PLGA Scaffold Preparation

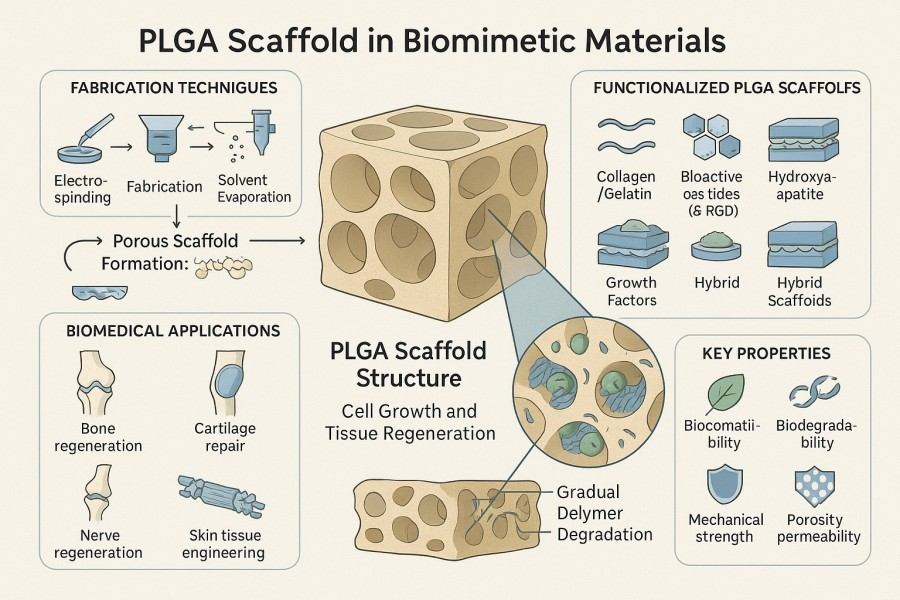

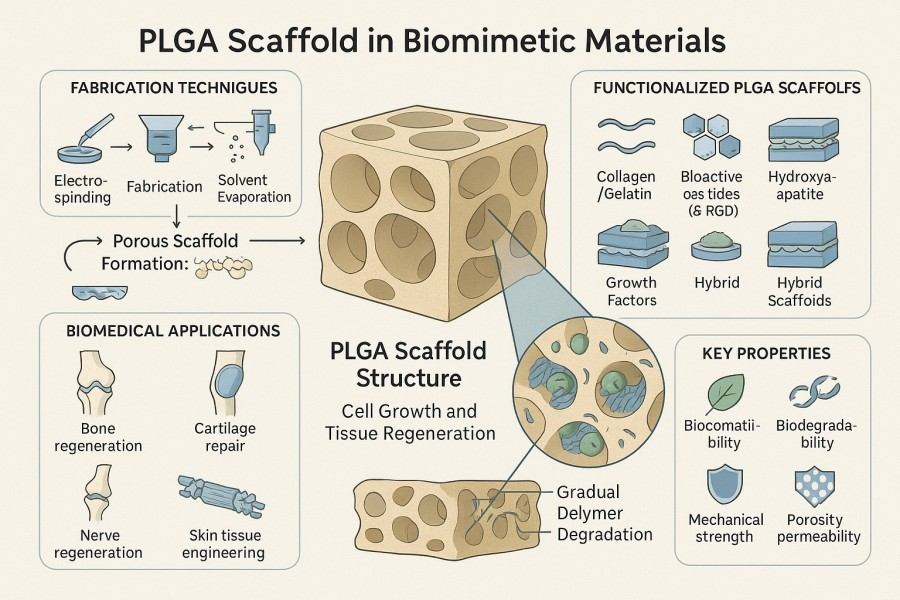

PLGA scaffold, short for poly(lactic-co-glycolic acid) scaffold, is a biodegradable material composed of polylactic acid (PLA) and polyglycolic acid (PGA) copolymerized in specific ratios. Owing to its excellent biocompatibility, controllable degradability, and mechanical strength, PLGA has been widely applied in tissue engineering, drug delivery, and regenerative medicine. In tissue engineering, scaffolds play a crucial role by mimicking the three-dimensional structure of the extracellular matrix (ECM), providing support for cell adhesion, proliferation, and differentiation, while enabling nutrient and waste exchange. By adjusting the PLA/PGA ratio, molecular weight, and fabrication process, PLGA scaffolds can be customized to exhibit different pore structures and degradation rates, meeting the diverse requirements of tissue engineering. BOC Sciences is dedicated to providing high-quality PLGA scaffold preparation and custom development services for research institutions, pharmaceutical companies, and biomaterials enterprises. Our one-stop solutions encompass material selection, fabrication process design, and functional modification. We focus on addressing customer needs in tissue engineering, drug-controlled release, biomimetic scaffold design, and customized functionalization, ensuring that every PLGA scaffold achieves optimal standards in structure, porosity, mechanical properties, and degradation performance. Through precise control of the lactic/glycolic acid ratio, molecular weight, and microstructure, we deliver personalized scaffold materials tailored to both research and production applications.

What We Offer

Looking for Reliable PLGA Scaffolds? Partner with BOC Sciences

With extensive experience and professional expertise, BOC Sciences offers a comprehensive range of PLGA scaffolds—from basic porous scaffolds to functional composite scaffolds. Whether for bone tissue, soft tissue, or drug carrier applications, we can tailor pore structures, mechanical properties, and functional characteristics to provide reliable support for scientific and industrial research.

Porous PLGA Scaffold

- Provides adjustable pore-size scaffolds suitable for bone, cartilage, and soft tissue applications.

- Customizable porosity and interconnectivity for enhanced cell adhesion and nutrient exchange.

- Supports drug or growth factor encapsulation for localized controlled release.

- Offers multiple PLA/PGA ratios and molecular weight options to meet specific degradation rate requirements.

