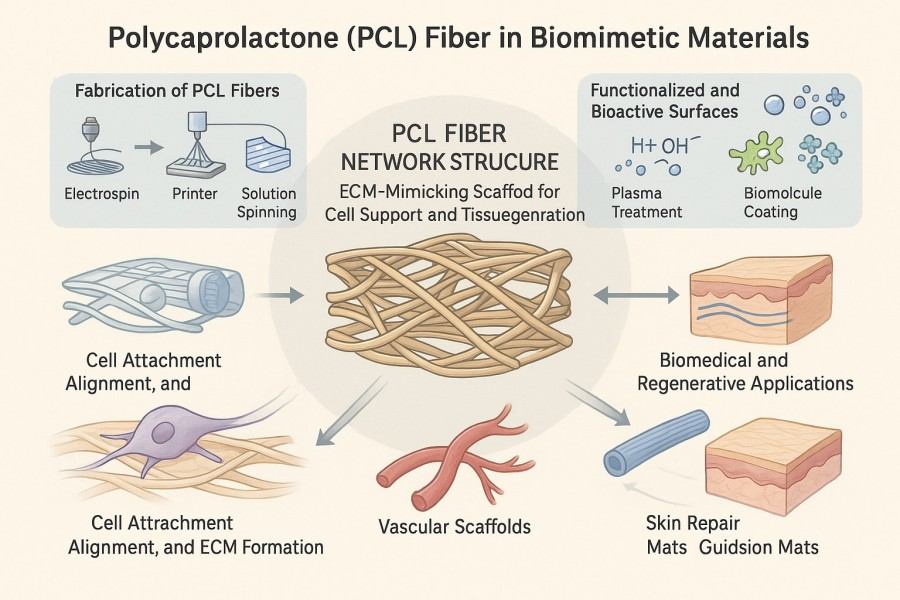

Polycaprolactone Fiber Preparation

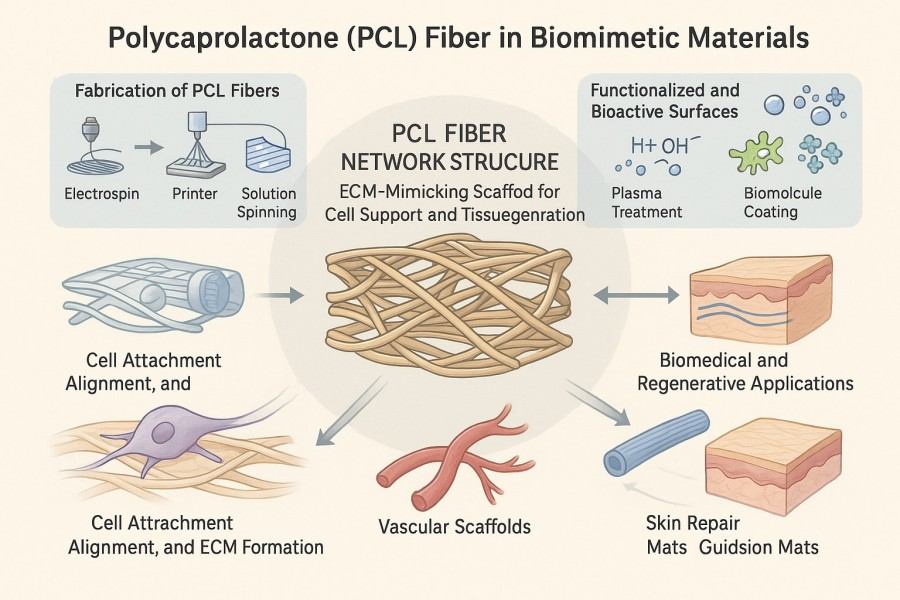

Polycaprolactone (PCL) fibers are a polymer material with excellent biodegradability, good biocompatibility, and adjustable degradation rates. The degradation process of PCL fibers is gentle and non-toxic, allowing them to gradually break down into harmless substances within the body. This makes them highly applicable in biomedical and environmental fields. At the same time, PCL fibers have good processability and mechanical properties, capable of meeting various customization needs. Therefore, PCL fibers are widely used in tissue engineering, drug delivery systems, wound repair, and environmental materials. At BOC Sciences, we are dedicated to providing high-quality PCL fiber preparation services to global customers. Our services cover all aspects, from the synthesis and functional modification of PCL fibers to surface treatments, ensuring that each custom solution meets the specific needs of our clients. By precisely controlling the molecular weight, structure, and performance parameters of PCL fibers, we offer tailored high-performance fiber solutions that help our customers succeed in biomaterial research and applications.

