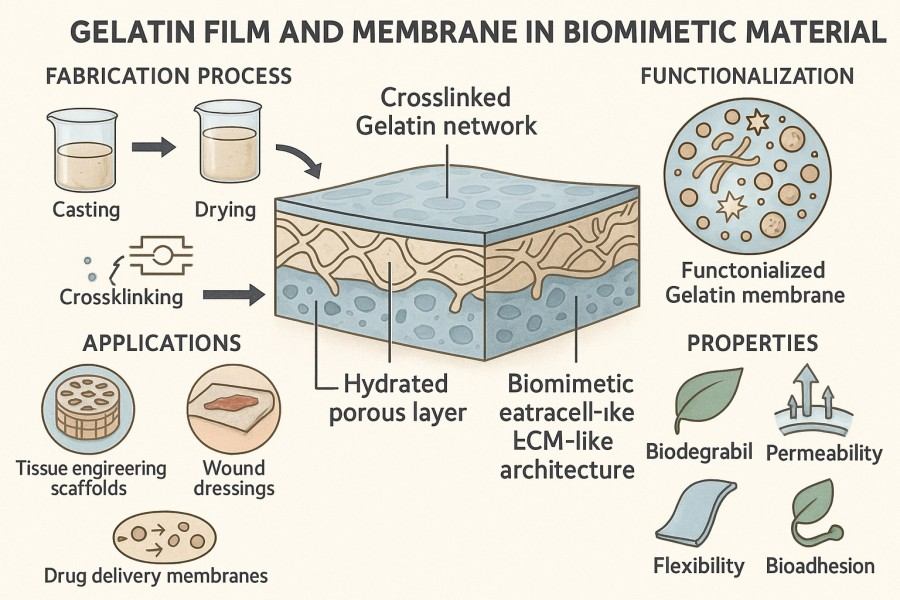

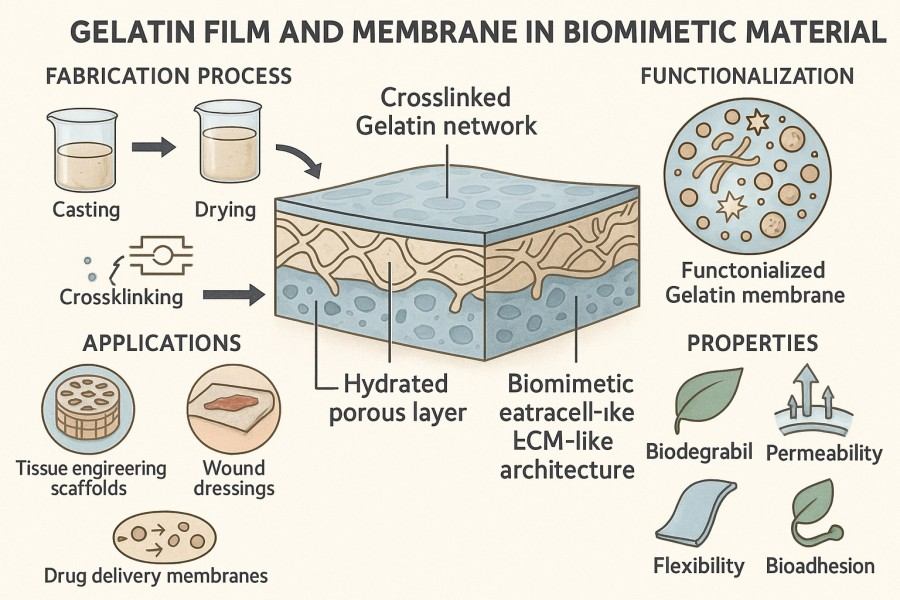

Gelatin Film/Membrane Preparation

Gelatin film and gelatin membrane have attracted significant attention in recent years as functional materials in biomimetic materials, biomedical applications, food packaging, and biodegradable polymers. With excellent biocompatibility, biodegradability, film-forming ability, and tunable properties, gelatin-based films are widely used in drug delivery systems, tissue engineering scaffolds, eco-friendly packaging, and smart responsive material design. As a global leader in polymer chemistry and materials R&D collaboration, BOC Sciences offers professional gelatin film/membrane preparation and development services, covering the full technical workflow from raw material selection, film formulation design, film formation optimization, chemical modification, to structural and performance characterization. We are committed to helping research institutions and industrial clients develop high-performance biomimetic film materials, providing reliable solutions for innovative drug delivery systems and advanced separation technologies.