Nanofibrous PLGA Scaffold

- Offers electrospun nanofiber scaffolds that mimic natural collagen fiber structures.

- Adjustable fiber diameter, alignment, and pore density to support skin, vascular, and stem cell culture applications.

- Supports drug or protein loading for functionalized nanofiber scaffolds.

- Provides surface modification and functional treatment to enhance cell adhesion and bioactivity.

Sponge-Like PLGA Scaffold

- Provides soft, compressible sponge-like porous structures ideal for soft tissue and wound repair.

- Adjustable pore size and distribution to create optimal cell growth environments.

- Supports drug loading and sustained release for local therapeutic use.

- Can be blended with natural polymers to enhance bioactivity and mechanical strength.

3D-Printed PLGA Scaffold

- Offers precisely customized 3D-printed scaffolds for complex, biomimetic tissue architectures.

- Adjustable pore gradient, channel orientation, and overall structure for personalized applications.

- Supports drug encapsulation and functional modification for controlled release and tissue guidance.

- Provides various material combinations and composite options to enhance mechanical and biocompatibility performance.

Drug-Loaded PLGA Scaffold

- Enables embedding of anticancer drugs, antibiotics, or growth factors for sustained local release.

- Customizable release profiles ranging from days to months.

- Supports multi-drug or multifunctional carrier development for complex therapeutic needs.

- Offers tailored scaffold structures and degradation rates to optimize drug release kinetics.

Functionalized/Composite PLGA Scaffold

- Provides PLGA scaffolds combined with collagen, gelatin, chitosan, or nanomaterials.

- Enables surface modification, functional coatings, or bioactivity enhancement treatments.

- Supports smart-responsive scaffold designs (e.g., pH-, temperature-, or enzyme-sensitive).

- Offers optimized composite material strategies for specific tissue types to enhance cell adhesion and vascularization.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Custom PLGA Scaffold Design and Fabrication Services

BOC Sciences offers comprehensive PLGA scaffold development services that integrate polymer chemistry, materials engineering, and drug delivery technologies, providing end-to-end solutions from molecular design to functional applications. Whether for research studies, controlled drug release, or complex tissue engineering, we deliver efficient and reliable technical support.

