Gelatin Fiber Preparation

Gelatin fibers are a class of biodegradable fibrous materials derived from natural biopolymer gelatin, prepared through physical or chemical methods. This material combines the bioactivity of natural peptides with the processability of fibrous structures and can be fabricated into micro- or nanoscale fibers using various techniques such as electrospinning, wet spinning, and dry spinning. Combining the biocompatibility of protein-based materials with the versatility of fibrous forms, gelatin fibers show broad application potential in tissue engineering, biomedical materials, drug delivery systems, and the cosmetics industry. BOC Sciences' gelatin fiber preparation services provide an integrated solution covering raw material selection, fiber fabrication, structural control, and functional modification, meeting preparation needs for fibers at different scales (micron and nanometer). By precisely controlling fiber diameter, porosity, alignment, and crosslinking density, fiber properties can be optimized to meet specific mechanical, degradation, and bioactivity requirements for diverse applications. Additionally, our services support composite fibers and functional design, providing reliable technical support for biomimetic material development and innovative applications, accelerating both research and industrial translation.

What We Offer

Gelatin Fiber Categories Offered by BOC Sciences

BOC Sciences possesses advanced expertise in polymer engineering and materials science, enabling the design and fabrication of diverse gelatin fiber systems tailored to various biomimetic material needs. Our services encompass structural control from the micron to nanometer scale, development from single-component to multi-component composites, and full-process support from fundamental research to industrial applications.

Gelatin Microfibers

BOC Sciences' gelatin microfiber preparation service focuses on controlled structures and optimized mechanical performance, widely used in tissue scaffolds, drug carriers, and degradable membrane development.

- Offers multiple fabrication methods, including wet spinning, electrospinning, and template-assisted approaches, to control fiber diameter and orientation.

- Adjustable gelatin concentration, crosslinking density, and fiber alignment to meet different mechanical strength and degradation requirements.

- Supports blending with other natural polymers (e.g., chitosan, silk fibroin) to form composite microfibers.

- Provides systematic analysis of microstructure and surface properties, including SEM imaging and porosity testing.

Gelatin Nanofibers

We focus on high-precision nanoscale structural control, providing gelatin nanofiber solutions with high surface area and porosity for biomimetic materials and regenerative medicine.

- Fabrication methods include electrospinning, electrospraying, and phase separation to produce uniform nanofibers.

- Fine-tuning of fiber diameter, surface roughness, and alignment at the nanoscale.

- Supports controlled encapsulation and sustained release of drugs or bioactive molecules within nanofibers.

- Offers multidimensional characterization, including fiber morphology, specific surface area, and thermal performance analysis.

Porous Gelatin Fibers

BOC Sciences can construct gelatin porous fibers with 3D interconnected pore structures for cell scaffolds, gas-exchange membranes, and adsorptive material applications.

- Precise control of pore size and density via solvent phase separation, gas foaming, or template dissolution methods.

- Customizable pore structures to meet various functions such as cell adhesion, nutrient exchange, or drug release.

- Supports porous composite design with materials like polylactic acid (PLA) or polycaprolactone (PCL).

- Provides comprehensive pore structure and mechanical performance analysis, including pore size distribution and compressive modulus testing.

Hollow Gelatin Fibers

We provide hollow gelatin fiber fabrication services, widely used in tissue engineering, membrane separation, and drug delivery systems.

- Hollow structures with adjustable lumen size achieved through coaxial electrospinning and template removal techniques.

- Supports multilayer wall design to achieve different diffusion rates or mechanical properties.

- Bioactive substances or cytokines can be encapsulated within the lumen for controlled release.

- Internal structure characterization includes lumen thickness, permeability, and surface modification analysis.

Crosslinked Gelatin Fibers

BOC Sciences enhances the stability and water resistance of gelatin fibers through various chemical or physical crosslinking methods, extending material lifespan and improving mechanical performance.

- Multiple crosslinking options, including glutaraldehyde, EDC/NHS, enzymatic, and UV treatments.

