Browse by

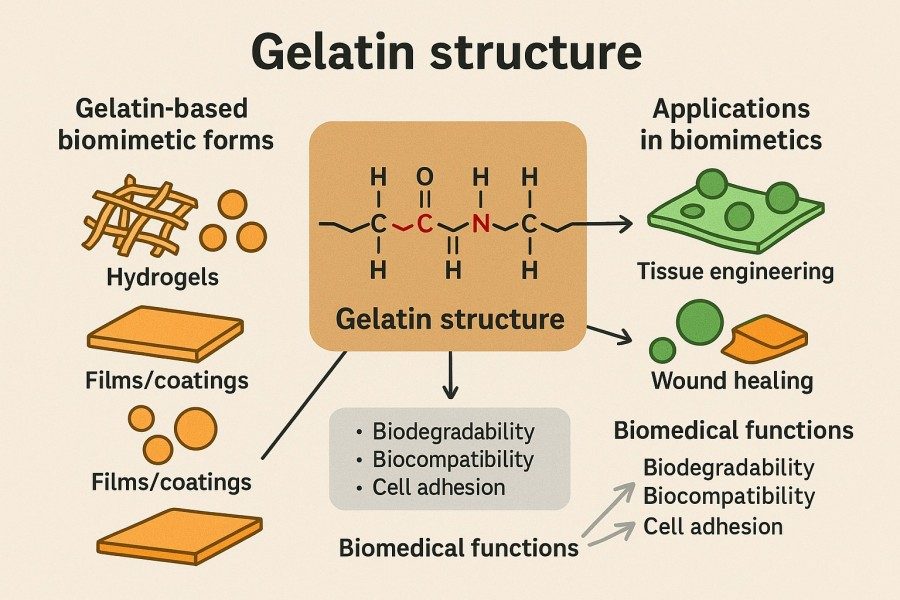

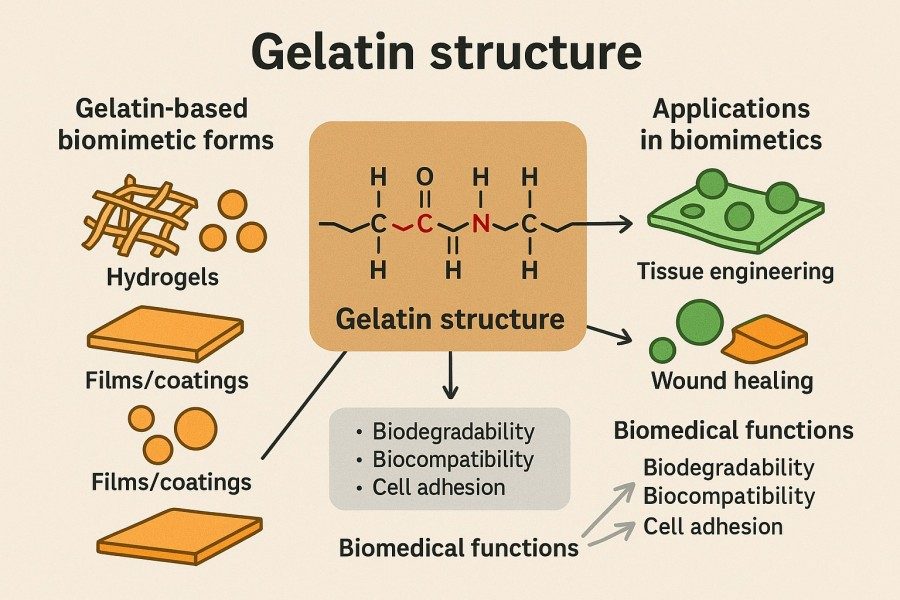

Gelatin is a high-molecular-weight protein derived from the partial hydrolysis of natural collagen, widely used in food, pharmaceuticals, biomaterials, and biomimetic material research. Its excellent biocompatibility, biodegradability, and chemical modifiability make it a key foundational material for tissue engineering scaffolds, drug delivery systems, and soft biomimetic devices. BOC Sciences has extensive experience in gelatin services, providing high-quality gelatin raw materials, custom synthesis, performance analysis, and material modification services to biomimetic material researchers, developers, and manufacturers worldwide. Combining advanced experimental platforms with a professional R&D team, we offer comprehensive technical support to accelerate innovation and application in biomimetic materials.

What We Offer

Gelatin Materials Offered by BOC Sciences

BOC Sciences provides a wide range of gelatin support services for biomimetic material research and development, addressing diverse needs from basic research to industrial-scale production. We can customize gelatin molecular weight, structural characteristics, and functional modification schemes according to client applications and performance requirements, supporting gelatin in hydrogels, films, microspheres, nanoparticles, and composite materials. With a professional team and advanced platforms, we deliver high-quality, controllable, and functionally rich gelatin material solutions to drive innovation in biomimetic materials.

