Alginate Microsphere Preparation

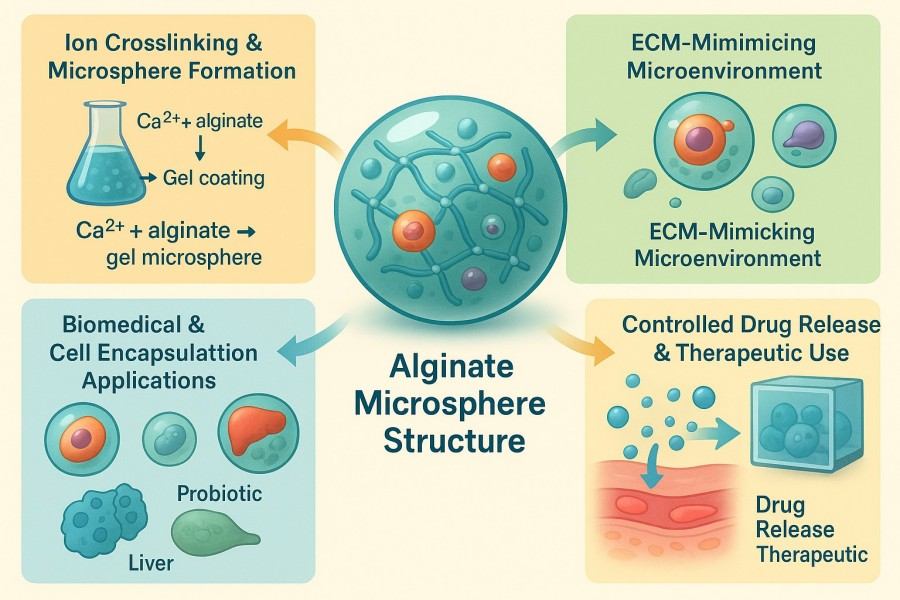

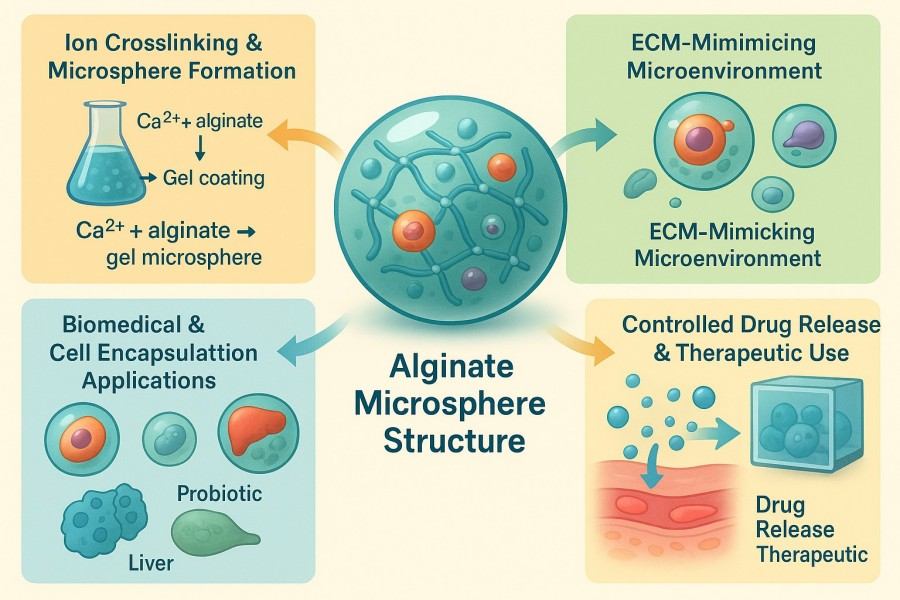

Alginate microspheres are three-dimensional spherical gel structures primarily composed of alginate, formed through ionic crosslinking, covalent crosslinking, or composite gelation. They combine the mildness and tunability of natural polymer materials and can encapsulate and achieve controlled release of various active substances such as drugs, enzymes, cells, proteins, and DNA. In recent years, they have become a research and application hotspot in functional materials and biotechnology. Leveraging an advanced polymer materials platform and extensive biochemical R&D experience, BOC Sciences provides global research and industrial clients with alginate microsphere/particle preparation and functional development services. Our services cover the entire process from raw material selection and structural design to multi-scale preparation and performance analysis, enabling the rapid realization of high-performance biomimetic materials.

