, beads can be combined with chitosan, gelatin, collagen, PVA, or nanomaterials to create multifunctional alginate hydrogel beads or nanocomposite beads. Custom solutions for drug loading, controlled release, biomimetic scaffolds, or magnetic responsiveness are provided.

5Analysis, Characterization, and Quality Control

Completed beads undergo comprehensive testing, including particle size distribution, porosity, mechanical properties, chemical composition, and biocompatibility. Detailed alginate beads protocols and analytical reports are provided to ensure every batch meets client standards and research or industrial application requirements.

6Project Delivery and Technical Support

Upon project completion, full process documentation, analytical data, and usage guidance are provided. Continuous technical support, problem diagnosis, and process optimization are available for subsequent experiments or industrial production, ensuring bead stability and high performance in application.

Applications

Major Applications of Alginate Beads

Alginate beads, due to their controllable pore structure, excellent biocompatibility, and mild preparation conditions, are core tools in biomimetic material development. By adjusting bead type, crosslinking method, and composite functionality, precise simulation of cellular environments, drug delivery, and biofactor modulation can be achieved. BOC Sciences provides full-process services from bead preparation and functional modification to analysis and characterization, offering reliable technical support for biomimetic material innovation.

Tissue Engineering and Regenerative Medicine

Calcium alginate beads and alginate–collagen beads serve as three-dimensional cell scaffolds, mimicking the natural extracellular matrix. Controllable pore structures provide adhesion and proliferation space for stem cells or adult cells while supporting differentiation and tissue formation, widely used in soft tissue, bone, skin repair, and regenerative medicine scaffold studies.

3D Cell Culture and Cell Encapsulation

Alginate hydrogel beads can encapsulate cells in a 3D environment, maintaining morphology and function. By adjusting bead size and crosslinking density, a stable culture space is provided for stem cell expansion, differentiation induction, and functional evaluation, commonly used for biomimetic tissue models and in vitro drug screening systems.

Biomimetic Drug Delivery Systems

Sodium alginate beads and chitosan–alginate beads can be loaded with drugs and provide controlled release. By adjusting bead porosity and crosslinking, drug release rates can be modulated. Beads protect active molecules from degradation, extend release duration, and enable targeted delivery, widely used in drug delivery and bioactive substance transport systems.

Biofunctional Scaffolds

Alginate beads combined with gelatin, PVA, or nanomaterials offer tunable mechanical properties and specific responsive functions. These beads can construct smart scaffolds or biomimetic materials, simulate tissue mechanics, support cell adhesion and proliferation, and provide temperature, pH, or magnetic responsiveness, enabling high-fidelity scaffold and functional material development.

Biomimetic Environmental Simulation

Alginate gel beads can simulate natural microbial culture or enzyme reaction environments. By adjusting bead porosity and diffusion characteristics, controlled substance release and environment regulation are achieved, reproducing physiological or natural conditions. These models support nutrient delivery, enzyme immobilization, microbial behavior studies, and complex reaction system biomimetic experiments.

Multifunctional Composite Biomimetic Systems

Nanocomposite alginate beads incorporate nanomaterials, proteins, or biofactors to enhance mechanics, signaling, or environmental responsiveness. These multifunctional beads support complex biomimetic material construction, enabling design of intelligent drug carriers, functional scaffolds, or responsive materials, meeting the multidimensional requirements of high-performance biomimetic systems.

FAQs

Frequently Asked Questions

-

What are alginate beads?

Alginate beads are three-dimensional spherical hydrogel structures primarily composed of alginate, formed through ionic crosslinking, covalent crosslinking, or composite gelation. They feature a highly hydrated and permeable internal network capable of encapsulating drugs, enzymes, cells, or other functional substances. Structurally, the carboxyl groups on alginate chains coordinate with divalent metal ions (e.g., Ca²⁺, Ba²⁺) to form an "Egg-box structure," creating a stable gel network. This structure provides excellent biocompatibility, mild preparation conditions, high porosity, controllable permeability, and superior encapsulation and tunable release properties, making alginate beads one of the most representative natural polymer microcarrier systems.

-

How to make alginate beads?

Alginate beads are formed primarily through ionic crosslinking. In common systems, an alginate solution is dropped into a divalent metal ion-containing solution (e.g., CaCl₂), where the metal ions coordinate with the G units of the alginate chain, forming a stable 3D gel network. This mild and controllable process avoids organic solvents or high temperatures, suitable for embedding active substances and producing biomaterials. Common preparation methods include dropwise addition, emulsion–gelation, spray drying, aerogel formation, electrospray, or microfluidic techniques.

-

How to make calcium alginate beads?

Calcium alginate beads are typically prepared by dropping a sodium alginate solution into a calcium-containing crosslinking solution to form gel spheres. By adjusting alginate concentration, droplet speed, crosslinker concentration, and reaction time, bead diameter, pore structure, and mechanical properties can be controlled, suitable for drug carriers or cell encapsulation.

-

How to make sodium alginate beads?

Sodium alginate beads are generally prepared using divalent cations (e.g., Ca²⁺) as crosslinkers. Sodium alginate solution is slowly dropped into the crosslinking solution, and by adjusting alginate concentration, addition rate, and crosslinking time, beads of different sizes, uniformity, and mechanical performance can be obtained for drug delivery or cell encapsulation.

-

What are alginate hydrogel beads?

Alginate hydrogel beads are hydrogel microspheres composed primarily of alginate, formed through ionic crosslinking. They offer high biocompatibility, well-defined pore structure, and controllable degradation, suitable for drug delivery, cell encapsulation, tissue engineering, and biomimetic material research, serving as an important carrier for constructing biomimetic microenvironments.

-

What are chitosan alginate beads?

Chitosan alginate beads are multilayered beads formed by combining alginate beads with chitosan, offering biocompatibility and controlled release properties. Chitosan enhances bead mechanical strength and surface functionality, making them suitable for drug sustained release, cell encapsulation, and tissue engineering, meeting diverse biomimetic and drug delivery system needs.

-

What is an alginate beads protocol?

An alginate beads protocol typically includes several key steps: preparing an appropriate alginate solution free of bubbles, preparing a crosslinking solution (e.g., containing calcium ions) for stable 3D gel network formation, forming beads via dropwise, spray, or microfluidic methods, crosslinking for a set duration, and washing to remove residual ions before drying or storage. Depending on the intended application, parameters such as alginate concentration, addition rate, crosslinking time, and temperature can be adjusted to control bead size, pore structure, mechanical properties, and functionality, suitable for drug delivery, cell encapsulation, and tissue engineering.

-

What are alginate beads uses?

Alginate beads are used for drug sustained release, cell encapsulation, enzyme immobilization, tissue engineering scaffolds, and functional biomimetic materials. By adjusting porosity, particle size, and degradation rate, they enable drug protection, cell support, and environmental simulation, providing a versatile platform for pharmaceutical, food, and biomaterial applications.