- Crosslinking density can be customized to regulate fiber strength and degradation rate.

- Supports multilayer and localized crosslinking for regional reinforcement or functional zoning.

- Crosslinking degree and residual content testing ensure biocompatibility and safety.

Composite Gelatin Fibers

We provide composite fiber fabrication based on gelatin and other polymers (natural or synthetic) to achieve synergistic performance and functional expansion.

- Can be combined with PLA, PCL, hyaluronic acid, silk fibroin, and other polymers.

- Supports multiple composite techniques, including blending, coaxial electrospinning, and layer-by-layer assembly.

- Enables multifunctional design, such as conductivity, antibacterial, light-responsive, or magnetic properties.

- Provides performance evaluation of composites, including thermal stability, swelling behavior, and biodegradability.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Gelatin Fiber Preparation and Development Capabilities

With extensive expertise in polymer chemistry and materials engineering, we offer systematic design and optimization of gelatin fibers across scales, structures, and functions. From laboratory research to pilot production, our services cover raw material selection, formulation design, fiber shaping, crosslinking and modification, composite construction, and performance characterization.

1Gelatin Fiber Preparation

We select the most suitable fabrication methods and solvent systems for different applications, precisely controlling fiber morphology and physical properties:

- Electrospun gelatin fibers: producing nanoscale fiber networks for tissue engineering and drug delivery.

- Wet-spun gelatin fibers: suitable for coarser biodegradable fibers.

- Dry spinning and solution blow spinning: for film and filter fiber fabrication.

- Temperature- and pH-responsive gelatin fibers: enabling smart material development.

- Continuous preparation and scale-up: supporting small-scale to large-scale production.

2Gelatin Fiber Modification & Blending

To improve mechanical performance and water resistance, we offer multiple modification and blending strategies:

- Chemical crosslinking: using glutaraldehyde, Genipin, EDC/NHS systems.

- Physical crosslinking: via UV, freeze-drying, or thermal dehydration.

- Blending and composite spinning: with PCL, PLA, chitosan, HA, PEG, and other polymers.

- Surface functionalization: grafting antibacterial peptides, growth factors, or functional molecules.

- Nanofiller incorporation: introducing silver nanoparticles, hydroxyapatite, and other functional enhancers.

3Functional Gelatin Fiber Development

We provide application-oriented functional design and custom development:

- Drug-loaded and controlled release fibers: tuning loading capacity and release profiles.

- Tissue engineering scaffold fibers: controllable pore size and biomimetic 3D structure.

- Antibacterial and antioxidant fibers: incorporating metal ions or bioactive components.

- Cosmetic and skincare fiber membranes: offering hydration and nutrient release functions.

- Edible or biodegradable packaging fibers: aligning with green and sustainable concepts.

4Gelatin Fiber Characterization and Analysis

BOC Sciences provides systematic structural and performance analysis for all types of gelatin fibers, ensuring stable quality and controllable parameters.

- Morphology analysis: SEM, TEM, and AFM observation of fiber diameter and surface structure.

- Performance testing: evaluating tensile strength, thermal stability, and degradation rate.

- Chemical characterization: FTIR and NMR assessment of functional group changes and crosslinking degree.

- Biocompatibility: water absorption, cell adhesion, and degradation behavior testing.

Advantages

Technical Advantages of Gelatin Fiber Services at BOC Sciences

- Comprehensive Fabrication Platform: BOC Sciences is equipped with electrospinning, wet spinning, dry spinning, and blow spinning systems, supporting multi-component co-spinning and nanoscale composites. We optimize processes for different gelatin sources to ensure fiber structure stability and controllable performance.

- Diverse Chemical Modification and Crosslinking Strategies: Our expertise covers multiple crosslinking chemistries, offering green and non-toxic techniques. Fiber degradation rates and mechanical strength can be finely tuned to optimize performance for different applications.

- Advanced Analysis and Quality Control: Equipped with instruments such as FTIR, NMR, TGA, SEM, and HPLC, BOC Sciences tracks the entire process from raw materials to final products, strictly adhering to industry standards to ensure material consistency and reliability.

