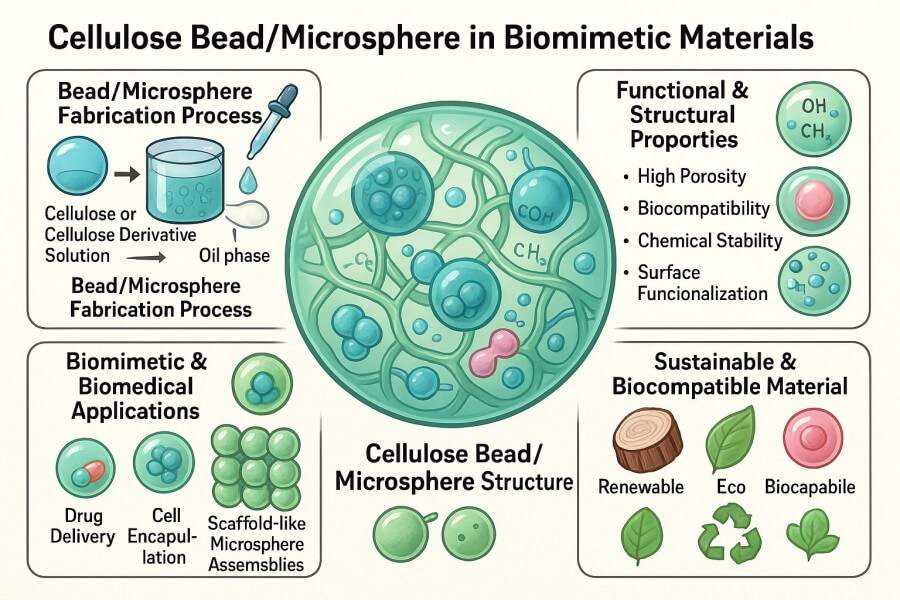

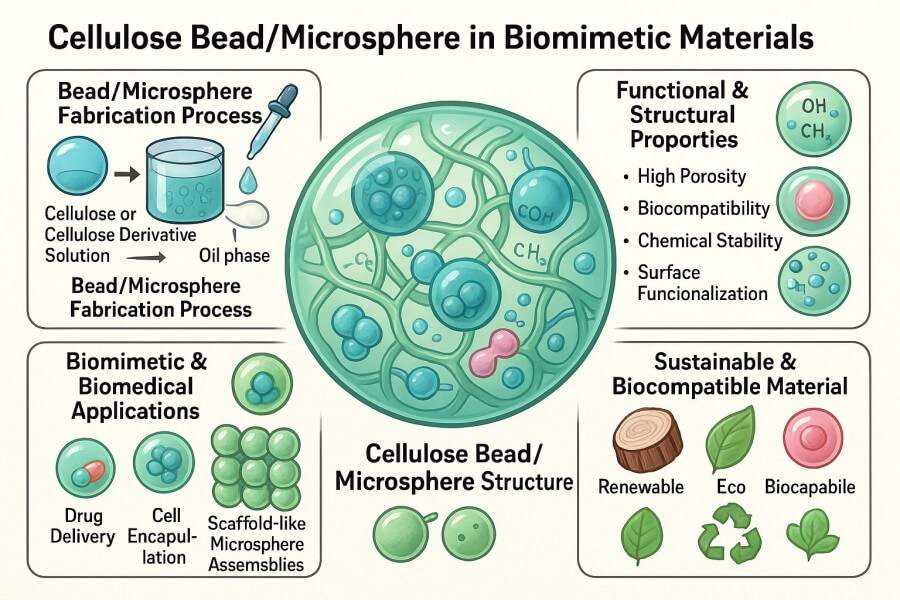

Cellulose Bead/Microsphere Preparation

Cellulose beads/microspheres are micron-sized spherical particles (typically 1–1000 μm) prepared from natural cellulose or its derivatives, such as carboxymethyl cellulose, cellulose acetate, and hydroxypropyl methylcellulose, using processes like solution phase separation, emulsion spheronization, or spray drying. These microspheres are generally classified into solid beads and porous beads. Currently, cellulose beads/microspheres are widely used in drug delivery, chromatographic separation, catalytic carriers, adsorption materials, biosensors, and tissue engineering due to their excellent biocompatibility, surface modifiability, chemical stability, and controllable pore structures. BOC Sciences offers comprehensive solutions from molecular design to material development, focusing on the preparation, performance regulation, and functionalization of cellulose beads. Our services cover a full range of products—from cellulose acetate beads to biodegradable cellulose beads, and from porous cellulose beads to magnetic cellulose beads—customizing synthesis routes and structural parameters to meet the diverse needs of biomimetic materials, pharmaceuticals, environmental, and energy applications.

