Polylactic Acid Film Preparation

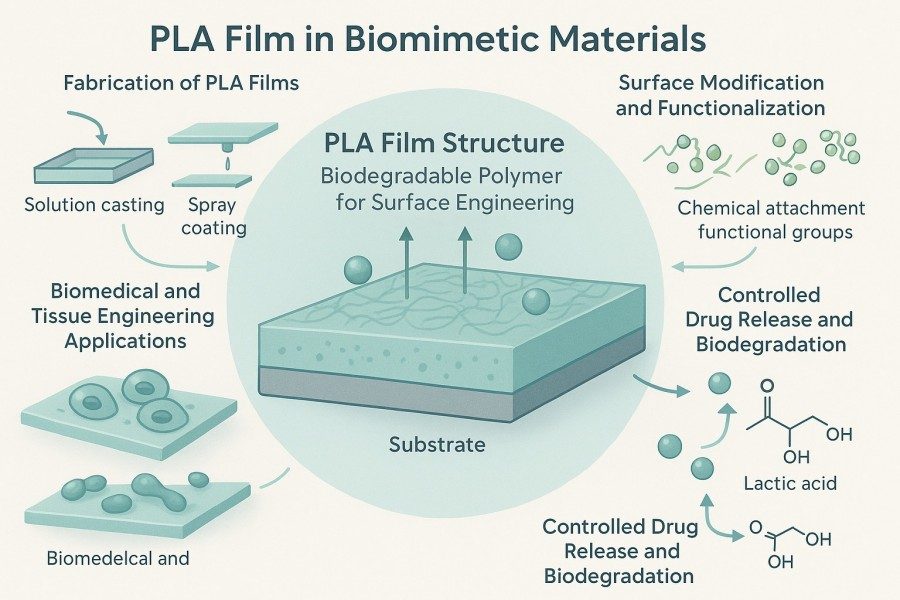

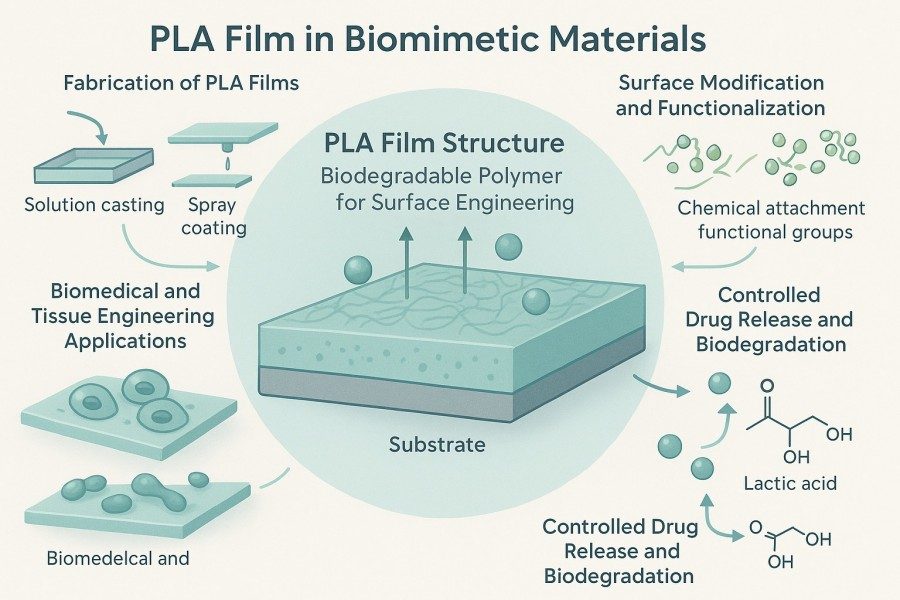

Polylactic acid (PLA) film is a continuous thin-film material primarily made from polylactic acid, prepared via methods such as film blowing, casting, or solution coating. Its thickness typically ranges from 10 microns to several hundred microns and can be adjusted according to application requirements. Structurally, PLA films are mainly composed of linear polylactic acid polymer chains, with repeating lactic acid units (-CH(CH₃)COO-). Depending on the chirality of the lactic acid monomer, PLA can be classified as PLLA (poly-L-lactic acid), PDLA (poly-D-lactic acid), or PDLLA (random poly-lactic acid), with differences in crystallinity and mechanical properties that affect the film's physical performance and processing. In the field of biomimetic materials, PLA films serve not only as structural materials but also as substrates that can be functionalized, compounded, or micro-/nano-structured to mimic natural tissues or surface properties. BOC Sciences provides end-to-end technical support services from PLA film preparation and development to custom manufacturing. Whether for research experiments, small-scale development, or industrial production, we deliver high-performance, customizable PLA film solutions, with unique advantages in biomimetic applications.

What We Offer

High-Quality PLA Films Tailored to Your Requirements

BOC Sciences offers a variety of PLA film types based on different polymer structures, including PLLA, PDLA, and PDLLA. We optimize film preparation processes according to structural characteristics and provide tailored services for diverse applications, such as porous films, composite films, micro-/nano-patterned films, and multilayer composite films, meeting needs in food packaging, medical, biomimetic, and high-performance functional films.

Porous PLA Film

- Controlled Pore Design: Customize pore size and porosity for biomimetic scaffolds, tissue engineering, or filtration applications.

- Multiple Preparation Methods: Available via solution casting, thermally induced phase separation, and template-based techniques.

- Functionalization Options: Incorporate bioactive compounds or plasticizers to enhance cell adhesion, biocompatibility, or flexibility.

Composite PLA Film

- Multi-Material Composites: Combine with hydroxyapatite (HA), collagen, nanoparticles, etc., to enhance mechanical strength and functionality.

- Tunable Properties: Adjust transparency, barrier performance, thermal properties, and flexibility according to application requirements.

