Alginate Coating Preparation

Alginate coating refers to a continuous film formed on solid surfaces or on materials such as microspheres, films, and fibers by techniques including dipping, spraying, spray drying, spin coating, or electrodeposition. The coating can typically be ionically crosslinked using crosslinking agents (such as divalent metal ions like Ca²⁺ or Ba²⁺) to form a stable three-dimensional gel network, enhancing the surface functionality and structural stability of the material. In the field of biomimetic materials, alginate coatings have become an indispensable tool for surface modification and functionalization due to their natural origin, strong biocompatibility, tunable properties, and excellent film-forming characteristics. As a professional polymer chemical supplier, BOC Sciences leverages extensive experience in custom synthesis and analytical modification to provide full-process alginate coating preparation and development services for researchers, developers, and manufacturers, helping clients achieve project goals efficiently.

What We Offer

Alginate Coating Capabilities by BOC Sciences

Leveraging expertise in polymer chemistry and biomimetic material research, BOC Sciences offers design, preparation, and performance optimization services for various types of alginate coatings, covering both fundamental research and industrial scale-up. Through formulation design, crosslinking system regulation, and structural engineering, we deliver customized solutions for diverse application scenarios.

Sodium Alginate Coating

We customize sodium alginate coating systems according to different material substrates and application objectives to achieve optimal mechanical strength, swelling behavior, and breathability.

- Select alginate raw materials with different M/G ratios to adjust flexibility and density of the film;

- Optimize solution concentration and viscosity for uniform and smooth film formation;

- Control film thickness and porosity for drug controlled release, food protection, or biological encapsulation;

- Provide surface adhesion enhancement and drying process optimization to improve film stability.

