Chitosan Hydrogel Preparation

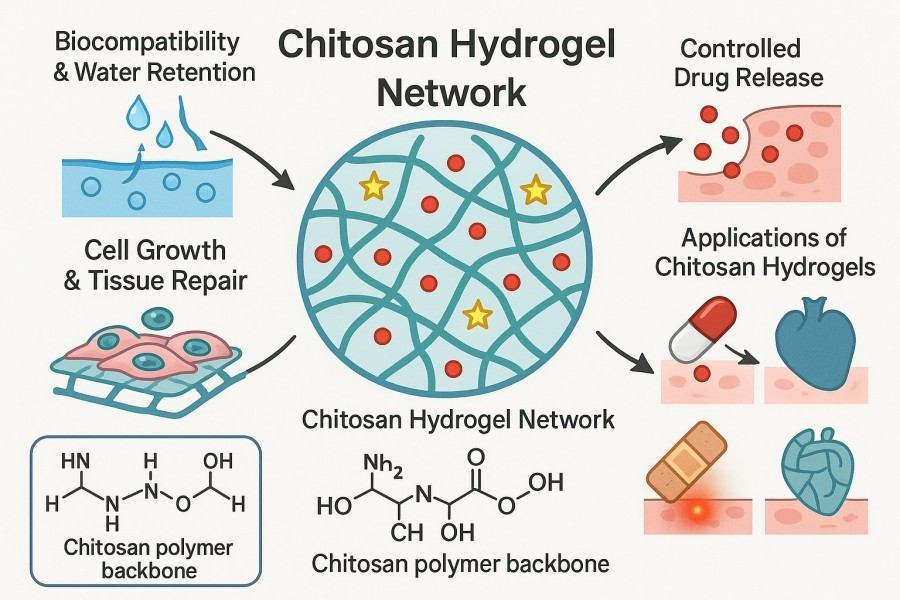

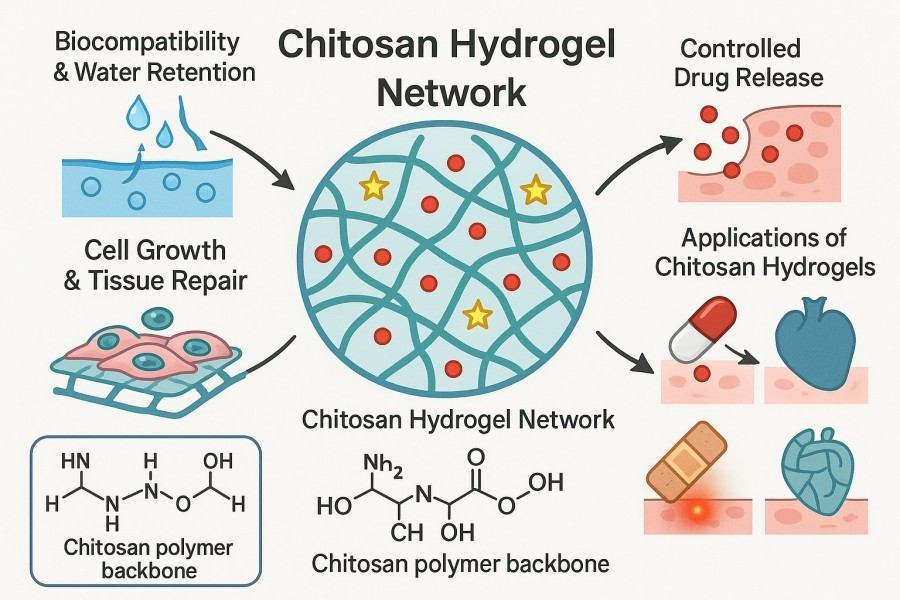

Chitosan is a natural cationic polysaccharide obtained by the deacetylation of chitin. It possesses unique amino functional groups that can form three-dimensional hydrogel networks through physical or chemical crosslinking. These hydrogel systems not only maintain a high water content in aqueous environments but also mimic the structure of natural extracellular matrices, providing an ideal platform for cell growth, drug release, or pollutant adsorption. Currently, chitosan hydrogels (chitosan gels) are a research and application hotspot in biomedical materials due to their natural origin, biodegradability, tunable structure, and modifiable functionality. Leveraging its strong polymer chemistry expertise, BOC Sciences offers one-stop services ranging from customized chitosan hydrogel design, raw material selection, preparation optimization, crosslinking strategy development, and performance analysis to scale-up production support, helping research and industrial clients efficiently advance biomimetic material development and applications.