- Custom Development: Supports small-batch R&D and industrial-scale production for food, medical, and biomimetic applications.

Micro/Nano-Patterned PLA Film

- Surface Structure Customization: Offers micropores, nanostructures, and biomimetic surface design services.

- Functional Applications: Improve surface wettability, anti-fouling properties, or optical characteristics for biomimetic and functional film needs.

- Multiple Fabrication Techniques: Supports molding, micro-/nano-processing, and coating modifications for versatile customization.

Multilayer Composite PLA Film

- Layered Functional Design: Each layer can provide different functionalities, such as barrier, flexibility, antibacterial, or heat-seal properties.

- Controllable Thickness and Structure: Customize layer count, thickness, and material combinations for biomimetic or medical applications.

- Industrial Support: Full service from laboratory development to mass production, ensuring consistent multilayer film performance.

Looking for Biomimetic Material Solutions?

From natural polymers to bio-inspired composites, BOC Sciences provides customized materials to accelerate your research and industrial applications.

Services

Custom PLA Film Preparation Services You Can Trust

BOC Sciences offers one-stop PLA film solutions covering design, development, preparation, and industrial-scale production. Our services span various polymer structures and diverse film types (porous, composite, micro-/nano-patterned, multilayer), helping clients achieve customizable, high-performance, biodegradable film applications.

1PLA Film Design Services

- Polymer Structure Optimization: Customize PLLA, PDLA, PDLLA, and stereocomplex PLA film structures according to application needs.

- Functional Molecule Design: Support plasticization, copolymerization, and composite modifications to enhance flexibility, thermal stability, and barrier properties.

- Micro-/Nano-Structure Planning: Design surface textures and pore distributions for biomimetic, microporous, or functional films.

- Multilayer Film Design: Customize multilayer structures based on barrier, flexibility, and functional requirements.

2PLA Film Development Services

- Functional Development: Antibacterial, anti-fog, UV-blocking, barrier properties, and surface hydrophilic/hydrophobic modifications.

- Biomimetic Support: Custom development for porous scaffold films, microstructured functional films, and smart responsive films.

- Performance Optimization: Improve mechanical properties and transparency through material modification, thickness control, and process parameter adjustment.

- Small-Batch Prototyping: Support lab-scale R&D and functional verification to provide data for industrial production.