What We Offer

High-Performance Gelatin Films/Membranes from BOC Sciences

BOC Sciences has a comprehensive polymer preparation and characterization platform, capable of providing various gelatin film/membrane design, development, and analysis services tailored to different biomimetic material research and industrial needs. Our services cover structural regulation and functional modification, supporting clients from proof-of-concept to commercial application.

Homogeneous Gelatin Film

Homogeneous gelatin films feature transparent, uniform thin-film structures, suitable for basic biomembranes, edible packaging, and pharmaceutical film development.

- Offers gelatin raw materials of various molecular weights and sources (Type A, Type B).

- Optimizes solution concentration and drying conditions to ensure film transparency and uniformity.

- Plasticizers (glycerol, PEG) can be added to adjust flexibility and mechanical strength.

- Applications include food packaging, oral films, and controlled-release drug carriers.

Porous Gelatin Film

Porous membranes have controllable pore sizes and 3D structures, suitable for cell culture, tissue engineering, and bio-separation.

- Prepared via phase separation or template methods to achieve controllable 3D porous structures.

- Pore size distribution (0.1–100 μm) and connectivity can be adjusted.

- Physical or chemical crosslinking enhances stability and water resistance.

- Applications include cell culture, artificial skin, filtration, and bio-separation systems.

Composite Gelatin Film

Composite gelatin films are achieved by blending with natural or synthetic polymers, enabling synergistic improvements in mechanical, barrier, and functional properties.

- Supports blending with PVA, chitosan, PLA, CMC, and other polymers.

- Provides ratio optimization and interfacial compatibility testing.

- Improves mechanical strength, barrier properties, and thermal stability.

- Used in biodegradable packaging, environmental adsorption films, and biomimetic composite materials.

Functionalized Gelatin Film

Functionalized films are endowed with antibacterial, antioxidant, conductive, or photosensitive properties via chemical grafting or nanoparticle incorporation.

- Introduces antibacterial, antioxidant, conductive, or photosensitive groups through chemical grafting.

- Supports nanoparticle doping (graphene oxide, silver, ZnO, SiO₂, etc.).

- Develops pH-responsive, temperature-responsive, or light-responsive film systems.

- Applications include smart drug release, sensors, and wearable devices.

Crosslinked Gelatin Film

Crosslinked films improve stability and water resistance through chemical or physical crosslinking.

- Provides multiple crosslinking systems (glutaraldehyde, EDC/NHS, Genipin, etc.).

- Supports physical crosslinking methods such as UV or heat treatment.

- Crosslinking degree can be controlled to regulate swelling and degradation rates.

- Suitable for long-term biomedical films, controlled-release carriers, and structural support films.

Biomedical Gelatin Membrane

Biomedical membranes are used for artificial corneas, wound dressings, and tissue scaffolds, requiring high biocompatibility.

- Uses pharmaceutical-grade or sterile gelatin raw materials.

- Offers sterilization and biocompatibility testing (cell adhesion, activity).

- Supports drug or bioactive factor encapsulation and release studies.

- Applications include artificial corneas, wound dressings, tissue scaffolds, and mucosal patches.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Gelatin Film Preparation and Development Capabilities

BOC Sciences provides full-process, customized support for research and industrial clients. From raw material selection to film structure design, from formulation optimization to functional modification, we combine systematic experimental validation and professional characterization to ensure each gelatin film meets precise requirements in mechanical properties, thermal stability, degradation rate, and functionality. Whether for pharmaceutical applications, food packaging, or tissue engineering scaffolds, we offer targeted development and optimization services to help clients efficiently advance projects.

1Precise Selection and Customization of Gelatin Raw Materials

High-quality gelatin raw materials are the foundation of high-performance films. BOC Sciences can perform precise selection and customization based on molecular weight, type, source, and purity to meet client requirements.

