Gelatin Coating Preparation

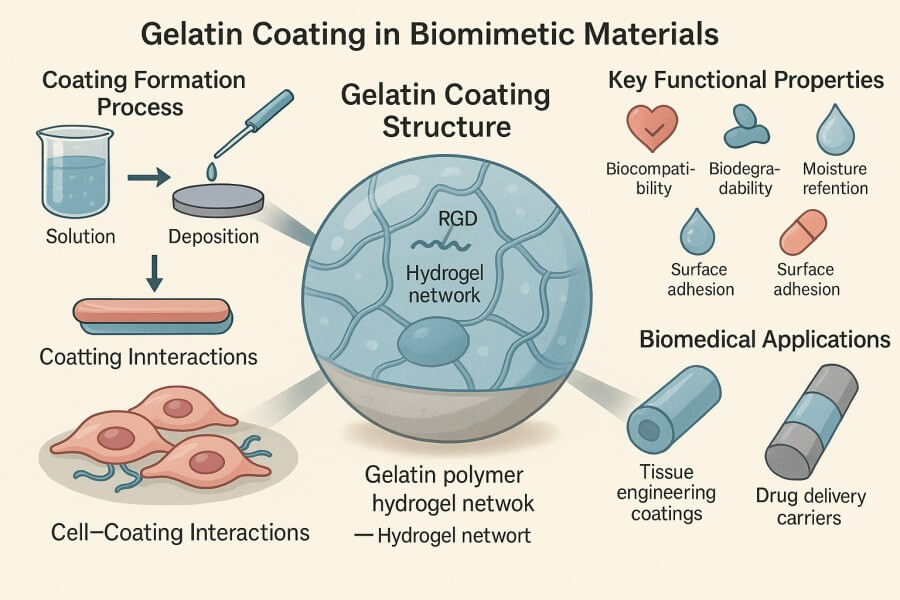

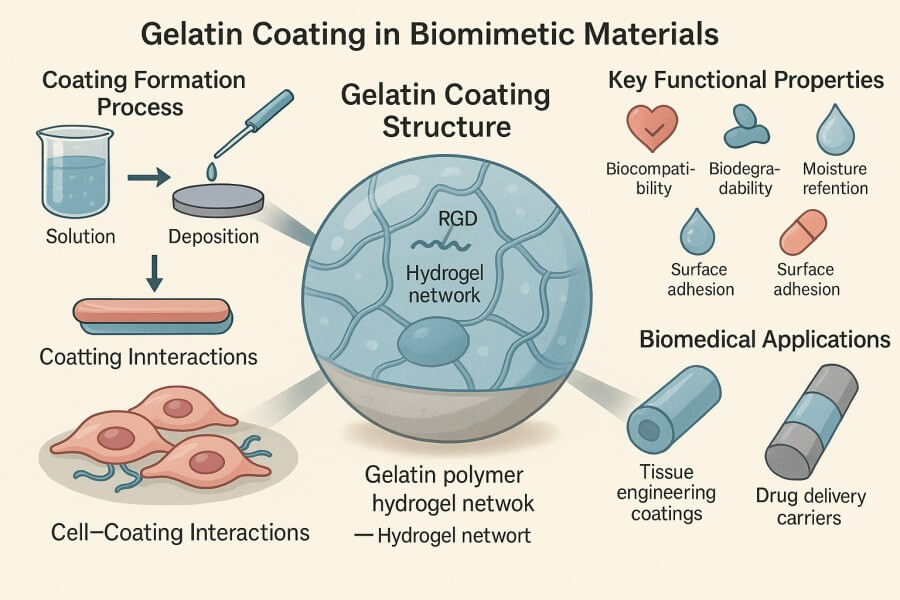

Gelatin coating refers to a thin film or encapsulation layer formed on the surface of various substrates using gelatin as the main material through physical or chemical methods. From a chemical perspective, gelatin is primarily composed of polypeptide chains and contains abundant amino acid residues, such as glycine, proline, and hydroxyproline. These amino acid residues impart tunable physicochemical properties to gelatin, enabling the formation of stable coatings on different substrates via solution coating, spraying, dipping, drying, and other processes. With its natural polymer characteristics, biocompatibility, biodegradability, and unique gel-forming ability, gelatin coating has become a key choice for surface modification and functionalization of biomimetic materials. BOC Sciences focuses on providing high-quality, customized gelatin coating preparation and development services, assisting research institutions, industrial enterprises, and biomaterials developers in achieving high-performance surface modification, drug carrier development, and functional material construction. Our gelatin coating services cover the full process, from material selection and preparation technology development to performance evaluation and functional optimization, ensuring scientific, reproducible, and scalable solutions for our clients.

What We Offer

Gelatin Coating Solutions Offered by BOC Sciences

BOC Sciences provides a full range of gelatin coating services, from basic pure gelatin to multifunctional composite coatings. Customized coating solutions are designed based on the client's material type, application scenario, and performance requirements, ensuring optimal protection, sustained release, mechanical performance, and biocompatibility.

Pure Gelatin Coating

- Offers multiple gelatin sources, including porcine skin, bovine bone, and fish gelatin, to meet various solubility and transparency requirements.

- Solution concentration and coating thickness can be adjusted according to application needs to achieve uniform coverage.

- Supports film, microparticle/particle forms, as well as dipping and spraying processes, suitable for food, pharmaceuticals, and basic biomimetic materials.

- Provides performance evaluation and customized functional optimization to ensure coating uniformity and biocompatibility.

Crosslinked Gelatin Coating

- Provides chemical crosslinking (glutaraldehyde, EDC/NHS) and physical crosslinking (thermal, UV) options.

- Enhances water resistance, mechanical strength, and long-term stability, suitable for medical implants and sustained-release microparticles.

