Polycaprolactone Scaffold Preparation

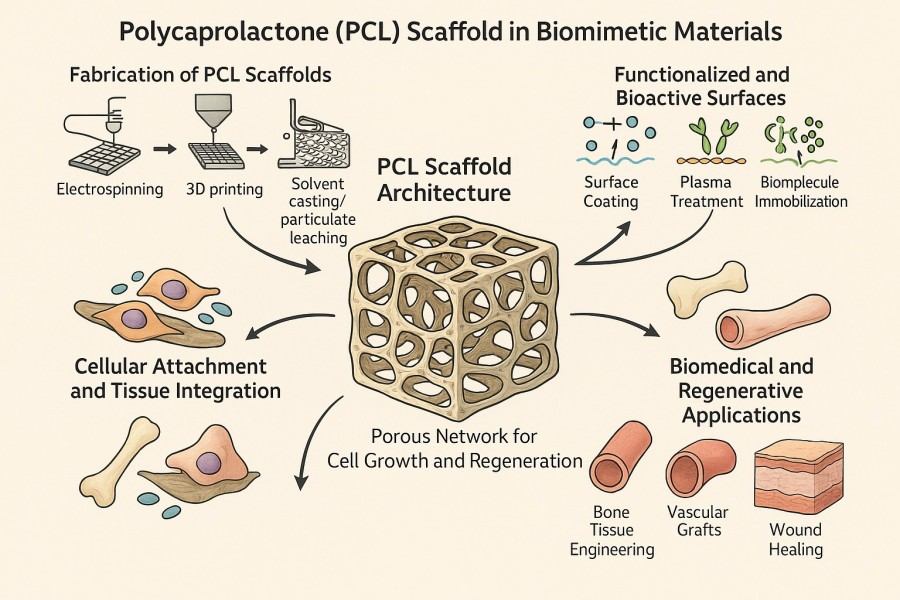

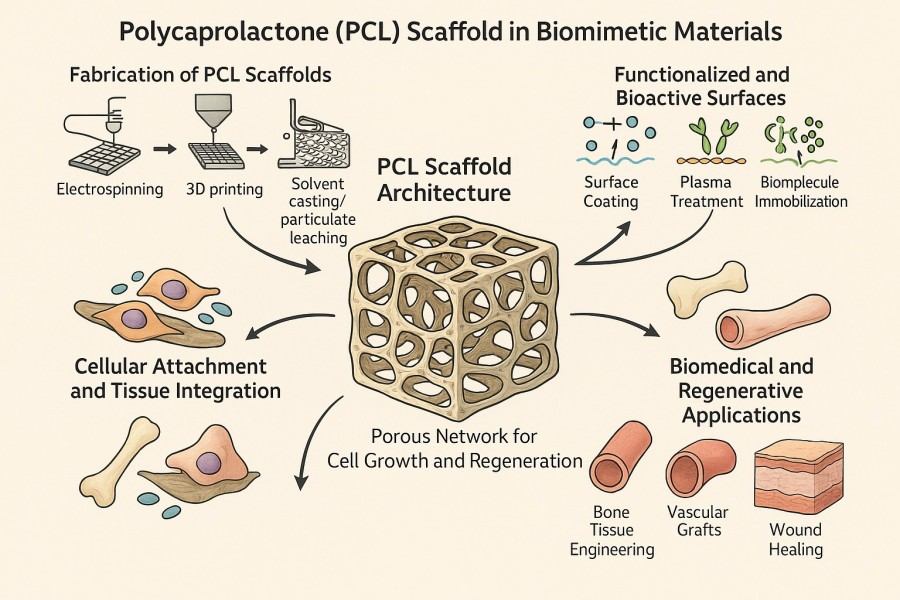

Polycaprolactone (PCL) is a synthetic, biodegradable polyester known for its excellent biocompatibility, processability, and controllable degradation rate. Due to its unique physicochemical properties, PCL has been widely used in tissue engineering, biomaterials, drug delivery systems, and degradable medical devices. Among these, polycaprolactone scaffold, with its three-dimensional porous structure, can mimic the extracellular matrix (ECM) microenvironment, providing ideal physical support and biochemical signals for cell adhesion, growth, and differentiation. It serves as a vital platform for tissue engineering and regenerative medicine research. By adjusting molecular weight, copolymer ratios, pore sizes, and surface chemical modifications, PCL scaffolds can be tailored to meet the specific needs of different tissue types (such as bone, cartilage, blood vessels, skin, etc.), thus achieving desired biological functions. BOC Sciences offers professional PCL scaffold preparation services, designing and manufacturing scaffolds that meet specific application requirements based on customer needs. By precisely controlling the scaffold's pore structure, size, morphology, and degradation rate, we ensure that each PCL scaffold provides an ideal biological environment to promote cell growth and differentiation, aiding in the regeneration of various tissues. Whether used for 3D printing, drug-controlled release systems, or personalized tissue repair, we provide high-quality, customized solutions.

What We Offer

Need Custom PCL Scaffolds? Let BOC Sciences Help

With its advanced polymer manufacturing platform, BOC Sciences provides a comprehensive range of customizable PCL scaffolds, covering structure, morphology, functionality, and composition to meet the rigorous requirements of various tissue engineering applications.

PCL Porous Scaffold

- Precise Control of Pore Structure: Customizable high porosity and wide pore size range (e.g., 100 μm - 500 μm), optimizing cell infiltration.

- Spongy and Foam-Like Structures: Providing high connectivity spongy or foam-like PCL porous structures suitable for tissue filling.

- Adjustable Degradation Rate: Customizable PCL/PLGA composite scaffolds for synchronized degradation control.

PCL Fibrous Scaffold

- Custom Nanofiber/Microfiber Structures: Precisely controlled fiber diameters to mimic natural ECM structures, improving surface area.

- Oriented and Randomly Arranged Fibers: Preparation of highly oriented fiber membranes (e.g., for nerve conduits) to guide cell directional growth.