1Polymer Synthesis and Custom Modification

- Custom synthesis of PLGA polymers with varied lactic/glycolic acid ratios to meet different degradation and mechanical requirements.

- Adjustable molecular weight, end-group modification, and polymer architecture for precise control of scaffold performance.

- Supports the development of functional copolymers with drug-binding sites, reactive groups, or smart-responsive structures.

- Provides scalable synthesis from small laboratory batches to pilot and large-scale production.

2Scaffold Synthesis and Structural Design

- Offers customized synthesis of porous, nanofibrous, sponge-like, and 3D-printed scaffolds.

- Adjustable porosity, pore size distribution, and 3D architecture for application-specific optimization.

- Provides mechanical property enhancement and morphology control for structural stability and cell compatibility.

- Supports composite material design combining PLGA with natural polymers or nanomaterials to enhance functionality.

3Scaffold Drug-Controlled Release Functionalization

- Enables embedding of anticancer drugs, antibiotics, or growth factors for localized and controlled delivery.

- Provides diverse release profile designs, from short-term to long-term controlled drug release.

- Supports multi-drug or multifunctional carrier systems for combination therapy strategies.

- Offers optimization of drug loading efficiency, degradation rate control, and release kinetics verification for performance stability.

4Scaffold Surface Modification and Bioactivation

- Provides coating of scaffolds with collagen, gelatin, or growth factors to improve cell adhesion and biological activity.

- Enables hydrophilization, plasma treatment, or chemical modification for surface functionalization and cell guidance.

- Supports smart-responsive surface designs sensitive to pH, temperature, or enzymatic stimuli for dynamic regulation.

- Offers bioactivity evaluation and optimization services to ensure scaffold performance in tissue engineering and drug delivery applications.

Characterization

PLGA Scaffold Analysis and Testing Services

Equipped with advanced analytical instruments and an experienced technical team, BOC Sciences provides comprehensive PLGA scaffold characterization services. Our analyses cover multiple dimensions—from raw material properties and scaffold structure to functional performance—ensuring optimal quality in porosity, mechanical strength, degradation rate, and drug release behavior to support high-standard research and industrial applications.

| Test Category | Test Item | Description / Purpose |

|---|

| Chemical Characterization | FTIR (Fourier Transform Infrared Spectroscopy) | Verify PLGA chemical structure, functional groups, and success of functional modifications. |

| NMR (Nuclear Magnetic Resonance) | Determine lactic acid/glycolic acid ratio, polymer structure, and end-group modifications. |

| GPC (Gel Permeation Chromatography) | Measure molecular weight and distribution, evaluate polymer uniformity and degradation properties. |

| Physical Structure Analysis | SEM (Scanning Electron Microscopy) | Observe scaffold surface microstructure, pore morphology, and fiber arrangement. |

| Micro-CT (Micro-Computed Tomography) | 3D reconstruction of pore structure, quantitative analysis of porosity, pore size, and connectivity. |

| DSC (Differential Scanning Calorimetry) | Analyze polymer thermal properties, glass transition temperature, and crystallinity. |

| Mechanical Testing | Compression/Tensile Testing | Measure scaffold mechanical strength, elastic modulus, and deformation characteristics to ensure structural stability. |

| Degradation and Swelling Performance | Hydrolytic Degradation Test | Determine scaffold degradation rate and mass changes in simulated physiological environment. |

| Swelling Ratio Test | Evaluate pore water absorption capacity and structural stability. |

| Drug Release and Functional Analysis | Drug Release Profile | Assess release rate and mechanism of drugs embedded in the scaffold. |

| Bioactivity Evaluation | Measure scaffold support for cell adhesion, proliferation, or differentiation. |

| Surface Characterization | Contact Angle Measurement | Evaluate surface hydrophilicity and cell adhesion potential. |

| XPS (X-ray Photoelectron Spectroscopy) | Analyze surface elemental composition and chemical modifications. |

Advantages

Technology-Driven Advantages Supporting PLGA Scaffold Fabrication

- Extensive Fabrication Technologies: Our fabrication capabilities include solvent casting, phase separation, freeze-drying, 3D printing, and supercritical fluid processing. The optimal manufacturing method is selected according to specific application requirements.