- Supports surface modification of various substrates, including metals, plastics, and porous scaffolds.

- Crosslinking density can be optimized to achieve controlled degradation and functional applications according to client requirements.

Gelatin-Polysaccharide Composite Coating

- Offers composite solutions combining gelatin with polysaccharides such as chitosan, hyaluronic acid, and alginate.

- Improves antibacterial properties, bioactivity, and cell adhesion, suitable for tissue engineering and biomimetic membrane applications.

- Coating thickness, porosity, and release properties can be customized for functional design.

- Supports dipping, spraying, and nanofiber composite processes, adaptable to various material forms and applications.

Gelatin-Polymer/Nanomaterial Composite Coating

- Provides customized coatings combined with polyvinyl alcohol (PVA), nanofibers, nanoparticles, and other nanomaterials.

- Enhances mechanical properties, porosity, and functionality, enabling high surface area and porous network design.

- Suitable for drug carriers, nanoparticle encapsulation, and biomimetic scaffold development.

- Supports electrospinning, spraying, and composite coating processes for functionalization and controlled release design.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Core Services of BOC Sciences: Gelatin Coating Preparation and Development

BOC Sciences provides end-to-end services, from gelatin substrate customization and coating technology development to chemical modification and functional molecule conjugation. Our core services are designed to meet diverse client needs in material performance, functional design, and application scenarios, enabling efficient, controllable, and scalable gelatin coating solutions for research and industrial development.

1Gelatin Substrate Customization & Purification

- Offers customized choices from porcine skin, bovine bone, fish gelatin, etc., to meet different solubility and isoelectric point requirements.

- Supports high-purity gelatin preparation and impurity removal to ensure biocompatibility and experimental reproducibility.

- Molecular weight distribution and gel properties can be adjusted according to application needs to optimize coating performance.

- Flexible options for small-scale experimental customization and large-scale industrial supply.

2Coating Technology & Process Optimization

- Provides multiple preparation techniques including dipping, spraying, electrospinning, and composite coating.

- Optimizes coating thickness, uniformity, and porosity to ensure material functionality and reliability.

- Customizes coating solutions for different substrates such as metals, polymers, and particles.