What We Offer

Need PCL Fibers? Discover Tailored Solutions from BOC Sciences

BOC Sciences focuses on providing customized PCL fiber solutions for the biomaterials field, precisely matching cell size, tissue mechanics, and regenerative requirements. Below are the four main categories of PCL fibers we offer, designed for your tissue engineering and drug delivery projects.

PCL Nanofibers

Nanofibers are essential for constructing highly biomimetic extracellular matrices (ECM).

- Ultra-fine Diameter Customization: We offer fibers with diameters as small as 50 nm, specifically designed for biomimetic ECM construction of sensitive tissues such as nerves and blood vessels.

- High Surface Area Activation: We provide low-temperature plasma or PEG grafted hydrophilic treatments to significantly enhance initial cell adhesion and spreading.

- Aligned Scaffold: Custom oriented nanofiber membranes that provide anisotropic signals, guiding nerve axons or muscle cells in directed growth.

PCL Microfibers

Microfibers focus on providing mechanical support and deep cell penetration.

- High Strength Mechanical Customization: Molecular weight is precisely controlled to produce microfibers with high elasticity modulus, meeting the long-term load-bearing needs of hard tissue scaffolds such as bone and cartilage.

- Large Pore Structure Optimization: Fiber diameter is controlled above 2 µm, forming deep penetration structures beneficial for cell cluster and endothelial tube growth.

- Mass Production Melt Blown Service: We offer melt-blown manufacturing of micron-level fibers, suitable for large-scale production of medical dressings and filtration materials.

PCL Composite Fibers

Composite fibers achieve multifunctionality and enhanced performance through material synergy.

- Bioactivity Enhancement Composite: PCL is co-spun with collagen, gelatin, or hydroxyapatite (HAp) to improve the scaffold's bone induction and cell recognition capabilities.

- Degradation-Mechanical Matching: PCL is co-polymerized/blended with PLA, PGA to precisely control degradation rate and mechanical properties, tailored for ligament/tendon repair cycles.

- Core-Shell Drug Encapsulation: We use coaxial electrospinning technology to encapsulate drugs or growth factors in the core layer, achieving multi-phase controlled release or sensitive drug protection.

Functionalized PCL Fibers

Functionalized fibers possess smart response and precise therapeutic potential.

- Bioligand Targeting: RGD peptide sequences or growth factor ligands are covalently grafted to the PCL surface to achieve highly selective recruitment of specific stem cells.

- Smart Response Systems: Customized drug-loaded PCL fibers integrating pH, temperature, or light-responsive units for on-demand drug delivery and precise release.

- Flexible Conductive Scaffolds: PCL is combined with graphene or carbon nanotubes to produce flexible conductive fibers for electrical stimulation and biosignal monitoring.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

PCL Fibers for Your Advanced Material Needs – Custom Options Available

At BOC Sciences, we are committed to providing precise PCL fiber preparation and development services for biomaterials and pharmaceutical materials. Due to its outstanding biodegradability, good biocompatibility, and adjustable degradation rate, PCL fibers are widely used in tissue engineering, drug delivery, and medical applications. Through advanced technologies and customized services, we ensure that PCL fibers perfectly meet customer needs and drive progress in related fields.

1PCL Fiber Custom Synthesis

- Molecular Weight Control: By precisely adjusting the molecular weight during polymerization, we optimize the degradation rate and mechanical properties of PCL fibers, ensuring their stability and functionality in the body.