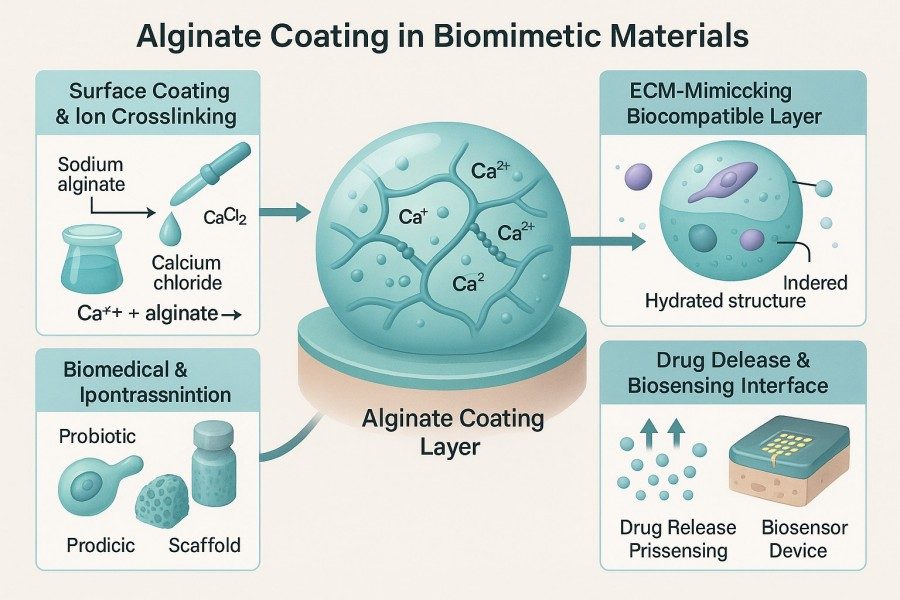

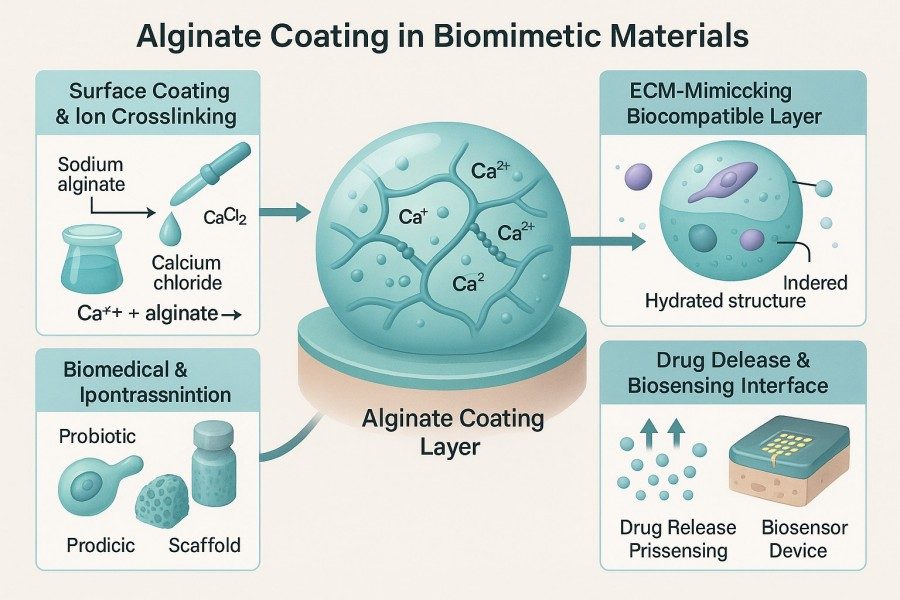

Calcium Alginate Coating

Using ionic crosslinking technology, calcium alginate coatings form structurally stable three-dimensional network films, suitable for medical protection and food packaging applications.

- Crosslink with Ca²⁺, Ba²⁺, or Sr²⁺ to adjust mechanical strength and swelling performance;

- Precisely control crosslinking time, temperature, and ion concentration to ensure uniformity;

- Prepare films with varying thickness, breathability, and humidity responsiveness;

- Support applications in drug delivery systems, cell encapsulation, and biointerface development.

Composite Alginate Coating

We can select appropriate composite ratios and crosslinking systems according to customer requirements, achieving precise control of mechanical properties, biological characteristics, and stability. Our capabilities include:

- Alginate–Chitosan: Construct layer-by-layer (LbL) cation/anion composite films with excellent antibacterial properties and stability;

- Alginate–Gelatin: Balance biocompatibility and mechanical performance for tissue engineering scaffolds and biodegradable coatings;

- Alginate–Collagen: Enhance cell adhesion and bioactivity for biomimetic skin and scaffold surface modification;

- Alginate–PVA: Improve film strength and moisture resistance for packaging materials and drug-controlled release films.

Functionalized Alginate Coating

BOC Sciences can impart specific functionalities to alginate coatings through chemical modification and surface functionalization, enabling multidimensional performance enhancement from structural protection to smart responsiveness.

- Introduce reactive groups such as carboxyl, amino, thiol, or hydroxyl to enhance binding capacity;

- Graft fluorescent tags, antibacterial agents, ligands, or targeting molecules for visualization or targeted recognition;

- Develop functional coatings responsive to pH, temperature, light, or enzymatic triggers;

- Applicable to smart drug release, biosensing, antibacterial protection, and environmentally responsive materials.

Alginate–Nanomaterial Systems

We have extensive experience in constructing alginate–nanocomposite coatings, offering nano-enhanced coating solutions for diverse functional requirements.

- Incorporate inorganic nanoparticles such as nanosilver, zinc oxide, titanium dioxide, or hydroxyapatite to enhance antibacterial properties and structural stability;

- Add graphene, nanoclay, or carbon nanotubes to improve conductivity, barrier performance, and mechanical strength;

- Optimize nanoparticle size, dispersion, and interface bonding for uniformity and functional stability;

- Widely applied in antibacterial protective films, functional packaging, sensors, and wearable devices.

Multilayer Alginate Coating

For projects requiring multifunctional composites or gradient control, we provide multilayer alginate coating preparation based on LbL or multiphase deposition techniques.

