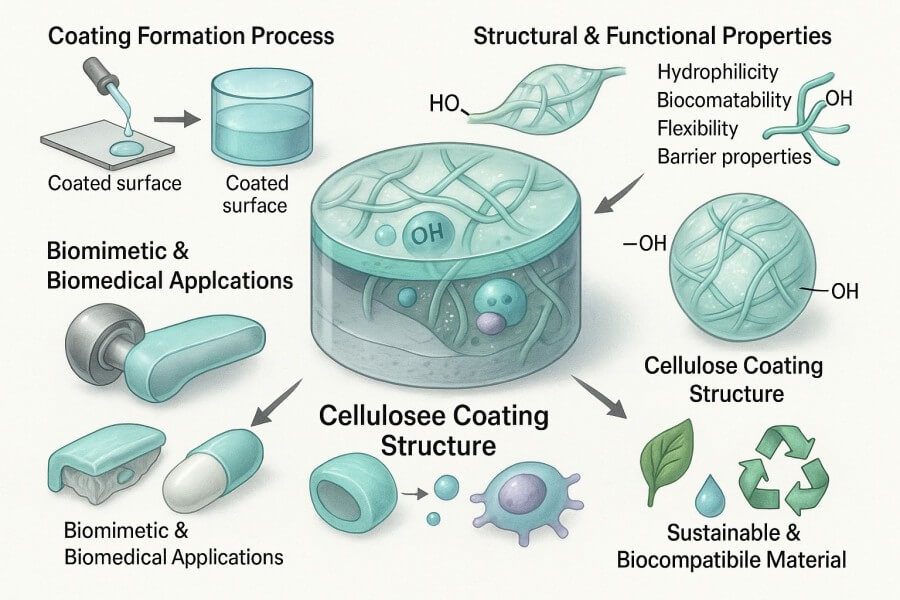

A cellulose coating is a protective or functional layer made from cellulose or its derivatives, applied to surfaces to improve durability, water resistance, or aesthetics. It is widely used in packaging, biomedical devices, and biomimetic materials. Cellulose coatings provide biocompatibility, chemical stability, and environmental friendliness. They can be tailored for specific applications by adjusting viscosity, thickness, or incorporating additives, making them ideal for industrial and research purposes.

- Home

-

Products

-

Monomers

- Acrylic Monomers

- Alcohol Monomers

- Allyl Monomers

- Amide & Imide Monomers

- Amine Monomers

- Anhydride Monomers

- Biodegradable Polymer Monomers

- Carboxylic Acid Monomers

- Cycloolefin

- Dendrimer Building Blocks

- Epoxide Monomers

- Halide Monomers

- Isocyanate Monomers

- Mercaptan Monomers

- Other Monomers

- Silicone Monomers

- Styrenic Monomers

- Vinyl Monomers

- Polymer Standards

-

Polymers

- Acid Functional Polymers & Salts

- Acrylic Polymers

- Alkene & Vinyl Polymers

- Amide and Imide Polymers

- Amine Functional Polymers & Salts

- Biodegradable Polymers

- Copolymers

- Dendrimers

- Epoxy Polymers

- Halogenated Polymers

- Natural Polymers & Derivatives

- Other Polymers

- Poly(ethylene glycol)s (PEGs) & Derivatives

- Polyester

- Polyether

- Silicones

- Styrenic Polymers & Derivatives

- π-Conjugated Polymers

- Reagents for Polymerization

-

Monomers

-

Custom Services

- Polymer Characterization Services

- Polymer Isolation and Purification

-

Custom Synthesis

- Monomer Synthesis Services

-

Polymer Synthesis Services

- Atom Transfer Radical Polymerization Technology

- Reversible Addition-fragmentation Chain Transfer Polymerization Technology

- Nitroxide-mediated Polymerization Technology

- Ring-opening Polymerization Technology

- Ring-opening Metathesis Polymerization Technology

- Free Radical Polymerization Technology

- Living Cationic Polymerization (LCP) Technology

- Living Anionic Polymerization Technology

- Copolymer Synthesis Services

- Polymer Additive Synthesis Services

- Polymer Initiator Synthesis Services

- Polymer Nanoparticle Synthesis

- Polymer Microsphere Synthesis

- Polymer Hydrogel Synthesis

- Polymer Micelle Synthesis

-

Polymer Modification Services

- Side/End Group Functionalization

- Side/End Group Protection

- Polymer Bioconjugation Services

- Biomimetic Materials

- Support

- About Us

- Contact Us