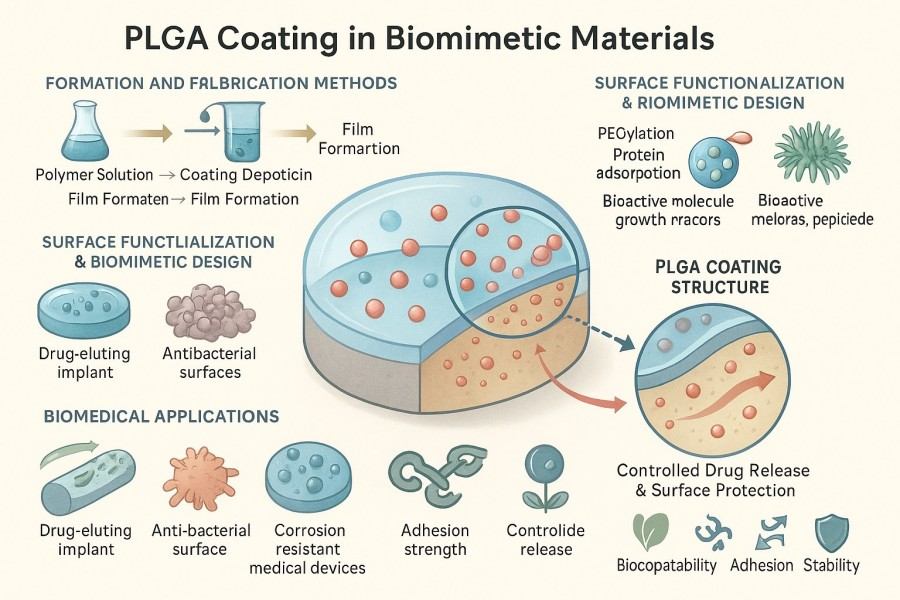

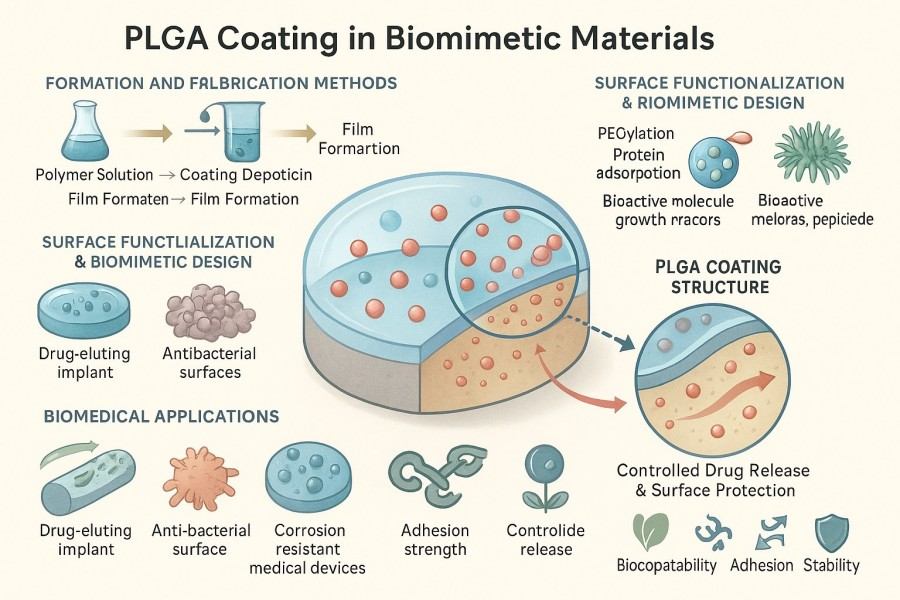

PLGA coating, also known as poly(lactic-co-glycolic acid) (PLGA) coating, is a surface modification technology based on biodegradable polymers. PLGA coatings form uniform thin films on medical devices, drug carriers, particles, or scaffolds, enabling controlled drug release, improved biocompatibility, and enhanced material performance. Due to their excellent biodegradability, tunable degradation rates, and strong drug-loading capacity, PLGA coatings have become a major focus in biomedical research. BOC Sciences offers end-to-end PLGA coating preparation and synthesis services, covering formulation design, process optimization, and functionalization development. We customize coating thickness, molecular weight ratios, and composite functionalities according to client requirements, enabling multifunctional applications such as controlled drug release, antimicrobial protection, growth factor loading, and smart responsive release, supporting material performance optimization and rapid project implementation.