What We Offer

Comprehensive Chitosan Hydrogel Preparation Services

With solid polymer chemistry foundations and advanced custom synthesis platforms, BOC Sciences provides development, preparation, and performance optimization services for various types of chitosan hydrogels. We can quickly supply standard products according to conventional formulations, and we also offer flexible adjustments of chitosan molecular weight, degree of deacetylation, crosslinking method, and gel characteristics according to specific research directions and application requirements, enabling full-process technical support from laboratory-scale trials to pilot-scale expansion.

By Material Composition

- Pure Chitosan Hydrogels: Formed solely from chitosan via physical or chemical crosslinking, without other polymers or nanocomponents.

- Composites with Natural Polymers: Such as gelatin, hyaluronic acid, or sodium alginate, enhancing bioactivity and biomimetic properties.

- Composites with Synthetic Polymers: Such as PVA, PEG, or PLGA, improving mechanical performance and processability.

- Nanomaterial-Enhanced Hydrogels: Incorporating graphene oxide, nanosilver, or magnetic nanoparticles to provide antibacterial, conductive, or magnetic responsiveness.

By Form and Application

- Bulk Hydrogel: Prepared as large gel blocks, such as scaffolds, implants, or tissue fillers, commonly used in tissue engineering.

- Micro/Nanogel: Produced via ionic crosslinking, emulsion polymerization, or similar methods, with particle sizes ranging from nanometers to microns, often used for drug delivery.

- Injectable Hydrogel: Delivered as a solution that gels in situ, minimizing trauma, suitable for soft tissue repair and localized treatment.

- Film/Coating Hydrogel: Formed as thin layers for wound dressings, food preservation coatings, or drug-releasing patches.

By Stimuli-Responsive Properties

- pH-Responsive Chitosan Hydrogel: Utilizes protonation of amino groups to control swelling and release, suitable for intestinal drug delivery or tumor microenvironment release.

- Temperature-Responsive Chitosan Hydrogel: Blended with thermosensitive materials, gelling near body temperature for injectable repair or local sustained release.

- Electro-/Magnetically Responsive Chitosan Hydrogel: Incorporates conductive or magnetic components to control swelling and release under external fields, used in sensing and controlled release.

- Multi-Responsive Chitosan Hydrogel: Responds to multiple stimuli, mimicking physiological changes for complex release systems in tumors or wound sites.

By Crosslinking Method

- Ionic Crosslinking: Uses multivalent anions (e.g., sodium tripolyphosphate) and chitosan amino groups for gelation, commonly used for nano/microsphere carriers.

- Covalent Crosslinking: Employs epoxy, aldehyde, acyl chloride, or similar agents to form stable 3D networks.

- Natural Crosslinkers: Uses more biocompatible agents such as tannic acid, citric acid, or chitosan oligosaccharide derivatives.

- Photo- and Click-Chemistry Crosslinking: Based on polymerizable groups on modified chitosan, rapidly cured with UV or visible light, suitable for 3D printing and complex structures.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Chitosan Hydrogel Development Technologies by BOC Sciences

With extensive experience in polymer chemistry and materials science, BOC Sciences offers comprehensive, customized technical support for chitosan hydrogel development. By combining advanced preparation methods, precise structural control techniques, and comprehensive performance analysis, we help research institutions and enterprises rapidly construct high-performance hydrogel systems tailored to application requirements. From laboratory-scale trials to pilot-scale expansion, BOC Sciences delivers one-stop technical solutions to ensure an efficient, reliable, and reproducible R&D process.

1Customized Development Services

- Multi-Specification R&D: Design hydrogels with different molecular weights, degrees of deacetylation, and crosslinking densities according to client needs.