- Structural Adjustment: Customizing the structure and crystallinity of PCL fibers according to application needs to adapt to various biomedical scenarios, such as tissue scaffolds and drug carriers.

- Diverse Sizes: Providing fibers from micron to nano-scale for flexible application in tissue engineering, drug delivery systems, and other fields, meeting the requirements for various sizes and pore structures.

2Functional Modification of PCL Fibers

- Drug Loading and Controlled Release: Drugs, antibiotics, anti-inflammatory drugs, or biological factors (e.g., TGF-β, PDGF) are loaded into PCL fibers to ensure long-term, controlled release for precise targeted therapy.

- Bioactivity Modification: By introducing cell adhesion factors or growth factors, we enhance the application of PCL fibers in tissue repair, promoting cell proliferation and differentiation.

- Antibacterial Function: Antibacterial molecules, such as silver or copper ions, are embedded to enhance the antibacterial properties of PCL fibers, widely used in medical dressings and absorbable sutures.

3Surface Modification of PCL Fibers

- Plasma Treatment: Plasma technology is used to improve the hydrophilicity and surface roughness of PCL fibers, promoting cell attachment and enhancing the cellular growth environment for tissue engineering scaffolds.

- Surface Coating Technology: Drugs or bioactive molecules are coated on the PCL fiber surface to achieve controlled release or functional modification, suitable for targeted drug delivery and tissue repair.

- Surface Functionalization: Through surfactant grafting, chemical grafting, and other methods, we further enhance the binding ability of PCL fibers with biomolecules or drugs, improving cell adhesion and biocompatibility.

4Composite Material Functionality

- Inorganic Material Composites: PCL is combined with bone-conductive materials such as hydroxyapatite (HAp) to significantly enhance the mechanical properties and bone induction capabilities of the fibers, suitable for orthopedic implants and bone repair applications.

- Natural Polymer Composites: Combining with natural polymers like collagen and hyaluronic acid to improve the cell recognition capabilities of fibers, promoting cell adhesion and differentiation for tissue engineering and wound healing.

- Smart Responsive Composites: Development of PCL composite materials with temperature and pH-responsive properties, suitable for smart drug delivery systems and adjustable scaffolds, meeting highly specialized clinical needs.

Characterization

PCL Fiber Analysis and Quality Control

To ensure the stability and high standards of every batch of PCL fibers, we provide comprehensive analysis and quality assurance services. Through advanced testing equipment and precise quality control processes, we ensure that PCL fibers meet optimal levels of biocompatibility, mechanical properties, and degradation rates, helping our clients obtain reliable data support and high-quality materials for their research and applications.

| Testing Item | Description | Testing Standards/Methods |

|---|

| Molecular Weight Distribution | Measure the molecular weight and distribution of PCL fibers to ensure controlled degradation rates and mechanical performance. | GPC (Gel Permeation Chromatography) |

| Mechanical Properties Testing | Test the tensile strength, elastic modulus, and elongation at break of PCL fibers to ensure their stability and durability for different applications. | Tensile Testing, Dynamic Mechanical Analysis (DMA) |

| Porosity and Pore Size Distribution | Measure the porosity, pore size distribution, and pore connectivity of PCL fibers to ensure suitability for tissue engineering scaffolds and drug delivery systems. | Scanning Electron Microscopy (SEM), Nitrogen Adsorption Method |

| Surface Hydrophilicity Testing | Measure the hydrophilicity of the PCL fiber surface to optimize cell adhesion and biocompatibility. | Water Contact Angle, Surface Energy Testing |

| Biodegradability Testing | Simulate in vivo and in vitro environments to test the degradation rate and degradation products of PCL fibers, ensuring safety and effectiveness in biological applications. | Weight Loss Method, HPLC for Degradation Products |

| Drug Loading and Release Testing | Measure the drug loading capacity and release rate of PCL fibers to ensure effective and sustained drug delivery. | UV-Vis Spectroscopy, HPLC |

| Cytotoxicity and Biocompatibility Testing | Assess the cytotoxicity and biocompatibility of PCL fibers in cell culture environments, ensuring suitability for medical and biomaterial applications. | MTT Assay, LDH Release Assay, Cell Adhesion and Proliferation Tests |

| Antibacterial Performance Testing | Measure the antibacterial properties of PCL fibers, especially their effectiveness against bacteria in medical applications. | Disc Diffusion Method, Colony Counting Method |

Advantages

Discover the Key Advantages of Our PCL Fiber Services

- Professional Technical Team: With extensive experience in polymer and biomaterials research and development, we provide full-process technical support from PCL fiber design to functional modification and composite material development.

