Polyurethane (PU) Services

Browse by

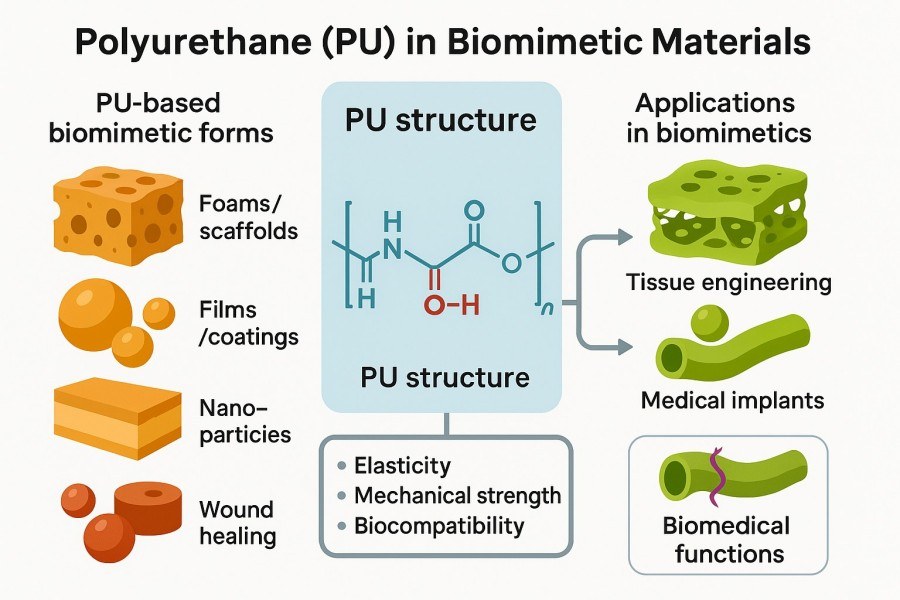

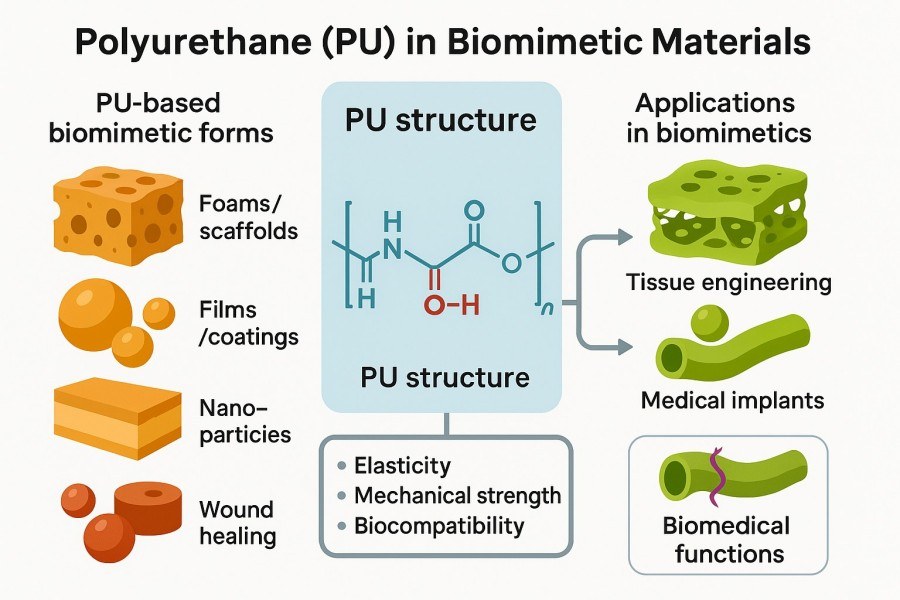

Polyurethane (PU) is a class of polymeric materials formed through the addition reaction of polyols and isocyanates. Its fundamental structural unit is the carbamate group (–NH–CO–O–), and in its chain structure, hard segments and soft segments usually alternate, providing PU with both flexibility and mechanical strength. Polyurethane is a highly tunable polymer with adjustable mechanical properties and chemical modifiability. Due to its flexibility, biodegradability, and processability, it finds significant applications in soft tissue biomimetics, bone tissue engineering, bioinspired skin, drug delivery carriers, and soft robotics. BOC Sciences is dedicated to providing comprehensive, customized solutions for polymer chemicals and monomers, particularly focusing on polyurethane and its applications in biomimetic materials. As an independent professional supplier, we offer research institutions, materials developers, and manufacturers one-stop services—from raw material customization, process development, and performance analysis to material modification—to accelerate the research, development, and application of PU biomimetic materials.