- Multi-Batch Production: Provide customized production from small-scale R&D samples to pilot or kilogram-scale expansion.

- Application-Oriented Optimization: Adjust hydrogel structure and functionality according to target applications such as drug delivery, tissue engineering, or biomimetic materials.

- Technical Coordination and Support: Full technical consultation, solution design, and performance validation to ensure materials meet client requirements.

2Precise Structural Control

- Molecular Weight Regulation: Select chitosan of different molecular weights to adjust gel network density and swelling properties.

- Degree of Deacetylation Adjustment: Control amino group content to optimize biocompatibility and crosslinking efficiency.

- Crosslinking Density Control: Fine-tune crosslinker dosage and reaction conditions to optimize mechanical strength, porosity, and degradation behavior.

- Composite Ratio Adjustment: Control the proportion of chitosan to other materials for precise matching of mechanical, responsive, and functional performance.

3Composite Material Design

- Polymer Composites: Combine chitosan with other biopolymers (e.g., gelatin, hyaluronic acid) to enhance biocompatibility and mechanical properties.

- Nanomaterial Composites: Introduce nanoparticles (e.g., nano-hydroxyapatite, carbon nanotubes) to improve mechanical strength or add conductivity, magnetism, etc.

- Protein or Biofactor Composites: Load growth factors or proteins to mimic natural tissue environments, improving cell adhesion and tissue regeneration.

- Multi-Functional Composite Strategies: Integrate different material properties to synergistically optimize mechanical strength, responsiveness, and functional applications.

4Scale-Up Preparation and Process Control

- Lab-Scale Optimization: Validate formulations, crosslinking methods, and gel performance to select optimal R&D conditions.

- Pilot-Scale Process Expansion: Optimize reaction conditions and workflows to ensure batch consistency and stable performance.

- Kilogram-Scale Production Preparation: Achieve controlled scale-up to meet industrial or preclinical material demands.

- Process Monitoring and Control: Real-time monitoring of critical parameters such as temperature, pH, and reaction time to ensure controllable hydrogel quality.

Characterization

Performance Analysis and Characterization of Chitosan Hydrogels

BOC Sciences leverages comprehensive analytical platforms and a professional technical team to provide full performance analysis and characterization services for chitosan hydrogels. These services cover structural confirmation, physicochemical property measurement, mechanical and rheological analysis, gel property evaluation, and stimuli-responsive behavior studies. We support all stages from fundamental research to industrial development, helping clients deeply understand material characteristics, optimize preparation processes, and achieve reproducible, scalable, high-quality product development.

| Category | Analysis Description | Purpose and Value |

|---|

| Chemical Structure Analysis | Techniques such as FTIR, NMR, and XPS are used to identify functional groups, crosslinking bonds, and modifications in chitosan. | Verify the effectiveness of chemical modifications and crosslinking reactions to ensure the material structure matches the design. |

| Physicochemical Characterization | Includes measurements of water content, swelling ratio, degradation rate, and pH sensitivity. | Reveal the stability, water absorption, and degradability of the hydrogel under different conditions for material selection and design. |

| Mechanical & Rheological Properties | Compression, tensile, and rheological tests to evaluate strength, elasticity, and flow behavior. | Understand structural stability and handling properties in application environments, supporting tissue engineering and injectable uses. |

| Pore Structure & Morphology | SEM, TEM, and laser particle size analysis to observe micro-pore structure and network morphology. | Optimize preparation parameters, control pore size distribution, and influence drug release rates and cell permeability. |

| Gelation Properties Evaluation | Measurement of gelation time, crosslinking density, gel fraction, and swelling kinetics curves. | Assess gelation behavior and structural stability, essential for injectable and in situ forming systems. |

| Stimuli-Responsive Properties | Study the hydrogel's response to pH, temperature, electric, or magnetic fields. | Develop smart responsive hydrogels for targeted delivery, dynamic scaffolds, or controlled release systems. |

| Drug Loading & Release Performance | In vitro drug release studies to determine drug loading capacity, release profiles, and kinetic models. | Provide key parameters for optimizing drug delivery systems, supporting sustained, targeted, or multi-responsive designs. |

Advantages

Advantages of Our Chitosan Hydrogel Services

- Diverse Preparation Techniques: Covers physical crosslinking, chemical crosslinking, composite hydrogels, and stimuli-responsive hydrogels.