- Personalized Customization: By adjusting the lactic/glycolic acid ratio, molecular weight, and porosity, we offer customized structural designs to meet diverse tissue engineering or drug delivery needs.

- Multifunctional Development: Our scaffolds can be designed for drug encapsulation, surface modification, composite material development, and smart-responsive functionality, providing a complete solution from basic scaffold preparation to advanced functional products.

- Rigorous Analysis and Quality Control: Equipped with FTIR, NMR, SEM, HPLC, and other analytical instruments, we ensure full-process monitoring from raw materials to final products, guaranteeing performance consistency and reliability.

- Experienced R&D Team: Our team of experts in biomaterials and polymer chemistry provides professional consultation and technical support, ensuring high-quality product delivery.

- Full-Process Service: We provide one-stop solutions covering material design, fabrication, functionalization, and quality control, ensuring every batch meets research and industrial standards in structure, performance, and functionality.

- Extensive Application Experience: Our experience spans bone, soft tissue, stem cells, and drug-controlled release applications in biomimetic materials, enabling highly customizable scaffold design and development support across multiple fields.

Service Process

Our Proven Workflow for Reliable PLGA Scaffold Production

BOC Sciences provides an end-to-end development process that covers every stage—from requirement communication, material selection, and formulation design to scaffold fabrication, functionalization, and performance evaluation. Our workflow ensures optimal porosity, mechanical properties, and degradation behavior while supporting advanced features such as drug-controlled release and surface modification. This enables us to deliver efficient, customizable solutions for both research and industrial applications.

1Requirement Communication

We work closely with clients to discuss application objectives, tissue types, pore size requirements, and functionalization needs for PLGA scaffolds. Comprehensive project background analysis and professional technical consultation are provided to ensure a scientifically sound development direction.

2Material Selection and Formulation Design

Based on application needs, we determine the appropriate PLA/PGA ratio, molecular weight, and scaffold type. Pore structure, mechanical properties, and drug-loading schemes are optimized to achieve ideal degradation rates, strength, and biocompatibility, ensuring a solid foundation for functional development.

3Fabrication and Processing

Using techniques such as solvent casting, phase separation, freeze-drying, electrospinning, and 3D printing, we achieve precise 3D scaffold fabrication. Nanofiber processing and composite material preparation can also be applied to meet various tissue engineering and biomimetic material requirements.

4Functionalization and Composite Development

We provide drug encapsulation, surface modification, and composite material preparation services according to customer specifications. Smart-responsive scaffolds can be designed to react to pH, temperature, or enzymatic stimuli, achieving controlled degradation and drug release for complex tissue engineering and controlled-release applications.

5Performance Evaluation and Quality Control

We evaluate porosity, pore size, mechanical strength, and degradation rate to ensure structural stability and reliability. Drug-loaded scaffolds undergo release profile testing and functional performance evaluation to ensure controlled drug release, reproducible performance, and compliance with scientific and industrial standards.

6Product Delivery and Technical Support

Customized PLGA scaffolds and detailed technical reports are delivered, ensuring transparency and traceability for each batch. Continuous R&D support and optimization recommendations are provided to help clients achieve the best experimental or industrial outcomes and ensure efficient project advancement.

Applications

Key Applications of PLGA Scaffolds in Biomedical Research

Due to its excellent biodegradability, biocompatibility, and tunable structural properties, PLGA scaffolds have become a central platform in biomimetic material and tissue engineering research. BOC Sciences offers highly customizable PLGA scaffolds designed to meet various requirements in tissue type, pore structure, mechanical strength, and functionalization. Our scaffolds support bone, cartilage, and soft tissue repair, as well as stem cell culture, drug-controlled release, localized therapy, and in vitro tissue model construction.