What We Offer

Polyurethane for Biomimetic Materials at BOC Sciences

With its flexible structure, tunable mechanical properties, and diverse chemical functionalities, polyurethane has become a core polymer in the field of biomimetic materials. PU can be processed into fibers, scaffolds, coatings, films, hydrogels, microspheres, and composites, each capable of mimicking biological tissue characteristics or performing specific functions. BOC Sciences is committed to providing researchers, developers, and manufacturers with comprehensive PU format support services, covering molecular design, synthesis, modification, analysis, process development, and scale-up production, ensuring that each material format meets customer requirements in mechanical performance, biocompatibility, structural complexity, and functionality. Below is an introduction to the main PU formats and service capabilities we offer:

PU fibers exhibit high elasticity, stretchability, and flexibility, suitable for biomimetic muscles, wearable electronics, and soft tissue simulation.

- Customizable fiber diameter, length, and elastic modulus to mimic the mechanical properties of different biological tissues.

- Supports electrospinning, nanofiber spinning, and thermally drawn fibers to form micro-biomimetic structures.

- Surface modification (hydrophilic/hydrophobic, antibacterial, or drug-loading) is available to meet cell culture or functional application needs.

- Laboratory-scale to pilot-scale production services ensure stable and controllable fiber performance.

PU scaffolds are widely used in tissue engineering and regenerative medicine, capable of mimicking the extracellular matrix (ECM) microenvironment.

- Porous, open/closed structure designs optimize cell adhesion, nutrient exchange, and growth conditions.

- Adjustable hard/soft segment ratios enable mechanical property customization for soft tissue or bone applications.

- Supports biodegradable PU scaffold design, capable of carrying drugs or growth factors for localized release.

- Various fabrication methods, including 3D printing, solution casting, and foam foaming, accommodate complex shapes and functionalization requirements.

PU coatings can be applied to bioinspired skin, medical dressings, organ surface protection, and protective films, offering controllable thickness, flexibility, and functionalization capabilities.

- Solution coating, spraying, and dipping processes achieve uniform coatings with controlled thickness.

- Supports modification with antibacterial, hydrophilic/hydrophobic, drug-loading, or photosensitive functionalities.

- Can integrate with flexible electronics, sensors, or implantable devices for functional biomimetic surfaces.

- Performance testing and analysis, including adhesion, wear resistance, tensile strength, and chemical resistance, ensure stable and reliable coatings.

PU films offer high flexibility, breathability, and processability, suitable for bioinspired skin, wearable electronics, and medical dressings.

- Customizable film thickness, transparency, and flexibility meet bioinspired skin or membrane material requirements.

- Supports solution casting, extrusion, and coating processes for uniform, continuous films.

- Surface functionalization and composite modification, such as antibacterial, waterproof, breathable, or drug-loading, are available.

- Mechanical performance, surface morphology, breathability, and biocompatibility analyses ensure reliable material application.

PU hydrogels combine high water absorption with flexibility, often used for biomimetic soft tissues, drug delivery systems, and tissue engineering scaffolds.

- Crosslinking degree and softness can be adjusted to simulate the mechanical properties of different soft tissues.

- Responsive hydrogel designs, such as temperature-, pH-, or light-responsive functions, enable smart release.

- Can carry drugs, growth factors, or bioactive molecules to support localized therapy or tissue regeneration.

- Water absorption, mechanical performance, and biocompatibility testing ensure reproducible experimental and application outcomes.

PU microspheres are commonly used in drug delivery, tissue engineering, and biosensors, featuring controllable size and surface functionality.

- Supports preparation from nanometer to micrometer scale to meet diverse application needs.

- Surface modification, drug loading, and functionalization enable targeted release or enhanced cell adhesion.

- Hollow or solid microspheres can be produced for drug release or tissue engineering microstructure design.

- Particle size distribution, drug release profiles, and mechanical analysis ensure stable quality and performance.

Polyurethane Composites

PU can be combined with natural polymers, inorganic fillers, or nanomaterials to form functional biomimetic composites with both mechanical performance and bioactivity.