- Hollow and Coaxial Fiber Customization: Hollow or coaxial electrospinning services for controlled release of drugs/growth factors.

Surface-Modified Scaffold

- Hydrophilic Functional Group Grafting: Chemical or plasma treatment to introduce hydrophilic groups on PCL surfaces, enhancing cell affinity.

- Covalent Grafting of Bioactive Molecules: Custom RGD peptides, growth factors, and other molecules grafted for specific cell recognition sites.

- LBL Multilayer Coating Services: Using layer-by-layer (LBL) self-assembly to create multifunctional bioactive surfaces.

Composite PCL Scaffold

- PCL-Inorganic Bone-Conducting Composites: Custom PCL/HAp or PCL/beta-TCP composite scaffolds to enhance mechanical and bone-inductive properties.

- PCL-Natural Polymer Blends: Offering PCL blends with collagen, silk fibroin, and others to optimize flexibility and biological signaling.

- Drug/Factor Integrated Systems: Custom PCL matrices integrated with antibiotics or growth factors for functional, sustained release.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Ready to Elevate Your Research? Get Expert PCL Scaffold Support

Our services extend beyond basic scaffold preparation, encompassing the entire process from formulation design, structural simulation, process optimization, surface functionalization, biological performance characterization, and application validation. Using various preparation techniques (such as electrospinning, 3D printing, freeze-drying, and solvent casting) and composite modification strategies (such as PCL/HA, PCL/PLGA blends, and surface bio-coatings), we offer customized solutions for different research directions.

1Material Design and Formulation Development

- Custom molecular weights (10,000 - 80,000 Da) and copolymer ratios (e.g., PCL-PEG, PCL-PLGA).

- Incorporating active components such as growth factors, nano-hydroxyapatite, and collagen.

- Designing porous structural parameters (pore size, porosity, surface area).

- Surface modification options: Plasma treatment, peptide/polysaccharide coatings, carboxylation or amination functionalization.

2Scaffold Preparation Technologies

- Electrospinning: Producing nanofiber membranes or three-dimensional fiber networks, suitable for skin and nerve tissue engineering.

- 3D Printing: Achieving precise control over porous geometric structures for bone or cartilage repair.

- Solvent Casting–Particulate Leaching: Producing high-porosity scaffolds for cell culture.

- Freeze-Drying: Creating highly porous structures to promote cell infiltration and nutrient exchange.

3Functionalization and Performance Optimization

- Scaffold surface bioactivation (collagen, RGD peptides, chitosan coatings).

- Controlling degradation rates and mechanical strength adjustments.

