Polylactic Acid Microsphere Preparation

Polylactic acid (PLA) microspheres are spherical particles at the micron scale made from polylactic acid. Due to their unique biocompatibility, controllable degradability, and excellent drug-carrying capability, they have become key materials in pharmaceuticals, tissue engineering, cosmetics, and agriculture. These microspheres generally have diameters ranging from 1 to 1000 μm, with tunable particle size, surface properties, and porosity according to different application needs. PLA microspheres can be used alone or in combination with other materials such as hydroxyapatite, chitosan, or polyvinyl alcohol to enhance performance and functionality. BOC Sciences is dedicated to providing high-quality, customized PLA microsphere preparation services for research institutions and enterprises. With extensive experience in polymer chemistry and nanomaterials, we precisely control particle size, porosity, and surface functionality to achieve tailored solid, hollow, porous, and functionalized microspheres. Additionally, we offer full-process support—from material selection and process optimization to scale-up production—combined with strict quality control systems, ensuring each batch meets structural, performance, and biocompatibility requirements, providing reliable solutions for drug delivery, tissue engineering, and biomimetic material development.

What We Offer

PLA Microspheres: From Molecular Design to Industrial Scale

BOC Sciences leverages extensive experience in polymer chemistry and nanomaterials to offer comprehensive PLA microsphere solutions. Whether micron-scale or nanoscale, solid, porous, hollow, composite, or functionalized, we utilize flexible preparation techniques, precise particle size control, and diverse surface functionalization to deliver fully customized solutions from research samples to industrial production.

Microscale PLA Microspheres

- Microspheres with diameters from 1–1000 μm, precisely controlled according to application requirements.

- Customized preparation for drug loading, tissue engineering scaffolds, and biomimetic material applications.

- Surface modification, porosity tuning, and composite development available to enhance functionality.

Nanoscale PLA Microspheres

- Diameters ranging from 50–500 nm, suitable for targeted drug delivery and high-precision biomimetic material design.

- Compatible with microfluidic preparation techniques for high uniformity, ideal for advanced research and industrial applications.

- Surface functionalization or composite modification available for nanoscale drug loading and targeted release.

Porous PLA Microspheres

- Adjustable porosity and pore size to meet needs for drug sustained release, cell adhesion, and tissue engineering.

- Prepared using double emulsion, microemulsion, template, or other methods.

- Can be combined with composites or surface functionalization to improve bioactivity and mechanical performance.

Hollow PLA Microspheres

- Internal cavities for gas carriers, drug sustained release, or reduced material density.

- Particle size, wall thickness, and cavity size customizable according to client requirements.

- Can be integrated with composites or surface modifications to expand biomimetic functionality.

Solid PLA Microspheres

- Dense internal structure suitable for sustained drug release and high mechanical strength applications.

- Particle size, molecular weight, and crystallinity can be customized to achieve different degradation rates.

- Surface functionalization or composite development supported to enhance application adaptability.

Composite PLA Microspheres

- Combined with PLGA, hydroxyapatite, chitosan, and other materials to optimize mechanical properties and bioactivity.

- Enables multi-functional drug loading or personalized tissue engineering scaffold design.

- Supports multi-dimensional customization of particle size, porosity, and surface chemistry.

Functionalized PLA Microspheres

- Surface modification with PEG, antibodies, or ligands for targeted drug delivery or cell adhesion.

- Chemical grafting or coating with polysaccharides, proteins, and other bioactive molecules available.

- Particle size, porosity, and composite optimization supported to meet advanced biomimetic material needs.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

PLA Microsphere Development and Manufacturing Support Services

BOC Sciences offers comprehensive support services from microsphere development and design to process optimization and large-scale manufacturing. We customize particle size, surface functionality, degradation rate, and composite structure according to specific client requirements, helping achieve scientific breakthroughs and industrial implementation.

1Microsphere Development and Design Support

- Personalized design for particle size, porosity, and molecular weight.

- Optimization of drug loading capacity, carrier functionality, and release profiles.

- Custom structural solutions for drug delivery, tissue engineering, or biomimetic material applications.

- Assistance with proof-of-concept and performance evaluation for functionalized or composite microspheres.

2Microsphere Preparation and Process Optimization

- Multiple preparation technologies: solvent evaporation, double emulsion, microfluidics, and spray drying.

- Precise control over particle size, uniformity, and porosity to meet diverse application requirements.

- Process parameter optimization to improve drug loading efficiency, stability, and reproducibility.

- Support for small-scale R&D samples and pilot-scale process validation.