- Composite design and synthesis with PU and hydroxyapatite, bioactive glass, collagen, cellulose, etc.

- Supports microstructural control to optimize porosity, toughness, and mechanical strength.

- Functional modifications, such as antibacterial, drug-loading, or smart-responsive features, are available.

- Structural characterization, mechanical analysis, and biocompatibility assessment ensure controllable and reliable material performance.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Support Services for Polyurethane Biomimetic Materials

BOC Sciences is committed to providing comprehensive polyurethane support services for researchers, developers, and manufacturers in the biomimetic materials field. We cover the complete service chain from custom synthesis, molecular design, functional modification, material analysis and characterization to process development and pilot-scale production, helping customers precisely control PU mechanical properties, chemical functionality, and processing formats. Whether it is flexible elastomers, rigid scaffolds, porous foams, film coatings, or micro/nano structured composites, BOC Sciences provides tailored solutions according to customer requirements, accelerating the translation of biomimetic materials from lab research to practical application while ensuring material performance stability and reproducibility.

1PU Custom Synthesis Services

BOC Sciences provides tailored PU synthesis based on customer requirements. For biomimetic materials research, we offer custom synthesis of low-, medium-, and high-molecular-weight PU monomers to ensure controllable and reproducible material performance.

- Polyol and isocyanate ratio design: Adjust hard/soft segment ratio to achieve desired mechanical properties.

- Functional segment design: Incorporate degradable segments, drug carrier segments, or bioactive segments.

- Special process customization: Such as solution polymerization, melt polymerization, and thermoplastic processing to meet different structural and application requirements.

2PU Material Modification Services

To meet complex application needs, BOC Sciences provides various PU modification solutions. For example, in bone tissue engineering scaffolds, PU can be combined with hydroxyapatite to enhance hardness and osteoconductivity.

- Mechanical property tuning: Optimize elasticity, rigidity, or toughness via crosslinking, segment length, and filler selection.

- Surface functionalization: Antibacterial, hydrophilic/hydrophobic regulation, drug-loading capability.

- Composite modification: Combine with inorganic fillers or natural polymers to enhance biomimetic material performance.

3PU Material Analysis and Characterization

Material reliability and performance evaluation are critical for biomimetic applications. Through precise characterization, we help clients optimize PU formulations and processing, ensuring reproducibility and reliability in research and production.

- Mechanical testing: tensile, compression, bending, fatigue, and dynamic mechanical analysis.

- Thermal analysis: thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), thermomechanical analysis (TMA).

- Structural characterization: FTIR, NMR, XRD, SEM, TEM, etc.

- Surface and porosity analysis: contact angle, pore size distribution, surface morphology observation.

- Degradation and biocompatibility testing: in vitro degradation rate, cell compatibility assessment, and more.

4PU Process Development and Production Support

For clients with scale-up requirements, BOC Sciences offers process development, pilot production, and technology transfer services. Whether for research samples, small-batch trials, or industrial-scale production, we provide technical support to help clients quickly validate and implement material applications.

- Laboratory to pilot scale: optimize reaction conditions and formulations to achieve controllable yield and stable performance.

- 3D printing and precision molding: support various PU processing formats, including elastomers, films, and micro/nano structures.

- Custom composite production: combine PU with natural polymers or inorganic fillers to enhance material functionality.

Advantages

Unlock the Benefits of Custom Polyurethane Services with BOC Sciences

- Professional R&D team: experts in polyurethane chemistry and biomimetic materials provide full technical support for formulation design, functional modification, and process optimization.

- Full-process custom services: from raw material selection, molecular design, synthesis, and modification to pilot-scale production, ensuring research and production needs are accurately met.

- Diverse processing capabilities: support foams, elastomers, films, coatings, fibers, microspheres, and composites.

- Precision analysis and characterization: comprehensive evaluation of mechanical properties, thermal performance, microstructure, surface characteristics, and biocompatibility.

- Functional modification solutions: antibacterial, hydrophilic/hydrophobic control, drug loading, smart responsiveness, and biodegradability can be tailored.

- Scale-up and production support: laboratory samples, pilot-scale, and mass production are all feasible, ensuring consistent and reproducible material performance.