- Alternate assembly of alginate with cationic polymers such as chitosan or polylysine to build charge-controlled multilayer films;

- Precisely regulate the number of layers, thickness, and ionic strength for hierarchical functionality;

- Enable multi-level responsiveness or sequential release for smart controlled release and bioprotection systems;

- Support scale-up from laboratory to pilot-scale production and performance testing.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Custom Alginate Coating Preparation and Functionalization Services

BOC Sciences offers one-stop services from raw material selection, formulation design, functional modification to bulk production. We not only supply high-purity alginate raw materials but also design optimal coating processes for various biomimetic substrates, such as films, microspheres, fibers, or micro-scaffolds. This full-process support significantly shortens R&D cycles, reduces experimental risks, and ensures a smooth transition from laboratory development to industrial production.

1Raw Material Selection & Formulation Design

We provide alginates of various sources and structures, including high-G, high-M, mixed-type, and chemically modified alginates.

- High-G alginate: forms rigid coatings suitable for abrasion resistance and structural protection;

- High-M alginate: provides flexibility and extensibility, ideal for covering complex shapes;

- Composite alginate: balances mechanical strength and flexibility;

- Functionalized alginate: with amino, carboxyl, or thiol groups for further chemical conjugation.

2Film Formation Conditions & Crosslinking System Optimization

Precise control of alginate solution concentration, pH, temperature, and ionic system optimizes coating uniformity, adhesion, and stability.

- Ionic crosslinking systems: Ca²⁺, Ba²⁺, Sr²⁺ form "egg-box" structures;

- Covalent crosslinking systems: EDC/NHS systems enhance durability;

- Multi-component blending systems: blended with chitosan, PVA, gelatin, etc., to enhance functionality.

3Coating Preparation & Film Formation Process Design

BOC Sciences supports multiple scales and process routes:

- Dip Coating: suitable for particles, sheets, and bio-substrates;

- Spray Coating: uniformly covers complex surfaces;

- Spin Coating: achieves high transparency and controllable thickness;

- Electrospinning: prepares nanofiber membranes for tissue engineering;

- Layer-by-Layer: constructs multilayer smart-responsive structures.

4Scale-Up Production & Quality Control

BOC Sciences is equipped with pilot and industrial-scale facilities, providing:

- Scale-up from milligram to kilogram levels;

- Rigorous quality control (QC) and analytical reports;

- Stable batch-to-batch consistency and traceable process management;

- OEM and collaborative R&D modes to meet differentiated customer needs.

Characterization

Analysis and Quality Assurance for Alginate Coatings

BOC Sciences provides comprehensive analysis and quality control support for alginate coatings, ensuring that all coating types meet performance, stability, and safety standards. For different systems—including sodium alginate, calcium alginate, and composite alginate coatings—we establish a complete testing framework, from physicochemical characterization to functional performance evaluation. By integrating advanced material analysis with biocompatibility assessments, we help clients achieve precise control over coating structure, uniformity, and functionality to meet both research and industrial application requirements.

| Category | Testing Item | Purpose |

|---|

| Physicochemical Characterization | Composition Analysis (FTIR, NMR) | Determines the chemical structure and functional group integrity of alginate and its composites. |

| Molecular Weight (GPC) | Measures polymer chain length distribution to ensure reproducibility and performance consistency. |

| Elemental Analysis (ICP-OES) | Quantifies metal ion content (e.g., Ca²⁺, Ba²⁺) for ion-crosslinked alginate coatings. |

| Structural & Morphological Analysis | Surface Morphology (SEM, AFM) | Evaluates coating smoothness, porosity, and surface topology. |

| Film Thickness & Uniformity | Ensures consistent coating layer thickness for reproducible performance. |

| Crosslinking Density | Determines the degree of gelation and mechanical strength correlation. |

| Mechanical & Thermal Properties | Tensile Strength/Elastic Modulus | Assesses coating durability and flexibility under stress. |

| Thermal Stability (TGA, DSC) | Evaluates heat resistance and degradation profile of coating systems. |

| Functional Performance | Swelling and Degradation Rate | Measures hydrophilicity and biodegradability for biomedical applications. |

| Ion Release/Diffusion Test | Quantifies controlled release or permeability behavior in functional coatings. |

| Adhesion Strength | Determines coating-substrate bonding reliability under operational conditions. |

| Biocompatibility & Safety | Cytotoxicity | Evaluates cell viability and safety for biomedical coatings. |

| Protein Adsorption & Cell Adhesion | Tests biological interaction and surface bioactivity of coatings. |

| Endotoxin/Microbial Contamination | Ensures biosafety for pharmaceutical and tissue engineering use. |

Advantages

Why Choose Our Alginate Coating Services?