- Drug or growth factor loading for localized release functionality.

- Composite materials (e.g., PCL/HA, PCL/PLLA) development to balance mechanical properties and biological activity.

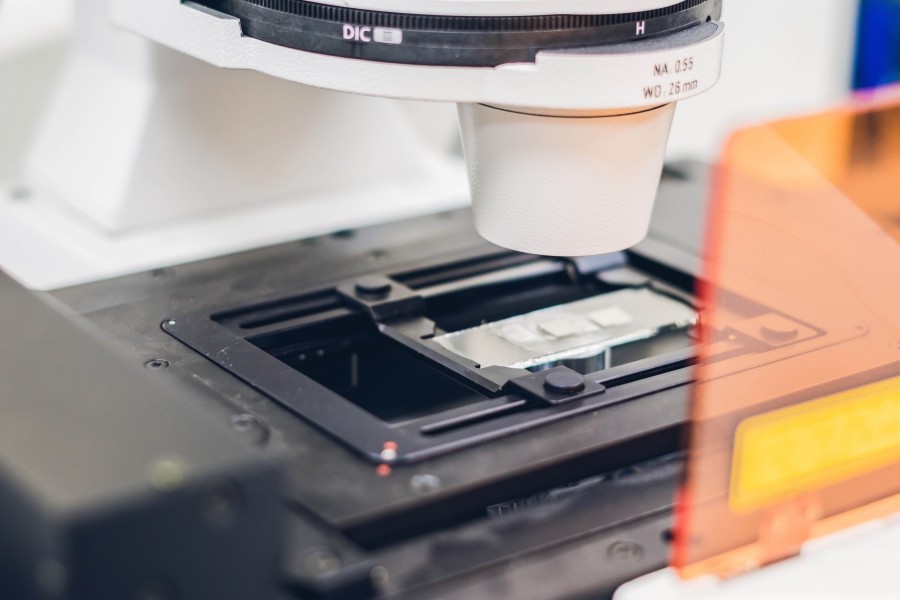

4Structural and Performance Characterization

- Scanning Electron Microscopy (SEM) to observe scaffold pore structure.

- FTIR, DSC, GPC analysis for chemical composition and thermal properties.

- Mechanical performance testing (compressive modulus, tensile strength).

- Biocompatibility and cytotoxicity testing.

- Degradation behavior and release kinetics evaluation.

Advantages

Why Choose BOC Sciences for Your PCL Scaffold Preparation?

- Expert Technical Team: Our team of experts with backgrounds in polymer chemistry, biomaterials, and tissue engineering provides full technical support from PCL polymer synthesis to scaffold functionalization development.

- Multi-Process Preparation Platform: Integration of electrospinning, 3D printing, freeze-drying, solvent casting, and other techniques, offering flexibility to meet various tissue type and mechanical performance needs.

- Controlled Structural Design: Precision control over scaffold pore size, porosity, fiber arrangement, and interlayer structures to create an ideal environment for cell adhesion, migration, and nutrient exchange.

- Surface and Composite Functionalization: Supports surface modification, bio-molecular coatings, and multiphase composite systems, significantly enhancing scaffold biocompatibility and functional performance.

- High-Standard Characterization and Validation: Providing multidimensional analysis for material chemistry, mechanical properties, biocompatibility, and degradation performance, ensuring that scaffold performance is verifiable and traceable.

- Customized Project Solutions: Tailored material formulations and process routes based on customer research directions (e.g., bone, cartilage, skin, or nerve tissue engineering) to facilitate successful result translation.

- Full-Cycle Client Support: Providing continuous and precise technical collaboration and after-sales service from initial technical consultations, experimental plan optimization to sample testing and report analysis.

Service Process

PCL Scaffold Preparation Service Process

BOC Sciences ensures the efficient progression and stable quality of each PCL scaffold project through a systematic and traceable R&D process. From requirements analysis to experimental validation, we provide a full-process, modular preparation and development support system to help clients quickly obtain biomimetic material samples that meet specific structural and performance requirements.

1Project Requirement Communication

At the project initiation stage, we engage in close communication with our clients to gain a deep understanding of their research goals and application needs. This process includes discussing the target tissue type, desired scaffold performance, degradation rate, and porosity requirements. Through this precise requirement analysis, we tailor a scientific technical plan and preparation route to ensure that the subsequent scaffold design and development align perfectly with the project needs.