What We Offer

Alginate Microspheres for Biomimetic Materials by BOC Sciences

Alginate microspheres/particles are spherical gel particles typically ranging from 1 μm to several hundred micrometers in diameter. Their formation is based on the ionic crosslinking between carboxyl groups on alginate chains and divalent metal ions (such as Ca²⁺, Ba²⁺, Sr²⁺). Segments enriched in guluronic acid (G blocks) can form a three-dimensional "egg-box model" structure with Ca²⁺, thereby stably constructing the gel spheres. BOC Sciences possesses a mature development and preparation technology platform for alginate microspheres and can provide multiple types of microspheres and particle products tailored to customer needs, including ionic crosslinked, composite, functionalized, and specialty microspheres, meeting diverse requirements in research, pharmaceuticals, tissue engineering, and industrial applications.

High-G Alginate Microspheres

- Rich in guluronic acid (G), providing strong mechanical strength and stable morphology.

- Dense structure with excellent compression and shear resistance, suitable for long-term storage and transport.

- Applicable for drug controlled release, cell scaffolds, and tissue engineering, providing solid support.

High-M Alginate Microspheres

- Rich in mannuronic acid (M), offering high flexibility and fracture resistance.

- Excellent swelling and water absorption properties, enabling sustained release of drugs or nutrients.

- Suitable for flexible biomimetic scaffolds, nutrient encapsulation, and delivery of bioactive substances.

Composite Alginate Microspheres

- Combined with chitosan, gelatin, collagen, or polyvinyl alcohol to achieve multifunctionality.

- Offers mechanical strength, controllable swelling, cell adhesion, and biodegradability.

- Applicable for drug carriers, tissue engineering scaffolds, functional foods, or catalytic supports.

Functionalized Alginate Microspheres

- Achieved through chemical conjugation, surface modification, or introduction of functional groups for targeted recognition or smart responses.

- Allows controlled release of drugs or active substances and enhances bioactivity or stability.

- Suitable for drug delivery systems, cell encapsulation, and diagnostic applications.

Magnetic Alginate Microspheres

- Magnetic nanoparticles (e.g., Fe₃O₄) are introduced to provide magnetic responsiveness.

- Applicable for targeted drug delivery, magnetic separation, or catalyst recovery.

- Supports MRI imaging or biomimetic research under controlled experimental conditions.

Fluorescent Alginate Microspheres

- Incorporates fluorescent dyes or quantum dots for visualization and tracking.

- Useful for cell imaging, drug distribution monitoring, and functional biomimetic material studies.

- Supports multi-channel labeling and quantitative analysis to enhance experimental control and data accuracy.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Performance Regulation and Functionalization of Alginate Microspheres

BOC Sciences has established a comprehensive system for alginate microsphere preparation and development. Our capabilities cover the entire process, from raw material selection, formulation optimization, and crosslinking control to structural characterization and performance evaluation, providing highly precise microsphere customization for various applications. Our lab and production facilities support multiple microsphere preparation techniques, including ionic gelation, emulsion crosslinking, spray drying, and microfluidic molding, enabling the design of microspheres with controlled particle size, uniform morphology, and tunable functions.

1Raw Material Selection and Modification Design

- Molecular weight control and oxidation modification: Enzymatic degradation or TEMPO oxidation adjusts alginate chain length and hydrophilicity, yielding different rheological properties.

- Crosslinking ion selection and concentration optimization: Ca²⁺, Ba²⁺, or Sr²⁺ ions are selected based on application requirements to regulate gel density and porosity.

- Multilayer composites and blending systems: Combined with gelatin, chitosan, or polyvinyl alcohol to tune charge, enhance mechanics, and design functional layers.

- Morphology control: Shear rate, spray parameters, or template guidance regulate particle size (1 μm–2 mm) and surface properties.

2Customizable Functionalization and Modification

- Surface coating modification: Chitosan or poly-L-lysine coating adjusts surface charge, controls permeability, and prevents drug leakage.

- Chemical modification: Hydroxypropyl, methyl, or sulfonate groups improve swelling behavior or pH responsiveness.