3Microsphere Functionalization and Composite Services

- Surface modification (PEGylation, ligand or antibody attachment) and coating with bioactive molecules.

- Preparation of composite microspheres (PLA/PLGA, PLA/hydroxyapatite, PLA/chitosan) to enhance mechanical performance and bioactivity.

- Joint optimization of porosity, surface properties, and drug-loading method to achieve multifunctional microspheres.

- Assistance in targeted delivery, tissue scaffold, or biomimetic material functionality validation.

4Microsphere Manufacturing and Quality Control

- Small-batch R&D samples and large-scale industrial production capabilities to meet varied client needs.

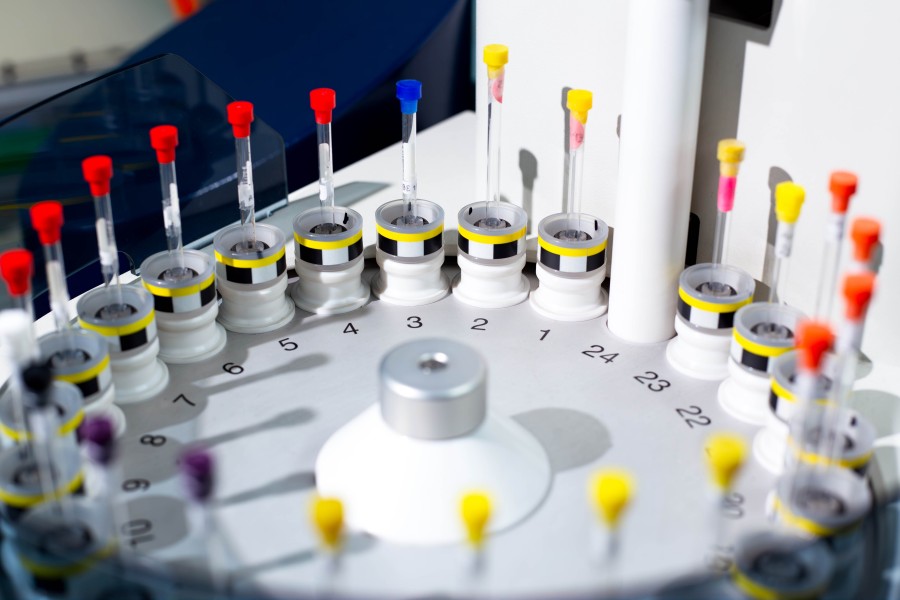

- Strict quality control system including particle size measurement, drug loading evaluation, purity, and degradation testing.

- Provision of standardized product reports and technical documentation upon request.

- Custom delivery schedules and continuous process improvement to ensure stable, reliable performance for every batch.

Characterization

PLA Microsphere Analysis and Quality Assurance Services

BOC Sciences has advanced analytical platforms and a rigorous quality management system, offering comprehensive microsphere characterization, functionality assessment, and quality assurance services. Our testing and analysis cover critical performance indicators from raw materials to finished microspheres, ensuring that each batch meets design specifications in terms of particle size, structure, drug-loading capacity, and degradation behavior.

| Test Category | Test Item | Service Description |

|---|

| Physical Properties | Particle Size & Size Distribution | Accurately measure particle size and uniformity using laser diffraction and dynamic light scattering (DLS) techniques. |

| Morphology Observation | Examine microstructure, surface morphology, porosity, and hollow structure using scanning electron microscopy (SEM) or transmission electron microscopy (TEM). |

| Density & Specific Surface Area | Determine microbead density and specific surface area to evaluate drug loading potential and scaffold performance. |

| Chemical & Composition | Polymer Composition & Molecular Weight | Analyze molecular weight and structural composition via gel permeation chromatography (GPC), nuclear magnetic resonance (NMR), and Fourier-transform infrared spectroscopy (FTIR). |

| Surface Chemistry Modification | Assess effectiveness of PEGylation, ligand or antibody modification, and quantify surface functional groups. |

| Functional Performance | Drug Loading & Encapsulation Efficiency | Measure drug loading capacity and encapsulation efficiency using high-performance liquid chromatography (HPLC) or UV spectrophotometry. |

| Drug Release Profile | Evaluate in vitro release behavior under simulated conditions and analyze release kinetics. |

| Degradation Behavior | Assess hydrolysis or degradation rate in simulated body fluids or buffer solutions and analyze degradation products. |

| Biocompatibility & Safety | Biocompatibility Evaluation | Perform in vitro cytotoxicity tests and related biocompatibility assessments to ensure safe application of microspheres. |

| Microbial Testing | Ensure microspheres are free from microbial contamination during production and storage. |

Advantages

PLA Microsphere Solutions with Proven Service Benefits

- Professional Technical Team: A team of experts with extensive experience in polymer chemistry, biomaterials, and nanotechnology provides full-process technical support for microsphere preparation, functionalization, and composite development.