What We Offer

Cellulose Beads and Microspheres Offered by BOC Sciences

BOC Sciences specializes in the customized development of cellulose beads and microspheres, supporting diverse cellulose systems and structural designs. We provide multi-dimensional solutions from raw material selection to structural tuning according to customer application requirements, including drug delivery, chromatography, biomimetic scaffolds, and catalytic carriers. Our product portfolio includes natural, modified, composite, and functionalized series, suitable for both research and industrial applications.

Natural Cellulose Bead/Microsphere

- Supports preparation via cellulose suspension, gelation, and microspherization

- Controllable particle size (100 nm–500 μm) suitable for separation and immobilization carriers

- Surface functionalization or crosslinking enhancement available

- High purity with no solvent residues, ideal for biomedical and pharmaceutical applications

Cellulose Derivative Bead/Microsphere

- Supports cellulose acetate beads, carboxymethyl cellulose, hydroxypropyl cellulose, etc.

- Hydrophilic/hydrophobic balance can be adjusted via chemical substitution

- High transparency and good mechanical properties

- Suitable for drug release and film-coating carriers

Solid Cellulose Bead/Microsphere

- Highly crosslinked, resistant to high temperature and acidic/alkaline environments

- Particle size and sphericity precisely controllable

- Supports various cellulose bead crosslinking systems

- Suitable as immobilized catalysts or filtration media

Porous Cellulose Bead/Microsphere

- Controllable pore size (5 nm–500 nm) to form porous cellulose beads

- Pore structure adjustable via phase separation or templating

- Suitable for adsorption, chromatography, and controlled drug release systems

- Supports multifunctional carrier development (composite adsorption or enzyme immobilization)

Magnetic Cellulose Bead/Microsphere

- Prepared by incorporating Fe₃O₄ or other magnetic nanoparticles

- Surface can be further modified with carboxyl, amino, or biological ligands

- Stable magnetic response enables rapid recovery and reuse

- Suitable for bioseparation, catalysis, and smart response systems

Biodegradable Cellulose Bead/Microsphere

- Constructed from natural or derivative cellulose to form biodegradable beads

- Degradation rate tunable via crosslinking degree and substitution level

- Environmentally friendly with no toxic byproducts

- Ideal for eco-materials and sustainable packaging applications

Functionalized Cellulose Bead/Microsphere

- Supports carboxylation, amination, esterification, graft copolymerization, and other modifications

- Can be conjugated with biomolecules (proteins, enzymes, antibodies, etc.)

- Enables specific adsorption, recognition, or catalytic functionality

- Widely used in bioseparation and analytical detection systems

Composite Cellulose Bead/Microsphere

- Composite with inorganic nanoparticles (e.g., SiO₂, TiO₂, Fe₃O₄)

- Supports design of cellulose bead nanoparticles and nano-reinforced systems

- Provides mechanical enhancement, optical tuning, or conductivity

- Suitable for biomimetic materials, smart response systems, and functional film development

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Custom Cellulose Bead and Microsphere Development Services

BOC Sciences offers one-stop custom development services for cellulose beads and microspheres, from material design to scale-up production. We are committed to tailoring high-performance cellulose beads, microspheres, and their modified derivatives for research institutions and industrial clients, meeting diverse demands in biomimetic materials, drug delivery, separation/purification, and catalytic carriers. Our services cover the entire process from molecular design to macroscopic material optimization, ensuring product controllability, reproducibility, and application stability.