- Interdisciplinary Technical Support: Our team of biochemistry and materials science experts provides systematic solutions from molecular design to biomimetic functionality verification, supporting custom development for research, pharmaceutical, and industrial projects.

- Highly Flexible Custom Services: We offer small-scale, pilot, and scaled-up production services, optimizing fiber diameter, porosity, and crosslinking density while providing analytical reports and application guidance to meet personalized customer needs.

- Green and Sustainable Approach: By using environmentally friendly solvents and bio-based raw materials, we promote gelatin fiber applications in biodegradable materials and eco-friendly packaging, aiming to build sustainable biomimetic material solutions for our clients.

Service Process

Gelatin Fiber Customized Service Workflow

At BOC Sciences, we provide comprehensive gelatin fiber development services, covering the full process from initial concept design to final sample delivery. Our goal is to transform client application needs into high-performance fibers ready for scalable production. Through a systematic service workflow, we ensure that fibers meet structural and performance expectations while providing technical guidance and application support to facilitate efficient development of research, pharmaceutical, and industrial projects.

1Requirement Analysis

At the project outset, we communicate closely with clients to understand the application background, functional requirements, and performance goals. Based on fiber use—such as tissue engineering scaffolds, drug carriers, or filtration membranes—we identify the required fiber type, dimensions, porosity, and functional characteristics, providing a scientific basis for subsequent solution design.

2Solution Design

Based on the requirement analysis, we develop detailed fiber fabrication and modification plans. This includes selecting the appropriate gelatin source (porcine skin, bovine bone, fish skin), determining the spinning method (electrospinning, wet spinning, dry spinning, etc.), designing crosslinking or composite strategies, and planning functional modifications to ensure both performance and feasibility.

3Experimental Development

Small-scale laboratory trials are conducted to evaluate fiber morphology, pore structure, diameter distribution, and preliminary mechanical performance. These trials verify the feasibility of the design plan while recording key parameters to support subsequent optimization.

4Structure Optimization

Based on experimental results and performance testing, fiber fabrication conditions—such as solution concentration, spinning speed, crosslinking strength, and composite ratio—are adjusted. Multiple optimization cycles improve fiber uniformity, mechanical strength, and degradation performance, ensuring optimal results in the target application.

5Performance Characterization

Systematic physicochemical performance testing is conducted, including fiber morphology, mechanical properties, thermal stability, swelling behavior, degradation rate, and biocompatibility assessment. This ensures fibers meet design requirements and establishes a reproducible characterization system for future research and industrial applications.

6Deliverables

Upon project completion, we provide clients with final samples, comprehensive performance data, and analytical reports. We also offer application guidance and technical advice to support further development in research, medical, or industrial production. Pilot-scale and large-scale production support can be provided as needed to ensure a smooth transition from laboratory to industrialization.