- Provides Type A, Type B, and functionalized gelatin materials covering different molecular weights and physical properties.

- Offers high-purity, low-impurity materials for biomedical or food-grade applications.

- Supports pre-crosslinked or chemically modified gelatin raw material development for functional films.

- Supplies from small R&D batches to pilot-scale materials, ensuring consistency between experiments and industrial scaling.

2Key Formulation Component Customization and Optimization

Film functionality depends on formulation design. BOC Sciences optimizes key components systematically to meet diverse application performance requirements.

- Precisely controls gelatin concentration and molecular weight to adjust film mechanical strength and flexibility.

- Optimizes plasticizer ratios (glycerol, PEG, sorbitol) for improved extensibility and stability.

- Selects appropriate crosslinkers (EDC/NHS, glutaraldehyde, Genipin) to regulate water resistance and degradation rate.

- Blends with other polymers (PVA, chitosan, PLA, CMC, etc.) to enhance barrier, thermal stability, and functional properties.

3Film Formation Techniques and Process Optimization

BOC Sciences employs advanced film-forming techniques to optimize process parameters based on structure and application requirements.

- Solution Casting: Produces homogeneous films for packaging, biomedical, and edible films.

- Phase Separation: Creates porous membranes for cell culture, filtration, and separation.

- Electrospinning: Produces nanofiber-structured films for tissue engineering and drug delivery.

- Physical/Chemical Crosslinking: Enhances membrane stability and water resistance.

- Drying and Heat Treatment Optimization: Ensures smooth surfaces, uniform thickness, and structural integrity.

4Composite and Modification Services

To meet high-performance and functional requirements, BOC Sciences offers customized composite and modification services to create multifunctional gelatin film systems.

- Blending Modification: Combines natural polysaccharides (chitosan, alginate) or synthetic polymers (PVA, PEG) to enhance mechanical, thermal, and barrier properties.

- Nanoparticle Incorporation: Adds graphene oxide, SiO₂, ZnO, or Ag nanoparticles to improve functionality and stability.

- Chemical Grafting or Surface Modification: Imparts antibacterial, conductive, photosensitive, or responsive properties.

- Layer-by-Layer Assembly: Builds multilayer composite films with integrated multifunctionality, suitable for biomimetic and smart film development.

Characterization

Structural and Performance Analysis of Gelatin Films

BOC Sciences provides systematic structural and performance characterization services, using advanced analytical techniques and specialized experimental protocols to help clients accurately understand the physical, chemical, and biological properties of films. We offer not only basic performance testing but also customized analysis based on functional requirements, providing scientific guidance for film optimization, application development, and industrial scaling. Our analysis services cover molecular structure, surface morphology, mechanical properties, thermal stability, and biocompatibility, ensuring reliable and reproducible data throughout R&D and production processes.

| Analysis Category | Testing Techniques | Analysis Content & Purpose | BOC Sciences Customization Services |

|---|

| Molecular Structure Analysis | FTIR, NMR, XRD, Raman | Confirm gelatin molecular structure, crosslinking degree, secondary structure changes. | Verify molecular structure of functionalized or composite films; provide custom spectrum interpretation and comparative analysis. |

| Surface & Microstructure | SEM, AFM, TEM | Film surface smoothness, pore size distribution, fiber network structure. | Measure pore size and fiber diameter for porous, nanofibrous, or composite films; provide 3D structural reconstruction. |

| Mechanical Properties | Tensile Testing, Dynamic Mechanical Analysis (DMA) | Elastic modulus, tensile strength, elongation. | Provide wet-state and dry-state mechanical testing; support mechanical parameter optimization. |

| Thermal Properties | DSC, TGA, Thermogravimetric Analysis | Glass transition temperature, thermal stability, decomposition temperature. | Evaluate thermal stability for composite or modified films; provide thermal treatment optimization suggestions. |

| Permeability & Barrier Properties | WVTR, Water Vapor Permeability, Gas Permeation Tests | Water vapor, oxygen, or other gas barrier capability. | Customize testing conditions (humidity, temperature, gas type) to simulate industrial application environments. |