- Precise and Controllable Structural Tuning: Mechanical, swelling, and responsive properties are adjusted through precise control of molecular weight, degree of deacetylation, crosslinking density, and composite ratios.

- Comprehensive Performance Analysis Platform: Provides structural characterization, swelling/degradation behavior analysis, pore structure evaluation, mechanical testing, and preliminary biocompatibility assessment.

- Innovative Design for Biomimetic Materials: Integrates functional units such as thermosensitive, pH-responsive, and electrically responsive components to construct intelligent chitosan hydrogel systems.

- Full-Chain Service from Lab to Pilot Production: Supports production from gram-scale research samples to kilogram-scale or larger, providing technical assurance for industrialization.

- Global Service Network: Offers professional customized services to research institutions, biotech companies, pharmaceutical enterprises, and new materials companies.

- Strong Chemistry and Materials Expertise: Team possesses integrated skills in polymer synthesis, material characterization, and biomimetic material design.

- Flexible Customization Capability: Supports multi-specification, multi-batch R&D and production to meet diverse project requirements.

- Rapid Response and High-Quality Delivery: Clear workflow, short turnaround, and smooth technical coordination ensure efficient project completion.

Service Process

Custom Development Process for Chitosan Hydrogels

BOC Sciences has established a systematic and standardized custom development workflow for chitosan hydrogel R&D and industrialization, efficiently connecting all stages from concept validation to product delivery. Whether for fundamental research, biomimetic material development, drug delivery, or tissue engineering applications, we can flexibly adjust technical routes according to client needs, providing full-process support for custom synthesis, formulation design, performance optimization, scale-up preparation, and quality testing. Through rigorous project management and technical collaboration, we help clients accelerate material translation, shorten development cycles, and ensure reproducibility and application value.

1Requirement Communication and Technical Assessment

At the project outset, we engage in thorough technical discussions with clients to clarify target applications, material performance requirements, crosslinking methods, gel characteristics, and expected scale. Our technical team assesses project feasibility based on chitosan molecular weight, degree of deacetylation, modification strategies, and provides preliminary technical routes and recommendations to guide subsequent R&D.

2Structural Design and Formulation Development

Once objectives are defined, we design chitosan hydrogel structures and develop formulations based on application needs, including backbone modifications, types and ratios of crosslinkers, reaction medium conditions, and functional component addition. Small-scale experiments and multifactor comparisons are performed to rapidly identify formulations with ideal gel properties and responsive characteristics, laying the foundation for performance optimization.

3Small-Scale Optimization and Validation Experiments

After preliminary formulation selection, systematic small-scale optimization is conducted, focusing on gelation time, pore structure, mechanical strength, swelling, and degradation behavior. Preliminary validation in simulated application environments ensures material stability and operability, providing reliable technical support for pilot-scale expansion.

4Process Scale-Up and Performance Stabilization

Based on small-scale results, pilot-scale expansion and standardization of process flows are carried out. Reaction conditions, raw material batch control, and crosslinking processes are optimized to ensure stable performance and batch consistency during scale-up. Key parameters are continuously monitored to enable efficient transition from laboratory to industrial production.

5Application-Oriented Functional Validation

For different application fields such as drug delivery, tissue repair, or smart responsive systems, application-specific functional validation experiments are conducted, including drug loading and release characteristics, cell compatibility, biodegradability, and response to external stimuli, ensuring material feasibility and performance in practical applications.

6Quality Testing and Delivery Support

In the final stage, customized chitosan hydrogels undergo comprehensive quality testing and performance characterization to ensure stability and traceability. Detailed analytical reports, technical documentation, and process parameter records can be provided according to client needs. Technical support is also offered for regulatory standards or industrial verification, facilitating smooth project delivery and subsequent applications.