Applications

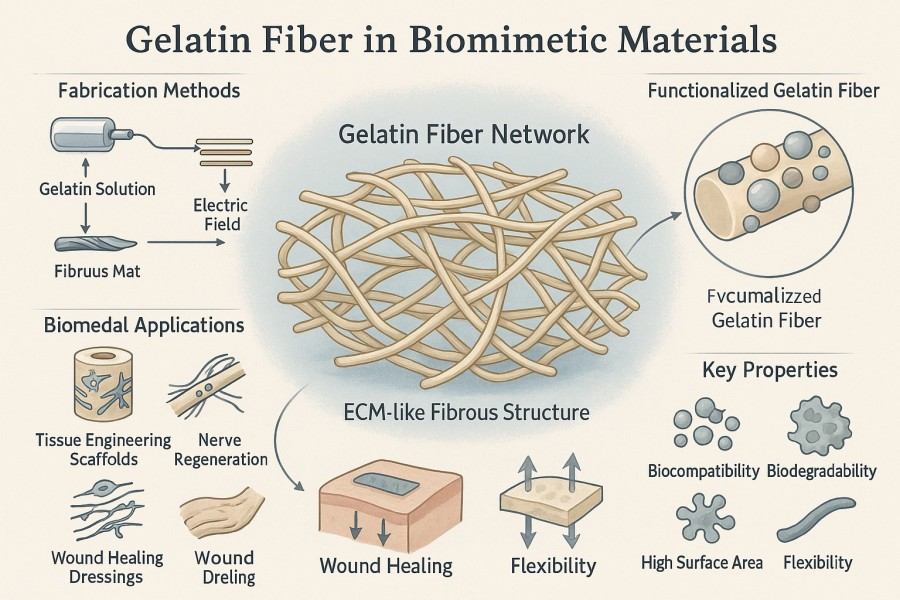

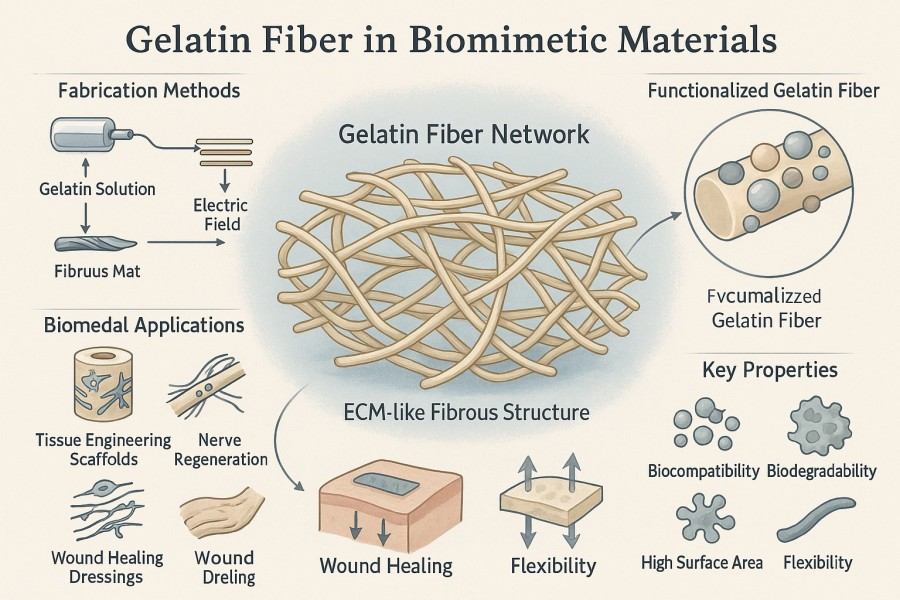

Typical Applications of Gelatin Fibers in Biomimetic Materials

Due to their excellent biocompatibility, biodegradability, and tunable microstructure, gelatin fibers are essential base materials in biomimetic materials. By finely adjusting fiber diameter, pore structure, and crosslinking degree, gelatin fibers can meet diverse requirements in tissue regeneration, drug delivery, medical dressings, and functional packaging.

Tissue Engineering Scaffolds

Gelatin fiber networks can mimic the microstructure and mechanical environment of the natural extracellular matrix, providing ideal support for cell adhesion, growth, and differentiation. Adjusting fiber alignment, pore size, and crosslinking density allows the fabrication of biomimetic scaffolds for bone, cartilage, skin, and vascular tissue regeneration. Multi-layered or composite scaffolds further meet the functional needs of complex tissues.

Drug Delivery and Controlled Release Systems

Gelatin nanofibers serve as drug carriers, encapsulating small molecules, proteins, or nucleic acids for sustained, targeted, or responsive release. Hollow or porous fiber structures enhance drug loading and allow precise control of release rates by tuning fiber wall thickness and porosity, making them widely applicable in local therapy, wound healing, and cosmetic product development.