- Application-oriented design: optimize material performance for biomimetic skin, soft tissues, bone scaffolds, soft robotics, and drug carriers.

- Rapid response and technical service: ongoing support including material usage guidance, processing optimization, and functional application consultation.

Service Process

Tailored Polyurethane Workflow for Biomimetic Materials

In biomimetic material research and production, BOC Sciences offers full-process PU services from requirement consultation to production-scale technology transfer, ensuring materials meet specific application requirements in performance, structure, and functionality. Our workflow covers custom design, synthesis optimization, functional modification, analysis and characterization, and process scale-up, helping research institutions and enterprises efficiently achieve their material development goals.

1Requirement Consultation and Solution Design

We first gain a deep understanding of the client's application scenarios, performance requirements, and processing methods. Combined with the characteristics of biomimetic materials, we provide personalized PU design solutions. Our team proposes material structures, mechanical properties, and functionalization strategies to ensure a precise and feasible R&D direction, forming a detailed experimental or production plan.

2Polyurethane Molecular Design and Custom Synthesis

Based on the design plan, we offer custom PU synthesis, including optimization of polyol and isocyanate ratios, introduction of functional segments, and specialized process preparation. From small, medium, to high-molecular-weight PU monomers, we ensure controllable structures and stable performance, laying a solid foundation for biomimetic applications.

3Performance Analysis and Characterization

After synthesis, we conduct comprehensive characterization of PU materials, including mechanical properties, thermal performance, microstructure, surface characteristics, and biocompatibility testing. Data analysis is used to optimize formulations and processes, ensuring materials meet R&D or production requirements in biomimetic performance, durability, and functionality.

4Functional Modification and Composite Development

For specific applications, BOC Sciences provides PU functional modification services, including antibacterial treatment, hydrophilic/hydrophobic adjustment, drug or growth factor loading, and composite development. By combining PU with natural polymers or inorganic materials, we create multifunctional biomimetic materials to meet complex research and application demands.

5Process Development and Pilot-Scale Scale-Up

We support production from laboratory preparation to pilot-scale scale-up, optimizing PU synthesis and processing techniques. Controlled production solutions are provided for foams, elastomers, films, coatings, fibers, microspheres, and composites, ensuring consistent material performance across batches and supporting both research validation and industrial applications.

6Technical Support and Application Guidance

After material delivery, BOC Sciences provides ongoing technical services, including processing guidance, performance optimization recommendations, and functional application support. Our expert team ensures clients can efficiently use PU materials during R&D, testing, or production, reducing trial-and-error costs and improving development efficiency.

Applications

Applications of Polyurethane in Biomimetic Materials

Polyurethane's highly tunable mechanical properties, excellent flexibility, chemical functionality, and biocompatibility make it a core polymer in biomimetic material development. Adjustable hard/soft segment ratios and modifiable molecular chains allow PU to mimic the mechanical and physiological properties of natural tissues. PU can be processed into various material formats, such as foams, films, coatings, scaffolds, fibers, hydrogels, and microspheres, providing complex structures and multifunctional solutions. These advantages make PU widely used in soft tissue simulation, bone tissue engineering, bioinspired skin, drug carriers, and wearable devices.

Soft Tissue Biomimetic Materials

Soft tissues include skin, muscles, blood vessels, and nerves, characterized by high elasticity and toughness. PU materials can precisely mimic natural tissue mechanics by adjusting soft/hard segment ratios:

- Bioinspired skin and wearable electronics: transparent flexible PU films simulate skin flexibility and stretchability, suitable for electronic skin, pressure sensors, and flexible displays.

- Vascular and catheter biomimetics: elastic PU tubing mimics vessel wall elasticity for artificial vascular scaffolds and catheters, with surface PEGylation improving antithrombogenicity.

- Muscles and soft robotics: PU elastomers combined with pneumatic or hydraulic actuation create soft biomimetic muscles capable of stretching and rapid recovery.

Bone and Hard Tissue Biomimetic Materials

Hard tissues, such as bones and teeth, require high strength and modulus. PU can be combined with hydroxyapatite (HA), bioactive glass, or other fillers to create bone biomimetic composites:

- Bone substitute materials: PU-HA composites offer high strength, with porous structures promoting osteoblast adhesion and growth to accelerate bone regeneration.

- Dental restorative materials: PU composite resins provide toughness and wear resistance for tooth filling and restoration, enduring long-term masticatory loads.