- Customized Solutions: Based on the specific needs of our clients, we offer flexible PCL fiber customization services, ensuring that molecular weight, size, and functionalization meet the requirements of various applications.

- Advanced Preparation Technology: Using advanced technologies such as electrospinning and solution spinning, we produce PCL fibers with diverse sizes and pore structures, meeting the application needs of tissue engineering and drug delivery systems.

- Strict Quality Control: We perform rigorous testing of mechanical properties, porosity, drug loading, and other parameters to ensure the quality stability and reliability of each batch of PCL fibers.

- Fast Response and Flexible Delivery: We offer rapid response services and flexible delivery cycles to meet both small-batch customization and large-scale production needs, ensuring projects proceed on time.

- Comprehensive Technical Support: We provide complete technical consultation and application optimization support, helping clients solve technical challenges in research and development, ensuring successful product conversion and application.

- Global Customer Support: We provide efficient pre-sale and after-sale services to global customers, ensuring that clients receive professional support throughout the product development and application process, enhancing customer satisfaction.

Service Process

Streamlined PCL Fiber Service Process for Your Custom Needs

At BOC Sciences, we offer a comprehensive and systematic PCL fiber service process, ensuring that every step from initial consultation to final delivery is carried out strictly according to customer needs. We focus on every detail to provide high-quality customized products and comprehensive technical support to meet the demands of different fields and applications.

1Demand Analysis and Consultation

We engage in deep communication with our clients to understand their specific needs and application backgrounds, providing professional technical consultation and solution suggestions to ensure the project meets expectations from the start.

2Solution Design and Confirmation

Based on the customer's needs, we develop a detailed PCL fiber design plan, covering molecular weight, size, morphology, and functionalization requirements, ensuring the design plan is confirmed by the client and meets the technical specifications.

3Sample Preparation and Verification

After confirming the design plan, we prepare samples and provide experimental validation to ensure they meet the client's requirements. We also conduct initial quality testing and performance evaluation to ensure product quality.

4Functional Modification and Optimization

Based on client requests, we carry out functional modifications on PCL fibers, incorporating drug loading, antibacterial properties, or other bioactive components to optimize product performance and meet specific application needs.

5Quality Testing and Verification

Throughout the production process, we perform rigorous quality testing, including mechanical properties, porosity, degradation rate, and other tests to ensure the stability and reliability of every batch of products.

6Delivery and After-Sales Support

After completing product preparation and quality verification, we deliver products on time and provide comprehensive after-sales support, including technical consultation, application optimization, and feedback collection, ensuring continuous assistance and improvements throughout the product's use.

Applications

Get the Best PCL Fibers for Your Industry from BOC Sciences

Polycaprolactone (PCL) fibers are widely used in the biomimetic materials field due to their excellent biocompatibility, degradability, and tunable physicochemical properties. As a highly customizable polymer, PCL fibers play a significant role in tissue engineering, drug delivery, wound repair, and other fields. By adjusting the structure, porosity, and mechanical properties of the fibers, PCL fibers can precisely mimic the characteristics of human tissues, effectively supporting cell growth, repairing damaged tissues, and enabling smart drug delivery.

Tissue Engineering Scaffolds

PCL fibers are widely used in the preparation of tissue engineering scaffolds, particularly for bone, cartilage, and skin tissue repair. PCL fibers offer excellent mechanical properties, tunable degradation rates, and superior cell compatibility, providing support for cells and promoting their proliferation and differentiation. The highly adjustable pore structure and surface properties make them ideal materials for tissue engineering scaffolds, effectively enhancing cell adhesion and tissue regeneration.