- Supports the development of gelatin hydrogels with tunable mechanical properties and degradation rates.

- Offers physical or chemical crosslinking schemes to enhance gel stability and biocompatibility.

- Widely used in tissue engineering scaffolds, cell culture media, and controlled drug delivery systems.

- Supports the preparation of transparent, thickness-controlled gelatin films or sheets.

- Provides crosslinking, grafting, or composite modification strategies to enhance mechanical strength, water resistance, and functional performance.

- Applicable in biomimetic skin repair, biodegradable dressings, and functional coatings.

- Supports the preparation of uniform, strongly adherent gelatin coatings.

- Offers functional modification options such as antibacterial, conductive, or drug-loading capabilities to enhance coating performance and stability.

- Applicable on biomimetic device surfaces, drug-controlled release coatings, and biomedical material surface modifications.

- Supports the fabrication of porous, three-dimensional, controllable gelatin scaffold structures.

- Provides composite, crosslinking, and surface functionalization strategies to enhance scaffold mechanical properties and cell compatibility.

- Suitable for tissue engineering, cell culture, and degradable biomimetic structural material research.

- Supports the development of gelatin fibers with controllable diameters and adjustable mechanical properties.

- Offers crosslinking, composite, or functional modification strategies to improve fiber strength, water resistance, and bioactivity.

- Widely used in biomimetic tissue scaffolds, wound dressing reinforcement layers, and degradable textiles.

- Supports the development of gelatin microspheres and nanoparticles with controllable particle sizes.

- Provides drug or bioactive molecule loading strategies for controlled release and targeted delivery.

- Applicable in drug carriers, tissue delivery systems, and functional biomimetic material research.

Gelatin Bioinks

- Supports the preparation of gelatin bioinks suitable for 3D printing and bioprinting.

- Offers cell-compatibility optimization and crosslinking control to ensure stable printed structures.

- Widely used in printing complex tissue models, cell printing, and drug screening platforms.

Gelatin Composites

- Supports the combination of gelatin with natural polymers, inorganic materials, or nanofibers.

- Provides composite ratio control and chemical modification strategies to enhance mechanical performance, stability, and functional responsiveness.

- Applicable in bone tissue engineering, soft tissue scaffolds, and functional biomimetic material development.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Gelatin Customization and Technical Support Platform

BOC Sciences offers comprehensive, tailored gelatin support services, covering the entire process from material design and synthesis to performance characterization. Leveraging advanced polymer experimental platforms and a professional R&D team, we provide high-quality gelatin materials and related technical solutions. Whether for basic research, biomimetic material development, or industrial-scale production, we can tailor gelatin molecular weight, structural characteristics, and functional modification schemes to ensure materials meet performance and application requirements, accelerating R&D and product translation.

1Custom Molecular Weight Gelatin Synthesis

- Controls gelatin molecular weight ranges according to client requirements to achieve varying mechanical properties and degradation rates.

- Supports multiple gelatin forms, including hydrogels, films, microspheres, and fibers.

- Meets the research needs of tissue engineering, drug delivery, and biomimetic material development.

2Gelatin Purification and Analysis

- Provides molecular weight determination, structural characterization, amino acid composition analysis, and gel strength testing.

- Ensures consistent, controllable gelatin product performance for research and industrial needs.

- Detailed analysis reports can be provided to support product registration and technical validation.

3Functional Gelatin Modification

- Offers chemical crosslinking, grafting, and composite material development solutions.

- Enhances gelatin mechanical strength, stability, and biofunctionality.

- Supports antibacterial, drug-loading, and responsive release functional applications.

4Small-Scale and Industrial Supply

- Offers gelatin powders and solutions with varying solubility, concentration, and viscosity.

- Supports laboratory research, small-scale pilot production, and industrial-scale manufacturing.

- Suitable for diverse biomimetic material preparation, 3D printing, and drug carrier development.

Advantages

Why Choose BOC Sciences for Gelatin Services?

- Professional R&D Team: Experienced experts in biochemistry and polymer materials, proficient in gelatin molecular design, functional modification, and composite material development.

- Comprehensive Customization: Tailored gelatin molecular weight, structural features, crosslinking methods, and composite ratios based on client needs.

- One-Stop Solutions: Supports hydrogels, films, microspheres, fibers, and bioinks for precise customization.

- Advanced Equipment and Technology Platforms: Equipped with polymer synthesis, characterization, and analysis platforms, including molecular weight determination, gel strength testing, and amino acid composition analysis.