- Offers process parameter optimization and reproducibility verification to enable smooth transition from laboratory to industrial production.

3Gelatin Chemical Modification & Crosslinking

- Provides chemical crosslinking (e.g., glutaraldehyde, EDC/NHS) and physical crosslinking (thermal, UV) services.

- Controls crosslinking density and polymer network structure to improve water resistance, mechanical strength, and thermal stability.

- Supports targeted modification and functional design to meet the performance requirements of sustained-release systems or bio-scaffolds.

- Offers performance evaluation and process optimization for crosslinked coatings to ensure a balance between functionality and degradability.

4Gelatin Functional Molecule Conjugation

- Allows conjugation of active molecules such as drugs, fluorescent probes, antibodies, or peptides to gelatin coatings.

- Supports controlled conjugation sites and quantities for targeted functionalization and stability optimization.

- Provides post-conjugation coating activity evaluation, biocompatibility, and release performance testing.

- Can be combined with composite coatings and nanostructure design to develop multifunctional biomimetic materials.

Characterization

Quality Control and Analytical Assurance of Gelatin Coatings

BOC Sciences provides systematic quality control and analytical services covering raw material purity, coating structure, physical properties, and biocompatibility, ensuring reproducibility, stability, and functionality. Our testing and analytical framework helps clients achieve reliable scientific validation while supporting high-standard quality requirements for industrial production.

| Test Category | Test Item | Purpose & Significance | Equipment / Method |

|---|

| Chemical & Composition Analysis | Gelatin Purity | Ensure low impurity content for biocompatibility | HPLC, UV-Vis Spectrophotometer |

| Molecular Weight Distribution | Control gel properties and mechanical performance of the coating | Gel Permeation Chromatography (GPC) |

| pH & Isoelectric Point | Ensure coating stability and suitability for different environments | pH Meter, Electrophoresis |

| Physical Properties | Coating Thickness | Control uniformity and functional performance | Microscope Measurement, Surface Profilometer |

| Mechanical Strength | Evaluate resistance to pressure, tension, and flexibility | Universal Testing Machine (UTM) |

| Surface Morphology | Analyze microstructure and porosity of the coating | Scanning Electron Microscope (SEM), Atomic Force Microscope (AFM) |

| Water Absorption/Solubility | Assess coating stability and degradability in different environments | Constant Temperature & Humidity Chamber, Water Bath, Gravimetric Analysis |

| Functional Tests | Crosslinking Degree | Ensure uniform crosslinking, optimize water resistance and release properties | FTIR Spectroscopy, UV-Vis Spectrophotometer |

| Drug/Molecule Loading Evaluation | Assess functional molecule conjugation or drug loading and release profile | HPLC, Fluorescence/UV Detection |

| Biocompatibility | Evaluate cell adhesion, proliferation, and cytotoxicity | Cell Culture, MTT/CCK-8 Assay, Fluorescence Microscopy |

| Surface & Structural Analysis | Porosity & Specific Surface Area | Control microstructure for drug release or tissue engineering scaffold applications | Nitrogen Adsorption-Desorption (BET), Micro-CT Scanning |

| Composite Uniformity | Analyze uniformity of components in composite coatings to ensure functional consistency | Energy Dispersive Spectroscopy (EDS), Fluorescence Microscopy |

Advantages

Key Benefits of Our Gelatin Coating Services

- Extensive Technical Experience: With years of experience in gelatin coating preparation and development, BOC Sciences is proficient in various techniques such as dipping, spraying, and electrospinning, capable of handling complex materials and diverse application requirements.

- Diverse Material Support: Offers porcine, bovine, and fish gelatin as well as composite polysaccharides, polymers, and nanomaterials to meet different biocompatibility, mechanical performance, and functionalization needs.

- Advanced Coating Technologies: Mastery of dipping, spraying, electrospinning, and crosslinking modification techniques, optimizing coating thickness, uniformity, and porosity to achieve high-performance coatings.