2Material Selection and Formulation Design

Based on the specific needs of the project, we provide custom material choices, ranging from basic PCL to copolymers (such as PCL-PLGA, PCL-PEG, etc.), adjusting molecular weight and copolymer ratios to achieve the desired performance. We can also incorporate other bioactive components, such as collagen, hyaluronic acid, and nano-hydroxyapatite, to enhance cell adhesion and tissue regeneration properties, ensuring that the scaffold delivers optimal performance for specific applications.

3Scaffold Preparation and Structural Forming

We employ various advanced scaffold preparation techniques, such as electrospinning, 3D printing, freeze-drying, and solvent casting, to ensure the scaffold has ideal porosity and mechanical properties. Electrospinning technology enables the creation of nano-scale fiber networks, ideal for mimicking the extracellular matrix (ECM); 3D printing can create complex three-dimensional structures suitable for bone, cartilage, and other applications. Each technique is optimized according to the project needs, ensuring high precision and functionality.

4Surface Modification and Functionalization

To improve the biocompatibility and functionality of PCL scaffolds, we offer surface modification services, including plasma treatment and chemical grafting, to increase hydrophilicity or introduce functional groups. By coating with bioactive substances such as collagen, RGD peptides, or hyaluronic acid, we significantly enhance cell adhesion and proliferation, further improving the scaffold's tissue induction and regenerative effects, particularly in scenarios requiring rapid cell penetration and growth.

5Performance Testing and Quality Verification

BOC Sciences provides comprehensive performance testing and quality verification services to ensure each PCL scaffold meets strict quality standards. We perform scanning electron microscopy (SEM) analysis to evaluate pore size and structure; thermal analysis (DSC) and molecular weight analysis (GPC) to assess material thermal properties and molecular structure; and mechanical testing to ensure the scaffold possesses the required strength and stability for application. We also provide biocompatibility testing to ensure the safety and effectiveness of the scaffold for in vivo applications.

6Report Delivery and Ongoing Support

Upon completion of the project, we provide clients with a detailed experimental report covering material formulations, preparation processes, performance testing results, and data analysis to ensure scaffold quality and reproducibility. We also offer continued technical support, including secondary optimization and long-term collaboration services. Whether for project continuation, material adjustments, or handling new requirements, our technical team is always available to provide professional advice and support, ensuring the continued success of the project.

Applications

Unlock the Power of PCL Scaffold Application for Your Research

Due to their excellent biocompatibility, degradability, and superior mechanical properties, PCL scaffolds have become one of the most promising scaffold materials in the field of biomimetic materials. The customizable PCL scaffolds offered by BOC Sciences not only replicate the structure and function of natural tissues but can also meet specific application needs through modification and composite design. They are widely applied in tissue engineering, drug delivery systems, wound repair, and regenerative medicine.

Bone Tissue Engineering and Repair

PCL scaffolds are used in bone tissue engineering, especially in bone defect repair. By adjusting pore size, porosity, and degradation rate, PCL scaffolds provide the necessary support for bone tissue regeneration, promoting the adhesion and proliferation of bone cells. When combined with hydroxyapatite (HA) or β-TCP, the scaffold enhances osteogenic ability and is eventually replaced by newly generated bone tissue.

Cartilage Tissue Repair

PCL scaffolds are used for cartilage repair, particularly in joint cartilage damage treatment. Using electrospinning and 3D printing technologies, PCL scaffolds mimic the elasticity and mechanical properties of cartilage, promoting the proliferation and differentiation of chondrocytes. When combined with natural polymers such as collagen and gelatin, PCL scaffolds help repair cartilage tissue and support the regeneration of articular cartilage.

Skin and Wound Repair

PCL scaffolds are widely used in skin regeneration and wound repair. Through electrospinning technology, PCL scaffolds are made into nanofiber membranes that mimic the structure of skin tissue, promoting the growth of fibroblasts and keratinocytes. These scaffolds can be loaded with antibiotics or growth factors to enhance wound healing and reduce infection risks, making them especially suitable for burn and chronic wound treatments.