| Swelling & Degradation Behavior | Dynamic Water Absorption, Buffer Solution Degradation Tests | Film swelling capacity, degradation rate, biodegradability. | Analyze degradation under different media and temperatures; guide controlled release and environmental applications. |

| Biocompatibility | Cell Adhesion Assay, MTT/Live-Dead Assay | Evaluate cell adhesion, growth, and viability on the film. | Assess biocompatibility of biomedical films or tissue engineering scaffolds; support FDA/ISO standard reporting. |

| Functional Performance Verification | UV-Vis, Fluorescence Spectroscopy, Conductivity Tests | Verify antimicrobial, photosensitive, conductive, or stimuli-responsive functions. | Provide custom testing for smart or composite films to ensure functional performance meets design specifications. |

Advantages

Benefits of Our Gelatin Film and Membrane Solutions

- Full-Process Customized Support: From raw material selection, formulation design, and film-forming processes to composite modification, we provide end-to-end customization to ensure each film meets client-specific requirements in structure, functionality, and performance.

- Extensive Film Preparation Technology Portfolio: Equipped with solution casting, phase separation, electrospinning, and crosslinking techniques, we enable high-quality preparation of homogeneous films, porous membranes, nanofiber films, and composite films for diverse research and industrial applications.

- Multidimensional Performance Characterization: We offer comprehensive analysis of mechanical, thermal, structural, permeability, and biocompatibility properties, helping clients accurately understand film performance and providing scientific guidance for product optimization and functionalization.

- Advanced Composite and Functionalization Services: We implement blending, nanoparticle incorporation, chemical grafting, and layer-by-layer assembly to create antibacterial, conductive, responsive, or smart films, meeting high-performance and multifunctional application needs.

- Rapid R&D and Industrial Scale-Up: Supporting laboratory research, small-scale samples, and kilogram-level industrial production, we ensure smooth transition from proof-of-concept to commercial manufacturing, accelerating product development cycles.

- Interdisciplinary Technology Integration: Combining expertise in polymer chemistry, materials science, and bioengineering, we deliver integrated structure–performance–function solutions, enabling clients to efficiently develop innovative biomimetic materials.

- High-Standard Quality Management and Traceability: Following strict laboratory operations and analytical protocols, we ensure reliable, reproducible test data while supporting quality traceability and standardized industrial production requirements.

Service Process

How We Prepare and Develop Gelatin Films and Membranes?

Relying on a professional technical team and advanced laboratory platform, BOC Sciences provides full-process support from concept design to industrial scale-up, ensuring every stage is precise, efficient, and tailored to client needs.

1Requirement Communication

Engage with clients to clarify the application scenario, performance criteria, and structural requirements of the films, including thickness, porosity, mechanical properties, and functional characteristics. Provide preliminary technical assessment and feasibility analysis to define development direction and strategy.

2Formulation Design and Experimental Plan Development

Based on requirement analysis, select appropriate gelatin raw materials, plasticizers, crosslinkers, and blending polymers to design film formulations. Develop experimental plans covering film preparation methods, parameter optimization, and expected performance to ensure rapid validation at the lab scale.

3Lab-Scale Film Preparation and Structural Characterization

Conduct small-scale laboratory film preparation using solution casting, phase separation, or electrospinning. Employ SEM, AFM, FTIR, NMR, and other analytical techniques for systematic characterization of surface morphology, microstructure, and molecular properties.

4Performance Evaluation and Data Optimization

Test small-scale films for mechanical, thermal, swelling/degradation, permeability/barrier, and biocompatibility properties. Optimize formulations or process parameters based on analysis and performance data to ensure films meet design requirements.

5Scale-Up and Validation Testing

Perform pilot or industrial-scale production based on optimized formulations, verifying performance consistency at large scale. Test structural, mechanical, and functional characteristics of batch films to ensure stability and application suitability.

6Reporting and Continuous Technical Support

Provide detailed experimental reports and data analysis, documenting film formulations, process parameters, and performance results. Offer ongoing technical support, including performance improvement recommendations, further functionalization development, and guidance for industrial application.