1Material Design & Raw Material Selection

- Supports various cellulose raw materials (natural cellulose, cellulose acetate, carboxymethyl cellulose, hydroxypropyl cellulose, etc.);

- Designs biodegradable cellulose beads and cellulose hydrogel beads for degradable and eco-friendly performance;

- Precisely controls substitution degree, solubility, and molecular structure to optimize film-forming and mechanical strength;

- Designs specialty systems like magnetic cellulose beads and porous cellulose beads.

2Custom Synthesis & Particle Size Control

- Covers the full preparation process of cellulose beads (solution, suspension, emulsion, gelation);

- Customizable particle size (10 nm–500 μm), pore size, and crosslinking degree;

- Flexible morphology control (dense, hollow, porous, core–shell structures);

- Multiple crosslinking methods (chemical, ionic, physical) to enhance stability.

3Surface Functionalization & Structural Modification

- Supports various surface modifications (hydroxyl activation, graft copolymerization, esterification, etherification, etc.);

- Can conjugate biomolecules (enzymes, antibodies, ligands) for bioseparation and recognition;

- Designs porous structures with adjustable surface area to enhance adsorption performance;

- Composites with magnetic, fluorescent, or nano-components for magnetic cellulose beads or cellulose nano beads.

4Process Optimization & Scale-Up Production

- Establishes standardized synthesis workflows for cellulose beads and microspheres;

- Supports scale-up from lab to industrial level (gram to ton scale);

- Optimizes process parameters (solvent system, stirring speed, temperature, etc.) to ensure batch consistency;

- Provides process monitoring and performance testing (particle size distribution, porosity, surface area, crosslinking degree, etc.).

Characterization

Performance Analysis & Structural Verification of Cellulose Beads and Microspheres

Our analytical team is equipped with advanced material characterization instruments and quantitative analysis platforms, enabling comprehensive quality evaluation of various samples, including cellulose beads, microspheres, cellulose acetate beads, and magnetic cellulose beads. All tests comply with industry standards, ensuring batch consistency, chemical stability, and reproducibility, providing a solid quality foundation for downstream applications.

| Testing Item | Test Description | Purpose of Analysis | Applicable Sample Type |

|---|

| Particle Size and Distribution Analysis | Measurement of particle size and distribution using laser diffraction or dynamic light scattering (DLS) | Evaluate uniformity and dispersion of microspheres | All types of cellulose beads/microspheres |

| Morphology and Structural Observation | Observation via SEM or TEM | Analyze sphericity, surface roughness, and internal pore structure | Porous, solid, and nano bead series |

| Specific Surface Area and Pore Size Analysis | BET surface area and pore size distribution measurement | Characterize adsorption properties and porosity | Cellulose porous beads, functionalized beads |

| Chemical Composition and Functional Group Identification | FTIR, XPS, and elemental analysis (EA) | Confirm functional modification and chemical structure changes | Cellulose acetate beads, functionalized beads |

| Crosslinking Degree and Swelling Performance | Measurement of physical/chemical crosslinking and swelling ratio | Assess mechanical stability and solvent responsiveness | Hydrogel and crosslinked beads |

| Thermal Performance Analysis | DSC and TGA thermal analysis | Determine thermal stability and decomposition temperature | Solid beads, composite beads |

| Magnetic Property Testing | Vibrating Sample Magnetometer (VSM) measurement | Evaluate magnetic responsiveness and stability | Magnetic cellulose beads |

| Mechanical Strength and Compression Testing | Single-particle compression or fluidized bed simulation | Assess mechanical integrity and wear resistance | Solid and porous beads |

| Surface Charge and Zeta Potential Measurement | Electrophoretic light scattering measurement of surface charge | Analyze colloidal stability and surface modification efficiency | Nano beads, functionalized beads |

| Purity and Residual Analysis | GC-MS, HPLC, and ICP-MS testing for solvent or metal residues | Ensure product purity and biocompatibility | All cellulose beads/microspheres |

| Degradation and Biocompatibility Evaluation | Biodegradation and cell compatibility testing | Assess biodegradability and biological safety | Biodegradable cellulose beads |

Advantages

Key Benefits of BOC Sciences' Cellulose Bead Preparation Services

- Advanced Preparation Techniques: Mastery of various cellulose microsphere preparation methods, including emulsion polymerization, spray drying, and solvent exchange, to meet different particle size and structural requirements.