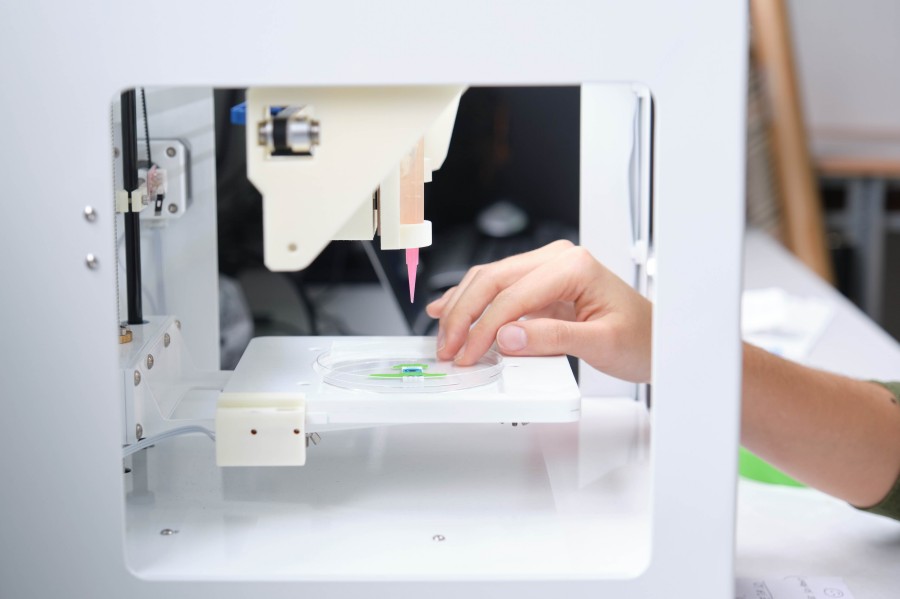

3PLA Film Preparation Services

- Multiple Fabrication Methods: Flexible selection of film blowing, casting, or solution coating to meet diverse film form requirements.

- Process Parameter Optimization: Control temperature, draw ratio, and cooling rate to balance mechanical performance and transparency.

- Micro-/Nano-Processing: Support molding, micro-/nano-processing, and template methods for microporous or patterned films.

- Composite Film Preparation: Combine with bioactive substances, nanoparticles, or plasticizers to achieve functionalization.

4PLA Film Manufacturing and Industrial Support

- Mass Production Capability: From laboratory-scale small batches to medium/large-scale industrial production, ensuring consistent film performance.

- Quality Control System: Test thickness, porosity, mechanical properties, and functional performance to ensure product stability.

- Process Technology Transfer: Provide full-process technical guidance and documentation from R&D to industrialization.

- Application-Specific Solutions: Professional manufacturing and application solutions for food packaging, medical, biomimetic, and functional film industries.

Characterization

PLA Film Analysis and Testing Services

BOC Sciences offers comprehensive PLA film analysis services, ensuring films meet customer requirements in mechanical, thermal, optical, and functional properties. Our analysis covers the entire process, from laboratory research and biomimetic material development to industrial production, providing reliable data support and performance assurance.

| Test Category | Test Item | Description | Instrumentation |

|---|

| Mechanical Properties | Tensile Strength | Measures the maximum stress the film can withstand during stretching, evaluating toughness and strength. | Universal Testing Machine (UTM) |

| Elongation at Break | Measures the strain at break, evaluating flexibility and elongation. | Universal Testing Machine (UTM) |

| Flexural Modulus | Measures film rigidity to assess mechanical stability. | Universal Testing Machine (UTM) or Dynamic Mechanical Analyzer (DMA) |

| Thermal Properties | Glass Transition Temperature (Tg) | Determines the softening temperature of the film, guiding processing and application conditions. | Differential Scanning Calorimeter (DSC) |

| Melting Temperature (Tm) | Determines the crystalline melting point, evaluating thermal stability. | Differential Scanning Calorimeter (DSC) |

| Thermogravimetric Analysis (TGA) | Analyzes thermal decomposition characteristics to predict heat resistance and process stability. | Thermogravimetric Analyzer (TGA) |

| Optical & Surface Properties | Transmittance | Measures film transparency, evaluating optical performance. | UV-Vis Spectrophotometer |