- Composite network construction: Combined with gelatin, PVA, or carboxymethyl cellulose to enhance mechanical stability.

- Magnetic/fluorescent functionalization: Fe₃O₄ or fluorescent nanoparticles introduced for tracking or controlled guidance.

- Targeted modification: Conjugation with antibodies, peptides, or sugar chains for specific tissue or cell targeting.

3Multiple Alginate Microsphere Preparation Techniques

- Ionic crosslinking: Multivalent cations (Ca²⁺) form a 3D "egg-box" with G blocks, yielding mechanically stable hydrogel microspheres with tunable porosity.

- Covalent crosslinking: EDC or glutaraldehyde reactions enhance swelling resistance and structural stability.

- Spray drying: Suitable for dry microspheres or loaded alginate particles, facilitating storage and redispersion.

- Microfluidic molding: Produces uniform, high-throughput microspheres for precise drug carriers or cell encapsulation studies.

4Scale-Up and Industrial Capability

- Continuous production from laboratory to industrial scale, from gram-level to kilogram-level.

- Continuous droplet reactors: Efficiently control microsphere formation rate and particle size consistency.

- Modular production systems: Support scale-up from gram, pilot, to kilogram levels.

- Automated monitoring and data tracking: Ensures stable control of temperature, pH, and ion concentration.

Characterization

Analysis and Characterization of Alginate Microspheres

Accurate analysis, characterization, and rigorous quality control are essential to ensure microsphere performance, functionality, and reproducibility. BOC Sciences has established a comprehensive analytical and quality assurance system, covering physicochemical properties, structural morphology, functional modifications, and biocompatibility. Through systematic testing and evaluation, we provide reliable and traceable microsphere materials for research, pharmaceutical, and industrial clients, laying a solid foundation for downstream applications and product development.

| Test Category | Test Item | Description & Advantage |

|---|

| Particle Size & Morphology | Dynamic Light Scattering (DLS), Laser Particle Size Analysis, Scanning Electron Microscopy (SEM) | Precisely measures microsphere size distribution, shape uniformity, and sphericity. |

| Surface Charge & Dispersibility | Zeta Potential Measurement, Particle Dispersion Evaluation | Assesses surface charge properties and colloidal stability, ensuring effective functionalization. |

| Chemical Composition & Crosslinking | Fourier Transform Infrared Spectroscopy (FTIR), X-ray Photoelectron Spectroscopy (XPS), Nuclear Magnetic Resonance (NMR) | Verifies chemical composition and crosslinking structure to ensure correct functional modifications. |

| Thermal & Mechanical Properties | Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA), Compression Modulus & Stress-Strain Tests | Evaluates thermal stability, mechanical strength, and pressure resistance of microspheres. |

| Swelling & Degradation Behavior | Swelling Tests under pH/Temperature Conditions, Degradation Rate Measurement | Controls drug release behavior and biodegradability to suit various application needs. |

| Biocompatibility & Safety | Cell Viability Assays, Endotoxin Testing | Ensures microspheres are safe for cells and tissues, free from microbial contamination. |

| Functional Validation | Fluorescence Intensity Measurement, Magnetic Responsiveness Evaluation, Chemical Conjugation Efficiency Testing | Confirms performance and stability of functionalized or composite microspheres. |

Advantages

Advantages of Alginate Microsphere Services

- Full-Process Customized Support: From raw material selection and microsphere preparation to functional modification, we provide end-to-end technical support to meet research and industrialization needs.

- Multi-Type Microsphere Development Capability: Capable of producing High-G, High-M, composite, and functionalized microspheres, with particle sizes ranging from nanometers to millimeters, covering diverse application scenarios.

- Precise Control of Particle Size and Structure: High-precision control of microsphere size, sphericity, and internal network structure through fluid dynamics regulation and crosslinking optimization.

- Functional Modification and Intelligent Design: Supports surface modification, chemical conjugation, magnetic or fluorescent labeling, enabling the development of targeted, traceable, and responsive microsphere systems.

- High-Standard Quality Control System: Equipped with comprehensive testing for particle size, morphology, chemical structure, mechanical properties, and biocompatibility, ensuring product stability and reproducibility.

- Rapid Scale-Up and Bulk Production Capability: From laboratory-scale small batches to pilot and kilogram-scale production, maintaining consistent microsphere performance and supporting smooth transition from research to industrial applications.