- Extensive Functionalization Experience: Expertise in surface modification, magnetization, and composite functionalization, supporting customized applications across multiple fields.

- Strict Quality Control System: Full-process quality monitoring, from raw materials to final products, complying with international standards to ensure stability and consistency.

- Multi-Dimensional Analytical Capability: Comprehensive testing of particle size, porosity, surface area, and chemical composition, providing data-supported performance verification.

- Customized Solutions: One-stop service from design and optimization to mass production, tailored to customer requirements.

- Professional Technical Support Team: Composed of experts in chemistry, materials, and biology, providing scientific guidance and problem-solving support.

- Detailed Testing Report Support: Complete testing reports for each batch, including experimental data, analysis results, and technical interpretations, ensuring transparency and traceability.

Service Process

Step-by-Step Cellulose Bead and Microsphere Preparation Process

BOC Sciences is committed to providing efficient and customizable cellulose bead/microsphere development services. Our workflow covers the full cycle from requirement assessment to batch production, ensuring that every step meets technical specifications and customer expectations while providing professional support and data feedback to accelerate research or industrialization.

1Requirement Communication & Technical Assessment

- In-depth discussion with customers on application scenarios and performance requirements;

- Evaluation of material type, particle size, pore structure, and functionalization needs;

- Provision of technical feasibility analysis and preliminary solution suggestions.

2Material Design & Raw Material Selection

- Selection of natural cellulose or derivatives according to application;

- Design of particle size range, crosslinking degree, and pore structure;

- Determination of functionalization or composite system development strategies.

3Lab-Scale Process Development

- Establishment of laboratory preparation routes (emulsion, phase separation, spray drying);

- Optimization of reaction conditions to ensure uniform particle size and stable performance;

- Evaluation of preliminary functionalization effects and physicochemical properties.

4Analysis & Performance Verification

- Testing of particle size, porosity, surface area, and chemical composition;

- Provision of structural and functional data support;

- Adjustment of formulation and process based on testing results.

5Pilot-Scale Upscaling & Optimization

- Execution of gram- to kilogram-scale scale-up experiments;

- Adjustment of reaction parameters to ensure batch consistency and stable performance;

- Verification of functionalization effects and process reproducibility.

6Mass Production & Delivery

- Industrial-scale production and packaging according to customer requirements;

- Provision of complete testing reports and performance data;

- Ongoing technical support and usage guidance to ensure optimal application.

Applications

Applications of Cellulose Microspheres in Biomimetic Materials

Due to their excellent biocompatibility, tunable structures, and multifunctional features, cellulose microspheres are an important component in biomimetic material research. They can mimic the microenvironment of natural tissues, providing controllable drug release, cell support, and molecular recognition, while offering superior adsorption, catalytic, and intelligent response capabilities. These properties enable diverse solutions in drug delivery, tissue engineering, separation and purification, and sensing.

Drug Delivery & Controlled Release Systems

- Controlled Release Carriers: Cellulose acetate beads and hydrogel beads with tunable pore size and swelling properties enable stable encapsulation and controlled release of hydrophilic or hydrophobic drugs.

- Targeted Delivery: Magnetic cellulose beads can precisely deliver drugs under an external magnetic field, improving drug concentration and bioavailability at target tissues.

- Eco-Friendly Degradation: Biodegradable cellulose beads degrade naturally after drug release, leaving no harmful residues and ensuring environmental safety.

- Multi-Functional Combination Strategies: Crosslinking regulation, surface functionalization, and nanoparticle incorporation allow for adjustable release rates and combined functionalities.

Biomimetic Scaffolds & Tissue Engineering

- 3D Cell Culture: Cellulose hydrogel beads with high water content, mechanical flexibility, and cell affinity simulate natural extracellular matrix environments, supporting adhesion, proliferation, and differentiation.

- Soft Tissue Engineering: Crosslinking degree, porosity, and elastic modulus can be tuned to design scaffolds for skin, cartilage, or muscle regeneration.

- Multi-Functional Modification: Surface functionalization with bioactive molecules (e.g., peptides or saccharides) enhances cell recognition and growth signaling.