- Bone scaffolds and implants: porous PU composite scaffolds support bone growth and can carry growth factors for localized functionality.

Biomimetic Sponges and Tissue Engineering Scaffolds

PU foams with controllable pore structure and flexibility serve as tissue engineering scaffolds and can carry drugs or growth factors:

- Porous cell scaffolds: casting, foaming, or 3D printing create porous PU structures simulating ECM to support cell adhesion, proliferation, and differentiation.

- Drug-release scaffolds: pores can serve as carriers for drugs or growth factors, enabling sustained local release for tissue repair.

- Soft-hard tissue interface scaffolds: designed with varying pore sizes and stiffness gradients to mimic soft-hard tissue junctions, supporting complex tissue engineering applications.

Biomimetic Films and Coatings

PU films and coatings are used for bioinspired skin, artificial organ surfaces, and waterproof breathable membranes, combining flexibility and functionality:

- Artificial skin coatings: PU films can be surface-modified for waterproofing, breathability, and antibacterial properties, suitable for wound dressings and implantable materials.

- Organ model surface materials: PU coatings simulate organ surface flexibility, providing realistic experience for medical training, surgical simulation, and drug testing.

- Protective and functional membranes: PU films can be made into breathable, waterproof, or smart-responsive membranes for wearable devices, bioinspired shells, or medical instrument surface protection.

FAQs

Frequently Asked Questions

-

What is PU polyurethane?

Polyurethane (PU) is a polymer formed from isocyanates and polyols, with tunable hardness, elasticity, and chemical functionality. PU can be processed into foams, films, coatings, fibers, hydrogels, and composites, widely used in biomimetic materials, medical devices, soft robotics, and industrial products. Its flexible structure and diverse performance make it an important choice for biomimetic material research.

-

Is PU biodegradable?

PU degradability depends on chemical structure and composition. Some types, such as hydrolytically sensitive PU or bio-based PU, are partially or fully biodegradable for eco-friendly materials or absorbable medical devices. Non-degradable PU is used in industrial and long-term applications, but degradable monomers and structural design can impart targeted biodegradability for biomimetic materials and sustainable design.

-

Is polyurethane a biomaterial?

Polyurethane can act as a biomaterial, especially in medical and biomimetic applications, exhibiting good biocompatibility and mechanical adaptability. PU can be used for tissue engineering scaffolds, artificial vessels, wound dressings, and wearable medical devices. Chemical modification or composite design can optimize degradation rate, antibacterial performance, and drug-loading capacity to meet physiological or biomimetic requirements.

-

What are the uses of polyurethane PU?

PU has wide-ranging applications, including foams, elastomers, films, coatings, fibers, hydrogels, and composites. Industrial applications include automotive, electronics, construction, footwear, and packaging. In biomimetic materials, PU can create soft tissue analogs, bone scaffolds, drug carriers, and smart wearable devices. Its tunable mechanical properties and versatile chemical functionality make it a preferred high-performance material across industries.

-

What are the biomedical applications of polyurethane materials and coatings?

PU is used in biomedical applications such as tissue engineering scaffolds, artificial vessels, wound dressings, and wearable medical device coatings. Surface modification enables antibacterial activity, controlled drug release, degradation control, and optimized blood compatibility, supporting bone and soft tissue regeneration as well as medical device functionality. PU is a key polymer choice for biomimetic and medical applications.

-

Is polyurethane a hydrogel?

Polyurethane is not inherently a hydrogel, but PU hydrogels can be prepared through chemical crosslinking or physical modification, offering high water absorption, flexibility, and tunable mechanical properties. PU hydrogels are widely used in soft tissue biomimetics, tissue engineering scaffolds, drug delivery systems, and bioinspired medical materials, with adjustable hydrophilicity, degradation rate, and biocompatibility according to application needs.

Polyurethane Fiber Preparation

Polyurethane Fiber Preparation

Polyurethane Coating Preparation

Polyurethane Coating Preparation

Polyurethane Scaffold Preparation

Polyurethane Scaffold Preparation

Polyurethane Film Preparation

Polyurethane Film Preparation

Polyurethane Hydrogel Preparation

Polyurethane Hydrogel Preparation

Polyurethane Microsphere Preparation

Polyurethane Microsphere Preparation