- Professional Customer Technical Support: Provides detailed experimental guidance, data analysis, and optimization suggestions, with rapid response to customer needs to accelerate R&D projects.

Service Process

Customized Alginate Microsphere Service Workflow

BOC Sciences offers a one-stop custom service from project concept to functional material development, covering requirement analysis, formulation design, laboratory validation, process scale-up, and final product delivery. Each stage is scientifically controlled and efficiently traceable. Our workflow is flexible and customizable, meeting diverse needs in research, drug development, and industrial applications.

1Requirement Communication and Project Assessment

- Conduct in-depth discussions with clients to define microsphere application goals, including drug carriers, biomimetic scaffolds, adsorbents, or functional materials.

- Collect key parameters such as particle size range, mechanical properties, biocompatibility, and specific functional requirements.

- Provide preliminary feasibility analysis to optimize project design direction and develop technical strategies.

2Formulation and Material Design

- Select appropriate alginate types (High-G, High-M, or composite) and M/G ratios to meet mechanical and swelling property requirements.

- Design crosslinking systems, including ionic crosslinking (Ca²⁺, Ba²⁺), covalent crosslinking, or composite crosslinking, optimizing microsphere stability and functionality.

- Integrate functional modification requirements at this stage, such as surface conjugation, fluorescent or magnetic labeling, to achieve intelligent microsphere design.

3Laboratory Validation and Process Optimization

- Prepare microspheres at small laboratory scale and assess particle size distribution, sphericity, and internal structure.

- Test swelling behavior, mechanical strength, and biocompatibility to ensure material performance meets project requirements.

- Optimize formulation and preparation parameters based on test results to guarantee controllable and stable microsphere performance.

4Microsphere Preparation and Characterization

- Employ precise microsphere preparation methods (ionic crosslinking, emulsion gelation, or spray drying) to produce particles with tunable size and uniform structure.

- Fully characterize the physicochemical properties of microspheres, including particle size, surface charge, chemical composition, and crosslinking degree.

- Perform fluorescent labeling, magnetic incorporation, or chemical conjugation verification if functionalization is required.

5Pilot Scale-Up and Production Process Development

- Scale up from laboratory parameters to pilot and industrial production, ensuring consistent performance from gram to kilogram scale.

- Verify key process parameters, including stirring speed, droplet addition rate, crosslinking ion concentration, and temperature control.

- Perform batch consistency verification and full quality control tracking to ensure reproducibility and traceability.

6Final Product Analysis and Delivery

- Conduct comprehensive characterization of final microspheres, including particle size, morphology, mechanical properties, swelling behavior, and functional verification.

- Provide detailed test reports and data analysis to support further research or applications.

- Offer formulation adjustments, long-term optimization, or large-scale production collaboration to provide ongoing support.

Applications

Applications of Alginate Microspheres/Particles in Biomimetic Materials

Alginate is a natural anionic polysaccharide derived from brown algae, composed of β-D-mannuronic acid (M) and α-L-guluronic acid (G) linked linearly by 1,4-glycosidic bonds. With excellent biocompatibility, mild gelation conditions, and controllable physicochemical properties, alginate has become a core material for constructing biomimetic materials, drug carriers, and cell scaffolds. Among various forms, alginate microspheres and alginate particles represent the most typical structural systems. Through ionic crosslinking, emulsification, or electrospraying, alginate can form three-dimensional gel spheres with controllable particle size and stable structure, applicable in drug sustained release, cell encapsulation, tissue engineering, enzyme immobilization, and environmental adsorption.

Drug Delivery Systems

- Encapsulation of small-molecule drugs, proteins, or peptides for sustained release and targeted delivery.

- Release rate can be adjusted based on pH, temperature, or ionic strength.

- Applications include oral insulin, anticancer drugs, and antibiotic sustained-release systems.

Cell Encapsulation and Regenerative Medicine

- Provides a three-dimensional biomimetic environment to maintain cell viability and function.

- Suitable for pancreatic islet transplantation, stem cell culture, and tissue repair.

- Supports RGD peptide modification and co-polymerization with matrix proteins to promote cell adhesion and signaling.

Tissue Engineering

- Alginate microspheres can serve as injectable scaffolds or bioinks for 3D bioprinting and tissue repair.