Drug Delivery and Controlled Release Systems

PCL scaffolds are used in drug delivery systems to achieve sustained and controlled release of drugs. By adjusting the porosity of the PCL scaffold, drugs can be evenly distributed and slowly released. These scaffolds are commonly used for the delivery of antibiotics, anti-inflammatory drugs, and growth factors, providing localized treatment, reducing side effects, and extending therapeutic efficacy.

Neural Tissue Engineering and Conduit Repair

PCL scaffolds are used in nerve repair to create nerve conduits that promote peripheral nerve regeneration. By precisely controlling the pore structure through 3D printing, scaffolds provide support and guide nerve axon growth. When combined with neurotrophic factors, PCL scaffolds accelerate nerve repair and help restore nerve function, especially in nerve injury treatments.

Ophthalmology and Retinal Repair

PCL scaffolds are used in ophthalmology for the repair of the retina and cornea. Their excellent biocompatibility and mechanical strength make them ideal materials for ophthalmic implants, supporting the regeneration of damaged retina or cornea. Using 3D printing technology, PCL scaffolds can be precisely matched to the structure of eye tissues, facilitating the repair of eye injuries and providing a new approach for vision restoration.

FAQs

Frequently Asked Questions

-

What is a PCL scaffold?

A PCL scaffold is a three-dimensional structure made from polycaprolactone, a biodegradable polymer. It is commonly used in tissue engineering to support the growth of new cells and tissues. Due to its slow degradation rate, PCL scaffolds provide long-term structural support, making them ideal for applications that require sustained tissue regeneration. These scaffolds can be customized for different tissue types and are often used in regenerative medicine, including bone and cartilage repair.

-

How is PCL used in tissue engineering?

PCL scaffolds play a vital role in tissue engineering by providing a matrix for cells to grow and form new tissues. Their biocompatibility and controlled degradation rate allow PCL scaffolds to support tissue regeneration over time. These scaffolds can be seeded with cells and growth factors to encourage tissue development, and they degrade naturally as the tissue forms, making them ideal for repairing bones, cartilage, and other tissues in the body.

-

What is a PCL 3D printed scaffold?

A PCL 3D printed scaffold is a custom-designed structure made using 3D printing technology with polycaprolactone (PCL). This method allows for precise control over the scaffold's geometry, porosity, and size, optimizing it for specific tissue engineering applications. 3D printing also enables the creation of complex structures that mimic the natural extracellular matrix, providing an ideal environment for cell growth and tissue regeneration. PCL 3D printed scaffolds are commonly used in the fields of regenerative medicine and drug delivery systems.

-

What is the difference between PCL Scaffold and PLGA Scaffold?

PCL scaffolds and PLGA scaffolds differ significantly in degradation rate and application areas. PCL degrades more slowly, typically taking several months to years to fully degrade, making it suitable for long-term tissue repair, such as bone repair and cartilage regeneration. In contrast, PLGA degrades faster, usually within weeks to months, making it more appropriate for short-term drug release or rapid tissue repair. Both can be blended to create composite materials, balancing degradation rate and biological function to meet various application needs.

-

Can drugs or growth factors be loaded into PCL scaffolds?

Yes, PCL scaffolds can be loaded with drugs or growth factors using various strategies for controlled release. Active substances can be embedded or adsorbed into the PCL scaffold using drug encapsulation, electrospinning blending, or surface adsorption methods. These drugs or growth factors are gradually released as the scaffold degrades, providing sustained therapeutic effects.

-

Can the degradation time of PCL scaffolds be adjusted?

Yes, the degradation time of PCL scaffolds can be adjusted by modifying the molecular weight of PCL, copolymerizing with other materials, or blending with other polyesters such as PLGA. Higher molecular weight PCL degrades more slowly, making it suitable for long-term tissue repair, while lower molecular weight PCL degrades more quickly, suitable for short-term applications. Through modification or blending, degradation time can be adjusted from several months to several years to meet different tissue engineering and clinical treatment needs.

-

Is biocompatibility testing available?

Yes, BOC Sciences provides comprehensive biocompatibility testing to ensure PCL scaffolds meet safety standards for tissue engineering. Tests include cell adhesion, proliferation, migration, and cytotoxicity to evaluate scaffold interactions with various cell types. These results verify in vivo safety and reliability for clinical use, ensuring suitability for medical applications.