- Strict Quality Control: Full traceability of production processes and detailed analysis reports ensure stable and reliable gelatin performance.

- Rapid Response and Technical Support: Professional support from sample preparation and performance optimization to batch production, shortening R&D timelines.

- Global Supply Capability: Supports laboratory research, small-scale pilot production, and industrial manufacturing to meet diverse global client needs.

Service Process

Step-by-Step Gelatin Service Workflow at BOC Sciences

The gelatin service workflow at BOC Sciences is efficient and transparent, covering the entire process from requirement communication to bulk production. Centered on client needs and leveraging advanced R&D platforms and professional technical teams, we ensure precision at every step, delivering high-quality gelatin products and technical support. This enables clients to accelerate biomimetic material research and applications, achieving smooth translation from laboratory exploration to industrial production.

1Requirement Communication

We engage in in-depth discussions with clients regarding gelatin application scenarios, performance requirements, and specifications. By fully understanding project objectives and technical challenges, we provide a solid data foundation for designing customized solutions and ensure precise R&D direction.

2Solution Design

Based on client requirements, we develop gelatin synthesis or modification plans, including molecular weight control, crosslinking method selection, and composite ratio optimization. Technical feasibility is evaluated in conjunction with application goals to ensure material performance aligns closely with research objectives.

3Sample Preparation

We provide laboratory- or pilot-scale gelatin sample preparation services, strictly controlling production processes and raw material quality. Initial performance testing and validation are conducted to provide materials ready for immediate use in R&D or application trials.

4Performance Analysis

Comprehensive analysis and characterization of gelatin samples are performed, including molecular weight, structure, gel strength, degradation rate, and degree of functionalization. Detailed performance data support clients in optimizing material selection and application strategies.

5Optimization and Iteration

Based on performance tests and client feedback, synthesis or modification plans are continuously optimized. Crosslinking methods, molecular weight, or composite ratios are adjusted to ensure the final gelatin products meet client requirements in mechanical properties, degradation rate, and functional characteristics.

6Bulk Supply and Technical Support

Small-scale or industrial production is completed with full technical guidance and support, including formula translation, process optimization, and application assistance, ensuring gelatin products are successfully applied in biomimetic material research, development, and production.

Applications

Applications of Gelatin in Biomimetic Materials

Gelatin, due to its excellent biocompatibility, biodegradability, and chemical modifiability, has broad applications in biomimetic materials. It can mimic the structure and function of natural extracellular matrices, providing an ideal base for tissue engineering, drug delivery, implantable devices, and bioprinting research. Gelatin can also be combined with other natural or synthetic materials to enhance mechanical properties and functional responsiveness, playing a key role in the development of diverse biomimetic materials. Key applications include:

Tissue Engineering Scaffold Materials

The core of tissue engineering lies in constructing 3D scaffolds that support cell growth and differentiation. Gelatin, as a protein-based material, can mimic natural extracellular matrix (ECM), providing suitable adhesion sites and nutrient environments. By combining with other natural or synthetic polymers (e.g., hyaluronic acid, gelatin–polyvinyl alcohol composites, gelatin–polylactic acid composites), scaffolds with varying mechanical properties can be prepared for bone, cartilage, skin, or vascular tissue engineering.

Drug Delivery and Controlled Release Systems

Gelatin can serve as a biomimetic drug carrier, leveraging its hydrogel properties to encapsulate small molecule drugs, proteins, or nucleic acids. In vivo, gelatin hydrogels degrade slowly, enabling sustained drug release while reducing toxicity to non-target tissues. Chemical modification can also achieve targeted delivery or responsive release, such as pH- or enzyme-sensitive gelatin hydrogel systems.

Tissue Regeneration and Wound Healing

Gelatin can mimic the microenvironment of natural connective tissues, promoting cell adhesion, proliferation, and migration. Gelatin-based hydrogels can be used as artificial skin or wound dressings, providing support and regulating moisture during healing. Combining with antibacterial agents, nanoparticles, or growth factors further enhances wound repair and infection resistance.

Biomimetic Soft Materials and Implantable Devices

Due to its flexibility and tunable mechanical properties, gelatin is used in developing biomimetic soft materials, such as artificial muscles, vessels, or implantable medical devices. Crosslinking or combining with other polymers allows gelatin-based materials to achieve adequate mechanical strength while maintaining softness and biodegradability, suitable for clinical implants.