- Full-Process Custom Support: From alginate raw material selection and crosslinking system optimization to film formation and characterization, we provide one-on-one technical support and full-cycle development services.

- Diverse Coating Development Capabilities: Support for single-layer, composite, multilayer, microporous, nanoscale, and functional coatings to meet various biomimetic material applications.

- Customized Functional Optimization: Adjust crosslinking methods, coating thickness, and structure according to customer requirements to achieve controlled release, antibacterial, targeted, or other functional designs.

- Advanced Fabrication Platforms: Offer multiple preparation technologies, including dip coating, spray coating, spin coating, and electrodeposition, ensuring coating uniformity and performance stability.

- Rapid Small-Batch Samples: Quickly prepare laboratory or pilot-scale samples for research validation and functional testing, accelerating R&D progress.

- Professional Data Analysis & Reporting: Provide reports on coating thickness, mechanical properties, and functional evaluation to support scientific decision-making and research outcomes.

- Ongoing Customer Support: Long-term assistance with process optimization, technical upgrades, and application consultation ensures smooth project implementation from R&D to production.

Service Process

Step-by-Step Alginate Coating Service Process

Our workflow spans all stages—from requirement discussion, formulation design, and sample preparation to pilot-scale and industrial production. Combining advanced technology platforms with professional analytical methods, we ensure each project efficiently and accurately achieves its goals while minimizing R&D risks and timelines.

1Requirement Discussion

BOC Sciences engages in in-depth communication with clients to understand substrate types, application areas, coating functions, and performance requirements, clarifying project goals and scale. Through technical consultation, we identify potential challenges and propose preliminary solutions, laying a solid foundation for subsequent customized development.

2Solution Design

Based on client needs and material characteristics, we design optimal coating solutions, including selecting alginate type (high-G, high-M, or composite), coating structure (single-layer, composite, multilayer, or nanoscale), thickness control, porosity design, and crosslinking method (ionic, covalent, or hybrid). Functionalization strategies, such as controlled release, antibacterial, or targeted modification, are also evaluated at this stage.

3Sample Preparation

Small-batch samples are rapidly prepared under laboratory conditions using advanced techniques such as dip coating, spray coating, spin coating, and electrodeposition, ensuring uniform coatings with strong adhesion. Samples can be used for research validation, functional testing, or internal client review, providing foundational data for process optimization.

4Performance Evaluation

Comprehensive testing of coatings includes thickness uniformity, mechanical strength, pore structure, drug or biomolecule release characteristics, and biocompatibility. Scientific data analysis provides clients with quantifiable performance reports to support R&D decisions and subsequent process improvements.

5Process Optimization

Based on performance evaluation results, formulation ratios, crosslinking conditions, and preparation parameters are adjusted to optimize coating performance and functional behavior. Multiple iterative cycles can be conducted to ensure the final solution meets expectations in mechanical strength, stability, functionality, and degradability, providing reliable support for pilot-scale and production applications.

6Pilot-Scale & Production

Optimized processes are smoothly scaled to pilot and industrial production, ensuring coating uniformity, functionality, and product stability. BOC Sciences provides full technical support from small-batch to large-scale production, along with batch records, performance data, and process standards, facilitating a smooth transition from R&D to industrialization.

Applications

Applications of Alginate Coating in Biomimetic Materials

Alginate coatings, as natural polymer-based functional films, play an increasingly important role in biomimetic materials due to their excellent biocompatibility, tunability, and film-forming performance. Their flexible three-dimensional network can effectively encapsulate drugs, proteins, enzymes, or cells, while crosslinking methods and coating structures can be adjusted to precisely control physical properties, degradation rates, and functional activity.