Applications

Applications of Chitosan Hydrogels in Biomimetic Materials

Chitosan-based hydrogels, with excellent biocompatibility, biodegradability, tunable structure, and functionalization potential, have become core materials in biomimetic material research and applications. In biomimetic material design, chitosan hydrogels can mimic the microenvironment of natural tissues. Controlled pore structures and mechanical properties provide ideal carriers for cell growth, tissue repair, and functional biomaterials. Additionally, their adjustable responsiveness (e.g., pH, temperature, electric field, magnetic field) enables smart controlled release, adaptive morphology, or dynamic responses, meeting application needs under complex physiological or environmental conditions.

Tissue Engineering Scaffolds

Chitosan hydrogels can form three-dimensional networks similar to natural extracellular matrices, providing supportive environments for stem cells and functional cells. Their tunable pore structures and mechanical properties promote cell adhesion, proliferation, and differentiation, widely applied in soft tissue, bone, and neural repair studies, fulfilling diverse tissue engineering requirements.

Injectable Soft Tissue Fillers

Injectable chitosan hydrogels gel in situ, filling tissue defects or wound sites while minimizing surgical trauma. Their degradable nature provides sustained support, promoting tissue regeneration and repair, and supports local drug delivery or biofactor loading, making them ideal for clinical and experimental research.

Smart Drug Delivery Systems

By designing pH-, temperature-, and multi-stimuli-responsive hydrogels, chitosan hydrogels can achieve site-specific and controlled drug release, suitable for localized tumor therapy, sustained-release formulations, and precision treatment systems. Tunable network structures and responsive behaviors enhance drug stability and release efficiency, supporting complex therapeutic strategy development.

Biomimetic Functional Materials

Incorporating conductive, magnetic, or photoresponsive nanocomponents, chitosan hydrogels can be developed into smart responsive coatings, wearable sensors, and dynamic biomimetic materials, enabling functional regulation under environmental or physiological conditions. Such composite hydrogels have broad application prospects in biomimetic material design and bioelectronic interfaces.

In Vitro Cell Culture and Regenerative Support

Chitosan hydrogels provide controllable pores and mechanical environments to simulate natural cell growth conditions, suitable for in vitro culture and tissue regeneration research. Excellent biocompatibility enhances cell survival, differentiation efficiency, and functional tissue construction, supporting biomedical and regenerative medicine research.

Environmental and Engineering Biomimetic Materials

Exploiting the adsorptive capacity and tunable porosity of chitosan hydrogels, adsorbent materials, controlled-release fertilizer carriers, and environmental remediation hydrogels can be developed. By mimicking natural functions and controlled release mechanisms, innovative solutions for engineering and environmental applications are achieved, supporting agriculture, environmental, and materials science.

FAQs

Frequently Asked Questions

-

What is chitosan alginate hydrogel?

Chitosan alginate hydrogel is a two-component hydrogel formed by the electrostatic interaction between chitosan and alginate, featuring excellent biocompatibility and biodegradability. Its pore structure is tunable, making it suitable for drug delivery, tissue engineering scaffolds, and cell encapsulation. By adjusting the ratio of chitosan to alginate, the gel's mechanical properties and degradation rate can be optimized, enabling personalized designs for different tissue types and drug release requirements.

-

What are the characteristics of chitosan glutaraldehyde hydrogel?

Chitosan glutaraldehyde hydrogel is formed by chemical crosslinking between chitosan amino groups and glutaraldehyde, creating a stable network. This hydrogel has high mechanical strength, structural stability, and controllable degradation. It is commonly used for drug controlled release, tissue engineering, and industrial applications. By adjusting the crosslinker concentration and reaction conditions, pore size, mechanical performance, and swelling behavior can be precisely controlled while maintaining good biocompatibility, suitable for long-term in vivo or in vitro use.

-

What are the advantages of chitosan hyaluronic acid hydrogel?