What We Offer

Discover Advanced PLGA Coatings for Your Projects

BOC Sciences provides a full range of customized PLGA coating services. Whether for drug release, bioactivity, antimicrobial protection, or composite material development, we design coating formulations, preparation processes, and functionalization strategies according to specific application needs, helping clients optimize material performance and practical applications. The main PLGA coating categories and our targeted services are described below:

Drug-Eluting PLGA Coating

- Customizable loading of small-molecule drugs, proteins, or peptides for localized sustained release.

- Adjustable PLGA lactic/glycolic acid ratios and molecular weight for release cycles ranging from days to months.

- Multiple preparation methods such as dip-coating, spray-coating, and solvent evaporation to ensure uniformity and reproducibility.

- Support for multi-layer or composite coatings to achieve combined controlled release functions.

Bioactive PLGA Coating

- Capable of loading growth factors, cell-adhesion peptides, or anti-inflammatory agents to enhance material biofunctionality.

- Offers porous structures and nanofiber coatings to improve cell adhesion and proliferation environments.

- Supports layer-by-layer assembly or composite coating development for multifunctional materials.

- Customizable local degradation rates and bioactive release profiles based on client requirements.

Antimicrobial PLGA Coating

- Encapsulation of antibiotics, silver ions, or natural antimicrobial agents to reduce implant infection risk.

- Customizable drug loading and release rates to meet various surgical or device applications.

- Available in uniform coatings, nanofiber coatings, and porous coatings.

- Supports composite development with anti-inflammatory, controlled-release, or targeted coatings for multifunctional protection.

Particle & Nanocarrier PLGA Coating

- Coating for microspheres, nanoparticles, or lipid particles to enhance stability and drug loading.

- Supports targeted modification or ligand conjugation for precise drug delivery.

- Offers services for drug loading, surface functionalization, and multi-layer coating development.

- Tunable degradation rates and release characteristics to suit different treatment timelines.

Medical Device & Scaffold PLGA Coating

- Coating on metal or polymeric scaffolds to enhance biocompatibility and mechanical protection.

- Can load drugs, antimicrobial agents, or growth factors for local therapeutic effects.

- Multiple preparation methods including spray-coating, dip-coating, and electrospinning to accommodate complex device shapes.

- Supports multifunctional composite coatings combining controlled release, antimicrobial, and bioactive properties.

Composite PLGA Coating

- PLGA can be combined with hydroxyapatite (HA), metal nanoparticles, or other polymers (PEG, chitosan, gelatin).

- Supports co-loading of drugs, antimicrobial agents, or growth factors for multifunctional controlled release.

- Multiple preparation techniques available, including layer-by-layer assembly and electrospun composite nanofibers, adaptable to different applications.

- Coating structure, thickness, and degradation rate can be customized for precise material design.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

End-to-End PLGA Coating Design and Synthesis Services

With advanced polymer synthesis technology and extensive development experience, BOC Sciences provides high-quality, full-process PLGA coating development and synthesis services. We design coating formulations, optimize preparation processes, and offer functionalization and performance testing support to ensure optimal results in drug release, tissue engineering, and medical device applications.

1Coating Formulation Customization and Design

- Design PLGA lactic/glycolic ratios and molecular weights for controllable degradation and drug release cycles based on client needs.

- Provide optimization for drug loading and bioactive molecules (e.g., growth factors, antimicrobial agents).

- Support composite coating design, such as PLGA-ceramic or PLGA-metal oxide multifunctional composites.

- Customize coating structure and thickness for various applications, including microspheres, nanoparticles, scaffolds, or device surfaces.

2Multiple Preparation Process Development

- Offer dip-coating, spray-coating, solvent evaporation, electrospinning, and layer-by-layer assembly methods.

- Optimize process parameters to ensure coating uniformity, adhesion, and stable drug distribution.

- Support single-layer or multi-layer composite coatings to meet complex functional requirements.

- Provide small-batch trial production and industrial-scale transition support for mass production.