Wound Healing and Biomedical Dressings

Gelatin fibers exhibit excellent water absorption, breathability, and flexibility, maintaining a moist wound environment and promoting tissue repair. Through fiber structure design and functionalization, antibacterial, hemostatic, or absorbable medical fiber membranes can be developed for wound dressings, burn care, and surgical aids, improving healing efficiency.

Functional Cosmetic Carriers

Fish-derived or plant-modified gelatin fibers, with high safety and skin compatibility, are commonly used as facial mask substrates, active ingredient release systems, and skin repair carriers. By controlling fiber porosity and swelling rate, fibers can provide moisture retention, nutrient delivery, and controlled release of repair-active components, enhancing cosmetic functionality and user experience.

FAQs

Frequently Asked Questions

-

What is gelatin fiber?

Gelatin fiber is a biopolymer derived from collagen, forming natural, biodegradable fibers with excellent biocompatibility. It is widely used in biomedical applications such as tissue engineering scaffolds, wound dressings, and drug delivery systems. Its unique properties, including adjustable porosity and mechanical strength, make it ideal for mimicking extracellular matrix structures. In addition, gelatin fibers can be combined with other polymers or functionalized to enhance stability, promote cell adhesion, or achieve controlled release of bioactive compounds, providing versatile solutions for research and industrial applications.

-

How is gelatin fiber made?

Gelatin fibers are typically produced through electrospinning, wet spinning, or dry spinning techniques. The process involves dissolving gelatin in a suitable solvent and forming fine fibers under controlled temperature, humidity, and voltage conditions. Crosslinking agents or physical treatments are often applied to improve fiber stability and mechanical properties. Process parameters can be adjusted to control fiber diameter, porosity, and surface morphology, enabling tailored scaffolds for biomedical, cosmetic, and industrial uses. Advanced techniques also allow blending with synthetic polymers for enhanced functionality and durability.

-

What are the key properties of gelatin fiber?

Gelatin fiber is biodegradable, biocompatible, and non-toxic, making it suitable for various biomedical and industrial applications. It exhibits good water absorption, flexibility, and adjustable mechanical strength. The fibers can be easily functionalized or crosslinked to improve stability, support cell adhesion, and control degradation rates. Additionally, gelatin fiber's porous structure facilitates nutrient and gas exchange, supporting tissue growth in scaffolds. Its thermal and chemical properties can be tuned for specific applications, from drug delivery systems to cosmetic membranes, making it a versatile material in research and manufacturing.

-

What are the main applications of gelatin fiber?

Gelatin fiber is widely used in tissue engineering, wound healing, drug delivery, and cosmetic products. In scaffolds, it mimics natural extracellular matrices, promoting cell attachment and proliferation. In wound care, gelatin fibers provide moisture retention and support tissue regeneration. They also serve as carriers for bioactive molecules, enabling controlled drug release. Beyond biomedical uses, gelatin fibers are applied in food, packaging, and filtration industries due to their biodegradability and film-forming ability. Functionalization and composite fabrication further expand their versatility for advanced industrial applications.

-

How should gelatin fiber be stored?

Gelatin fibers should be stored in a cool, dry environment away from direct sunlight and moisture to maintain their structural integrity. Humidity and high temperature can lead to fiber degradation or aggregation. For long-term storage, sealed containers with desiccants are recommended. Handling should minimize mechanical stress to prevent fiber breakage. When crosslinked or combined with other materials, storage requirements may vary slightly depending on the composite's stability. Proper storage ensures the fibers retain their biocompatibility, mechanical properties, and suitability for biomedical or industrial applications.

-

Can gelatin fiber be combined with other materials?

Yes, gelatin fiber can be blended or coated with synthetic polymers, bioactive molecules, or nanoparticles to enhance functionality. Combining with polymers like PLA or PCL improves mechanical strength and stability, while bioactive compounds can provide antibacterial or growth-promoting effects. Surface modifications allow targeted applications, such as drug release or tissue regeneration. Such composites expand gelatin fiber's usability in scaffolds, wound dressings, and biomedical devices, offering tailored properties for specific industrial or research needs. Functionalization is key for optimizing performance in complex applications.