Chitosan hyaluronic acid hydrogel combines the structural support of chitosan with the bioactivity of hyaluronic acid to form a three-dimensional scaffold. This hydrogel promotes cell adhesion, proliferation, and differentiation while supporting tissue regeneration. Its tunable pore size and mechanical properties can meet diverse tissue engineering needs, and it can serve as a carrier for drugs or biofactors to achieve sustained release. It is widely used in soft tissue repair, wound healing, and regenerative medicine research.

-

What are the characteristics of chitosan PEG hydrogel?

Chitosan PEG hydrogel is formed by combining chitosan with polyethylene glycol (PEG) to enhance solubility, biocompatibility, and mechanical properties. The hydrogel enables drug sustained release and injectable applications, with PEG chains reducing immune response and improving stability. Pore structure and responsiveness can be tuned, making it suitable for smart hydrogel design. It is widely applied in drug delivery systems, injectable tissue repair materials, and multifunctional stimuli-responsive biomimetic material development.

-

What is the application of PVA chitosan hydrogel?

PVA chitosan hydrogel, formed by blending polyvinyl alcohol with chitosan, enhances mechanical strength and elasticity. Its flexibility and biocompatibility make it suitable for soft tissue scaffolds, wound dressings, and biomedical materials. Gelation rate, pore size, and degradation behavior can be controlled through freeze-thaw cycles or crosslinker adjustments, enabling customized functional applications that meet mechanical and biological performance requirements in drug delivery or tissue engineering.

-

What are chitosan hydrogel beads used for?

Chitosan hydrogel beads are microspherical hydrogels made from chitosan, featuring controllable pore structures and large surface area. They are commonly used for drug controlled release, enzyme immobilization, and cell encapsulation. By adjusting crosslinking density and pore size, different release rates and degradation behaviors can be achieved. Their excellent biocompatibility and biodegradability make them widely applicable in biomedicine, tissue engineering, and functional material research, enabling long-term drug delivery and controlled biocatalytic reactions to meet research and industrial needs.

-

Is chitosan hydrogel for wound healing suitable for wounds?

Chitosan hydrogel for wound healing provides a moist environment, promotes hemostasis, and supports tissue regeneration. Its natural antibacterial properties reduce infection risk, and it can serve as a carrier for drugs or growth factors for localized sustained release. The hydrogel is flexible and conforms to wound shape, protecting new tissue. It is suitable for chronic wounds, burns, and postoperative injuries, supporting tissue repair and regenerative medicine research. Tunable pore structure and mechanical properties give it strong potential for clinical and research applications.

-

How to make chitosan hydrogel?

Chitosan hydrogel can be prepared by physical methods (e.g., ionic crosslinking, temperature induction) or chemical crosslinking (e.g., glutaraldehyde). Preparation steps include dissolving chitosan, adding crosslinkers, and controlling gelation conditions. By adjusting chitosan concentration, pH, temperature, and crosslinker ratio, pore structure, mechanical properties, and degradation rate can be controlled, producing hydrogels suitable for drug delivery, tissue engineering, or smart responsive systems. This method is flexible and can be optimized for functional and controllable properties according to specific application needs.

-

Is there a standard chitosan hydrogel protocol?

A standard chitosan hydrogel protocol usually involves dissolving chitosan in an acidic solution, selecting physical or chemical crosslinking methods, controlling gelation time and temperature, and performing sterilization and performance characterization. By adjusting chitosan molecular weight, degree of deacetylation, and crosslinker concentration, pore structure, mechanical properties, and biocompatibility can be precisely controlled. This protocol is suitable for drug controlled release, tissue engineering scaffolds, or biomimetic material development, ensuring stable and reproducible hydrogel performance for research and industrial applications.

-

Is 3D printing of chitosan hydrogels feasible?

3D printing of chitosan hydrogels allows chitosan hydrogels to be prepared as printable bioinks for constructing three-dimensional scaffolds. By adjusting chitosan concentration, crosslinking method, and printing parameters, scaffolds with controllable porosity and precise shapes can be produced, suitable for tissue engineering, regenerative medicine, and biomimetic material research. This method enables the construction of complex tissue structures, functional design, and supports drug or biofactor loading to meet research, clinical, and customized application requirements.