- Functional Molecule Conjugation Capability: Ability to conjugate drugs, fluorescent probes, antibodies, or peptides to the coating, enabling targeted delivery, sustained release, or functional surface design.

- Systematic Quality Control: Provides full-process quality assurance, from raw material purity and molecular weight to mechanical performance, biocompatibility, and functional testing, ensuring reproducibility and stability.

- Customized Solutions: Tailored gelatin coating strategies designed according to client application scenarios and performance requirements, supporting both laboratory development and industrial production.

- Professional Customer Support: Technical consultation, solution optimization, and experimental guidance are provided to support the entire project implementation, ensuring efficient and reliable coating development.

Service Process

Gelatin Coating Service Process Overview

BOC Sciences implements a complete, scientific service workflow, covering all steps from requirement analysis, material selection, coating preparation, functional modification, to quality assessment. Through systematic management and technical optimization, we ensure every step of the client project is controlled and reproducible, delivering high-performance, biocompatible, and customized gelatin coating solutions.

1Requirement Communication and Solution Design

Engage with clients to fully understand project applications, coating goals, functional requirements, and performance specifications. Based on this information, detailed R&D plans are developed, including material selection, coating type, processing techniques, and functional strategies, ensuring scientific and client-aligned solutions.

2Gelatin Substrate Customization and Preparation

Select appropriate gelatin sources (porcine, bovine, or fish) based on application needs and perform high-purity extraction and molecular weight optimization. Precise purification and pre-treatment processes provide high-quality, stable substrates for coating preparation, ensuring that the final coating meets designed physical and chemical performance standards.

3Coating Technology Development and Process Optimization

Integrate dipping, spraying, electrospinning, and composite coating techniques to optimize thickness, uniformity, and porosity. Through experiments and parameter adjustments, coatings achieve optimal adhesion, mechanical properties, breathability, and biocompatibility, enabling smooth transition from lab-scale to industrial production.

4Chemical Modification and Functional Conjugation

Provides various chemical modification and crosslinking methods (e.g., glutaraldehyde, EDC/NHS, thermal or UV crosslinking) to enhance coating stability and water resistance. Functional molecule conjugation is also available to attach drugs, fluorescent probes, antibodies, or peptides, enabling targeted release, sustained delivery, or specific functional designs.

5Quality Control and Performance Evaluation

After coating completion, comprehensive quality control is performed, including chemical composition analysis, molecular weight determination, coating thickness and uniformity testing, mechanical property assessment, and biocompatibility validation. Functional testing such as crosslinking degree, drug loading, and release performance is conducted simultaneously, ensuring each batch is stable, reliable, and reproducible.

6Technical Delivery and Continuous Support

Upon completion of coating development and performance verification, clients receive detailed technical reports and usage guidance. Ongoing support is provided for process optimization, functional modification, and large-scale production, ensuring long-term performance and stability of coatings in research, product development, or industrial applications.

Applications

Applications of Gelatin Coatings in Biomimetic Materials

Biomimetic materials are designed by mimicking natural biological structures or functions and are widely used in tissue engineering, drug delivery, biosensing, and functional coatings. As a naturally derived protein, gelatin offers excellent biocompatibility, biodegradability, and processability, playing a critical role in biomimetic materials. Gelatin coatings can create microenvironments similar to the natural extracellular matrix (ECM) on material surfaces, enabling precise control over cell behavior, drug release, and functional molecule delivery. Key application areas include:

Tissue Engineering and Regenerative Medicine

- Mimics natural ECM to support cell adhesion and proliferation.

- Regulates coating thickness, porosity, and crosslinking density to optimize tissue repair environments.

- Promotes growth of stem cells, fibroblasts, or chondrocytes.

- Composite polysaccharides or nanomaterials enhance mechanical strength and bioactivity.

- Suitable for skin, bone, and soft tissue regeneration applications.

Medical Devices and Implants

- Improves biocompatibility and reduces immune response risks.