- Full-Process Customization: From molecular design and material selection to microsphere fabrication and industrial production, we offer personalized customization of particle size, drug loading, porosity, and surface functionality.

- Advanced Preparation Technologies: Mastery of solvent evaporation, double emulsion, spray drying, and microfluidic techniques ensures uniform particle size, controllable structures, and compatibility with diverse applications.

- Functionalization and Composite Services: Support for surface PEGylation, antibody or ligand modification, and composite microsphere development enhances drug delivery, tissue engineering, and biomimetic material performance.

- Strict Quality Control: A comprehensive testing system—including particle size, morphology, drug loading, degradability, and biocompatibility—ensures each batch of microspheres is stable, reliable, and meets client standards.

- Rapid Response and Technical Support: Full support for R&D samples, small-batch validation, and industrial-scale production, with quick response to client needs, process optimization, and problem-solving solutions.

- Client-Oriented Delivery: Flexible solutions to accommodate various project timelines and production scales, providing customized delivery plans and continuous technical support to accelerate client research and product implementation.

Service Process

Efficient PLA Microsphere Preparation: Our Process Explained

BOC Sciences is committed to providing high-quality, customized PLA microsphere services, ensuring full support from R&D design to industrial production. Our workflow is scientifically rigorous, ensuring every batch meets client requirements in particle size, functionality, and quality, while offering professional technical guidance and optimization recommendations to accelerate project development and implementation.

1Requirement Communication and Project Assessment

We start with in-depth communication to understand the project's application background, particle size, drug loading, degradation cycle, and surface functionalization needs. Based on this information, our technical team conducts feasibility evaluations, formulates preliminary plans, and provides material selection, process route, and potential optimization recommendations, ensuring a scientifically sound project from the outset.

2Raw Material Selection and Molecular Design

According to project goals, we provide high-purity PLA polymers and related composite materials, designing molecular weight, crystallinity, and copolymer ratios. For functionalized or composite microspheres, specific surface functional groups or composite components can be designed to meet requirements for drug sustained release, tissue engineering scaffolds, or biomimetic material performance, achieving full customization from molecular structure to microsphere properties.

3Microsphere Fabrication and Process Development

We utilize solvent evaporation, double emulsion, spray drying, and microfluidic techniques, selecting the most suitable method according to particle size and porosity requirements. Process parameters such as emulsification rate, stirring speed, solvent ratio, and drying conditions are precisely controlled to ensure uniform particle size and stable structure. Lab-scale and pilot-scale process validation is performed to lay the foundation for industrial-scale production.

4Functionalization and Composite Treatment

To meet diverse application needs, we offer surface modification, PEGylation, ligand or antibody grafting, and can combine PLA with PLGA, hydroxyapatite, chitosan, or other materials to produce multifunctional microspheres. By controlling porosity, wall thickness, and surface chemistry, we enhance drug carrier efficiency, cell adhesion, or mechanical properties, achieving multidimensional functional optimization for biomimetic materials, tissue engineering, and targeted drug delivery.

5Analysis, Testing, and Quality Control

Each batch undergoes rigorous testing and quality control, including particle size and distribution, morphology, drug loading, release behavior, degradation rate, and biocompatibility evaluation. Advanced analytical techniques such as SEM, TEM, DLS, HPLC, GPC, and FTIR are used to generate standardized reports, ensuring every batch meets R&D or industrial application requirements, and providing comprehensive technical data support to clients.

6Delivery and Continuous Technical Support

We provide full-cycle delivery for R&D samples, small-batch validation, and industrial production, continuously optimizing processes based on client feedback. Our technical team offers guidance on microsphere applications, troubleshooting, and customized solutions, ensuring stable and reliable performance from lab research to industrial implementation, maximizing client R&D efficiency and success rate.