- In bone tissue engineering, alginate-hydroxyapatite composite microspheres promote osteoblast differentiation.

- In cartilage repair, microsphere scaffolds mimic extracellular matrix, supporting chondrocyte function.

Environmental and Catalytic Applications

- Alginate microspheres can be used as adsorbents or catalytic carriers for wastewater treatment and environmental remediation.

- Heavy metal ion adsorption: Alginate carboxyl groups strongly chelate metal ions such as Pb²⁺ and Cu²⁺.

- Nanocatalyst immobilization: Metal nanoparticles incorporated into the microsphere network enable efficient catalytic reactions.

FAQs

Frequently Asked Questions

-

What are sodium alginate microspheres?

Sodium alginate microspheres are made from the natural polysaccharide polymer sodium alginate, which offers excellent biocompatibility, biodegradability, and cost-effectiveness. These microspheres are typically prepared through ionic crosslinking of sodium alginate solution with divalent cations, such as calcium ions, forming a stable hydrogel network. Due to their unique structure, sodium alginate microspheres can efficiently encapsulate therapeutic substances such as drugs, proteins, or living cells, enabling controlled and sustained release, which enhances drug efficacy and reduces dosing frequency.

-

How are alginate microparticles prepared?

Alginate microparticles are prepared mainly through ionotropic gelation, where sodium alginate solution is dropped into a divalent cation solution such as Ca²⁺ or Ba²⁺. Alternative methods include emulsion gelation, spray drying, or covalent crosslinking. Parameters like alginate concentration, droplet size, and stirring rate are controlled to achieve desired particle size, morphology, and encapsulation efficiency. This allows controlled release of drugs, proteins, or cells.

-

What are alginate holmium microspheres with liposomes?

Alginate holmium microspheres with liposomes are hybrid particles combining radioactive holmium and liposome-encapsulated drugs. The alginate matrix stabilizes the liposomes and controls release, while holmium provides imaging or therapeutic functions. They are used in targeted therapy, controlled drug delivery, and biomedical research, offering multifunctionality and enhanced bioavailability.

-

How are alginate microspheres coated?

Alginate microspheres can be coated with materials such as chitosan, PEG, or other polymers to improve stability, control release, or modify surface properties. Coating enhances mechanical strength, reduces burst release, and protects encapsulated molecules. Multi-layer coatings or functional modifications allow the microspheres to meet diverse biomedical or industrial requirements.

-

How are alginate microspheres used in drug delivery?

Alginate microspheres encapsulate drugs, proteins, or nucleic acids for controlled or sustained release. Their porous gel structure protects sensitive molecules and allows tuning of release kinetics. By adjusting particle size, alginate type, crosslinking density, or surface coating, microspheres can achieve targeted delivery, enhanced bioavailability, and application in oral, injectable, or implantable formulations.

-

How are alginate microspheres made using emulsions?

Emulsion gelation forms alginate microspheres by dispersing alginate droplets in an oil phase, followed by crosslinking with divalent cations. This method produces uniform micro- or nanoparticles suitable for encapsulating hydrophilic or lipophilic compounds. Droplet size, surfactant type, and crosslinking conditions determine particle uniformity and structural stability.

-

Can alginate microspheres deliver proteins?

Yes, alginate microspheres can encapsulate proteins to maintain stability and achieve controlled release. The hydrogel matrix protects proteins from denaturation, while particle size, alginate concentration, and crosslinking conditions are optimized. Functional coatings or modifications can further enhance biocompatibility and release performance, making them suitable for therapeutic and research applications.

-

How are alginate microspheres formulated?

Alginate microsphere formulation involves choosing alginate type, concentration, crosslinking ions, and optional additives. Parameters like particle size, porosity, swelling, and mechanical strength are adjusted based on application. Advanced formulations may include coatings, composite materials, or loaded bioactive molecules to achieve controlled release, targeted delivery, or enhanced stability.

-

Are alginate microspheres hydrogels?

Yes, alginate microspheres are hydrogels with a three-dimensional polymer network that retains high water content. This structure enables encapsulation of drugs, proteins, or cells while maintaining biocompatibility, swelling behavior, and controlled release. Their soft, elastic properties make them suitable for biomedical, tissue engineering, and drug delivery applications.