3Coating Functionalization and Surface Modification

- Surface charge modification: Adjust coating surface charge to enhance cell adhesion or drug adsorption.

- Hydrophilicity modification: Introduce PEG chains to increase hydrophilicity and reduce nonspecific protein adsorption.

- Bioactive molecule modification: Load growth factors or ligands for targeted delivery or enhanced selective adhesion.

- Multifunctional composite modification: Combine charge, PEG, and bioactivity for controlled release, antimicrobial, and targeting functions.

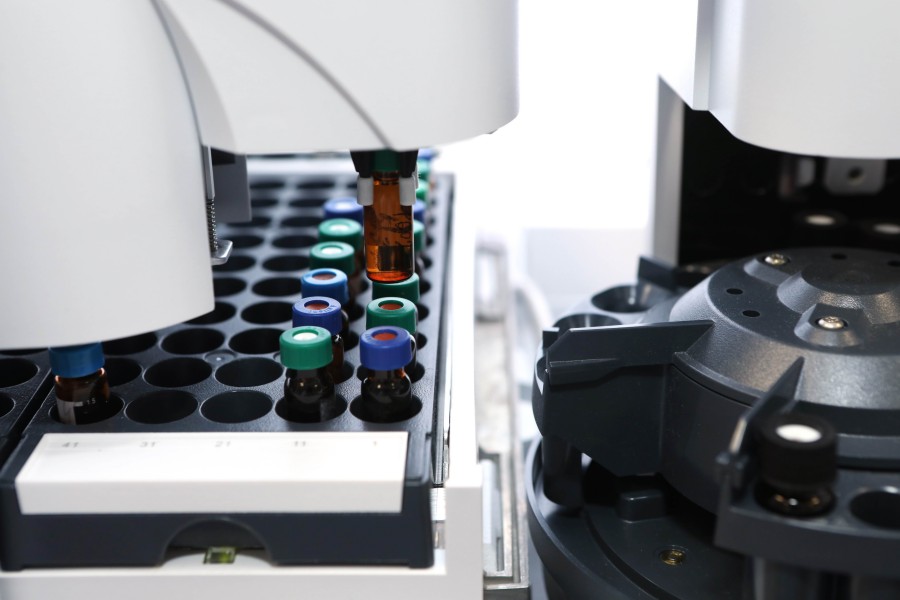

4Surface Analysis and Characterization Services

- Coating surface morphology, roughness, and porosity characterization (SEM, AFM, etc.).

- Chemical composition and functional group analysis (FTIR, XPS, NMR, etc.).

- Coating thickness and uniformity measurements to ensure process stability.

- Quantitative analysis of drug loading and release performance (HPLC, UV/Vis, etc.).

Advantages

Benefits of Choosing BOC Sciences for PLGA Coatings

- Customized Solutions: Design PLGA molecular weight, lactic/glycolic acid ratio, and coating thickness according to client-specific requirements, enabling precise control of drug release and functionalized surface customization to meet performance needs across different materials and applications.

- Multiple Preparation Techniques: Provide various coating methods including dip-coating, spray-coating, electrospinning, and layer-by-layer assembly. Optimal processes are selected based on substrate shape, structural complexity, and functional requirements to achieve high uniformity and reproducibility.

- Strict Quality Control: Equipped with advanced analytical instruments such as HPLC, FTIR, NMR, SEM, and TGA to monitor raw materials, coatings, and final products throughout the process, ensuring consistent coating thickness, uniformity, and functional performance, thereby guaranteeing material reliability and safety.

- Full-Process Development Support: From PLGA coating design, drug loading, and functionalization development to degradation performance and release profile evaluation, we provide one-stop technical services to help clients smoothly transition from R&D to application.

- Multifunctional Composite Coating Development: Support customization of PLGA coatings with antibacterial, anti-inflammatory, growth factor loading, and targeted delivery capabilities, integrating multiple functions to meet complex biomedical or drug delivery system requirements.

- Rapid Response and Small-Batch Validation: Quickly provide small-batch coating preparation and performance verification to meet laboratory R&D, pilot production, and preclinical testing needs, accelerating project development and reducing R&D risks.

Service Process

How We Develop High-Performance PLGA Coatings?