Applications

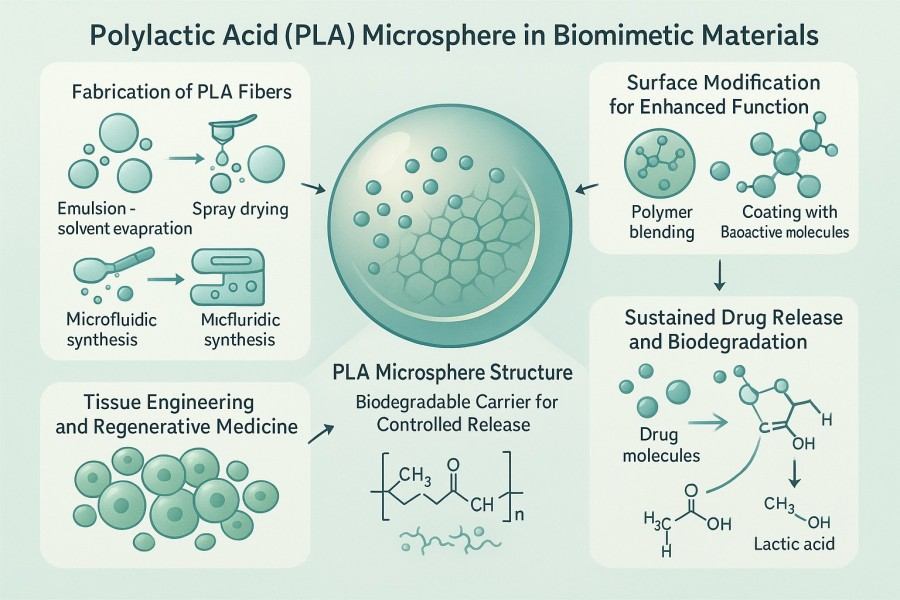

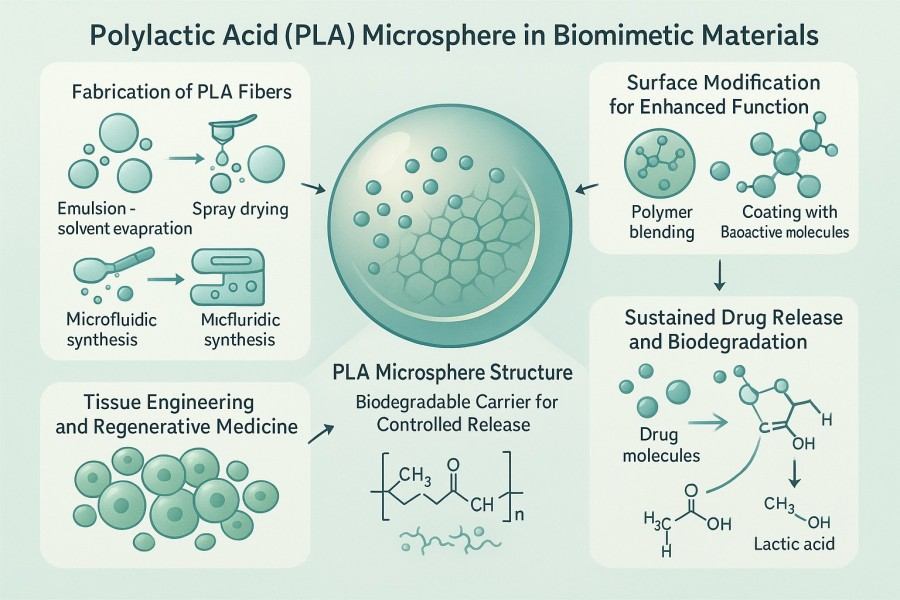

Applications of PLA Microspheres in Biomimetic Materials

Through precise control of particle size, porosity, and surface functionality, PLA microspheres can mimic the microenvironment of natural tissues, serving as ideal carriers for drug delivery, tissue engineering, scaffold construction, and functional material development. BOC Sciences provides customized microsphere solutions to support innovative applications in biomimetic materials for research institutions and enterprises.

Tissue Engineering Scaffold Construction

PLA microspheres can serve as basic units for 3D scaffolds. Through porosity design and composite integration, they mimic the natural extracellular matrix (ECM), promoting cell adhesion, proliferation, and differentiation, widely used in bone, cartilage, and soft tissue engineering.

Drug Sustained Release and Functional Carriers

Particle size and surface chemistry can be tuned for targeted delivery and sustained release of drugs, proteins, or growth factors. In biomimetic materials, PLA microspheres can be embedded into scaffolds or coatings to form bioactive material systems.

Composite Biomimetic Material Development

PLA microspheres can be combined with hydroxyapatite, chitosan, or other natural or synthetic polymers to improve mechanical performance, bioactivity, and degradation rate, developing biomimetic materials that provide structural support while modulating cell behavior.

Microenvironment Simulation and Tissue Regeneration

By adjusting microsphere porosity, surface functionalization, and degradation rate, controllable microenvironments can be created to support cell migration, angiogenesis, and tissue regeneration, providing a reliable platform for high-precision biomimetic material research.