Tissue Engineering & Cell Scaffolds

Alginate coatings can be applied to scaffold surfaces to provide a microenvironment for cell adhesion, proliferation, and differentiation. Specific applications include:

- Bone Tissue Engineering: Coating porous ceramics or PLA scaffolds with alginate to mimic natural bone matrix, enhancing calcification and cell adhesion.

- Soft Tissue Engineering: Applying alginate on gelatin or collagen scaffolds improves cell migration and proliferation.

- Microenvironment Regulation: Embedding growth factors (e.g., VEGF, BMP-2) within the coating for localized controlled release to promote tissue regeneration.

Drug Delivery & Controlled Release Systems

Alginate coatings can form protective layers on drug carriers for controlled release:

- Microsphere Coatings: Coating drug-loaded microspheres prolongs the in vivo half-life of therapeutics.

- Nanoparticle Coatings: Protects labile protein drugs from degradation in the gastrointestinal tract.

- Oral Delivery Systems: Crosslinked coatings provide acid-resistant layers for controlled release in the stomach or targeted release in the intestine.

Medical Devices & Biomimetic Coatings

Alginate coatings can be applied to medical devices to enhance biocompatibility and functionality:

- Catheter Coatings: Reduce bacterial adhesion and infection risk.

- Cardiovascular Stent Coatings: Enable release of antithrombotic or antiproliferative agents to reduce restenosis risk.

- Wound Dressings: Maintain a moist environment, promote healing, and enable drug delivery.

Environmental Biomimetic Materials

Alginate coatings are also used in biomimetic environmental materials, such as water treatment or biosensor surfaces:

- Biomimetic Adsorbents: Coatings can adsorb heavy metal ions or organic pollutants.

- Sensor Surface Functionalization: Coatings immobilize enzymes or antibodies for biological recognition functions.

FAQs

Frequently Asked Questions

-

What is alginate coating?

Alginate coating is a functional coating based on alginate, forming a stable film through physical adsorption or ionic crosslinking. It offers biocompatibility, controllable swelling, and excellent encapsulation capability, suitable for drug release, food preservation, biomimetic materials, and biosensors, serving both research and industrial applications.

-

What are the characteristics of sodium alginate coating?

Sodium alginate coating is primarily composed of the sodium salt form of alginate. It is water-soluble and can form stable films through ionic crosslinking or composite modification. It offers high transparency, mechanical flexibility, and controlled degradability, suitable for drug encapsulation, food protection, and biomaterial surface modification.

-

How to optimize the alginate coating process?

The alginate coating process includes solution preparation, coating, crosslinking, and drying. Optimization involves adjusting alginate concentration, solution pH, ionic crosslinking conditions, coating thickness, and drying methods to achieve uniform films, controllable porosity, desired mechanical properties, and consistent functionality for research and industrial use.

-

What is alginate edible coating?

Alginate edible coating is a food-grade alginate film applied to fruits, vegetables, seafood, etc. It slows water loss, inhibits microbial growth, and extends shelf life. Being natural, safe, and non-toxic, it can be combined with other natural polymers or functional additives for multifunctional food protection.

-

What are the applications of alginate microspheres coating?

Alginate microspheres coating encapsulates active substances in microspheres via ionic crosslinking. It is widely used for controlled drug release, enzyme protection, and cell carriers. The coating regulates release rates, enhances bioactivity stability, and can be surface-modified or combined with other materials to improve targeting and mechanical strength.

-

What are the advantages of chitosan coated alginate nanoparticles?

Chitosan coated alginate nanoparticles are alginate nanoparticles coated with chitosan. The cation/anion complex improves stability, biocompatibility, and loading efficiency, while providing controlled release, antibacterial properties, and targeting potential, making them valuable in drug delivery and functional nanomaterials.

-

How to prepare alginate coated chitosan microparticles?

Alginate coated chitosan microparticles are formed by applying an alginate layer onto chitosan microparticles. Preparation can involve ionic crosslinking, spray drying, or droplet methods to ensure uniform coverage. This coating enhances particle stability, controlled release, and biocompatibility, suitable for drug delivery, nutrient delivery, and biomimetic material development.