| Surface Roughness | Analyzes surface microstructure, guiding micro/nano-patterned film development. | Profilometer or Atomic Force Microscope (AFM) |

| Contact Angle | Measures surface hydrophilicity/hydrophobicity, providing design data for functional films. | Contact Angle Goniometer |

| Barrier Properties | Oxygen Transmission Rate (OTR) | Measures oxygen barrier performance, suitable for food packaging and medical films. | Oxygen Transmission Rate Tester (OTR Tester) |

| Water Vapor Transmission Rate (WVTR) | Measures water vapor barrier performance, affecting shelf life and packaging functionality. | Water Vapor Transmission Rate Tester (WVTR Tester) |

| Functional Properties | Antibacterial Performance | Evaluates inhibition of bacterial growth for composite antibacterial films, suitable for medical and food applications. | Incubator, Inhibition Zone Test Equipment, Microbial Analysis System |

| Micro/Nano Surface Structure Observation | Observes micro/nano patterns via SEM or AFM to evaluate surface morphology. | Scanning Electron Microscope (SEM) or Atomic Force Microscope (AFM) |

| Multilayer Adhesion Strength | Measures interlayer adhesion of multilayer PLA films to ensure structural stability. | Peel Strength Tester or Universal Testing Machine (UTM) |

Advantages

Expert PLA Film Services: Benefits for Your Projects

- High Biocompatibility: PLA films can be directly used in medical biomimetic materials and tissue engineering, supporting cell growth and tissue repair while ensuring biological safety and compatibility.

- Customizability: Film thickness, porosity, mechanical properties, and functional layers can be flexibly designed to meet diverse biomimetic, medical, and packaging application requirements.

- Professional Team: Composed of experts in polymer chemistry, biomaterials, and nanotechnology, providing full technical support for film preparation, functionalization, and performance optimization.

- End-to-End Custom Solutions: Covering molecular design, material selection, film preparation, functional development, and industrial-scale production, delivering complete customized solutions.

- Functional Development Advantages: Supports functional design for porous films, composite films, multilayer films, and micro-/nano-patterned films to meet the needs of biomimetic and high-performance applications.

- Quality and Safety Assurance: Preparation processes comply with international standards, ensuring stable film performance and reliable biodegradability, suitable for high-standard medical and biomimetic applications.

- Rapid Technical Response: Provides customized solutions and technical guidance, quickly addressing challenges in film development, functionalization, and production to improve R&D efficiency.

- Full Customer Support: From requirement analysis and experimental development to industrial-scale production, we provide technical support and project management to ensure smooth film development.

Service Process

How Our PLA Film Preparation Service Works?

To ensure every PLA film meets customer performance and functional requirements, BOC Sciences provides a systematic, end-to-end service. From initial requirement analysis to industrial-scale production, we carefully control each stage to deliver high-quality, customizable, and functional films.

1Requirement Analysis

- Engage in in-depth discussions with clients to understand application scenarios and functional needs, specifying thickness, porosity, mechanical properties, and barrier performance.

- Analyze actual use environments and processing requirements to provide data support and foundational guidance for subsequent design and development.

2Material and Formulation Design

- Select PLA type and composite materials according to functional requirements, designing combinations of plasticizers, copolymers, or functional additives.

- Optimize formulations to meet multiple performance criteria, including mechanical, thermal, transparency, and functional properties.

3Film Preparation and Process Development

- Choose appropriate processes—film blowing, casting, or solution coating—based on film type to ensure uniform thickness and structural stability.

- Optimize mechanical performance and transparency by controlling temperature, draw ratio, cooling rate, and other process parameters.

4Functionalization and Structural Optimization

- Provide design and functional processing solutions for micro-/nano-patterned films, porous films, composite films, and multilayer films.

- Enhance surface properties, biocompatibility, and barrier performance to meet biomimetic and medical application requirements.

5Performance Validation and Analytical Testing

- Conduct comprehensive testing and data analysis of mechanical, thermal, optical, barrier, and functional properties.

- Ensure film performance meets application standards, providing reliable data and optimization recommendations for industrial production.