Applications

Applications of Gelatin Films/Membranes in Biomimetic Materials

Gelatin films/membranes are essential base materials for biomimetic research due to their excellent biocompatibility, tunable mechanical properties, and controlled degradability. By precisely adjusting structure, porosity, and functional characteristics, gelatin films can mimic natural tissue microenvironments, supporting cell adhesion, growth, and functional expression, with wide applications in biomedical, food technology, and smart material fields.

Biomimetic and Tissue Engineering

- Serve as substrates or 3D scaffolds for cell adhesion, proliferation, and differentiation.

- Can be blended with collagen, hyaluronic acid, or polysaccharides for soft tissue repair, corneal regeneration, or vascular scaffolds.

- Controlling pore structure, fiber alignment, and crosslinking degree allows precise degradability and mechanical property matching.

Drug Controlled-Release and Delivery

- Used as drug carrier membranes for oral, transdermal, or implantable sustained-release applications.

- Adjust film thickness, crosslinking degree, and nanoparticle doping to precisely control drug release rates.

- Functional modifications (light-sensitive, pH-responsive) enable targeted or responsive drug delivery.

Medical Dressings and Wound Healing

- Serve as wound dressings or absorbable membranes, promoting healing and tissue regeneration.

- Can incorporate antibacterial, hemostatic, or bioactive agents to enhance clinical efficacy.

- Adjust moisture absorption and mechanical strength for stable support in wet environments.

Food and Edible Film Applications

- Used as edible packaging or food protective films to extend shelf life.

- Can be blended with plasticizers and natural polysaccharides to improve flexibility and barrier properties.

- Biodegradable and environmentally friendly, reducing traditional plastic usage for sustainable packaging.

Smart Responsive and Biosensing

- Produce temperature-, light-, pH-sensitive, or conductive films for environmental responsiveness.

- Applied in wearable sensors, smart drug release systems, or biomimetic microenvironment monitoring.

- Composite materials or surface modification can fine-tune response rate and sensitivity.

Biomimetic Filtration and Separation Systems

- Porous membranes can mimic biological barriers for selective permeation of proteins, enzymes, or small molecules.

- Adjustable pore size and distribution meet bio-separation, microfluidic, or nanofiltration needs.

- Functional modifications allow anti-fouling, antibacterial, or selective adsorption properties.

FAQs

Frequently Asked Questions

-

What is gelatin film?

Gelatin film is a thin, flexible, and biodegradable sheet made from gelatin, a natural protein derived from collagen. Gelatin films are widely used in food packaging, pharmaceutical capsules, edible coatings, and biomedical applications due to their excellent film-forming ability, transparency, and biodegradability. They provide a sustainable alternative to synthetic polymer films and can be enhanced with additives for improved mechanical strength, moisture resistance, and functional properties.

-

How to make gelatin film?

To make gelatin film, gelatin powder is first dissolved in warm water to form a uniform solution. Optional plasticizers such as glycerol or sorbitol can be added to improve flexibility and reduce brittleness. The solution is then cast onto a flat surface or mold and allowed to dry at controlled temperature and humidity until a thin, transparent film forms. The resulting gelatin film can be further treated, cut, or coated depending on its intended application in food, pharmaceuticals, or biomedical fields.

-

What types of gelatin membranes can you prepare?

BOC Sciences can prepare a variety of gelatin membranes, including homogeneous films, porous membranes, electrospun nanofiber membranes, and composite or functionalized films. Each type can be tailored to specific mechanical, thermal, or biological requirements.

-

Can you provide custom formulations for gelatin film preparation?

Yes. We offer precise customization of gelatin molecular weight, concentration, crosslinkers, plasticizers, and polymer blends. This ensures the final film meets desired properties such as flexibility, transparency, biodegradability, or drug release behavior.

-

What membrane preparation technologies does BOC Sciences use?

We employ multiple preparation techniques including solution casting, phase separation, electrospinning, and chemical or physical crosslinking. Each method can be optimized to achieve uniform structure, porosity, and functional performance of the gelatin film.

-

Does BOC Sciences provide performance and structural analysis for gelatin membranes?

Yes. Our services include mechanical testing, thermal analysis, surface and microstructure characterization, permeability and barrier testing, biodegradability studies, and biocompatibility evaluation. Custom analysis ensures your gelatin membranes meet research or industrial standards.