- Injectable Microsphere Scaffolds: Beads can form 3D tissue scaffolds via injection, enabling minimally invasive procedures and in vivo applications.

Separation & Purification Media

- High-Efficiency Chromatography Carriers: Porous cellulose beads and functionalized microspheres are suitable for separation of proteins, nucleic acids, peptides, and small molecules, offering high selectivity and good flow properties.

- Surface Chemistry Control: Polarity adjustment and introduction of carboxyl, amino, or ion-exchange groups allow selective binding and elution of target molecules.

- Porous Structure Advantages: Adjustable pore size and surface area enhance adsorption capacity and mass transfer efficiency, ideal for large molecules or complex mixtures.

- Composite Functional Development: Magnetic, hydrophilic, or hydrophobic modifications enable smart separation and rapid recovery.

Catalytic & Adsorption Materials

- High-Efficiency Adsorbents: Aminated, thiolated, or phosphorylated cellulose microspheres exhibit high binding capacity for heavy metals, dyes, or organic pollutants, suitable for environmental purification and water treatment.

- Composite Nano-Catalysts: Loading metal nanoparticles or metal oxides enables cellulose bead nanoparticles to act as efficient, recyclable heterogeneous catalysts.

- Surface Function Control: Pore structure, surface groups, and particle size can be tuned to enhance exposure of catalytic sites and reaction efficiency.

- Wide Application Range: Applicable to chemical synthesis, environmental catalysis, energy conversion, and biocatalysis.

FAQs

Frequently Asked Questions

-

What are cellulose beads?

Cellulose beads are small, spherical particles made from natural or modified cellulose. They possess high surface area, excellent biocompatibility, and strong chemical stability. These beads can be engineered to carry drugs, enzymes, or other bioactive molecules. Their uniform size and porous structure make them suitable for applications in drug delivery, chromatography, cosmetics, and as adsorbents in environmental treatments.

-

How to make cellulose beads?

Cellulose beads are typically produced via methods such as emulsion crosslinking, precipitation, or phase separation. In these processes, cellulose or its derivatives are dissolved in a suitable solvent, emulsified, and then solidified into spherical beads. Parameters like temperature, stirring speed, and crosslinker concentration can be adjusted to control bead size, porosity, and surface functionality, optimizing them for specific applications like drug delivery or catalysis.

-

Are cellulose beads biodegradable?

Yes, most cellulose beads are biodegradable because they are derived from natural cellulose or cellulose derivatives. Microorganisms can enzymatically degrade them into harmless byproducts like glucose. Their biodegradability makes them environmentally friendly alternatives to synthetic polymer beads, especially in pharmaceutical, cosmetic, and environmental applications where residue accumulation must be minimized.

-

Are cellulose beads bad for the environment?

Generally, cellulose beads are considered environmentally safe because they are biodegradable and derived from renewable cellulose sources. Unlike plastic microbeads, they break down naturally without leaving toxic residues. However, environmental impact depends on bead composition and additives; modified cellulose beads with non-biodegradable crosslinkers may persist longer, so careful selection is essential for sustainable applications.

-

What are cellulose beads used for?

Cellulose beads have versatile applications across pharmaceuticals, cosmetics, food, and environmental sectors. They are widely used in controlled drug delivery, enzyme immobilization, chromatography, and adsorption of pollutants. In cosmetics, they serve as exfoliants or carriers for active ingredients. Their tunable porosity, chemical stability, and biocompatibility allow customization for specific industrial or research needs.

-

What are cellulose microspheres?

Cellulose microspheres are similar to cellulose beads but typically smaller in size, often in the micro- or nanoscale range. They provide higher surface area and better dispersion properties, making them ideal for advanced applications like targeted drug delivery, bioseparation, and tissue engineering. Their spherical shape and porous structure allow for efficient loading of active compounds and controlled release.

-

What are cellulose acetate beads?

Cellulose acetate beads are a type of chemically modified cellulose bead where hydroxyl groups are partially acetylated. This modification improves hydrophobicity, mechanical strength, and chemical resistance. They are commonly used in chromatography, controlled drug release systems, filtration, and as carriers for hydrophobic compounds. Their tunable surface properties enable applications in pharmaceuticals, cosmetics, and industrial separations.