Bone and Soft Tissue Engineering

- Provides porous scaffolds that support bone cell growth and promote bone defect and fracture repair.

- Mimics ECM structures of soft tissues, offering ideal support for cartilage, skin, and vascular regeneration.

- Adjustable pore size, porosity, and mechanical strength to replicate native bone microenvironments.

- Supports composite material development to enhance bioactivity and mechanical stability in bone regeneration scaffolds.

Stem Cell Culture and Tissue Modeling

- Provides 3D scaffolds offering ideal microenvironments for stem cell proliferation and differentiation.

- Suitable for drug screening, toxicology testing, and in vitro tissue model construction to enhance reproducibility.

- Scaffold structures can be adjusted to support various stem cell types and co-culture systems.

- Offers functionalized scaffolds for mimicking complex tissue microenvironments and biological signaling pathways.

Drug-Controlled Release and Localized Therapy

- Acts as a localized drug carrier for sustained release of anticancer drugs, antibiotics, or growth factors.

- Enables controlled drug release rates to minimize systemic side effects and enhance therapeutic efficacy.

- Supports multi-drug composite loading for combination or multi-stage therapy strategies.

- Provides smart-responsive designs to regulate drug release in response to pH, temperature, or enzyme stimuli.

Biomimetic Material Development and Experimental Platforms

- Offers customizable PLGA scaffolds for in vitro biomimetic studies and complex tissue construction.

- Scaffolds can simulate vascularized tissue and organ microenvironments for high-fidelity experimental models.

- Supports smart drug delivery system development for research and drug discovery applications.

- Customizable pore structure, mechanical properties, and functional modifications to meet diverse research needs.

FAQs

Frequently Asked Questions

-

What is a PLGA scaffold?

A PLGA scaffold is a biodegradable material made from poly(lactic acid) (PLA) and poly(glycolic acid) (PGA) copolymers. It is widely used in tissue engineering and biomimetic material research, featuring excellent biocompatibility, controllable degradation, and tunable structure to support cell growth, tissue repair, and drug-controlled release applications.

-

In which tissue engineering fields can PLGA scaffolds be applied?

PLGA scaffolds are extensively used in bone, cartilage, skin, vascular, and neural tissue engineering. They are also suitable for stem cell culture, in vitro tissue model construction, controlled drug release, and smart biomimetic material development, providing reliable support for research and preclinical studies.

-

How can the pore structure and mechanical properties of PLGA scaffolds be customized?

By adjusting the lactic/glycolic acid ratio, molecular weight, fabrication technique, and processing parameters, pore size, porosity, and mechanical strength can be precisely controlled. BOC Sciences offers fabrication technologies such as 3D printing, freeze-drying, and electrospinning to meet various tissue engineering requirements.

-

Can PLGA scaffolds achieve drug-controlled release functionality?

Yes. PLGA scaffolds can be loaded with anticancer drugs, antibiotics, or growth factors for sustained and controlled local release. The release rate can be precisely regulated through material composition, scaffold pore structure, and composite functionalization to meet different therapeutic and research needs.

-

Can PLGA scaffolds be functionalized or modified?

Yes. PLGA scaffolds can undergo surface modification, bioactivation, or composite material integration, such as coating with collagen, gelatin, or nanomaterials. Functionalized scaffolds enhance cell adhesion and differentiation capabilities and can be designed with smart-responsive behavior for dynamic control and precise drug release.

-

How does BOC Sciences ensure the quality and performance of PLGA scaffolds?

BOC Sciences implements full-process quality control, including chemical characterization (FTIR, NMR, GPC), physical structure analysis (SEM, Micro-CT), mechanical testing, degradation assessment, and drug release evaluation. Each batch is accompanied by detailed technical reports to ensure stable, reproducible performance that meets research and industrial standards.