- Forms a flexible protective layer on metal, ceramic, or polymer surfaces.

- Minimizes friction and inflammation between implants and tissue.

- Chemical modification can achieve antibacterial or targeted functionalization.

- Supports long-term in vivo stability.

Drug Delivery and Sustained-Release Systems

- Enables controlled drug release for improved therapeutic precision.

- Adjust coating thickness, crosslinking density, or molecular conjugation for accurate release.

- Gelatin-polysaccharide or nanoparticle composites improve drug loading efficiency.

- Applicable for oral, injectable, and local delivery systems.

- Supports effective delivery of hydrophilic or hydrophobic drugs.

Biomimetic Membranes and Functional Coatings

- Constructs selective permeability, antibacterial, or bioresponsive membranes.

- Molecular conjugation or nanoparticle composites provide optical, chemical, or biological response functionality.

- Enhances intelligent and functional performance of coatings.

- Suitable for wearable sensors and environment-responsive materials.

- Biocompatible, biodegradable, and environmentally safe.

Nanofibers and Porous Structure Materials

- Prepares electrospun nanofiber networks or porous structure materials.

- High surface area, good mechanical properties, and controllable porosity.

- Suitable for tissue scaffolds, drug carriers, and biomimetic filtration materials.

- Gelatin-nanomaterial composites can enhance conductivity, optical properties, or bioactivity.

- Supports advanced biomimetic material research and industrial applications.

In Vitro Cell Models and 3D Printing

- Constructs 3D cell culture models and 3D-printed scaffolds.

- Modulates coating composition, crosslinking method, and composite material type to simulate different tissue environments.

- Precisely controls cell behavior to create functional tissue models.

- Improves 3D-printed structure stability and biocompatibility.

- Supports drug screening, disease modeling, and tissue engineering applications.

FAQs

Frequently Asked Questions

-

What is gelatin coating?

A gelatin coating is a thin layer of gelatin applied to surfaces such as culture dishes, scaffolds, or biomaterials. It enhances cell attachment, spreading, and proliferation by mimicking aspects of the natural extracellular matrix. This coating is widely used in cell culture, tissue engineering, and biomedical research to improve surface biocompatibility and support cellular growth. Gelatin coatings can be applied in different concentrations depending on the application and desired cell behavior.

-

What is 0.1% gelatin coating solution?

A 0.1% gelatin coating solution is a dilute mixture of gelatin dissolved in sterile water or buffer at a concentration of 0.1% (w/v). This low concentration is commonly used to coat cell culture surfaces, providing a thin, uniform layer that promotes cell adhesion without excessively altering surface properties. It is particularly suitable for delicate cell types and experiments requiring minimal matrix interference while still improving attachment efficiency.

-

How is gelatin coating performed?

Gelatin coating typically involves dissolving gelatin in sterile water or buffer, sterilizing the solution, and applying it evenly to the surface to be coated. After incubation at room temperature or 37°C for sufficient adsorption, excess solution is removed, and the surface is allowed to dry or remain hydrated depending on the application. Parameters such as concentration, incubation time, and surface type are optimized to ensure uniform coverage and enhanced cell adhesion.

-

Why use gelatin coating for cell culture?

Gelatin coating improves cell adhesion, spreading, and proliferation by mimicking the extracellular matrix environment. It is particularly beneficial for primary cells or stem cells that may not attach efficiently to standard plastic or glass surfaces. The coating provides bioactive sites for integrin-mediated adhesion and supports healthy cell morphology and growth, making it widely used in tissue engineering, regenerative medicine, and in vitro cell experiments.

-

How to make a gelatin coating?

To make a gelatin coating, dissolve gelatin in sterile water or buffer at the desired concentration (commonly 0.1–1%). Sterilize the solution by filtration or autoclaving. Apply the solution evenly to the surface and incubate at room temperature or 37°C to allow adsorption. Remove excess solution and either use immediately or store the coated surface under sterile conditions. Adjust concentration and incubation time based on cell type and application.