BOC Sciences follows strict scientific and industrial standards in PLGA coating development, covering the full process from requirement discussion to scaled-up production, ensuring each step meets material performance and application needs. The main workflow includes:

1Requirement Discussion and Evaluation

- Clients provide information on material type, coating function, drug loading, and application scenario.

- Feasibility assessment and technical solutions are provided to ensure a rational and achievable project design.

- Potential challenges and risks are analyzed, with optimization strategies proposed for informed development.

- Project communication mechanisms are established to align R&D teams with client objectives, improving development efficiency.

2Coating Design and Formulation Optimization

- Design PLGA molecular weight, lactic/glycolic acid ratio, and coating thickness based on functional requirements to achieve precise controlled release and degradation.

- Optimize drug loading and composite factor ratios for uniform and stable release.

- Select suitable formulations and preparation processes according to substrate type and application scenario to improve adhesion and mechanical performance.

- Conduct small-scale trials and simulation tests to validate formulation feasibility and adjust as necessary.

3Preparation and Preliminary Verification

- Choose appropriate methods such as dip-coating, spray-coating, electrospinning, or layer-by-layer assembly to ensure coating structure and functionality.

- Conduct preliminary verification of coating thickness, uniformity, surface morphology, and mechanical properties to ensure process control.

- Test drug distribution and preliminary release performance to evaluate coating functionality.

- Adjust processes based on verification results to meet R&D objectives.

4Functional Evaluation and Performance Testing

- Systematically assess drug release profiles, degradation rates, and biocompatibility to ensure coating safety and efficacy.

- Perform antibacterial, anti-inflammatory, or targeting performance tests as required to validate functionality.

- Provide detailed testing data and analysis reports as references for optimization and industrial development.

- Support clients in verifying performance under real biomimetic material or medical device application scenarios.

5Optimization and Scale-Up Development

- Optimize formulations and processes based on test results to enhance coating performance and stability.

- Support small-batch validation to provide technical and data foundations for industrial production.

- Assist clients in smooth transition from laboratory R&D to pilot and mass production, ensuring consistent coating performance.

- Provide process parameters and operational guidelines to maintain quality control during batch production.

6Technical Support and After-Sales Service

- Provide preparation process parameters, operational guidance, and project technical consultation to help clients complete coating development successfully.

- Offer recommendations for coating improvement and upgrading to support ongoing optimization and new applications.

- Deliver comprehensive after-sales support throughout the project to address technical issues in usage or processes.

- Establish long-term cooperation mechanisms to ensure sustained success in PLGA coating applications.

Applications

Explore the Wide Applications of PLGA Coatings

Due to its excellent biodegradability, biocompatibility, and controllable drug release, PLGA coating has become a core technology in biomimetic material research and applications. Through surface functionalization and composite coating design, PLGA coatings not only optimize material structure and mechanical properties but also enable precise delivery of drugs, antimicrobial agents, and growth factors. BOC Sciences leverages extensive polymer chemistry and biomaterial development experience to provide tailored coatings for tissue engineering scaffolds, medical devices, microsphere nanocarriers, and other biomimetic materials, enhancing functionality and facilitating practical applications.

Drug Release and Local Delivery

PLGA coatings encapsulate drugs on substrate surfaces for sustained or delayed release. Examples include:

- Antibiotic coatings: PLGA layers loaded with antibiotics on orthopedic implants prevent surgical site infections.

- Anti-cancer drug coatings: Chemotherapy drug coatings on scaffolds or microspheres enable high local drug concentrations at tumor sites.

- Anti-inflammatory drug release: PLGA coatings on cardiovascular stents reduce inflammatory responses.

Tissue Engineering and Regenerative Medicine

PLGA coatings improve scaffold cell adhesion and growth environments:

- Bone tissue engineering: Coated scaffolds carrying growth factors (e.g., BMP) promote bone regeneration.

- Cartilage regeneration: PLGA coatings enhance scaffold wettability and porosity to support chondrocyte growth.

- Skin and vascular scaffolds: Controlled degradation rates allow scaffolds to gradually degrade during tissue repair.

Medical Device Surface Modification

PLGA coatings modify metal or polymeric device surfaces to improve biocompatibility and functionality:

- Cardiovascular stent coatings: Delay thrombosis formation and promote endothelial cell coverage.