Degradable Functional Materials

PLA microspheres can serve as degradable fillers or functional units embedded in biomimetic systems, creating lightweight, degradable, and tunable functional materials suitable for medical devices, implantable scaffolds, and tissue repair materials.

Biomimetic Functional Coatings and Smart Materials

PLA microspheres can be used to fabricate biomimetic functional coatings or smart materials. Through controllable degradation and functionalized surfaces, precise control over drug release, stimulus response, or cell behavior can be achieved, supporting the development of intelligent biomimetic medical devices.

FAQs

Frequently Asked Questions

-

What are PLA microspheres used for?

PLA microspheres are widely applied in biomedical and pharmaceutical fields, including drug delivery, tissue engineering, regenerative medicine, and controlled release systems. Their biodegradable and biocompatible nature allows them to encapsulate a variety of therapeutic agents, such as small-molecule drugs, proteins, and growth factors, while providing sustained and targeted delivery. They are also used as scaffolding components in biomimetic materials and in research for developing novel medical devices.

-

How are PLA microspheres prepared?

PLA microspheres are typically prepared using techniques such as emulsion solvent evaporation, spray drying, and microfluidics, which enable precise control over particle size and morphology. During preparation, factors like polymer concentration, solvent type, emulsifier selection, and stirring conditions are carefully optimized to produce uniform, stable microspheres. Advanced methods, such as microfluidic-assisted fabrication, allow the production of monodisperse microspheres for highly specific biomedical applications.

-

Can the size of PLA microspheres be controlled?

Yes, the size and size distribution of PLA microspheres can be precisely controlled through adjustments in processing parameters. These include polymer molecular weight, polymer-to-solvent ratio, emulsifier type and concentration, and agitation speed. By fine-tuning these factors, microspheres ranging from a few nanometers to several micrometers in diameter can be produced, allowing customization for different drug delivery profiles, tissue engineering scaffolds, and research purposes.

-

How do PLA microspheres degrade in the body?

PLA microspheres degrade gradually through hydrolysis of their ester bonds, forming lactic acid, which is naturally metabolized by the body via the Krebs cycle. The degradation rate can be tailored by modifying polymer molecular weight, crystallinity, or copolymer composition. This controlled biodegradation ensures sustained release of encapsulated drugs or bioactive molecules, minimizes side effects, and supports tissue regeneration without the need for surgical removal.

-

Are PLA microspheres safe for biomedical applications?

PLA microspheres are highly biocompatible, biodegradable, and generally recognized as safe (GRAS) for biomedical use. Extensive research and clinical studies have demonstrated their low toxicity, minimal immune response, and suitability for applications such as injectable drug carriers, implantable scaffolds, and wound healing systems. Their safety profile makes them a preferred material in regenerative medicine, controlled drug delivery, and other biomedical technologies.

-

What advantages do PLA microspheres offer in drug delivery?

PLA microspheres provide several key advantages in drug delivery, including controlled and sustained release, protection of sensitive therapeutic molecules from degradation, and the potential for site-specific targeting. Their surface can be modified to enhance cellular uptake or to attach targeting ligands. Additionally, their biodegradability reduces the risk of long-term accumulation in the body, improving patient safety while enhancing therapeutic efficacy in treatments ranging from cancer therapy to protein and peptide delivery.

-

What are the key performance characteristics of PLA microspheres?

Biocompatibility: PLA is an FDA-recognized biodegradable material. Its degradation product, lactic acid, is metabolized by the human body without significant toxicity, making PLA microspheres suitable for in vivo drug release and tissue engineering scaffolds.

Controllable Degradability: The degradation rate of PLA microspheres can be adjusted by molecular weight, crystallinity, copolymer type (e.g., PLA-PEG, PLGA), and particle size. Generally, larger particle sizes and higher crystallinity result in slower degradation, enabling sustained drug release.

Excellent Drug Loading Capability: PLA microspheres can encapsulate various drugs, proteins, nucleic acids, and other bioactive molecules. Surface modification or porosity control allows for different release profiles, including rapid, delayed, or sustained release.

Surface Modifiability: The surface of PLA microspheres can be functionalized through physical adsorption, chemical grafting, or coating with other polymers. Common modifications include PEGylation, hydroxyapatite coating, and targeted ligand attachment.

Physicochemical Stability: PLA microspheres exhibit good thermal and mechanical stability at room temperature but gradually hydrolyze in aqueous environments. Adjusting fabrication processes allows control over density and porosity to meet diverse application requirements.