Bioprinting and 3D Printed Scaffolds

With the development of bioprinting technology, gelatin has become one of the most commonly used bioinks. Its solubility and temperature sensitivity facilitate shaping during printing, and post-printing crosslinking maintains 3D structures. Gelatin bioinks can carry cells to print complex 3D tissue models for drug screening, tissue engineering, or regenerative medicine research.

Composite Biomimetic Materials

Gelatin can be combined with nanofibers, polymers, or inorganic materials to improve mechanical properties, structural stability, and biological functionality. These composites are widely used in bone tissue engineering, soft tissue scaffolds, and functional biomimetic material development, meeting diverse demands in complex biological environments.

FAQs

Frequently Asked Questions

-

What is gelatin made of?

Gelatin is a natural high-molecular-weight protein obtained by partial hydrolysis of animal collagen, mainly sourced from pig skin, bovine skin, bones, and fish scales. Collagen is converted into soluble gelatin through hot water or acid/alkali treatment. It primarily consists of protein and a small amount of water and is rich in amino acids such as glycine, proline, and hydroxyproline. Due to its biocompatibility, biodegradability, and chemical modifiability, Gelatin is widely used in food, pharmaceuticals, cosmetics, and biomimetic materials.

-

Is gelatin a biomaterial?

Yes, gelatin is a natural biomaterial derived from animal collagen, with excellent biocompatibility and biodegradability. It can be recognized and adhered to by cells, degrades safely in the body, and has minimal toxicity. Gelatin can be chemically or compositely modified to enhance functionality and is widely used in tissue engineering scaffolds, drug carriers, bioprinting, and implantable devices.

-

What are the biomedical applications of gelatin?

Gelatin's biomedical applications include tissue engineering scaffolds, drug delivery systems, wound dressings, implantable devices, and bioprinting scaffolds. It can be processed into hydrogels, films, microspheres, fibers, and composites to support cell growth, controlled drug release, or tissue regeneration. Its biodegradability and functional modification capability make it suitable for antibacterial dressings, targeted drug delivery, and 3D-printed artificial tissues.

-

What is the use of gelatin in tissue engineering?

In tissue engineering, gelatin is used to fabricate 3D scaffolds that mimic natural extracellular matrices, providing an environment for cell adhesion, proliferation, and differentiation. By controlling molecular weight, crosslinking, and pore structure, gelatin scaffolds achieve tunable degradation and mechanical properties, suitable for bone, cartilage, skin, and vascular regeneration. Combined with growth factors or drugs, gelatin enhances tissue repair, making it indispensable in tissue engineering and regenerative medicine.

-

Is gelatin a scaffold?

Gelatin itself can serve as a scaffold material for tissue engineering and biomimetic materials. It can be processed into porous 3D structures that support cell adhesion, proliferation, and differentiation while mimicking the natural ECM environment. Gelatin scaffolds can be strengthened via physical or chemical crosslinking and combined with nanofibers or inorganic materials to improve functionality and stability.

-

Does gelatin rebuild cartilage?

Gelatin provides a microenvironment for cell growth and differentiation in cartilage regeneration research through porous scaffolds and hydrogels. Scaffolds support chondrocytes or stem cell adhesion and proliferation and can be combined with growth factors or drugs to promote cartilage tissue reconstruction. While gelatin does not directly generate cartilage, it serves as a structural and biological support for cartilage regeneration in vitro or in vivo.

-

What is the method of synthesis of gelatin?

Gelatin is synthesized by hydrolyzing animal collagen, using either acid hydrolysis (Type A) or alkaline hydrolysis (Type B). High temperatures partially break the collagen triple-helix structure, converting it into soluble gelatin. Molecular weight and gel properties are controlled by adjusting acid/alkali concentration, temperature, and time, producing gelatin suitable for various applications such as food, drug carriers, or tissue engineering scaffolds.

-

What is the process of making gelatin?

Gelatin preparation involves raw material selection, pretreatment, collagen extraction, and drying/forming. Impurities and fat are removed from pig skin, bovine skin, or bones, followed by acid or alkali treatment to soften collagen. Soluble gelatin is then extracted using hot water or steam, concentrated, filtered, and dried to obtain the final product. Molecular weight, gel strength, and transparency are controlled to meet requirements for food, pharmaceuticals, and biomimetic materials.

Gelatin Coating Preparation

Gelatin Coating Preparation

Gelatin Hydrogel Preparation

Gelatin Hydrogel Preparation

Gelatin Film/Membrane Preparation

Gelatin Film/Membrane Preparation

Gelatin Scaffold Preparation

Gelatin Scaffold Preparation

Gelatin Fiber Preparation

Gelatin Fiber Preparation

Gelatin Microsphere/Nanoparticle Preparation

Gelatin Microsphere/Nanoparticle Preparation