- Catheter and sensor surfaces: Reduce protein adsorption and inflammatory responses.

- Degradable surgical instruments: Enable surface drug release and self-degradation functions.

Particle and Nanocarrier Coating

PLGA coatings modify microspheres, nanoparticles, or lipid particle surfaces:

- Drug nanocarriers: Enhance nanoparticle stability and control drug release.

- Vaccine delivery systems: Protect antigens and improve immunogenicity.

- Targeted drug delivery: Conjugation with ligands or antibodies enables site-specific delivery.

FAQs

Frequently Asked Questions

-

What is PLGA coating?

PLGA coating is a biodegradable film formed by copolymerizing polylactic acid (PLA) and polyglycolic acid (PGA) to modify material surfaces, providing controlled degradation rates, drug loading, and local release capabilities. Key features include:

Biodegradability: PLGA gradually hydrolyzes into lactic acid and glycolic acid in body fluids, which can be metabolized, reducing long-term implantation risks.

Excellent Biocompatibility: Suitable for cell culture, tissue engineering, and drug delivery without significant toxicity.

Controlled Degradation and Release: By adjusting lactic/glycolic ratios, molecular weight, and coating thickness, degradation cycles and drug release profiles can range from days to months.

Multifunctional Potential: Can load small molecules, large proteins, peptides, or antimicrobial agents while providing controlled release and surface functionalization.

PLGA coatings are suitable not only for medical device surfaces but also for microspheres, nanoparticles, scaffolds, and membrane structures, meeting diverse biomimetic material requirements.

-

What are chitosan coated PLGA nanoparticles?

Chitosan coated PLGA nanoparticles are polymeric nanoparticles where PLGA (poly(lactic-co-glycolic acid)) forms the core, and chitosan, a natural cationic polymer, forms the outer layer. This coating enhances biocompatibility, provides positive surface charge for improved cellular uptake, and allows for controlled drug release. They are widely used in drug delivery, gene therapy, and targeted therapies due to their ability to protect drugs, improve stability, and facilitate mucoadhesion, making them a versatile platform in pharmaceutical and biomedical applications.

-

How does antibacterial coating PLGA work?

Antibacterial coating PLGA integrates antimicrobial agents, such as silver nanoparticles or antibiotics, into a PLGA polymer matrix. This coating slowly releases the antibacterial agents at the surface, inhibiting bacterial adhesion and biofilm formation. It is commonly applied in medical devices, implants, and wound dressings to reduce infection risks. By combining the biodegradable properties of PLGA with the antibacterial function, it ensures sustained protection while gradually degrading without leaving harmful residues.

-

What are the benefits of antimicrobial PLGA coating?

Antimicrobial PLGA coating offers long-term protection against bacterial contamination by slowly releasing embedded antimicrobial agents. It prevents biofilm formation, reduces the risk of infections on medical devices, and improves patient safety. The PLGA matrix ensures controlled degradation, biocompatibility, and minimal cytotoxicity. Applications include orthopedic implants, catheters, and tissue engineering scaffolds, where combining mechanical support with antimicrobial functionality enhances clinical outcomes and extends device longevity.

-

Why use magnetic nanoparticles coated with PLGA?

Magnetic nanoparticles coated with PLGA combine the magnetic properties of iron oxide or other magnetic cores with the biocompatible, biodegradable PLGA shell. This coating enhances stability, prevents aggregation, and allows for drug loading or surface functionalization. Such nanoparticles are widely used in targeted drug delivery, hyperthermia cancer therapy, and MRI contrast enhancement, where magnetic guidance or imaging is required. The PLGA coating ensures controlled release and improved circulation time in biological systems.

-

What is PLGA PEG coating and its advantages?

PLGA PEG coating involves modifying PLGA nanoparticles with polyethylene glycol (PEG), a hydrophilic polymer. This PEGylation improves particle solubility, reduces protein adsorption, and prolongs circulation time in the bloodstream. PEG-coated PLGA nanoparticles are commonly used for drug delivery, gene therapy, and vaccine delivery, as they enhance bioavailability and reduce immune recognition. The combination of PLGA's biodegradability and PEG's stealth properties creates an efficient, safe, and versatile delivery system.