6Industrial Production and Technical Support

- Support transition from laboratory R&D to medium- and large-scale industrial production, ensuring consistent batch-to-batch performance.

- Provide process optimization, quality control, and application guidance to enable smooth scale-up of customer projects.

Applications

Applications of PLA Films in Biomimetic Materials

With excellent biodegradability, biocompatibility, and customizable micro-/nano-structure features, PLA films show great potential in tissue engineering, functional scaffolds, smart responsive films, and biomimetic surface materials. BOC Sciences offers tailored preparation and functional optimization of porous films, composite films, multilayer films, and micro-/nano-patterned films to help research institutions and companies develop high-performance biomimetic materials, supporting the full workflow from experimental research to industrial application.

Biomimetic Scaffold Film

- Form: Porous PLA films or microporous films prepared via solution casting or thermally induced phase separation.

- Application: Mimics natural extracellular matrix (ECM) for tissue engineering, bone, and soft tissue repair.

- Features: Adjustable porosity and pore size to facilitate cell adhesion, proliferation, and differentiation.

Biomimetic Protective Film

- Form: Single-layer or composite PLA films with antibacterial, UV-blocking, or waterproof functional coatings.

- Application: Mimics the skin barrier for wound coverings, biodegradable medical dressings, and wearable biosensors.

- Features: Good flexibility and controllable breathability, providing physical protection while supporting biological activity.

Biodegradable Biomimetic Packaging Film

- Form: Transparent or semi-transparent PLA films, some with microstructured surfaces simulating natural surfaces (e.g., leaf or insect wing structures).

- Application: Mimics plant surface structures to control moisture evaporation, light refraction, or microbial growth.

- Features: Surface micro-/nano-structuring enhances functionality, such as water resistance, anti-fouling, or optical regulation.

Biomimetic Smart Film

- Form: PLA combined with functional polymers or nanoparticles to create smart responsive films.

- Application: Mimics biological tissue responses to environmental stimuli such as temperature, humidity, or pH changes.

- Features: Suitable for biodegradable sensors, smart medical films, or biomimetic mechanical structures.

FAQs

Frequently Asked Questions

-

What is polylactic acid film?

Polylactic acid (PLA) film is a biodegradable and biocompatible polymer film derived from renewable resources such as corn starch or sugarcane. It is widely used in packaging, biomedical applications, and biomimetic materials. PLA film can be customized into various forms, including porous, multilayer, composite, or micro/nano-patterned films, offering mechanical strength, transparency, and functional properties suitable for diverse applications.

-

How is the PLA film made?

PLA film is manufactured using processes such as solution casting, extrusion, blow molding, or film blowing. The choice of process depends on the desired film properties, thickness, and structure. Parameters such as temperature, cooling rate, and stretching ratio are optimized to achieve uniform thickness, transparency, and mechanical strength. Functionalization or composite incorporation can be added during fabrication to produce porous membranes, multilayer films, or films with micro/nano structures for biomedical or biomimetic applications.

-

What are the properties of PLA film?

PLA film features biodegradability, high transparency, and good mechanical strength. It exhibits excellent biocompatibility, making it suitable for medical and tissue engineering applications. Depending on the preparation method, PLA films can be porous, multilayered, or textured at the micro/nano scale. They also offer adjustable thermal and barrier properties, and can be functionalized with additives, nanoparticles, or composites to enhance flexibility, antimicrobial properties, or optical performance.

-

Is PLA film biodegradable?

Yes, PLA film is biodegradable and highly suitable for medical and biomimetic applications. In tissue engineering, medical devices, and bioresorbable scaffolds, PLA films gradually degrade into non-toxic byproducts, supporting cell growth and tissue regeneration.

-

What is the cost of PLA film?

The cost of PLA film varies depending on film type, thickness, functionalization, and production scale. Basic PLA films are generally more affordable, while multilayer, micro/nano-patterned, or composite films with specialized functionalities may have higher costs due to added materials and processing complexity. Pricing also depends on batch size, customization requirements, and industrial-scale production capabilities. BOC Sciences provides tailored solutions to balance performance requirements and cost-efficiency for different applications.