Drug Delivery Systems

PCL fibers also perform excellently in drug delivery systems, especially in controlled drug release. By loading drugs into PCL fibers, slow release of the drugs can be achieved, ensuring sustained therapeutic effects over long-term treatment. PCL fibers not only have a prolonged degradation time but can also precisely control the drug release rate by adjusting the fiber's porosity and surface functionalization. They are widely applied in cancer treatment, antibacterial therapy, and other localized treatment fields.

Wound Repair and Dressing

Due to their excellent biodegradability and antibacterial properties, PCL fibers are widely used in the development of wound repair and dressing materials. By combining PCL fibers with bioactive molecules or antibacterial components, wound healing can be accelerated, and infection can be prevented. PCL fibers are used to prepare absorbable dressings, bandages, and dressings with adjustable drug release, helping to speed up wound healing and tissue regeneration.

Biosensors and Smart Materials

PCL fibers can be used as one of the base materials for sensors to detect biological signals. By combining PCL fibers with sensing elements (such as metal nanoparticles or conductive polymers), the sensitivity and selectivity of the sensors can be improved. These sensors can be used to monitor biological signals such as pH levels and electrical potential changes within the body.

FAQs

Frequently Asked Questions

-

What are PCL fibers?

Polycaprolactone (PCL) fibers are biodegradable synthetic fibers made from the polymer PCL. These fibers offer excellent biocompatibility, controlled degradation rates, and high tensile strength, making them ideal for various biomedical applications, including tissue engineering, drug delivery systems, and wound healing.

-

How are PCL fibers used in tissue engineering?

PCL fibers are widely used in tissue engineering due to their biodegradability and ability to support cell growth. They can be used to create scaffolds for the regeneration of various tissues, including skin, bone, and cartilage, by providing structural support while promoting cell infiltration and tissue formation.

-

Can PCL fibers be used in drug delivery systems?

Yes, PCL fibers are commonly used in controlled drug delivery systems. Their biodegradable nature allows for the slow release of drugs over extended periods, improving the efficacy and reducing side effects. PCL-based fibers can be engineered to deliver various types of drugs, including proteins, peptides, and small molecules.

-

How are PCL fibers manufactured?

PCL fibers are typically produced through electrospinning or melt-spinning techniques. Electrospinning allows for the creation of fine fibers with nanometer-scale diameters, while melt-spinning involves extruding the polymer into fiber form at high temperatures. Both methods ensure the fibers retain the desired mechanical properties and biodegradability.

-

What are PCL nanofibers?

PCL nanofibers are ultra-fine fibers made from polycaprolactone (PCL) polymer, with diameters typically in the nanometer range. These fibers are known for their high surface area, flexibility, and biocompatibility, making them ideal for applications in tissue engineering, drug delivery, and wound healing. PCL nanofibers can be fabricated using electrospinning techniques, allowing for precise control over their structure and properties. Due to their biodegradable nature, they are especially valuable in medical applications, offering temporary structural support that degrades as the tissue regenerates.

-

What are PLGA-PCL nanofibers?

PLGA-PCL nanofibers are composite fibers made from a blend of poly(lactic-co-glycolic acid) (PLGA) and polycaprolactone (PCL). These fibers combine the properties of both polymers, offering enhanced mechanical strength, controlled degradation rates, and improved drug release profiles. PLGA provides rapid biodegradability and is suitable for short-term applications, while PCL ensures longer-lasting structural integrity. PLGA-PCL nanofibers are widely used in biomedical fields, including drug delivery systems, wound healing, and tissue scaffolds, where both biocompatibility and controlled release are essential.

-

What are the benefits of using PCL nanofibers?

PCL nanofibers have a high surface-to-volume ratio, making them ideal for applications such as drug delivery, wound dressing, and tissue engineering. Their small diameter and porous structure facilitate cell attachment and growth, and their controlled degradation allows for long-term tissue regeneration and drug release.